compressor wheel "physics"

#1

Honda-Tech Member

Thread Starter

I have done a lot of searching in the net but found only a few studies about this subject and couldn't figure out well:

1. More blades equals less compressor flow at high pressure ratios and rpms but earlier spool up and better flow at lower presure ratios?

(ie if i want more lb/min flow at 1 bar and faster spool up, i would choose more or less blades?)

2. Blade angle sould be at about 65 degrees (found some studies that agree too)? Less blade-cartridge angle means faster spool up but also less flow at high pressure ratios?

3. Higher blade height increases the max wheel flow but also increases surge effects? Why do they sell these higher height compressor wheels?

4. What is the effect of tip height and tip angle to total flow and spool up? There are some opinions that the larger the angle and so the height (i.e. the more swept back it looks), the more efficient the wheel tends to be at high pressure ratios, but the smaller the angle, the more quickly the wheel tends to build pressure and less flow is produced at high pressure ratios.

5. Is it right to assume that the more blade surface we have at the compressor wheel the more flow the wheel can produce, but also more surge effects come up? Thats why GTX 11 blade wheels have this "by pass" air tube to the compressor housing in order to minimize surge?

1. More blades equals less compressor flow at high pressure ratios and rpms but earlier spool up and better flow at lower presure ratios?

(ie if i want more lb/min flow at 1 bar and faster spool up, i would choose more or less blades?)

2. Blade angle sould be at about 65 degrees (found some studies that agree too)? Less blade-cartridge angle means faster spool up but also less flow at high pressure ratios?

3. Higher blade height increases the max wheel flow but also increases surge effects? Why do they sell these higher height compressor wheels?

4. What is the effect of tip height and tip angle to total flow and spool up? There are some opinions that the larger the angle and so the height (i.e. the more swept back it looks), the more efficient the wheel tends to be at high pressure ratios, but the smaller the angle, the more quickly the wheel tends to build pressure and less flow is produced at high pressure ratios.

5. Is it right to assume that the more blade surface we have at the compressor wheel the more flow the wheel can produce, but also more surge effects come up? Thats why GTX 11 blade wheels have this "by pass" air tube to the compressor housing in order to minimize surge?

#2

Honda-Tech Member

Ill answer what i know altho i might be wrong since im not a profesional at turbochargers.

Altho in my opinion most things at the end fall on the paricular end design and its very difficult to generalise.

Altho in my opinion most things at the end fall on the paricular end design and its very difficult to generalise.

I have done a lot of searching in the net but found only a few studies about this subject and couldn't figure out well:

1. More blades equals less compressor flow at high pressure ratios and rpms but earlier spool up and better flow at lower presure ratios? Yes that's what the theory says.

(ie if i want more lb/min flow at 1 bar and faster spool up, i would choose more or less blades?)

You would choose the lighter compressor with the biggest trim for your hp. Altho again at the end a newer design compressor wheel might be better regardless.

2. Blade angle sould be at about 65 degrees (found some studies that agree too)? Less blade-cartridge angle means faster spool up but also less flow at high pressure ratios?

Blade angle on compressors mean better ability to compress aka higher pressure ration. Smaller angle better flow capacity.

3. Higher blade height increases the max wheel flow but also increases surge effects? Why do they sell these higher height compressor wheels?

Not sure really. Extended tip imo really was designed for diesels(like most of the things). But i might be terribly wrong. I allways believed its was a way to have a faster spooling

turbo (in theory..) with the same flow of a bigger wheel.

4. What is the effect of tip height and tip angle to total flow and spool up? There are some opinions that the larger the angle and so the height (i.e. the more swept back it looks), the more efficient the wheel tends to be at high pressure ratios, but the smaller the angle, the more quickly the wheel tends to build pressure and less flow is produced at high pressure ratios.

5. Is it right to assume that the more blade surface we have at the compressor wheel the more flow the wheel can produce, but also more surge effects come up? Thats why GTX 11 blade wheels have this "by pass" air tube to the compressor housing in order to minimize surge? Garrett " designed that 11 blades for less noise i believe and not for us. Maybe for mercedes cars. I never liked the 11 blade design. The hype was much higher than what the compressor maps said.And guess what. Garrett had to release what others did YEARS ago . A normal "billet" 6-7 blade design that actually works for us.And call it gen II

1. More blades equals less compressor flow at high pressure ratios and rpms but earlier spool up and better flow at lower presure ratios? Yes that's what the theory says.

(ie if i want more lb/min flow at 1 bar and faster spool up, i would choose more or less blades?)

You would choose the lighter compressor with the biggest trim for your hp. Altho again at the end a newer design compressor wheel might be better regardless.

2. Blade angle sould be at about 65 degrees (found some studies that agree too)? Less blade-cartridge angle means faster spool up but also less flow at high pressure ratios?

Blade angle on compressors mean better ability to compress aka higher pressure ration. Smaller angle better flow capacity.

3. Higher blade height increases the max wheel flow but also increases surge effects? Why do they sell these higher height compressor wheels?

Not sure really. Extended tip imo really was designed for diesels(like most of the things). But i might be terribly wrong. I allways believed its was a way to have a faster spooling

turbo (in theory..) with the same flow of a bigger wheel.

4. What is the effect of tip height and tip angle to total flow and spool up? There are some opinions that the larger the angle and so the height (i.e. the more swept back it looks), the more efficient the wheel tends to be at high pressure ratios, but the smaller the angle, the more quickly the wheel tends to build pressure and less flow is produced at high pressure ratios.

5. Is it right to assume that the more blade surface we have at the compressor wheel the more flow the wheel can produce, but also more surge effects come up? Thats why GTX 11 blade wheels have this "by pass" air tube to the compressor housing in order to minimize surge? Garrett " designed that 11 blades for less noise i believe and not for us. Maybe for mercedes cars. I never liked the 11 blade design. The hype was much higher than what the compressor maps said.And guess what. Garrett had to release what others did YEARS ago . A normal "billet" 6-7 blade design that actually works for us.And call it gen II

#3

Honda-Tech Member

Thread Starter

thank you for your time.

Seems i started a huge thread with too meny sub-subjects and its tough to get answers, though i am seeking answers from your personal experience such as " i ve replaced my stock 6/6 wheel for an 11 blade GTX style and it was bs/perfect/more power at high rpms", etc...

Seems i started a huge thread with too meny sub-subjects and its tough to get answers, though i am seeking answers from your personal experience such as " i ve replaced my stock 6/6 wheel for an 11 blade GTX style and it was bs/perfect/more power at high rpms", etc...

#4

Honda-Tech Member

I'm confused which direction you were referring to as for the angle of the blades, so I'll make new references for it for better understanding:

blade angle closer to parallel with the shaft will flow higher volume but will be capable of less pressure. They also surge easier.

blade angle closer to perpendicular to the shaft will flow less volume but will be capable of higher pressure. They are more resistent to surge.

taller blades (at the inducer) grab more air and on an airflow standpoint almost always increase airflow, but it is dependent on blade angle. the downside is more mass, which increases lag.

extended tips increase the velocity of the air coming off the exducer, which increases the potential pressure, and typically has a mild increase in potential overall airflow at all compressor rpm's. It effectively increases the exducer diameter without requiring modifications to the housing to accept a larger wheel, because the extended tips are pointed not flat.

through lots and lots of personal hands on research, I have found that 11 blade wheels do in fact flow more air, and are capable of a little higher pressure, but spool slower from the added mass. And vice versa; 6+6 blade wheels spool much faster but don't flow as much air, and the half sized blades actually HURT airflow at higher rpms and higher pressures.

blade angle closer to parallel with the shaft will flow higher volume but will be capable of less pressure. They also surge easier.

blade angle closer to perpendicular to the shaft will flow less volume but will be capable of higher pressure. They are more resistent to surge.

taller blades (at the inducer) grab more air and on an airflow standpoint almost always increase airflow, but it is dependent on blade angle. the downside is more mass, which increases lag.

extended tips increase the velocity of the air coming off the exducer, which increases the potential pressure, and typically has a mild increase in potential overall airflow at all compressor rpm's. It effectively increases the exducer diameter without requiring modifications to the housing to accept a larger wheel, because the extended tips are pointed not flat.

through lots and lots of personal hands on research, I have found that 11 blade wheels do in fact flow more air, and are capable of a little higher pressure, but spool slower from the added mass. And vice versa; 6+6 blade wheels spool much faster but don't flow as much air, and the half sized blades actually HURT airflow at higher rpms and higher pressures.

#5

Honda-Tech Member

as far as blade angle goes, think of it like a plane wing, or helicopter rotor. too little angle, and it's super aerodynamic but very little lift. As you slowly increase the angle, lift increases quickly, drag also increases but not that fast. But then as you get past a certain point and keep increasing the angle, it actually starts losing lift very rapidly and increases drag also very rapidly.

#6

Honda-Tech Member

Thread Starter

Impressive. I think i have all my questions...answered.

I found very intresting the half blade airflow hurt and the helicopter example. Clarifies that bigger blade area makes bigger

inertial mass and air flow drag but also stronger airflow (and lift).

Its seems that if you want more flow without changing housing you must get a compressor with more blades, higher blade height (shaft direction) and extended tips.

I found very intresting the half blade airflow hurt and the helicopter example. Clarifies that bigger blade area makes bigger

inertial mass and air flow drag but also stronger airflow (and lift).

Its seems that if you want more flow without changing housing you must get a compressor with more blades, higher blade height (shaft direction) and extended tips.

Trending Topics

#9

Honda-Tech Member

Thread Starter

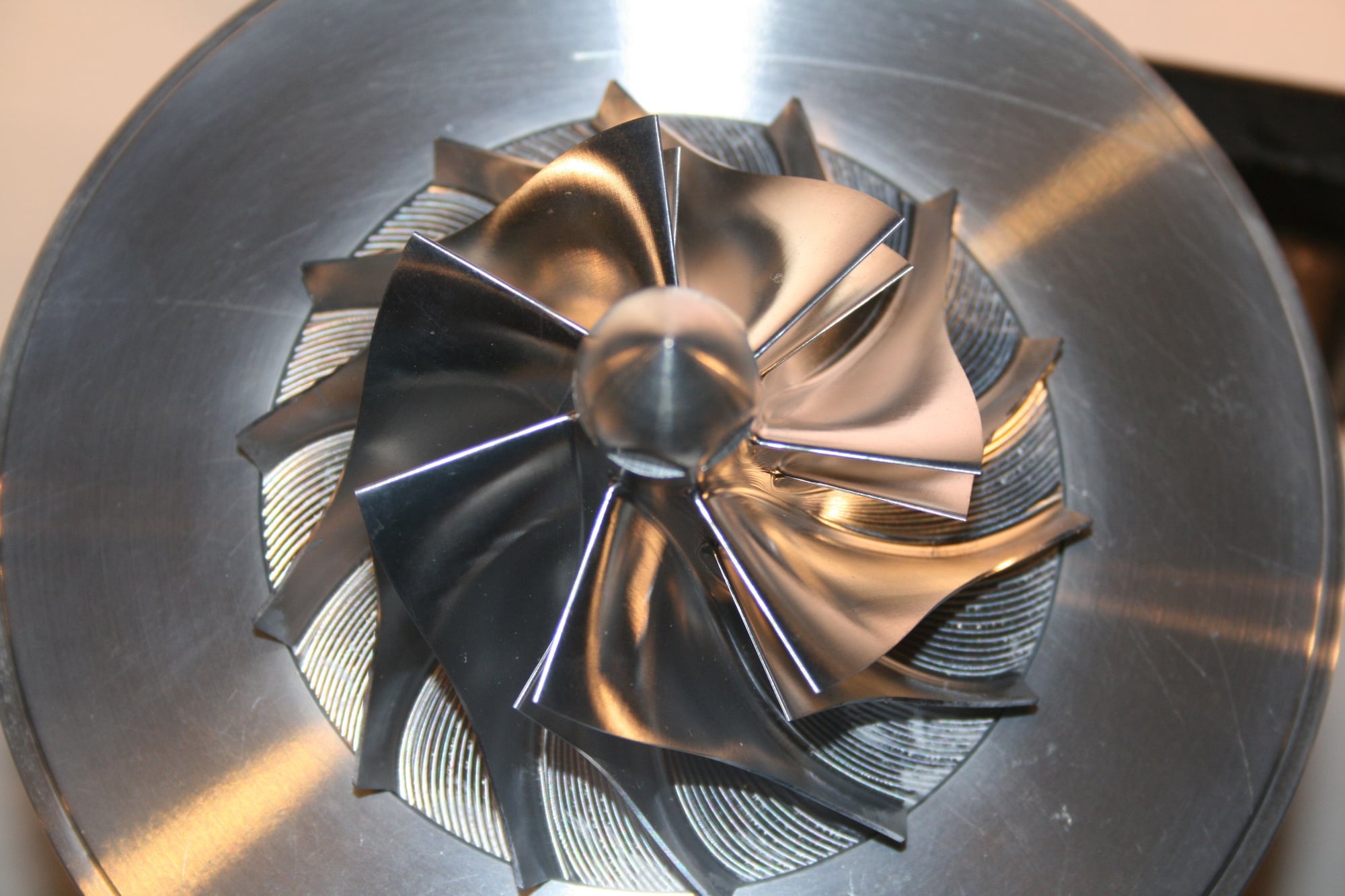

i can see that on the first picture the compressor wheel has extended tip, thinner nut and taller blades.

So i have decided what turbo to use for my application (1.6 si): Due to cost matters i will buy a used td05-16G6 (mitsubishi turbo from EVO 3-10) which has 68mm exducer compressor wheel. After installing the turbo kit and making the first dyno chart, the turbo will be serviced and the compressor wheel will be replaced by an 11 taller blades, extended tip wheel (GTX style) into the stock compressor housing. After balancing and installing the turbo i will do second dyno trying to have same conditions (turbo pressure, external temperature, same AFR, etc).

The td05-16G "large" turbo supposes to make about 350-380 hp at max efficient pressure, so i will see if there will be any gains with the 11 blade wheel.

So i have decided what turbo to use for my application (1.6 si): Due to cost matters i will buy a used td05-16G6 (mitsubishi turbo from EVO 3-10) which has 68mm exducer compressor wheel. After installing the turbo kit and making the first dyno chart, the turbo will be serviced and the compressor wheel will be replaced by an 11 taller blades, extended tip wheel (GTX style) into the stock compressor housing. After balancing and installing the turbo i will do second dyno trying to have same conditions (turbo pressure, external temperature, same AFR, etc).

The td05-16G "large" turbo supposes to make about 350-380 hp at max efficient pressure, so i will see if there will be any gains with the 11 blade wheel.

Last edited by turbomaniac; 11-20-2017 at 12:06 AM.

#10

Honda-Tech Member

Thread Starter

To complete this thread now i am sure; 11 blade wheel makes more power (+5-7%) at high rpms and higher pressure ratios without loosing too much spooling. The most important thing is that 11 blade "GTX" style proved to make more power at very high pressure ratios (ie 35psi) that the 6/6 or 7/7 compressor wheels had given out. 11 blade also makes less sound, although for some people this is not an advantage.

The 6/6 - 7/7 compressor might make more torque at low rpms and spool up a little earlier so probably fits better for road use.

When choosing a billet wheel without changing compressor housing its important to buy the one with the smaller nose dia, taller blades, extended tip and choose blades by application; 6/6 for more torque and spool up and 11 for high rpm power. The high reving honda engines seem to make a match for GTX style 11 blades. Its also important after installing the new wheel always to balance the turbo even if the manufacturer claims that its already balanced and ready to.... race. I have read meny turbo fails from people that didnt do the balancing.

here is a nice link of some GT VS GTX dyno results from perrin:

https://www.perrin.com/blog/post/gar...comparo-part-2

The 6/6 - 7/7 compressor might make more torque at low rpms and spool up a little earlier so probably fits better for road use.

When choosing a billet wheel without changing compressor housing its important to buy the one with the smaller nose dia, taller blades, extended tip and choose blades by application; 6/6 for more torque and spool up and 11 for high rpm power. The high reving honda engines seem to make a match for GTX style 11 blades. Its also important after installing the new wheel always to balance the turbo even if the manufacturer claims that its already balanced and ready to.... race. I have read meny turbo fails from people that didnt do the balancing.

here is a nice link of some GT VS GTX dyno results from perrin:

https://www.perrin.com/blog/post/gar...comparo-part-2

Thread

Thread Starter

Forum

Replies

Last Post

antoni

Forced Induction

37

10-01-2019 03:17 PM

Blitzkrieg

Forced Induction

33

09-23-2006 03:41 AM