Porting head

#1

Dur Da Dur

Thread Starter

iTrader: (1)

Join Date: Aug 2015

Location: Jackson, New Jersey

Posts: 526

Likes: 0

Received 0 Likes

on

0 Posts

am i doin' it rite? I'm using 180 grit sand paper, and i'm starting by taking the casting flaws out, the 'seams' in the ports. This is a D16z6 btw.

#2

Honda-Tech Member

Read my replies here:

https://honda-tech.com/engine-machining-assembly-164/b18c1-exhaust-port-questions-3256785/

Same rules apply to most Honda cylinder heads. Concentrate on blending the bowls/seats and the chamber.

https://honda-tech.com/engine-machining-assembly-164/b18c1-exhaust-port-questions-3256785/

Same rules apply to most Honda cylinder heads. Concentrate on blending the bowls/seats and the chamber.

#6

I was watching this video which was working a Hyundai head which is also an aluminum cast head.

Some really great tips and tricks and catered to fuel injection instead of the old carb methods and theories.

I still have the last 10 minutes to watch where he does the exhaust side. 16 hours shrunk to 20 minutes of video.... Some serious work polishing and porting.

Some really great tips and tricks and catered to fuel injection instead of the old carb methods and theories.

I still have the last 10 minutes to watch where he does the exhaust side. 16 hours shrunk to 20 minutes of video.... Some serious work polishing and porting.

#7

I was watching this video which was working a Hyundai head which is also an aluminum cast head.

Some really great tips and tricks and catered to fuel injection instead of the old carb methods and theories.

I still have the last 10 minutes to watch where he does the exhaust side. 16 hours shrunk to 20 minutes of video.... Some serious work polishing and porting.

Some really great tips and tricks and catered to fuel injection instead of the old carb methods and theories.

I still have the last 10 minutes to watch where he does the exhaust side. 16 hours shrunk to 20 minutes of video.... Some serious work polishing and porting.

Trending Topics

#9

He should figure out if it's true or not once he has a flow bench and other monitoring equipment.

The tips and tricks is on the tools used, hiding the chuck and taping the seats etc. And just the basic idea of clean up.

As for "design" in the porting, well, those are trade secrets that no one shares. Just like you said in your work, I can't tell you.

Same is true with camshaft design.

So, you say hack job but no one is willing to share what they know.

It's still an interesting theory and I'd love to see two intakes, one old school roughed and one with tumble theory smooth and rough dyno tested.

There is other equipment too besides just a flow bench but for the life of me, I've forgotten what it is. CFM alone isn't all of the equation.

The tips and tricks is on the tools used, hiding the chuck and taping the seats etc. And just the basic idea of clean up.

As for "design" in the porting, well, those are trade secrets that no one shares. Just like you said in your work, I can't tell you.

Same is true with camshaft design.

So, you say hack job but no one is willing to share what they know.

It's still an interesting theory and I'd love to see two intakes, one old school roughed and one with tumble theory smooth and rough dyno tested.

There is other equipment too besides just a flow bench but for the life of me, I've forgotten what it is. CFM alone isn't all of the equation.

#10

I read this article awhile back and is where I learned, it's not about CFM and fixating on big CFM only can actually be the death of a good head.

Tech Talk #70 ? Airflow Fallacies: Avoiding the Pitfalls of the Flow Bench | Reher Morrison Racing Engines

And is why I like the guy thinking out side the box and doing something different than everyone else. What I don't get to see is a dyno comparison of one design over the other so really.... Without the proper equipment and knowing all the parameters....

Anyways, some of you might find the article interesting.

Been looking into the effects of smooth vs rough surface and I think it's an interesting idea the person was trying but I think process should be opposite. The smooth top will cause a a slow down up top so in theory cause a reverse tumble situation as the rough bottom will cause the mini eddies that let the flow cruise on by.

So maybe do the smooth shiny finish on the bottom so the slow down happens at the bottom creating a forward tumble to happen towards the top.

The effect can be seen here:

Recent studies and information on smooth pipe rough pipe, putting it here so not to lose it:

Turbulent flow in smooth and rough pipes | Philosophical Transactions of the Royal Society of London A: Mathematical, Physical and Engineering Sciences

Recent mathematics study chapter of pipe flows:

Pipeflow_intro.pdf

Tech Talk #70 ? Airflow Fallacies: Avoiding the Pitfalls of the Flow Bench | Reher Morrison Racing Engines

And is why I like the guy thinking out side the box and doing something different than everyone else. What I don't get to see is a dyno comparison of one design over the other so really.... Without the proper equipment and knowing all the parameters....

Anyways, some of you might find the article interesting.

Been looking into the effects of smooth vs rough surface and I think it's an interesting idea the person was trying but I think process should be opposite. The smooth top will cause a a slow down up top so in theory cause a reverse tumble situation as the rough bottom will cause the mini eddies that let the flow cruise on by.

So maybe do the smooth shiny finish on the bottom so the slow down happens at the bottom creating a forward tumble to happen towards the top.

The effect can be seen here:

Recent studies and information on smooth pipe rough pipe, putting it here so not to lose it:

Turbulent flow in smooth and rough pipes | Philosophical Transactions of the Royal Society of London A: Mathematical, Physical and Engineering Sciences

Recent mathematics study chapter of pipe flows:

Pipeflow_intro.pdf

Last edited by TomCat39; 11-26-2015 at 09:42 AM.

#11

#12

I've been looking at a lot of papers concerning flow characteristics through pipes. And there has been a **** ton of formulas but I was struggling to find the bit about how the surface impacts air velocity. The usual answer was almost always an equation and my old feeble brain doesn't pick up the math like it used to.

However I finally found the earth tube talking about the same exact math formulas and theories here:

Earth Tube Equations - Home in the Earth

And in it, it says what I suspected based on a diagram or two:

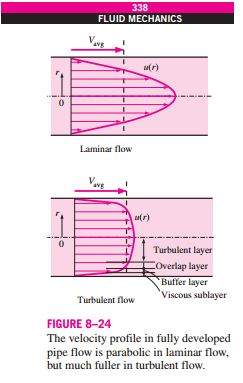

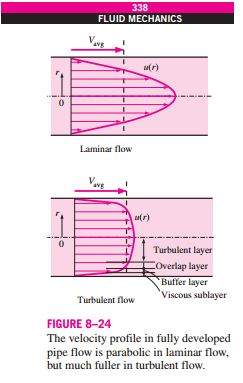

What I have noticed is the laminar flow may have the higher velocity flow in it's center profile, while the turbulent flow may have reduced velocity flow but more of the flow is a consistent velocity.

Now, some questions come to mind with this.... Turbulence is helpful in the combustion chamber... Which is more important, turbulence or velocity?

I am thinking when the valves open, if you have a laminar flow you will be receiving multiple velocity air flows into the combustion chamber and so based on piston design will determine how turbulent the laminar flow becomes upon hitting the piston.

So now, with current day fuel injection where there is no atomization benefit in the intake manifold itself due to the position of the injector compared to the carburetor model, do you want to attempt getting as close to the laminar model with the smoothest surfaces possible for the highest flow velocity, or do you want to reduce the top velocity by creating a turbulent air flow prior to entering the combustion chamber with the roughest surface possible?

The difference looks like this in flows:

Found this on the corvette forums which seems to be in line with all the technical paper findings and fits what is seen between old technology and new technology:

However I finally found the earth tube talking about the same exact math formulas and theories here:

Earth Tube Equations - Home in the Earth

And in it, it says what I suspected based on a diagram or two:

However, even without entering numbers, the equations tell most of what you need to know about the relationship between the parameters. Understanding these relationships leads to design insight.

The DArcy equation predicts the frictional pressure losses in ducted air systems like Earth Tubes

The friction losses are due to viscous interactions between the air and the pipe walls and can be expressed with the D’Arcy-Weisbach Equation. In this equation;

–∆Pf = frictional pressure drop

–λf = friction factor (based on material, Re and Dm)

–L = length of duct

–v = mean duct velocity

–g = gravitational constant

–Dm = hydraulic mean diameter (cross sectional area / perimeter)

Some things are immediately apparent from the equation; for instance, the pressure drop is proportional to the friction factor. In other words, the rougher the pipe wall, the higher the frictional pressure loss (which seems pretty obvious). This should affect your material choice; PVC is 200 times smoother than concrete, HDPE is even smoother. Increased length is also a factor; while we want length to provide more contact for heat exchange, too much and the flow could stop. Velocity is very important because this is squared. In other words, if you double the velocity, the pressure drop is affected by a power of 4. If we reduce our velocity from 700 to 175 ft/min, we reduce the velocity by a factor of 4, and our pressure losses by a factor of 16. Passive systems tend to move the air relatively slowly, but adding a fan to increase the velocity may actually be counter productive (choose a fan with high pressure rather than high velocity ratings).

The DArcy equation predicts the frictional pressure losses in ducted air systems like Earth Tubes

The friction losses are due to viscous interactions between the air and the pipe walls and can be expressed with the D’Arcy-Weisbach Equation. In this equation;

–∆Pf = frictional pressure drop

–λf = friction factor (based on material, Re and Dm)

–L = length of duct

–v = mean duct velocity

–g = gravitational constant

–Dm = hydraulic mean diameter (cross sectional area / perimeter)

Some things are immediately apparent from the equation; for instance, the pressure drop is proportional to the friction factor. In other words, the rougher the pipe wall, the higher the frictional pressure loss (which seems pretty obvious). This should affect your material choice; PVC is 200 times smoother than concrete, HDPE is even smoother. Increased length is also a factor; while we want length to provide more contact for heat exchange, too much and the flow could stop. Velocity is very important because this is squared. In other words, if you double the velocity, the pressure drop is affected by a power of 4. If we reduce our velocity from 700 to 175 ft/min, we reduce the velocity by a factor of 4, and our pressure losses by a factor of 16. Passive systems tend to move the air relatively slowly, but adding a fan to increase the velocity may actually be counter productive (choose a fan with high pressure rather than high velocity ratings).

Now, some questions come to mind with this.... Turbulence is helpful in the combustion chamber... Which is more important, turbulence or velocity?

I am thinking when the valves open, if you have a laminar flow you will be receiving multiple velocity air flows into the combustion chamber and so based on piston design will determine how turbulent the laminar flow becomes upon hitting the piston.

So now, with current day fuel injection where there is no atomization benefit in the intake manifold itself due to the position of the injector compared to the carburetor model, do you want to attempt getting as close to the laminar model with the smoothest surfaces possible for the highest flow velocity, or do you want to reduce the top velocity by creating a turbulent air flow prior to entering the combustion chamber with the roughest surface possible?

The difference looks like this in flows:

Found this on the corvette forums which seems to be in line with all the technical paper findings and fits what is seen between old technology and new technology:

Dry airflow should be mirror polished to get the most flow out of a given Intake runner.

Wet air flow "with fuel suspended" requires turbulance and heat to keep the fuel a mist instead of dropletts.

It's apples and oranges trying to compare a carburated single plane manifold to a dry air ported and polished Super Ram or LS1-lS6 intake.

You have to think about intake dynamics. For more than 1/2 the time in a running 4 cycle motor no air is moving in the intake port

Read more: http://www.corvetteforum.com/forums/...#ixzz3slBcQKW4

Wet air flow "with fuel suspended" requires turbulance and heat to keep the fuel a mist instead of dropletts.

It's apples and oranges trying to compare a carburated single plane manifold to a dry air ported and polished Super Ram or LS1-lS6 intake.

You have to think about intake dynamics. For more than 1/2 the time in a running 4 cycle motor no air is moving in the intake port

Read more: http://www.corvetteforum.com/forums/...#ixzz3slBcQKW4

Last edited by TomCat39; 11-27-2015 at 08:14 PM.

#13

Now I'm finding some other interesting information that thickens the plot.

Concerning capillary tension. Also another tidbit which I suspected. The velocity is such that you will never have laminar flow in the intake tubes, which I suspected at first but being my feeble mind struggles with all the math now a days, I couldn't piece together so had to humor the thought of laminar flow and it's possibilities until someone could explain otherwise reasonably.

In a turbulent flow, capillary tension is a large nuisance to the flow and reduces velocity even further than what it's reduced already by going turbulent.

This latest info I have found is people discussing this exact subject and the finding of what the major race intake manifolds use. Racing is nothing but research and development so you know very well they have tried every combination out there to see what works and what does not.

I'm not sure why some of the latest LS engine manifolds are mirror smooth unless it's maybe a forced induction setting.

Anyways, there seems to be some really solid information in this thread:

Polished intake manifolds are VERY BAD! - Page 2 - RX7Club.com

Of note, the consensus based off the high end racing manifolds is a smooth finish of about 220 grit. Smooth to the finger with a touch of rough to the fingernail. But not mirror smooth.

And here from that thread is a very clear explaination of why the mirror smooth idea is impractical in engines today even if fuel injected:

From all of this, I gather 80 grit might be a bit rough for best results but not detrimental like casting slag and mirror smooth is hoping for something that is so highly improbable in the real world that it's not worth the time or effort as it is likely to back fire in your face when the air goes turbulent.

So now that the surfacing is covered pretty well for the intake, what are the best shaping practices?

I am aware there is two different possible goals, performance and economy.

Performance, a tumble outcome of the air is desirable and economy a swirl outcome is desirable.

What shaping causes what?

Also this still begs the question, would doing a super smooth surface on the short radius on the head cause a last minute tumble to happen? The exact reverse of what the guy did in the video I posted.

Concerning capillary tension. Also another tidbit which I suspected. The velocity is such that you will never have laminar flow in the intake tubes, which I suspected at first but being my feeble mind struggles with all the math now a days, I couldn't piece together so had to humor the thought of laminar flow and it's possibilities until someone could explain otherwise reasonably.

In a turbulent flow, capillary tension is a large nuisance to the flow and reduces velocity even further than what it's reduced already by going turbulent.

This latest info I have found is people discussing this exact subject and the finding of what the major race intake manifolds use. Racing is nothing but research and development so you know very well they have tried every combination out there to see what works and what does not.

I'm not sure why some of the latest LS engine manifolds are mirror smooth unless it's maybe a forced induction setting.

Anyways, there seems to be some really solid information in this thread:

Polished intake manifolds are VERY BAD! - Page 2 - RX7Club.com

Of note, the consensus based off the high end racing manifolds is a smooth finish of about 220 grit. Smooth to the finger with a touch of rough to the fingernail. But not mirror smooth.

And here from that thread is a very clear explaination of why the mirror smooth idea is impractical in engines today even if fuel injected:

Airflow over any surface creates a boundary layer, which in very simplistic terms is like a thin film of air that follows the surface to help the rest of the air flow around it. As was stated before, if your intake is fairly straight without any bends or protrusions, then you want the inside surface to be as smooth as possible, because it helps maintain the initial laminar boundary layer, which in a perfect world is the best and smoothest layer. Unfortunately, intakes are rarely completely straight and smooth, and a laminar boundary layer is extremely fragile; it doesn't take much aerodynamically to upset a laminar boundary layer, and the numerous bends and twists in an intake basically make it impossible for a laminar boundary layer to exist.

The next stage of boundary layer airflow before it separates from the surface completely and tumbles into a wake (which slows down airflow drastically and creates pressure drag) is called a turbulent boundary layer. The advantages of this stage of boundary layer is that it has more energy, which gives the airflow momentum (and speed) to follow gentle curves and bends that the laminar boundary layer cannot.

The rough internal surface basically "trips" the airflow into the turbulent boundary layer stage more quickly, so that the airflow can follow the bends of an intake with more speed. It's the same concept as the dimples in a golf ball; the dimples create an earlier formation of turbulent boundary layer that allow the airflow to maintain speed and cling to the trailing surface of the ball longer, reducing drag and allowing the ball to travel farther.

The next stage of boundary layer airflow before it separates from the surface completely and tumbles into a wake (which slows down airflow drastically and creates pressure drag) is called a turbulent boundary layer. The advantages of this stage of boundary layer is that it has more energy, which gives the airflow momentum (and speed) to follow gentle curves and bends that the laminar boundary layer cannot.

The rough internal surface basically "trips" the airflow into the turbulent boundary layer stage more quickly, so that the airflow can follow the bends of an intake with more speed. It's the same concept as the dimples in a golf ball; the dimples create an earlier formation of turbulent boundary layer that allow the airflow to maintain speed and cling to the trailing surface of the ball longer, reducing drag and allowing the ball to travel farther.

So now that the surfacing is covered pretty well for the intake, what are the best shaping practices?

I am aware there is two different possible goals, performance and economy.

Performance, a tumble outcome of the air is desirable and economy a swirl outcome is desirable.

What shaping causes what?

Also this still begs the question, would doing a super smooth surface on the short radius on the head cause a last minute tumble to happen? The exact reverse of what the guy did in the video I posted.

Last edited by TomCat39; 11-28-2015 at 10:37 AM.

Thread

Thread Starter

Forum

Replies

Last Post