t25 manifold & turbo flange issue

#1

Honda-Tech Member

Thread Starter

iTrader: (3)

Join Date: Feb 2002

Location: MN

Posts: 12,561

Likes: 0

Received 0 Likes

on

0 Posts

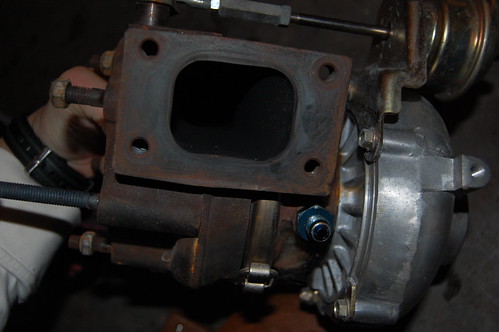

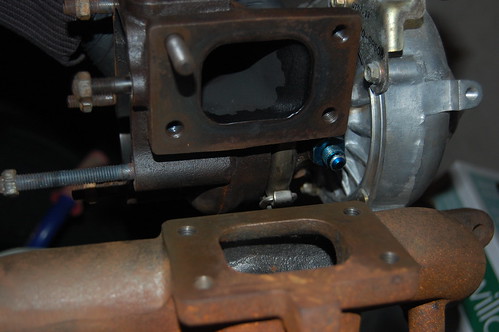

I have an issue regarding the bolts/nuts for my manifold turbo combo.

The HKS manifold is designed for the studs to come upward.

*notice the front bolts could be bolted from TOP down, but the rears can only be bolted BOTTOM up (since they go upward into the runners)

The Apexi P13 turbo however is designed for the studs to come TOP down.

I could just weld them together... lol.

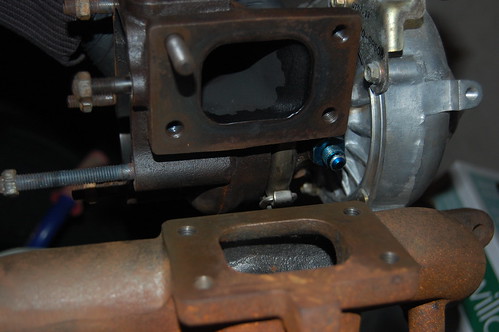

This sounds stupid but I think I need a T25 to T25 "adapter" plate.

That way the plate that would allow me to bolt the manifold studs BOTTOM up & the turbo studs TOP down.

Any idea on who would make such a plate even it if it custom?

The HKS manifold is designed for the studs to come upward.

*notice the front bolts could be bolted from TOP down, but the rears can only be bolted BOTTOM up (since they go upward into the runners)

The Apexi P13 turbo however is designed for the studs to come TOP down.

I could just weld them together... lol.

This sounds stupid but I think I need a T25 to T25 "adapter" plate.

That way the plate that would allow me to bolt the manifold studs BOTTOM up & the turbo studs TOP down.

Any idea on who would make such a plate even it if it custom?

#4

Honda-Tech Member

Thread Starter

iTrader: (3)

Join Date: Feb 2002

Location: MN

Posts: 12,561

Likes: 0

Received 0 Likes

on

0 Posts

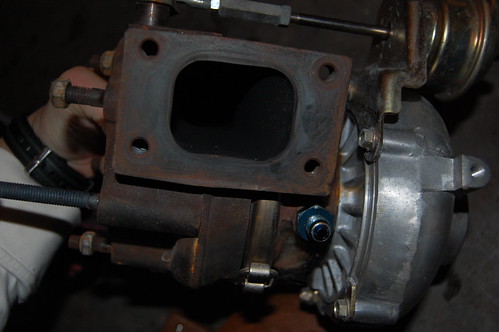

Notice that the "2 front holes" of the manifold will bolt onto the P13 just fine....

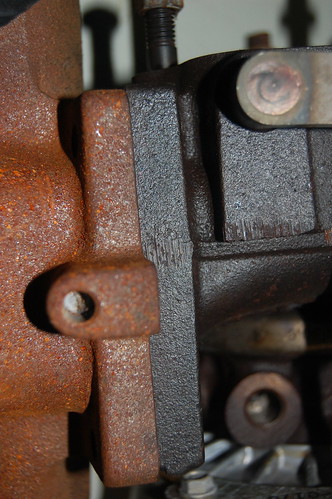

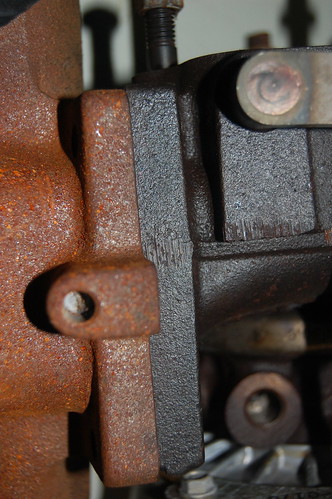

But the issue is the "2 back holes".

The turbo manifold has threaded holes going INTO the turbo(into the cast runner)

The P13 has threaded holes too, but on the exit side there is no room at all for a nut, let alone trying to screw a stud upward.

But the issue is the "2 back holes".

The turbo manifold has threaded holes going INTO the turbo(into the cast runner)

The P13 has threaded holes too, but on the exit side there is no room at all for a nut, let alone trying to screw a stud upward.

#5

Honda-Tech Member

Join Date: Aug 2001

Location: Fort Worth, TX, USA

Posts: 1,842

Likes: 0

Received 0 Likes

on

0 Posts

To be honest, I don't think its going to work without adding at least an inch or more of distance between the manifold and turbo. You could make an adaptor plate, but it would be need to be twisted or rotated slightly because you can't use 2 bolts back to back. They would need to either be offset from each other or have a significant amount of space between them, so that you can get the thread into the holes. You might also be able to weld a V-band inbetween them so that your clamping from the side.

But, its more just a simple case of "not compatible" I think. You could weld them together if you don't have any future plans for them seperatly. Just make sure they are compatible metals.

But, its more just a simple case of "not compatible" I think. You could weld them together if you don't have any future plans for them seperatly. Just make sure they are compatible metals.

#7

Honda-Tech Member

Join Date: Aug 2001

Location: Fort Worth, TX, USA

Posts: 1,842

Likes: 0

Received 0 Likes

on

0 Posts

Trending Topics

#8

Honda-Tech Member

How so? Each side "expects" studs to secure them to the other piece. So if studs are welded in to say the turbo, then it fits the requirements of the manifold needing studs to come through.

Or just drill out the threads in the turbo flange where needed and run 2 studs off the back and bolts up front

Or just drill out the threads in the turbo flange where needed and run 2 studs off the back and bolts up front

#9

Honda-Tech Member

Join Date: Mar 2000

Location: Toronto, ON, Canada

Posts: 2,859

Likes: 0

Received 0 Likes

on

0 Posts

How so? Each side "expects" studs to secure them to the other piece. So if studs are welded in to say the turbo, then it fits the requirements of the manifold needing studs to come through.

Or just drill out the threads in the turbo flange where needed and run 2 studs off the back and bolts up front

Or just drill out the threads in the turbo flange where needed and run 2 studs off the back and bolts up front

I have the HKS manifold before so I know what he's talking about.

I would get a fab shop and have them weld on V-band flanges on both the turbo and manifold. Purchase a 2" V-band set, and weld V-band flanges on both sides. This will eliminate the need for any nuts and bolts, and keeping it as low profile as possible (less than 1" overall height increase), and no more gaskets or leaks, and you can spin the turbo at any rotation.

#12

Honda-Tech Member

Join Date: Mar 2000

Location: Toronto, ON, Canada

Posts: 2,859

Likes: 0

Received 0 Likes

on

0 Posts

If there are any doubts, you can also build an external brace using those existing threaded holes I see on the pictures. I am sure you can rig up a custom bracket to hold the turbo and take the weight stress off the welded joint.

To further relieve the stress on the welded joint, you may want to build a sturdy bracket on the downpipe as well (bracket that bolts the downpipe onto the block or transmission) so that your welded joint is barely supporting any weight (which prevents failures in case the weld is not 100% perfect).

For 2" V-band flanges, I know Vibrant makes one.. You can also check out the fabrication forums and visit the vendor links for hardware and such. I know you can also grab some off Ebay, but make sure you get something nice... The OBX ones would work, but I'd use them as a last resort.

Thread

Thread Starter

Forum

Replies

Last Post