New composite pieces I built for a customer

#1

Thread Starter

Join Date: Oct 2002

Location: Eagle Mountain, UT, USA

Posts: 1,708

Likes: 0

Received 0 Likes

on

0 Posts

Continued from the post about the molds:

http://www.racingcomposites.net/unt?id=836

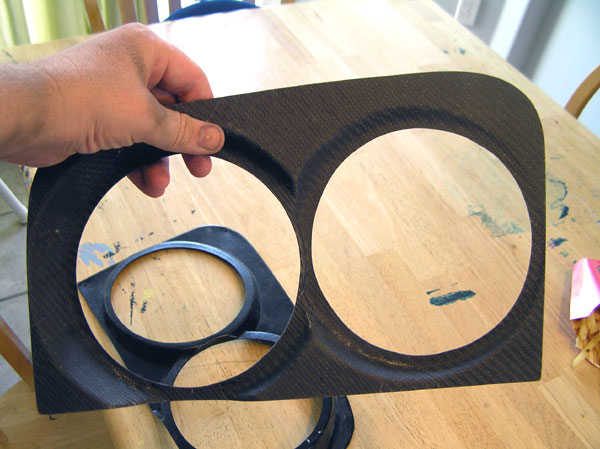

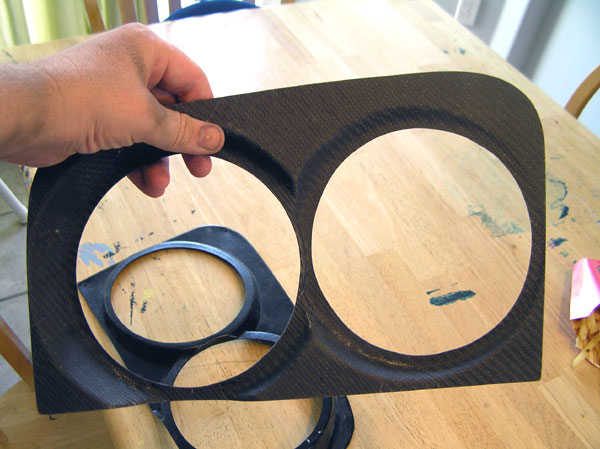

These parts were vacuum infused and trimmed by yours truly. They aren't for a Honda but I thought I'd show you guys anyway. Please don't ask what car they are for, I'd like to keep that to myself. If you know please keep it to yourself. Anyway I built the first set and sent them to the customer for a trial fit before I build more. This is how the parts looked right out of the molds as far as finish goes. Of course I did have to trim them but other than that they came out nice. I used marine grade clear gel coat by Valspar out of an hvlp gun and 2.0 tip. Then laid up the fabric and infused the parts in sets with VE infusion resin. Each mold can build two parts at once. The first pic shows the right and left sides and the last pic shows right and left as well. Although the pieces were the same shape they are just trimmed different to fit. I had to build trimming jigs for each of the 4 parts in the set. These parts released perfectly the first shot. Vacuum infusion can be a lovely way to go. These parts are about the same thickness as the originals but much more stiff. I built the plugs, molds, and then these parts.

This part worried me a little but turned out great:

These two parts haven't been trimmed yet and are sitting next to the original factory piece. Notice how the weave direction is opposite for both parts. You have to cut the carbon 90 degrees opposed to get this effect when viewed from each side of the vehicle...details details

http://www.racingcomposites.net/unt?id=836

These parts were vacuum infused and trimmed by yours truly. They aren't for a Honda but I thought I'd show you guys anyway. Please don't ask what car they are for, I'd like to keep that to myself. If you know please keep it to yourself. Anyway I built the first set and sent them to the customer for a trial fit before I build more. This is how the parts looked right out of the molds as far as finish goes. Of course I did have to trim them but other than that they came out nice. I used marine grade clear gel coat by Valspar out of an hvlp gun and 2.0 tip. Then laid up the fabric and infused the parts in sets with VE infusion resin. Each mold can build two parts at once. The first pic shows the right and left sides and the last pic shows right and left as well. Although the pieces were the same shape they are just trimmed different to fit. I had to build trimming jigs for each of the 4 parts in the set. These parts released perfectly the first shot. Vacuum infusion can be a lovely way to go. These parts are about the same thickness as the originals but much more stiff. I built the plugs, molds, and then these parts.

This part worried me a little but turned out great:

These two parts haven't been trimmed yet and are sitting next to the original factory piece. Notice how the weave direction is opposite for both parts. You have to cut the carbon 90 degrees opposed to get this effect when viewed from each side of the vehicle...details details

#5

Honda-Tech Member

Join Date: Jul 2004

Location: I'm everywhere Focker

Posts: 5,463

Likes: 0

Received 2 Likes

on

2 Posts

Wow...this is kind of weird we aren't allowed to know what car they are for. At first glance I thought they were taillight bezels, then went through my mind of cars that have round taillights. So that isn't it, then I read that they are for headlights, so hmmmm.

Is there a reason it's secret? This might really drive me insane for the day.

Is there a reason it's secret? This might really drive me insane for the day.

#6

Thread Starter

Join Date: Oct 2002

Location: Eagle Mountain, UT, USA

Posts: 1,708

Likes: 0

Received 0 Likes

on

0 Posts

No I'm not kidding about what car its for, my customer who is reselling these asked me not to... Maybe he wants to put his brand name on them which is fine. I am allowed to post a few pics since its a fairly obscure vehicle so I thought I would share. Anyone have any fab questions?

Trending Topics

#11

Thread Starter

Join Date: Oct 2002

Location: Eagle Mountain, UT, USA

Posts: 1,708

Likes: 0

Received 0 Likes

on

0 Posts

Well since I don't have any hood molds it would be expensive to do one hood but several hoods would reduce the cost to around $7-800 just a ballpark, it really depends which materials I use.

#15

Thread Starter

Join Date: Oct 2002

Location: Eagle Mountain, UT, USA

Posts: 1,708

Likes: 0

Received 0 Likes

on

0 Posts

LOL took me a second. Thats the only downside to running my own operation is crappy food and sometimes long hours. I signed up for it though and I love my job. Gotta get back out there now

#17

Thread Starter

Join Date: Oct 2002

Location: Eagle Mountain, UT, USA

Posts: 1,708

Likes: 0

Received 0 Likes

on

0 Posts

Well first I built some temporary 3/d posterboard trimming jigs so I knew where to cut based on the factory parts. Then I rough cut them with a 3/4" diamond coated cut off wheel in a Dremel. Then I removed the material to the cut line minus a little with a 2" sanding drom in a drill press. Then I hit all the edges with 150 grit paper by hand and then a final 220 grit. This leaves the edge completely undamaged. No matter what you cut composite with you are going to damage the edge to some extent so honing in on the final shape with less and less damaging methods is the key to a perfect edge.

#19

Thread Starter

Join Date: Oct 2002

Location: Eagle Mountain, UT, USA

Posts: 1,708

Likes: 0

Received 0 Likes

on

0 Posts

From the first paragraph of the post:

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by crx12 »</TD></TR><TR><TD CLASS="quote"> Please don't ask what car they are for, I'd like to keep that to myself. If you know please keep it to yourself. </TD></TR></TABLE>

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by crx12 »</TD></TR><TR><TD CLASS="quote"> Please don't ask what car they are for, I'd like to keep that to myself. If you know please keep it to yourself. </TD></TR></TABLE>

Thread

Thread Starter

Forum

Replies

Last Post

jdmboyef9

Honda CRX / EF Civic (1988 - 1991)

120

06-01-2017 06:01 PM

N20civicB18

Forced Induction

56

09-24-2005 12:33 PM