Broken RTA bushing bolt

#1

Honda-Tech Member

Thread Starter

iTrader: (1)

Join Date: Mar 2001

Location: Providence, RI, USA

Posts: 1,654

Likes: 0

Received 0 Likes

on

0 Posts

Replacing rear RTA bushings on my 2000 EJ8 since I have a rare day off. Driver side went smoothly. Got to passenger side and the inboard bolt on the bushing came out about 3 turns and STOPPED. Lots of PB Blaster, tighten/loosen, got it slowly running out and it snapped. Now I've got a 1/2" or more of this bolt broken off and seized inside the body. Looking for some ideas or input on what I might do from here.

Thinking about trying to drill up through the center of the broken piece, but worried I'm going to damage the threads inside the body. Since the bolt has a shoulder, and the threads are so far up in the body, I'm not clear on whether it could be helicoiled or not.

Thinking about trying to drill up through the center of the broken piece, but worried I'm going to damage the threads inside the body. Since the bolt has a shoulder, and the threads are so far up in the body, I'm not clear on whether it could be helicoiled or not.

#2

Once drilled out, you could rivnut it.

Or since the nut will still be welded inside the frame, you might look at a timesert setup.

Or since the nut will still be welded inside the frame, you might look at a timesert setup.

#3

Fish Twig

Join Date: Nov 2005

Location: Still hunting that foo up there

Posts: 15,555

Received 309 Likes

on

285 Posts

Find a drillbit that is slightly smaller than the bolt and go at it, than tap the hole again with the same thread pitch. As long as that nut is still welded in place you should be fine to tap it properly. Also go junkyard hopping for that rta bushing bolt.

#4

I never narc'd on nobody!

iTrader: (1)

It'll be a minor miracle if that welded nut survives being drilled and tapped. A timesert on a welded nut? No way, man. Get a bolt extractor, or reverse drill bit. They're easy to use. Get the bolt remnants out without risking ruining the nut, because if you damage the nut (or break the spot welds, which is stupidly easy to do), then you're in for a world of pain trying to fix that.

#5

It'll be a minor miracle if that welded nut survives being drilled and tapped. A timesert on a welded nut? No way, man. Get a bolt extractor, or reverse drill bit. They're easy to use. Get the bolt remnants out without risking ruining the nut, because if you damage the nut (or break the spot welds, which is stupidly easy to do), then you're in for a world of pain trying to fix that.

The fix is simply a rivnut but use a standard metric size like M10x1.5 and then order some 12.9 grade M10x1.5 bolts to replace what broke.

It's what I'm having to do for my passenger side torque mount that the inside nut weld broke.

#6

Honda-Tech Member

Thread Starter

iTrader: (1)

Join Date: Mar 2001

Location: Providence, RI, USA

Posts: 1,654

Likes: 0

Received 0 Likes

on

0 Posts

Thank you all so much for advice and input.

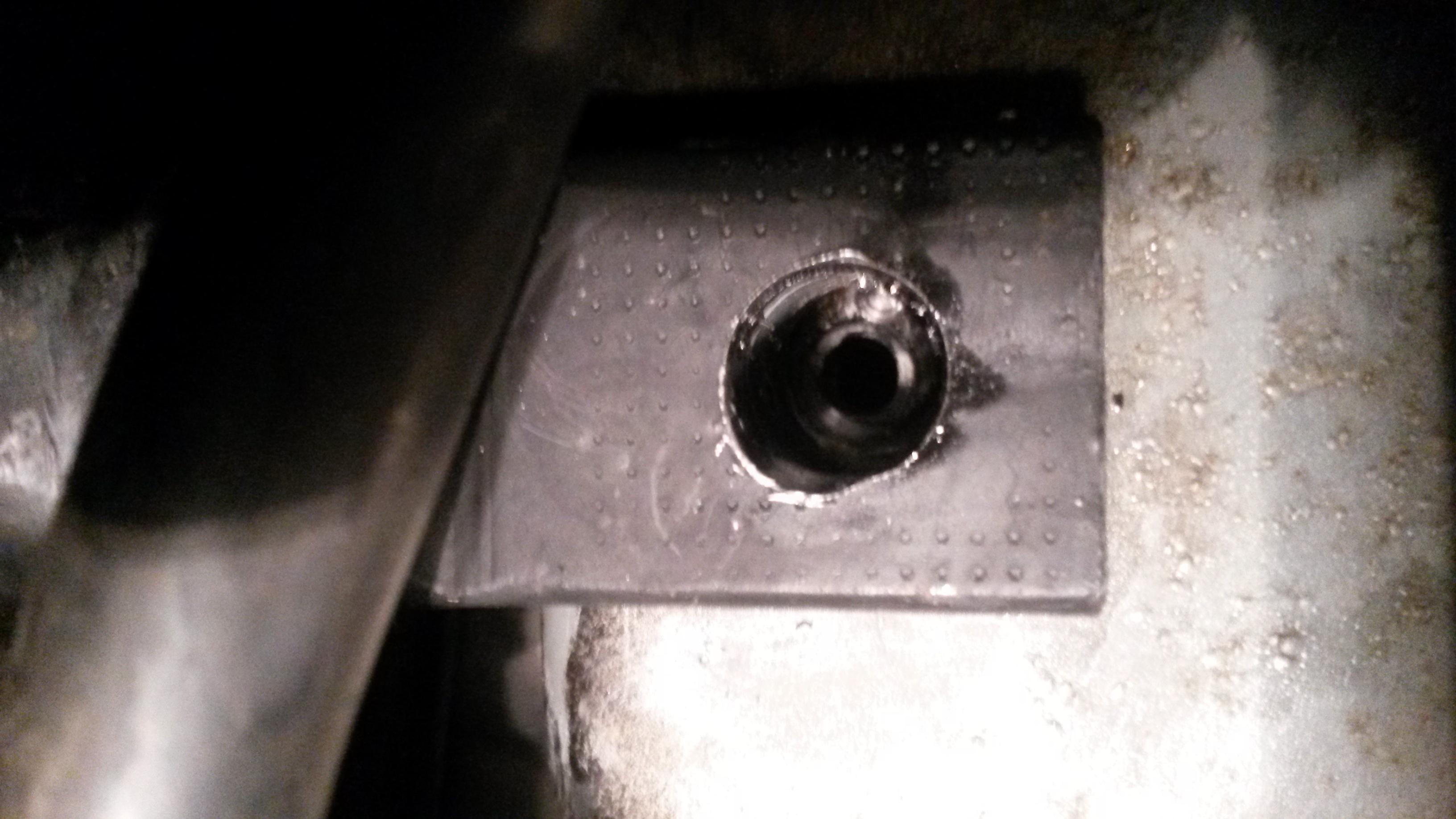

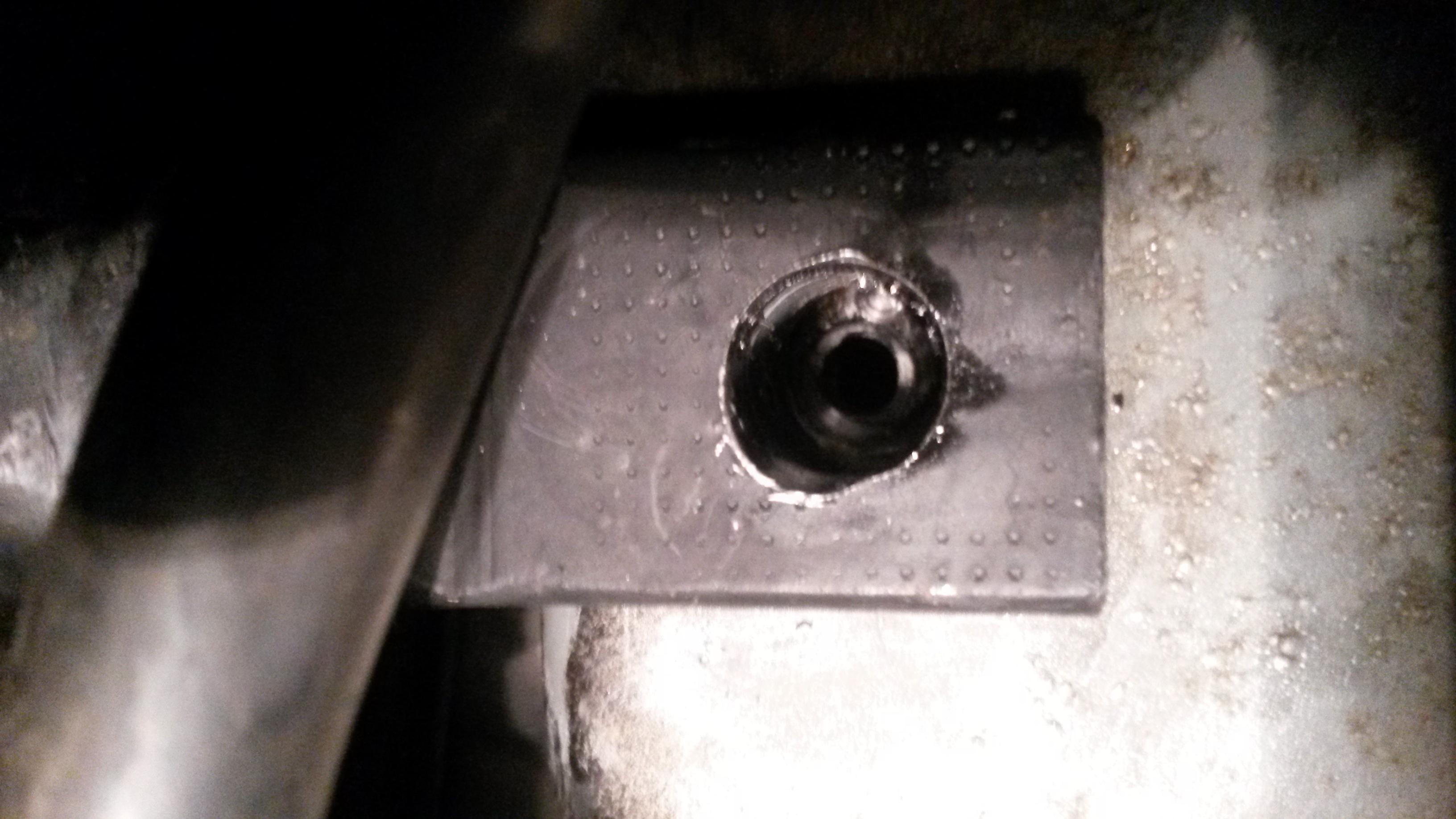

I figured that was the best way to start. See photos below. Now I'm wondering if it can be tapped.

I've got some bad memories of broken extractors and can't afford one to snap off in the hole as deep as it is. BUT, I took your advice and hunted down some reverse drill bits. Tough to find and Harbor Freight was the only local place to get them today. Pretty decent set for $7.99, but the largest bit was 1/4". Good news, I'm through the broken piece up to the 1/4". Bad new, I'm off center and it's not backing the piece out. The break was rough and the center was tough to find so deep in the hole. At very least, I not got some PB blaster to the back side of the bolt.

This shot tries to show how deep the hole is before the threads and broken piece start. I can stress how much of the PITA this is.

This bolt is M12x1.25x60. Majestic should have it and I might even have spares. I've also got a local Fastenal.

RivNut was my first thought, but I'm not mounting THROUGH a material that's 1/8" thick. It's not so much a hole but a "tube" that's now ~1.5" deep with the broken piece and threaded nut still in place. If it's just compressed against the walls of that tube, could the RivNut pull put with a downward force?

It'll be a minor miracle if that welded nut survives being drilled and tapped. A timesert on a welded nut? No way, man. Get a bolt extractor, or reverse drill bit. They're easy to use. Get the bolt remnants out without risking ruining the nut, because if you damage the nut (or break the spot welds, which is stupidly easy to do), then you're in for a world of pain trying to fix that.

This shot tries to show how deep the hole is before the threads and broken piece start. I can stress how much of the PITA this is.

It's not that bad to fix except that Honda uses non standard metric bolt sizes like M11x1.25. It's unheard of and nearly impossible to order and find except dealership. Also can't find rivnuts of that size.

The fix is simply a rivnut but use a standard metric size like M10x1.5 and then order some 12.9 grade M10x1.5 bolts to replace what broke.

It's what I'm having to do for my passenger side torque mount that the inside nut weld broke.

The fix is simply a rivnut but use a standard metric size like M10x1.5 and then order some 12.9 grade M10x1.5 bolts to replace what broke.

It's what I'm having to do for my passenger side torque mount that the inside nut weld broke.

RivNut was my first thought, but I'm not mounting THROUGH a material that's 1/8" thick. It's not so much a hole but a "tube" that's now ~1.5" deep with the broken piece and threaded nut still in place. If it's just compressed against the walls of that tube, could the RivNut pull put with a downward force?

#7

Fish Twig

Join Date: Nov 2005

Location: Still hunting that foo up there

Posts: 15,555

Received 309 Likes

on

285 Posts

If you remove all of the old bolt than you should be able to retap the hole, I can't really tell if you did just that or drill a smaller hole through the broken bolt.

Trending Topics

#8

Thank you all so much for advice and input.

I figured that was the best way to start. See photos below. Now I'm wondering if it can be tapped.

I've got some bad memories of broken extractors and can't afford one to snap off in the hole as deep as it is. BUT, I took your advice and hunted down some reverse drill bits. Tough to find and Harbor Freight was the only local place to get them today. Pretty decent set for $7.99, but the largest bit was 1/4". Good news, I'm through the broken piece up to the 1/4". Bad new, I'm off center and it's not backing the piece out. The break was rough and the center was tough to find so deep in the hole. At very least, I not got some PB blaster to the back side of the bolt.

This shot tries to show how deep the hole is before the threads and broken piece start. I can stress how much of the PITA this is.

This bolt is M12x1.25x60. Majestic should have it and I might even have spares. I've also got a local Fastenal.

RivNut was my first thought, but I'm not mounting THROUGH a material that's 1/8" thick. It's not so much a hole but a "tube" that's now ~1.5" deep with the broken piece and threaded nut still in place. If it's just compressed against the walls of that tube, could the RivNut pull put with a downward force?

I figured that was the best way to start. See photos below. Now I'm wondering if it can be tapped.

I've got some bad memories of broken extractors and can't afford one to snap off in the hole as deep as it is. BUT, I took your advice and hunted down some reverse drill bits. Tough to find and Harbor Freight was the only local place to get them today. Pretty decent set for $7.99, but the largest bit was 1/4". Good news, I'm through the broken piece up to the 1/4". Bad new, I'm off center and it's not backing the piece out. The break was rough and the center was tough to find so deep in the hole. At very least, I not got some PB blaster to the back side of the bolt.

This shot tries to show how deep the hole is before the threads and broken piece start. I can stress how much of the PITA this is.

This bolt is M12x1.25x60. Majestic should have it and I might even have spares. I've also got a local Fastenal.

RivNut was my first thought, but I'm not mounting THROUGH a material that's 1/8" thick. It's not so much a hole but a "tube" that's now ~1.5" deep with the broken piece and threaded nut still in place. If it's just compressed against the walls of that tube, could the RivNut pull put with a downward force?

M12x1.25 is sourceable. That's what I'm picking up from Fastenal this week here in BC.

I was debating weather to cut the bolts down to M11x1.25 with my die or if I should tap the bolt holes to M12x1.25 using Molybdenum grease as cutting oil and just use the one rivnut for the nut that broke inside my frame. That one will be a M10x1.50 bolt.

Your's is very deep set but I still think a timesert would be a solid alternative to fix that bad boy if necessary.

Cobalt bits would be your friend for the drill out. Not a lot of pressure and it cuts/drills through hardened steel very well.

One thing you might try to do is take a flaat tip screw driver and set it on the edges of the bolt (now that there is a hole through it) and beat the snot out of it with a hammer. The vibration and impacts might loosen the bolt up from the nut. Mind you, just a few love taps aint gonna do much. You will have to beat on it pretty good in at least 4 quadrants if not 8 quadrants.

Also if you have a mini torch / pen torch (butane usually) you can apply some heat to the hole without burning any undercoating etc. With the cold of the winter the metal is contracted gripping the bolt that much tighter.

Heat and beating on it should loosen it. Reverse thread taps are an interesting way to go. If it breaks free during tapping (after heat and beating on it) you are home free and if not, you've reverse threaded it for a grade 12.9 reverse thread bolt to be your extractor.

#10

Honda-Tech Member

Thread Starter

iTrader: (1)

Join Date: Mar 2001

Location: Providence, RI, USA

Posts: 1,654

Likes: 0

Received 0 Likes

on

0 Posts

I also considered drilling through the body under the rear seat to try and access the other side of the nut. I could use a 2" hole saw and just pop a rubber body plug in there afterward so it can be serviced again.

One thing you might try to do is take a flaat tip screw driver and set it on the edges of the bolt (now that there is a hole through it) and beat the snot out of it with a hammer. The vibration and impacts might loosen the bolt up from the nut. Mind you, just a few love taps aint gonna do much. You will have to beat on it pretty good in at least 4 quadrants if not 8 quadrants.

Also if you have a mini torch / pen torch (butane usually) you can apply some heat to the hole without burning any undercoating etc. With the cold of the winter the metal is contracted gripping the bolt that much tighter.

Heat and beating on it should loosen it. Reverse thread taps are an interesting way to go. If it breaks free during tapping (after heat and beating on it) you are home free and if not, you've reverse threaded it for a grade 12.9 reverse thread bolt to be your extractor.

Also if you have a mini torch / pen torch (butane usually) you can apply some heat to the hole without burning any undercoating etc. With the cold of the winter the metal is contracted gripping the bolt that much tighter.

Heat and beating on it should loosen it. Reverse thread taps are an interesting way to go. If it breaks free during tapping (after heat and beating on it) you are home free and if not, you've reverse threaded it for a grade 12.9 reverse thread bolt to be your extractor.

I'm worried that, since I'm off center, it's just not going to back out. I guess I can slowly step up my bit size before the re-tap and see what happens though. I've got a mini-butane torch and it's going to be ~20F when I get home tonight.

Time-Sert seems like my plan B. I'm just unsure whether I should try and seat it 1" deep in this tube, or if it can even be done. The diameter of the countersink bit appears to be too large to go into the hole. I might have to just install it flush with the body and switch to a bolt WITHOUT a shank.

For YOUR torque mount bolt, RivNut seems perfect, although I'd say you're going to need the RivNut tool to compress if it the motor is in the car. How come you're stepping up to M12 there?

#11

I was thinking the same thing for your situation of the flush mount timsert and changing to a non shanked bolt for that one. But if you can get the seized part out successfully, that won't be necessary. I like yours less than mine.

As for my situation, I have the rivnut tool. Picked it up on amazon.ca for less than 60 bucks and it does M4, M6, M8, M10 and M12 rivnuts. Just waiting for the rivnuts to come in from from Fastenal.

And the reason to switch bolt sizes is the torque mount bolts are M11 x 1.25 and the heads don't fit the billet torque mounts very well. M11 x 1.25 is impossible to source outside of the dealership so I was thinking it might be better to change the setup to common metric bolt sizes. The M12 x 1.25 bolt with alan hole heads are grade 12.9 so will be more than sufficient for the job.

The bad thing is the one nut snapped on the passenger side so it will be the oddball as I wasn't able to find M12 x 1.25 rivnuts. As it is, I will have to take my bumper rail off and use a long grabber tool to get the seized bolt and nut out of the frame once I cut the head off.

#13

Honda-Tech Member

Thread Starter

iTrader: (1)

Join Date: Mar 2001

Location: Providence, RI, USA

Posts: 1,654

Likes: 0

Received 0 Likes

on

0 Posts

I HAVE NOT torqued it all the way though. I stopped at 25 ft/lbs, spec is 47 ft/lbs. Am I being overcautious? Can I leave it a bit under with the addition of some threadlock?

#14

Fish Twig

Join Date: Nov 2005

Location: Still hunting that foo up there

Posts: 15,555

Received 309 Likes

on

285 Posts

I think to be on the safe side just drop a dot of blue loctite on there, A DROP, and torque it back to 25lbs. I'll wait for others to drop in and leave there opinions.

#15

I'm not an expert on fasteners. However, I can add a question or two that may help pull the information that would prove helpful.

Is bolt stretch the factor involved in all fasteners in a vehicle or only critical components? How important is bolt/fastener stretch in holding components together? At what point is the torque not for bolt stretch but for securing so as to not back out?

Is bolt stretch the factor involved in all fasteners in a vehicle or only critical components? How important is bolt/fastener stretch in holding components together? At what point is the torque not for bolt stretch but for securing so as to not back out?

#16

Honda-Tech Member

Thread Starter

iTrader: (1)

Join Date: Mar 2001

Location: Providence, RI, USA

Posts: 1,654

Likes: 0

Received 0 Likes

on

0 Posts

It may depend on application. The stretch of a head bolt is definitely to create clamping force. Compare to the force applied to this RTA bushing bolt, on a pivot joint, mounted only to a rubber isolator.

The other factor is size. This is possibly the largest bolt used on any suspension component on the car. Is it being stretched at only 47lb/ft?

How does thread pitch factor in? 1.25 is pretty fine for a 12mm bolt.

The other factor is size. This is possibly the largest bolt used on any suspension component on the car. Is it being stretched at only 47lb/ft?

How does thread pitch factor in? 1.25 is pretty fine for a 12mm bolt.

Thread

Thread Starter

Forum

Replies

Last Post

BrokenBone

Honda Civic / Del Sol (1992 - 2000)

2

01-08-2014 07:23 AM

aimbot

Acura Integra

7

08-07-2008 03:03 PM

truevietluv636

Honda Civic / Del Sol (1992 - 2000)

11

06-06-2007 07:13 AM