Eagle Rod Fitment

#1

Thread Starter

Join Date: Dec 2001

Location: Queens, NY, USA

Posts: 208

Likes: 0

Received 0 Likes

on

0 Posts

When installing Eagle Rods into a d16z6 motor I heard that you have to modify the block. What exactly do you have to do to the block? Thanks

#3

Taken from http://www.theoldone.com

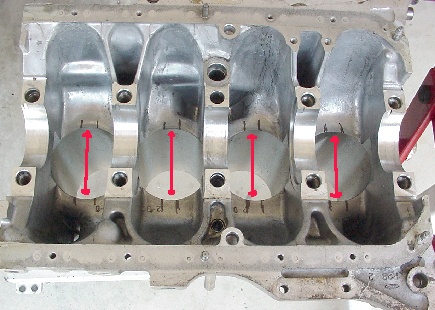

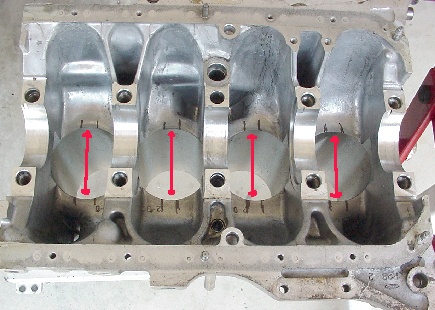

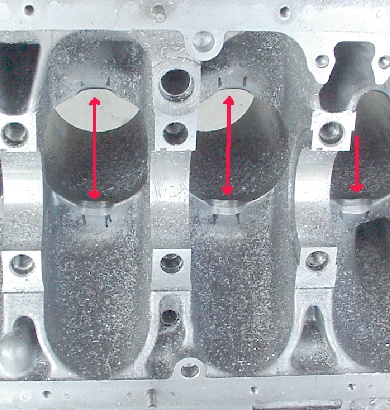

We mark an area that's 3/4" wide and approximately centered on each side of the block's cylinder bores. 3/4" is plenty of distance to clear the rods' beams ans we'll taper the cut from outside the lines back to the cylinder bores. If you put a mark that's 1/4" into the block and 1/4" down into the bores, that's the amount you'll be removing...effectively straight-lining the area with your grinder.

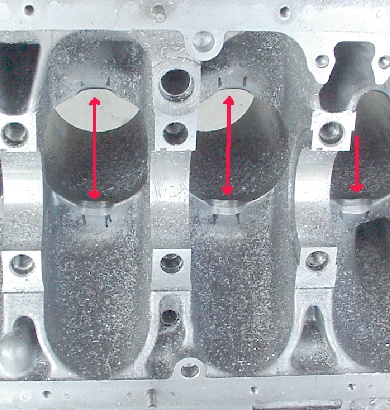

This photo shows the block after about 10 minutes with a die grinder and a carbide cutter. Notice how the corners of the reliefs are tapered back to the original lower edge of the cylinder. You do not want square edges in these areas, as stress risers could develop. make sure when you're grinding in these areas on the block that you wear eye protection, as the cast iron particles from the cylinder liner will rust in your eyes and having them "drilled" out, isn't a pleasant experience. Obviously, the block will need to be cleaned after this operation, as is evidenced by the grinding debris in the photo.

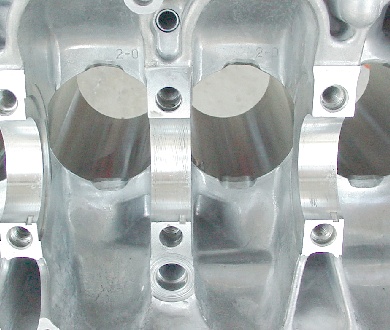

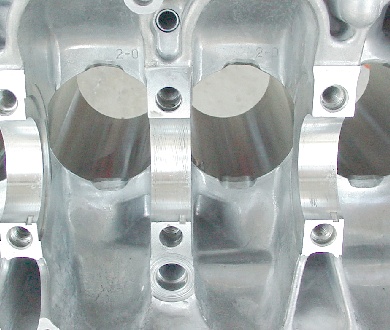

Here's the finished product. The reliefs have been just "touched" by a 60 grit cartridge roll and a tiny radius has also been placed on the bottom of the cylinder bore. This will make the transition back up the cylinder wall a little less "wearing" for the pistons' skirts. The block has been thoroughly cleaned with a solvent and then it's been scrubbed with hot soapy water, prior to the final rinse with hot water. Blow the block dry, including all the bolt holes. Make a good sized roll of Bounty towels on some sticks (paint stirrers work great), spray them with some WD-40 and wipe the cylinder bores until there's no hint of dirt, or surface rust showing.

We mark an area that's 3/4" wide and approximately centered on each side of the block's cylinder bores. 3/4" is plenty of distance to clear the rods' beams ans we'll taper the cut from outside the lines back to the cylinder bores. If you put a mark that's 1/4" into the block and 1/4" down into the bores, that's the amount you'll be removing...effectively straight-lining the area with your grinder.

This photo shows the block after about 10 minutes with a die grinder and a carbide cutter. Notice how the corners of the reliefs are tapered back to the original lower edge of the cylinder. You do not want square edges in these areas, as stress risers could develop. make sure when you're grinding in these areas on the block that you wear eye protection, as the cast iron particles from the cylinder liner will rust in your eyes and having them "drilled" out, isn't a pleasant experience. Obviously, the block will need to be cleaned after this operation, as is evidenced by the grinding debris in the photo.

Here's the finished product. The reliefs have been just "touched" by a 60 grit cartridge roll and a tiny radius has also been placed on the bottom of the cylinder bore. This will make the transition back up the cylinder wall a little less "wearing" for the pistons' skirts. The block has been thoroughly cleaned with a solvent and then it's been scrubbed with hot soapy water, prior to the final rinse with hot water. Blow the block dry, including all the bolt holes. Make a good sized roll of Bounty towels on some sticks (paint stirrers work great), spray them with some WD-40 and wipe the cylinder bores until there's no hint of dirt, or surface rust showing.

Thread

Thread Starter

Forum

Replies

Last Post

d16dcoe45

All Motor / Naturally Aspirated

9

10-23-2006 07:45 AM