8 Honda Engineering Developments

Soichiro Honda owned a small subcontractor manufacturing piston rings shortly after WWII, but with one factory wrecked by bombers and another by earthquake. He sold off that company to Toyota in 1946, and sank the money into a venture which he thought had more promise in war ravaged Japan: Adapting a military portable generator motor to drive a bicycle. This allowed people to get around a country where the roads had been destroyed, and used very little gas doing so. From there Mr. Honda never looked back, and time and again applied new, sometimes radical, thinking to the problems facing the world.

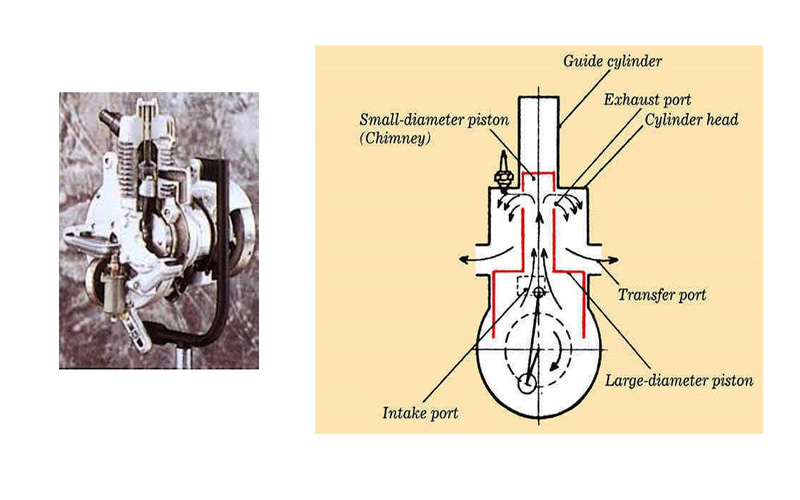

1. The “Chimney” Engine

The radical 2 stroke design for Honda’s “Chimney” engine had a cylinder with a piston, inside of another cylinder. One of the cylinders would move up and down, with the traditional piston inside of it, allowing port timings that could not be achieved otherwise. On top of that, both pistons compressed the mixture for a higher compression ratio and more power. Unfortunately, it proved to be well ahead of the machine tools his little factory had available in 1946. A prototype was made, but that is as far as it went. 50 years later, the engineering department at Honda would produce a replica and find it had more power and less fuel consumption that anything of a similar displacement made during that era.

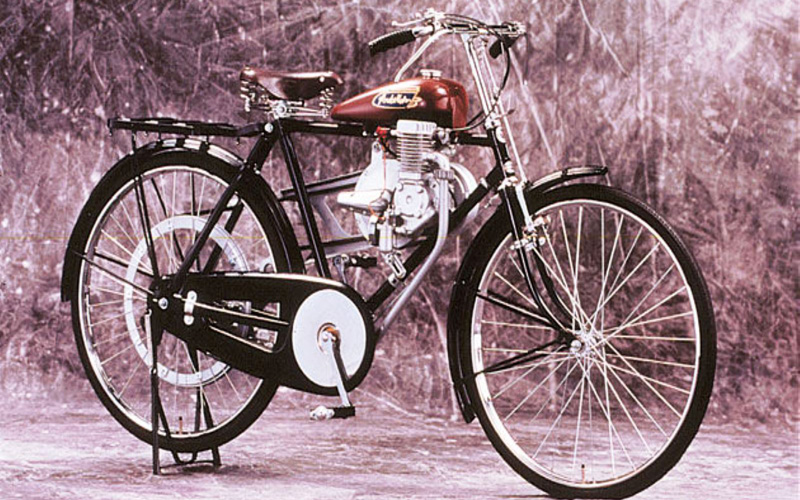

2. 1947 Honda A-Type Bike Motor

At the point the generator engine supply was drying up, Honda was little more than a garage workshop with a handful of employees. Many people would have folded up shop and gone to look for a real job, but not Mr. Honda. He set aside the innovative chimney motor design and built a much-improved convention 2-stroke motor. Among the new ideas in this design were the rotary intake valve, which gave much better low-end power than a typical 2-stroke, and lower fuel consumption. Looking far ahead to large scale production, Honda also insisted on die casting the parts instead of sand casting or machining them. The fuel tank was also a die cast aluminum unit, done at a factory which was to become Enkie, which had mounting bosses and other utilitarian features cast right into it.

3. Honda D-Type Motorcycle

The 1949 Honda “Dream” was the first totally original vehicle to wear the Honda name (The C-Type was a larger A-Type motor in a bespoke bicycle frame made by a 3rd party). Having tried earlier to move from bicycle engines to complete powered bicycles, Mr. Honda was frustrated by the amount of time and effort involved in a traditional bike frame. Bike frames also proved to be weak when subjected to power, and the poor roads in Japan. His solution was the stamped steel frame of the D-Type, which became known as the first Honda Dream. The engine was now over 100cc, and instead of a manual clutch integral with the belt drive, it used an automatic engaging clutch, which made it much easier for beginners to ride, and a 2-speed transmission. The stamped steel frame proved to be much less expensive to produce, and more durable when ridden over rough roads.

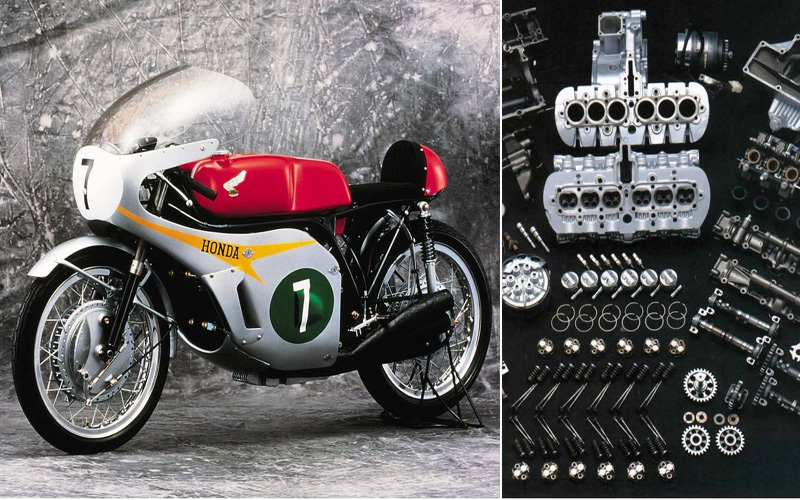

4. The Early Race Bikes

Just a handful of years after their first clamp on bike engines Honda was building some of the most innovative racing motorcycles anywhere. If you are a Honda car fan you may never have heard about the lengths Honda went to in the 1950s to be taken seriously. First, in 1955, were the overhead cam motors fitted to the new Dreams with 250cc and 350cc SOHC motors which raced in modified form in events around Japan. By 1959, after studying the best Europe had to offer, Honda appeared at the Isle of Man races with the RC142 DOHC 4 valve per cylinder 125cc twins and finished 6th, 7th, 8th and 11th in class. For races in Japan, they built the RC160 DOHC 4 valve 250cc 4 cylinder, which redlined at 14,000rpm, just like the smaller twin. These were improved and developed for years, eventually leading to a 4 cylinder 125cc bike and a 6 cylinder 250 which would rev to 18,000rpm. These bikes were both works of art as they were advanced racing machines.

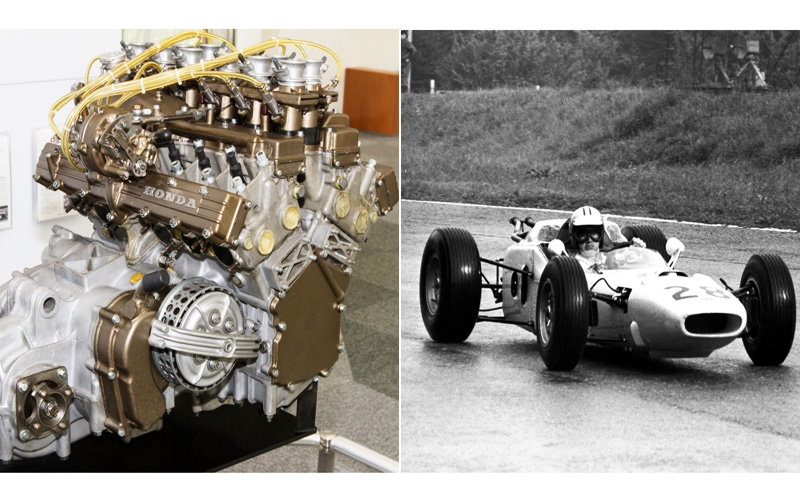

5. 1960s Honda Formula 1 V12

Having only really entered motorcycle racing ten years earlier, Mr. Honda was determined to compete with the best in the world in the most advanced motorsport, namely Formula 1. In what may seem obvious, the Honda 1.5 liter V12 looks almost like 2 banks of their 6 cylinder Grand Prix motorcycles on a common crankcase. Not only was it unusual to have a V12, when everyone else had V8 motors, Honda mounted the motor across the chassis, with power taken off the center of the crankshaft. This design allowed the internal parts to be lighter, and the whole motor to rev higher: Max power was over 13,000, and it could safely rev to 14,000. With just 1.5 liters Honda was able to make nearly 270hp, without a turbo, or V-TEC.

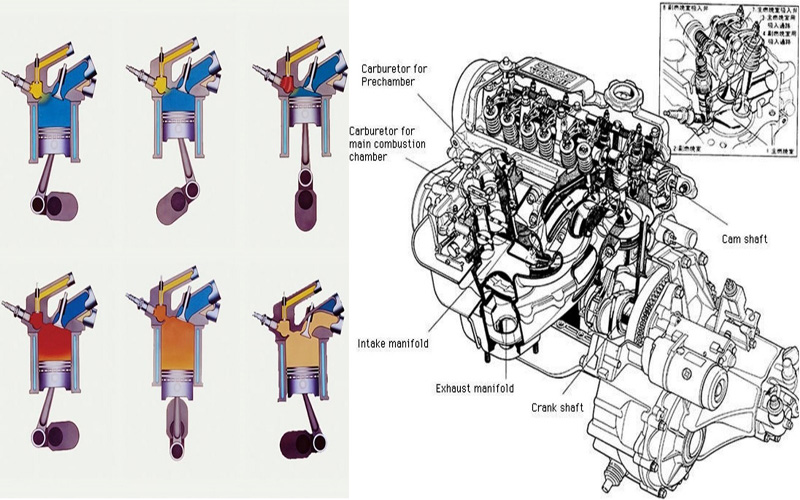

6. Honda CVCC Motor

Soichiro Honda believed that there was no reason an internal combustion motor needed to produce pollution. He tried from nearly the beginning to make his motors fuel efficient and low pollution, which is why as soon as he could he was engineering and producing 4 -stroke motors, instead of the dirtier 2-stroke. With smog and pollution laws coming into play all over the world, Honda was hard at work with their car R & D department to make a cleaner burning motor. The unique design, with a tiny intake valve and pre-combustion chamber, allowed Honda to meet 1970s emission standards without catalytic converters, or fuel injection and make better power with lower fuel consumption. Legend has it that the Honda lab even borrowed a Chevy Caprice and converted the big V8 to a CVCC system, embarrassing GM with how powerful, clean and fuel efficient it was. The Honda company patented more than 200 inventions and innovations based on this motor.

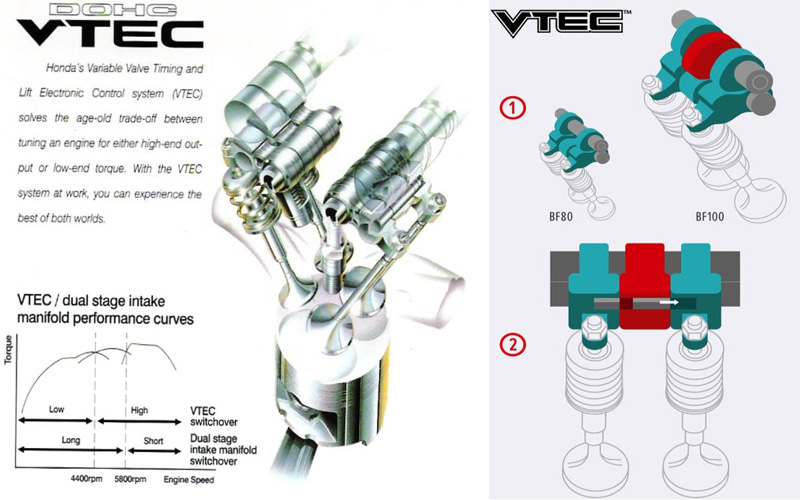

7. VTEC variable Valve Timing

Honda again went to the drawing board in 1984 to create a clean running motor, which had both good low-end torque and good high-end power. They also wanted a motor that would get good fuel economy in normal driving but have plenty of power when you needed it. The simple system of an extra camshaft lobe and a locking pin between rockers was elegant in its simplicity, worked as advertised and became synonymous with the Honda brand. Other manufacturers, including high-priced European car companies, again had to play catch up to the low cost, mass produced economy cars from Japan.

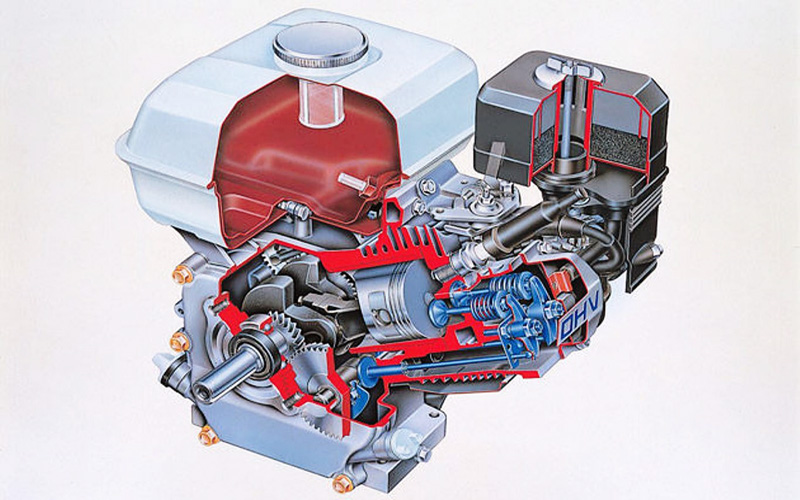

8. Honda ZE Series Small Engine

It is hard to imagine living in a world without the ubiquitous Honda ZE series OHV lawn mower motor. 35 years ago when the first ones appeared most mowers were still powered by Tecumseh and Briggs & Stratton side valve designs that had not changed much since before WWII. Honda, always a leader in engineering and technology, set out in the 1970s to design a modern small engine for agricultural and other uses that would have similar durability to these old standbys, but weigh less, and use less gasoline. By switching from a flathead, side valve design, to an overhead valve design, they could make similar power from a small displacement motor, meaning it would weigh less. As an added benefit, the modern wedge-shaped combustion chamber burned cleaner and more efficiently, so less pollution came out the exhaust pipe. All you have to do is look in the back of the local gardener’s truck and you will see that Honda motors are now in everything, and if it isn’t a Honda motor it is a different brand but a similar design.

For more information on maintenance and repairs, please check out our do-it-yourself technical articles at https://honda-tech.com/how-tos/.