GE sleeve users, WTH is this?

#1

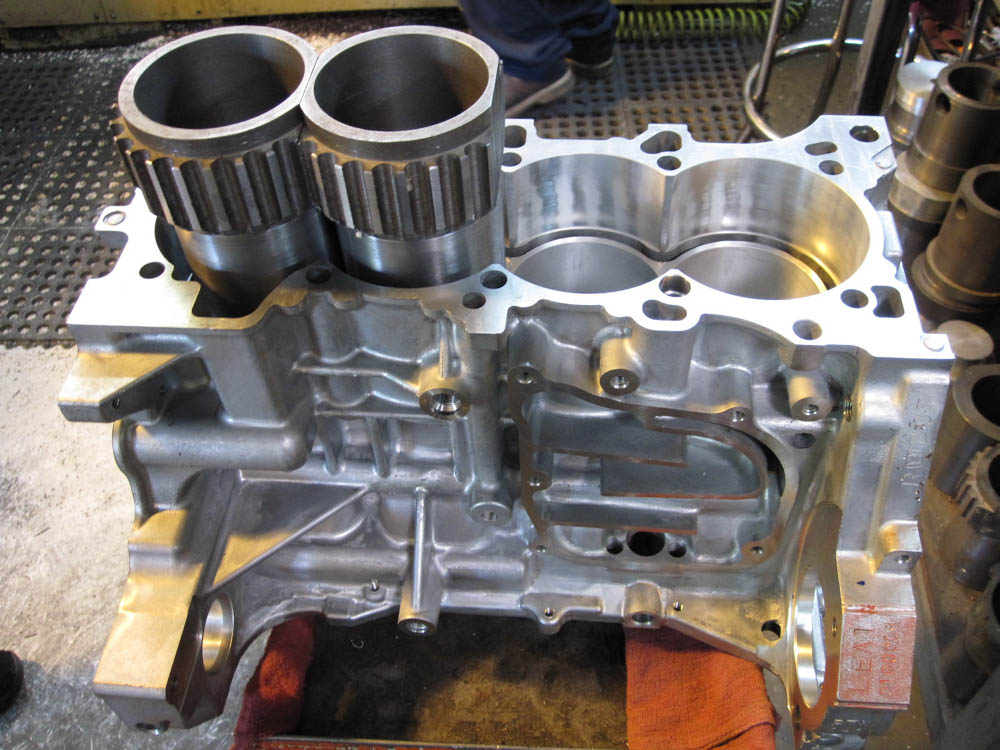

OK, I will spare you the LOOOONG backstory at this point because I just want straight answer WITH PICS. This is my block back from GE. I have never used a sleeved block before this nitrous build and felt really good about GE based on many testimonials here. I know that I may be overreacting and not informed enough so that is why I am asking GE users to school me on this WITH PICS. I am not going to believe what is said without a picture verification. I have been on the phone with Bob (owner) of GE and got what I believe is some disputable info.

I asked Him about the gap perferation above each main saddle just below the sleeves and he said this was normal. OK, it may be. But what purpose does it serve to remove main webbing in a block that is litterally gutted to install sleeves? No answer from Bob, just it's normal. There is at least 1/2" of critical support to the lower main bridgework with a large hole in between the three inner saddles. Again, IMO, if you look closely at this it does not seem needed to remove metal here to install the sleeves above.

The other question I have is why is there an epoxy ring under the support webbing on the sleeves. I was told by Bob @ GE that these sleeves are made from four pieces of metal. I am totally lost on that one! Every picture I can produce suggests that they are one continuous machined piece. The close up of the deck enforcement webbing shows a continuous machine line in the radius and not a parting line. I put a camera inside the block and could find no evidence of a four piece design either. What is true? The epoxy on the sleeves in the water jacket may not look imposing at first, but think about this. ALOT of research has been done on the thermal characteristics of racing motors and the cylinders ability to transfer heat without distortion (loosing ring seal) and deformation at structural attachments. This epoxy is around the sleeve at about 2" down or very near the ring land. This epoxy can not transfer heat as well as the base metal can and therefore may/can create a localized hot spot/circumfrence zone where the rings need to seal and get rid of piston heat.

Am I overreacting? Are your motors the same as this? Have you been told your B series sleeves are four pieces?

I may have read too much in the past about this thermal deformation that I see flaws that are not being addressed.

I would not have posted this at all except that my broker (Speed Factory) and the owner of GE Bob, would not send a simple picture of a similar block configuration to quell this inquiry. No disrespect at all towards Matt at Speed Factory, he is a stand up guy and didn't have a B series there to send a pic, so I understand.

I just want the truth, whatever it is. I don't care if I look like a noob for asking a question. That is how I learn from people that know.

I asked Him about the gap perferation above each main saddle just below the sleeves and he said this was normal. OK, it may be. But what purpose does it serve to remove main webbing in a block that is litterally gutted to install sleeves? No answer from Bob, just it's normal. There is at least 1/2" of critical support to the lower main bridgework with a large hole in between the three inner saddles. Again, IMO, if you look closely at this it does not seem needed to remove metal here to install the sleeves above.

The other question I have is why is there an epoxy ring under the support webbing on the sleeves. I was told by Bob @ GE that these sleeves are made from four pieces of metal. I am totally lost on that one! Every picture I can produce suggests that they are one continuous machined piece. The close up of the deck enforcement webbing shows a continuous machine line in the radius and not a parting line. I put a camera inside the block and could find no evidence of a four piece design either. What is true? The epoxy on the sleeves in the water jacket may not look imposing at first, but think about this. ALOT of research has been done on the thermal characteristics of racing motors and the cylinders ability to transfer heat without distortion (loosing ring seal) and deformation at structural attachments. This epoxy is around the sleeve at about 2" down or very near the ring land. This epoxy can not transfer heat as well as the base metal can and therefore may/can create a localized hot spot/circumfrence zone where the rings need to seal and get rid of piston heat.

Am I overreacting? Are your motors the same as this? Have you been told your B series sleeves are four pieces?

I may have read too much in the past about this thermal deformation that I see flaws that are not being addressed.

I would not have posted this at all except that my broker (Speed Factory) and the owner of GE Bob, would not send a simple picture of a similar block configuration to quell this inquiry. No disrespect at all towards Matt at Speed Factory, he is a stand up guy and didn't have a B series there to send a pic, so I understand.

I just want the truth, whatever it is. I don't care if I look like a noob for asking a question. That is how I learn from people that know.

Last edited by Tyler Dirden; 08-31-2013 at 11:37 AM.

#3

I suppose that is what he could have meant. Though he didn't say it like that at all. He made it sound like the epoxy was there to hold it together, not just in. I mean what else could explain the ring of epoxy around the webbing support?

I found a couple pics of B20B webbing in the crank area and they are recessed a bit, just not cut through like these. I suppose that that aspect is normal as part of the machining process, but the sloppy epoxy ring is a surprise still.

I found a couple pics of B20B webbing in the crank area and they are recessed a bit, just not cut through like these. I suppose that that aspect is normal as part of the machining process, but the sloppy epoxy ring is a surprise still.

#4

The Grumpiest

iTrader: (4)

Join Date: May 2008

Location: Oak Ridge, TN, USA

Posts: 28,333

Likes: 0

Received 16 Likes

on

15 Posts

That epoxy around the webbing area, as you call it. Is that not where the GE sleeves sit on to of the remainder of the stock sleeves?

And not that I know anything about it but how do you know for a fact that the epoxy does not conduct heat as well?

And not that I know anything about it but how do you know for a fact that the epoxy does not conduct heat as well?

#5

Thank you for the time you offer here. I do know that there is no remaining sleeves from the old motor left after machining. These get epoxied into a steped recess in the bottom webbing.

As for the epoxy and heat transfer, well I can say that in various industries (power plants, refineries) that I have worked in; special epoxies were used with conductive powder or flake to increase heat transfer for critical use. Again, I am probably overreacting to it's use here, just wanted to know if other GE users had this also. Since soo many of these are holding up to much greater power than I intend to make, I should just be happy I could afford to go this route for the insurance for my nitrous build.

As for the epoxy and heat transfer, well I can say that in various industries (power plants, refineries) that I have worked in; special epoxies were used with conductive powder or flake to increase heat transfer for critical use. Again, I am probably overreacting to it's use here, just wanted to know if other GE users had this also. Since soo many of these are holding up to much greater power than I intend to make, I should just be happy I could afford to go this route for the insurance for my nitrous build.

#7

That makes complete sense now. You know just a moment of their time to explain a $1500. machining process is all I asked for. I got , just use it it's good for twice the power your making, were the best at this. I just wanted a straight and informed answer like you provided.

I couldn't find any pics on their web site like they use to have before I was paying close attention to this little stuff. I remember seeing lots of motors in different stages of sleeving.

Thank you for helping me understand this better.

I couldn't find any pics on their web site like they use to have before I was paying close attention to this little stuff. I remember seeing lots of motors in different stages of sleeving.

Thank you for helping me understand this better.

Trending Topics

Thread

Thread Starter

Forum

Replies

Last Post

SOUNDEFFECTS

Forced Induction

23

02-04-2003 08:07 PM