Why do people make their t3 collectors round?

#1

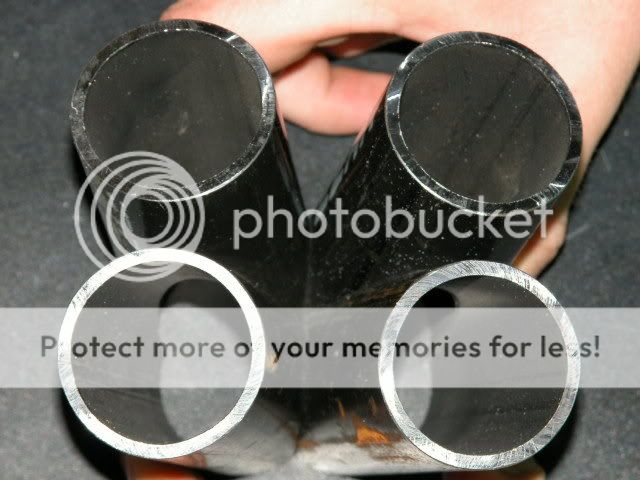

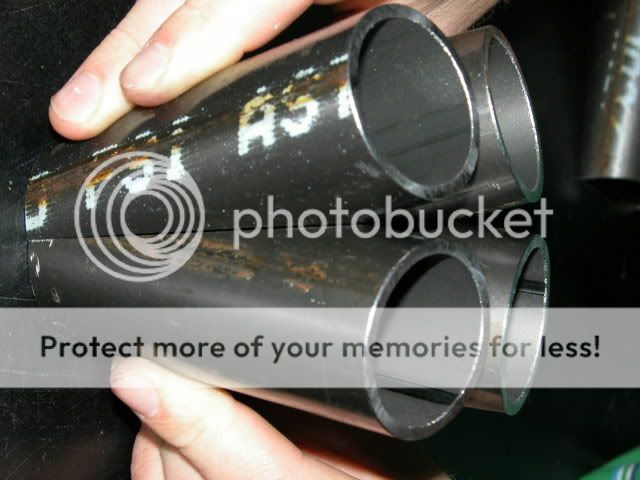

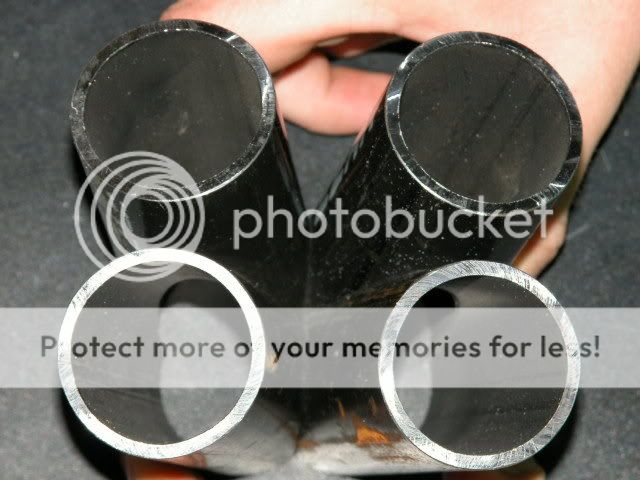

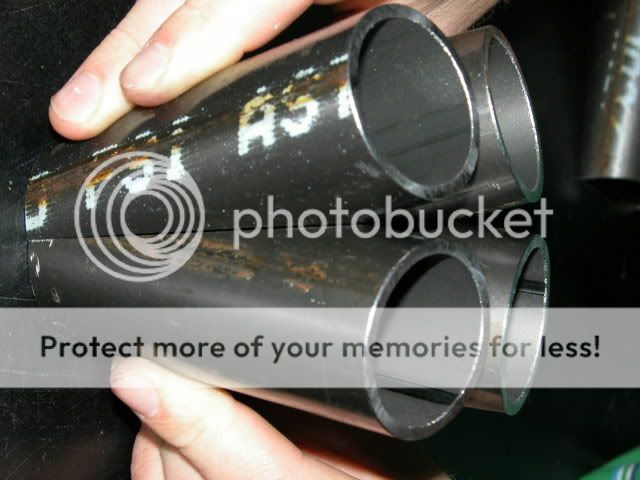

Why do people make their t3 collectors round? The turbine inlet on a t3 is rectangle, so why not make them in a rectangle shape. I just made a couple t3 collectors, 15 degree angle, 1.25"sch40 mild steel, cut on a mill.

You can also see I cut the 15degree angle at the bottom of the collector where it mate to the flange ahead of time, seems most of the collectors I see don't do that, seems kind of backwards

Here are some pics of a collector I cut for a variable vane turbo with a circle inlet:

You can also see I cut the 15degree angle at the bottom of the collector where it mate to the flange ahead of time, seems most of the collectors I see don't do that, seems kind of backwards

Here are some pics of a collector I cut for a variable vane turbo with a circle inlet:

#4

Thanks it really does fit together great. I don't have any pics of my jig, I don't have a digital camera and the mill is not mine, its a friends shop, the jig stays there. I will try and get some pictures sometime though, we came up with a really simple and easy jig, superstrong and perfect repeatability between collectors.

#6

damn, looks great.

you should sell the pipes already cut, and let other people weld them up (or mess them up in my case )

)

especially if the repeatability is dead on like that

you should sell the pipes already cut, and let other people weld them up (or mess them up in my case

)

)especially if the repeatability is dead on like that

#7

I was planning on selling some yes, I will have to make another jig for 1.5" pipe though for all you DOHC guys, for people like me running and 8v these are perfect. I made these for vw tdi and IDI engines.

Trending Topics

#10

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by beasty=eg »</TD></TR><TR><TD CLASS="quote">hey thats nice ....hey i wanna get a collector but with two tube cut with the flang so that I can try to make a top mount out the top half of my header I've seen it done on a single cam </TD></TR></TABLE>

Huh? I'm not picking up what you are throwing down, can you explain this better?

Huh? I'm not picking up what you are throwing down, can you explain this better?

#11

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by dave@passenger »</TD></TR><TR><TD CLASS="quote">Huh? I'm not picking up what you are throwing down, can you explain this better?  </TD></TR></TABLE>

</TD></TR></TABLE>

i think he wants you to make hima merge collector,

but he only need to pipes to merge.

he will be adding an extention onto the bottom of a header.

like this:

</TD></TR></TABLE>

</TD></TR></TABLE>i think he wants you to make hima merge collector,

but he only need to pipes to merge.

he will be adding an extention onto the bottom of a header.

like this:

#16

verry nice job. I think most people that make collectors don't do two different agles because it would take twice as long to make one collector.

Doing it the way you did, it defenetlly makes it way nicer to weld to a t3 flange.

I usually just make them the same and put it in a vice and make the collecotr rectangular to mate to the t3 flange.

Doing it the way you did, it defenetlly makes it way nicer to weld to a t3 flange.

I usually just make them the same and put it in a vice and make the collecotr rectangular to mate to the t3 flange.

#17

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by beasty=eg »</TD></TR><TR><TD CLASS="quote">CAN SOMEONE HELP US ??????????????

</TD></TR></TABLE>

might want to start your own thread, instead of whoring this guys thread up,

or pm him

</TD></TR></TABLE>

might want to start your own thread, instead of whoring this guys thread up,

or pm him

#19

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by Kelly. »</TD></TR><TR><TD CLASS="quote">i think he wants you to make hima merge collector,

but he only need to pipes to merge.

he will be adding an extention onto the bottom of a header.

like this:

</TD></TR></TABLE>

</TD></TR></TABLE>

Maybe I am just stupid but I still don't get it. Did you mean "two" instead of "to"?

but he only need to pipes to merge.

he will be adding an extention onto the bottom of a header.

like this:

</TD></TR></TABLE>

</TD></TR></TABLE>Maybe I am just stupid but I still don't get it. Did you mean "two" instead of "to"?

#20

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by Running925 »</TD></TR><TR><TD CLASS="quote">i'd definatly be interested in purchasing the 4 pipes pre-cut so that i could form my own collector.

1.5 inch tho.

when do you think you could make some more of those!?!?</TD></TR></TABLE>

I could make them whenever, I don't need 1.5" collectors myself so if I am going to make them for somone I want to make a few so its worth my while, and they aren't going to be dirt cheap either, it takes a while to make a jig and cut everything on a mill, but the fitement and repeatability is perfect, you get what you pay for. As you can see I also cut my collectors angle (say 15degrees) so that they sit flush on the flange, seems most of the ones I see here don't, I'm not sure how these guys go about cutting those afterwards or if they even do. Also the ends that mate to the primaries are also surfaced on the mill. I think I am gonna cad up the base of my collectors and get Sam at BMCrace to mill the shape and angle into the flange to make an ultra smooth flowing collector/flange

1.5 inch tho.

when do you think you could make some more of those!?!?</TD></TR></TABLE>

I could make them whenever, I don't need 1.5" collectors myself so if I am going to make them for somone I want to make a few so its worth my while, and they aren't going to be dirt cheap either, it takes a while to make a jig and cut everything on a mill, but the fitement and repeatability is perfect, you get what you pay for. As you can see I also cut my collectors angle (say 15degrees) so that they sit flush on the flange, seems most of the ones I see here don't, I'm not sure how these guys go about cutting those afterwards or if they even do. Also the ends that mate to the primaries are also surfaced on the mill. I think I am gonna cad up the base of my collectors and get Sam at BMCrace to mill the shape and angle into the flange to make an ultra smooth flowing collector/flange

#21

Hogged it off with a cutter and the ends with an end mill.

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by legendboy »</TD></TR><TR><TD CLASS="quote">mind my asking if u use a slitting saw and then bounced over them with a cutter or just hog it off with a cutter?</TD></TR></TABLE>

#22

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by redboost10 »</TD></TR><TR><TD CLASS="quote">this is how i did my collectors, it takes more time to set it up to make two different cuts, but it fits on the flange so much better, its worth it.</TD></TR></TABLE>

No doubt

No doubt

#23

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by dave@passenger »</TD></TR><TR><TD CLASS="quote">

I could make them whenever, I don't need 1.5" collectors myself so if I am going to make them for somone I want to make a few so its worth my while, and they aren't going to be dirt cheap either, it takes a while to make a jig and cut everything on a mill, but the fitement and repeatability is perfect, you get what you pay for. As you can see I also cut my collectors angle (say 15degrees) so that they sit flush on the flange, seems most of the ones I see here don't, I'm not sure how these guys go about cutting those afterwards or if they even do. Also the ends that mate to the primaries are also surfaced on the mill. I think I am gonna cad up the base of my collectors and get Sam at BMCrace to mill the shape and angle into the flange to make an ultra smooth flowing collector/flange </TD></TR></TABLE>

</TD></TR></TABLE>

If your willing to cut the pipes for a resonable price i'll take 2 sets of them, i'll weld them together, i just like your cuts & the only equiptment i have to do the cuts would be my sawzall & a vice, so you can see why i would like to have the pre-cut pipes. let us know. Also PM me if you decide you can do them. I might be able to get a couple more sets from you if the price is right.

tony

I could make them whenever, I don't need 1.5" collectors myself so if I am going to make them for somone I want to make a few so its worth my while, and they aren't going to be dirt cheap either, it takes a while to make a jig and cut everything on a mill, but the fitement and repeatability is perfect, you get what you pay for. As you can see I also cut my collectors angle (say 15degrees) so that they sit flush on the flange, seems most of the ones I see here don't, I'm not sure how these guys go about cutting those afterwards or if they even do. Also the ends that mate to the primaries are also surfaced on the mill. I think I am gonna cad up the base of my collectors and get Sam at BMCrace to mill the shape and angle into the flange to make an ultra smooth flowing collector/flange

</TD></TR></TABLE>

</TD></TR></TABLE>If your willing to cut the pipes for a resonable price i'll take 2 sets of them, i'll weld them together, i just like your cuts & the only equiptment i have to do the cuts would be my sawzall & a vice, so you can see why i would like to have the pre-cut pipes. let us know. Also PM me if you decide you can do them. I might be able to get a couple more sets from you if the price is right.

tony

#24

Somebody complained that this looked like a commercial thread, so please be careful and don't start selling stuff in a tech forum.