Some Dummy's Welding Photos

#1

Honda-Tech Member

Thread Starter

Join Date: May 2007

Location: Orlando, Fl, USA

Posts: 12

Likes: 0

Received 0 Likes

on

0 Posts

I weld race cars for a living. I've been welding a little over a year. Here's some stuff I've done within the past six months.

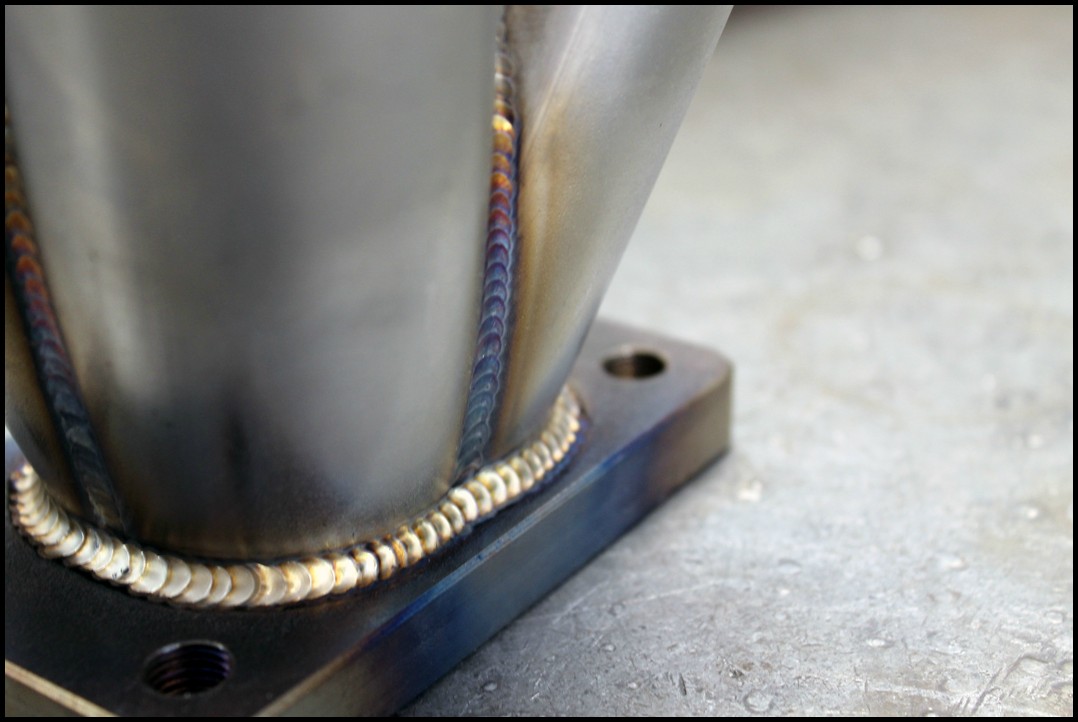

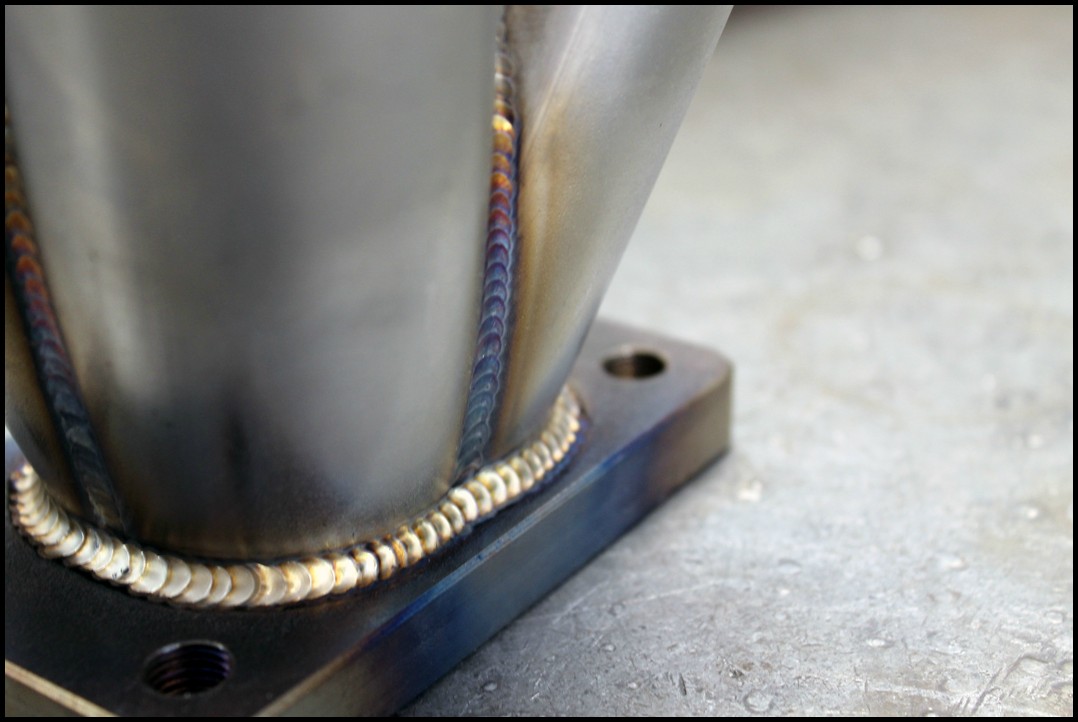

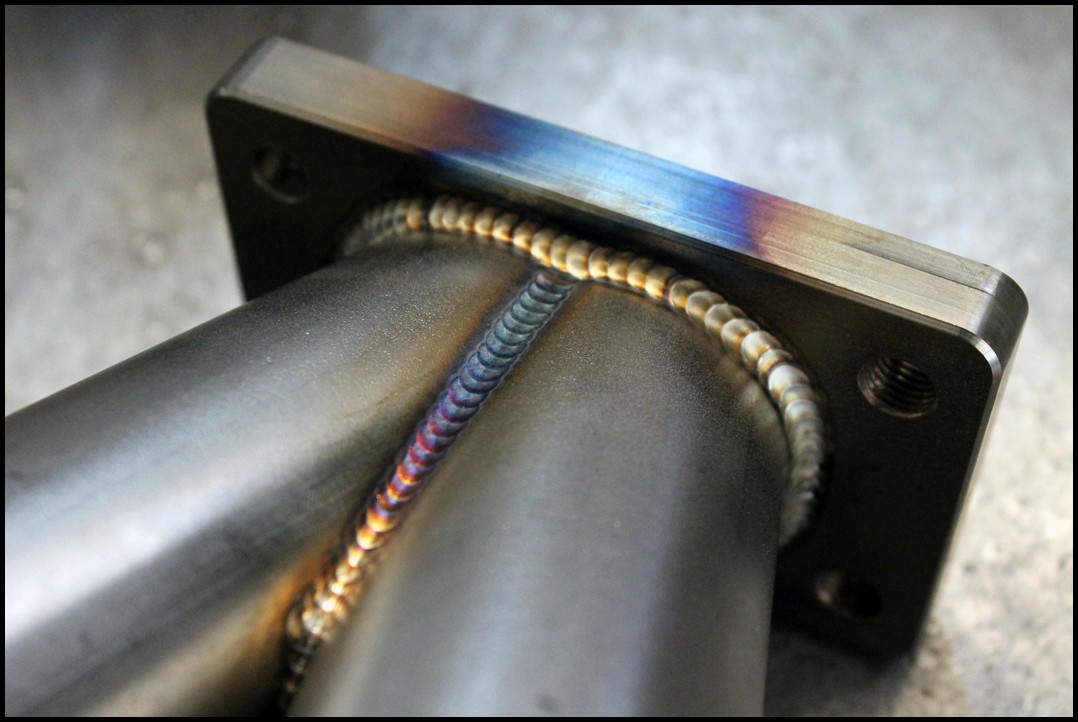

KA24DE manifold.

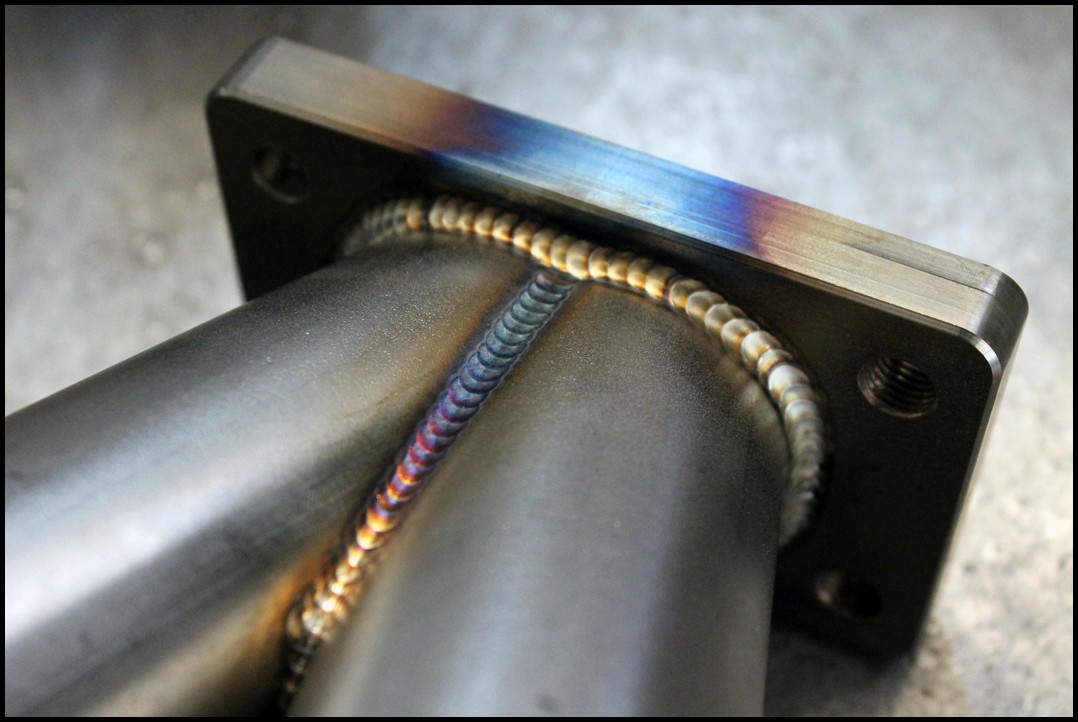

New axle bits for a S chassis.

An SR20DET manifold with four EGT bungs.

SR20DET intake manifolds to fit RHD and LHD cars. I later started sanding these a lot more smooth.

My torch setup I use a lot of the day and skin cancer forming on my filler rod hand.

Bonus pictures.

Collector crazy.

Some times I MIG weld.

Oh yeah, 56K warning! Welp, that's my post see ya!!

KA24DE manifold.

New axle bits for a S chassis.

An SR20DET manifold with four EGT bungs.

SR20DET intake manifolds to fit RHD and LHD cars. I later started sanding these a lot more smooth.

My torch setup I use a lot of the day and skin cancer forming on my filler rod hand.

Bonus pictures.

Collector crazy.

Some times I MIG weld.

Oh yeah, 56K warning! Welp, that's my post see ya!!

#5

Honda-Tech Member

Join Date: Jun 2004

Location: Kent, WA, USA

Posts: 426

Likes: 0

Received 0 Likes

on

0 Posts

Looking good I take it that you're using .035 filler rod for welding onto pipe? What are your thoughts on full penetration regarding butt welds for your turbo manifolds is it sufficient enough withstand a lot of pressure? I haven't built any turbo manifolds yet so I have a lot of questions on what works and what doesn't

#6

Honda-Tech Member

Thread Starter

Join Date: May 2007

Location: Orlando, Fl, USA

Posts: 12

Likes: 0

Received 0 Likes

on

0 Posts

I bounce around a bit on my filler size depending, and I don't want to tell you something that will stick in your mind as the gospel. You'll see what works and what doesn't. In general the rod size should rest inside the root of the weld, and adjust it from there. Again, depending on pulse width, amperage, metal thickness, etc.

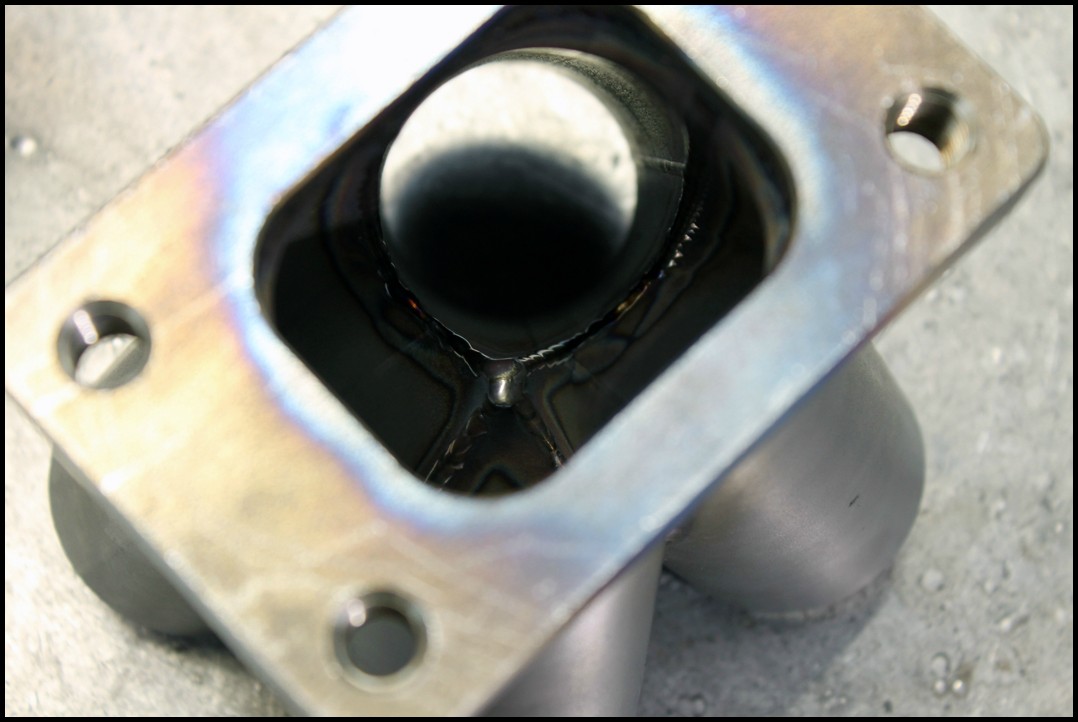

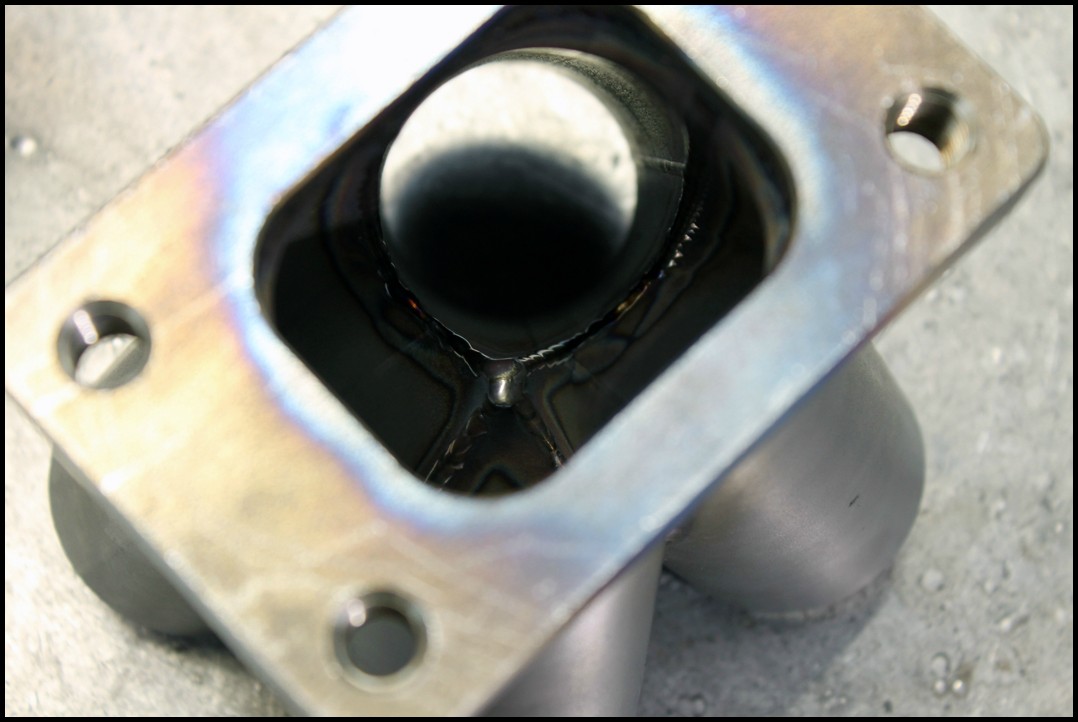

I bevel the pipe and elbows and allow for an open root on the collector to runner pieces (which seem to have the most stress due to vibration) and my penetration is acceptable to me. I back purge the whole time I am welding to eliminate sugaring and I shoot for 99% penetration if that makes sense. I am trying to leave the inside of the runners smooth where the pieces fit together and I cut apart test pieces from time to time and I pretty much hit what I am going for pretty constant. Yes, a properly fitted and penetrated piece will be smooth on the inside if welded correctly, but I cannot see inside every section of every runner so I am leaving myself some breathing room for flow.

See what works for you, because what I do might not be how you feel comfortable.

I bevel the pipe and elbows and allow for an open root on the collector to runner pieces (which seem to have the most stress due to vibration) and my penetration is acceptable to me. I back purge the whole time I am welding to eliminate sugaring and I shoot for 99% penetration if that makes sense. I am trying to leave the inside of the runners smooth where the pieces fit together and I cut apart test pieces from time to time and I pretty much hit what I am going for pretty constant. Yes, a properly fitted and penetrated piece will be smooth on the inside if welded correctly, but I cannot see inside every section of every runner so I am leaving myself some breathing room for flow.

See what works for you, because what I do might not be how you feel comfortable.

#7

Honda-Tech Member

Thread Starter

Join Date: May 2007

Location: Orlando, Fl, USA

Posts: 12

Likes: 0

Received 0 Likes

on

0 Posts

I go to a few American Welding Society meetings when I can, and I've brought projects for the welding inspectors to go over and it's very humbling. I recommend it to everyone who is serious about welding.

Trending Topics

#9

Honda-Tech Member

Join Date: Feb 2008

Location: Orlando, FL

Posts: 123

Likes: 0

Received 0 Likes

on

0 Posts

Nice work, meticulous for sure. What's your approach to fight the runners moving when being welded? Obviously alternating sides of the pipe, but wondering if you take anything else into consideration to battle the issue.

How are you making repeatable cuts at the same angle and depth on 90's?

Those plennums look like a blast to weld, are the pipe and sheet being plasma cut for those? What machine?

How are you making repeatable cuts at the same angle and depth on 90's?

Those plennums look like a blast to weld, are the pipe and sheet being plasma cut for those? What machine?

#11

Honda-Tech Member

Thread Starter

Join Date: May 2007

Location: Orlando, Fl, USA

Posts: 12

Likes: 0

Received 0 Likes

on

0 Posts

#12

Honda-Tech Member

Thread Starter

Join Date: May 2007

Location: Orlando, Fl, USA

Posts: 12

Likes: 0

Received 0 Likes

on

0 Posts

Nice work, meticulous for sure. What's your approach to fight the runners moving when being welded? Obviously alternating sides of the pipe, but wondering if you take anything else into consideration to battle the issue.

How are you making repeatable cuts at the same angle and depth on 90's?

Those plennums look like a blast to weld, are the pipe and sheet being plasma cut for those? What machine?

How are you making repeatable cuts at the same angle and depth on 90's?

Those plennums look like a blast to weld, are the pipe and sheet being plasma cut for those? What machine?

The runners for intakes are cut with a sheer and trimmed to the correct dimensions with a CNC 3-axis machine.

#13

Honda-Tech Member

Join Date: Jun 2004

Location: Kent, WA, USA

Posts: 426

Likes: 0

Received 0 Likes

on

0 Posts

That is what I'm trying to figure out. I get your idea of 99% penetration and if I were to tackle a manifold project like yours I would think your process would be ideal. The question is since everyone is shooting for full penetration on these weld els would that even be more beneficial than the welds you've produced as far as cracking, longevity and etc... I have my own opinion on why manifolds can crack and I'll blame the 304 itself for being inferior for the type of application it's being used for and improper welding technique if its present.

#14

Honda-Tech Member

Thread Starter

Join Date: May 2007

Location: Orlando, Fl, USA

Posts: 12

Likes: 0

Received 0 Likes

on

0 Posts

I just cut apart another test piece today this is what I shoot for. Totally no penetration.

The only problems I've had is from making waste gate dump tubes from sch. 10 cast material, it acted a bit like a lever and would crack the steel in the heat effected zone and leave the weld still attached. I'd say a lot of problems stems from the material coming from all over the place, so a lot of smaller places don't know what they are getting.

The only problems I've had is from making waste gate dump tubes from sch. 10 cast material, it acted a bit like a lever and would crack the steel in the heat effected zone and leave the weld still attached. I'd say a lot of problems stems from the material coming from all over the place, so a lot of smaller places don't know what they are getting.

#15

Honda-Tech Member

Join Date: Jun 2004

Location: Kent, WA, USA

Posts: 426

Likes: 0

Received 0 Likes

on

0 Posts

I just cut apart another test piece today this is what I shoot for. Totally no penetration.

The only problems I've had is from making waste gate dump tubes from sch. 10 cast material, it acted a bit like a lever and would crack the steel in the heat effected zone and leave the weld still attached. I'd say a lot of problems stems from the material coming from all over the place, so a lot of smaller places don't know what they are getting.

The only problems I've had is from making waste gate dump tubes from sch. 10 cast material, it acted a bit like a lever and would crack the steel in the heat effected zone and leave the weld still attached. I'd say a lot of problems stems from the material coming from all over the place, so a lot of smaller places don't know what they are getting.

#16

Why would you actively shoot for no penetration? As stated earlier all your doing is wasting gas purging w/o penetration. If you want minimal backfill why not run a fusion root pass?

Also making dumptubes of schedule 10 is ridiculous.

Also making dumptubes of schedule 10 is ridiculous.

#17

Honda-Tech Member

Thread Starter

Join Date: May 2007

Location: Orlando, Fl, USA

Posts: 12

Likes: 0

Received 0 Likes

on

0 Posts

I purge because I leave an open root on the collector, and I allow for a 1/16" open root on the runners. I just leave in the purging tubes and junk hooked up the whole time I am welding (I don't pay for argon out of my own pocket or anything heh).

I just do it the way I do because it works for me. Some people want a root and a cover pass, I'd rather just hammer it out in one pass and be done. I prefer to whip method MIG welding, some people prefer that circle business. Different strokes, I guess.

Also, yeah I fought that sch. 10 dump tube **** for a year before I could order some thinner material. Baby steps.

I just do it the way I do because it works for me. Some people want a root and a cover pass, I'd rather just hammer it out in one pass and be done. I prefer to whip method MIG welding, some people prefer that circle business. Different strokes, I guess.

Also, yeah I fought that sch. 10 dump tube **** for a year before I could order some thinner material. Baby steps.

#19

Honda-Tech Member

Join Date: Feb 2008

Location: Orlando, FL

Posts: 123

Likes: 0

Received 0 Likes

on

0 Posts

Im sure he was being sarcastic when he said it had no penetration. People just have different view points on what that means i suppose.

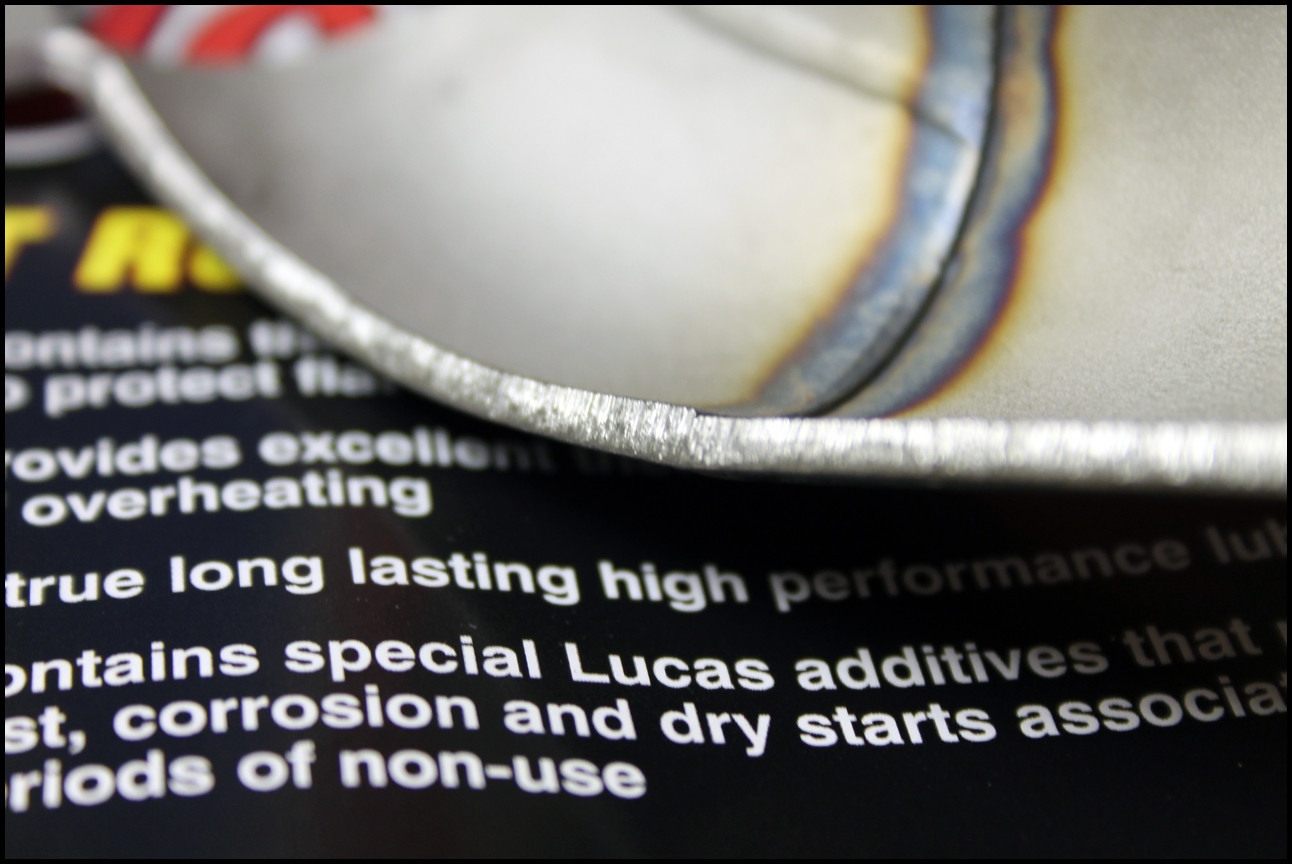

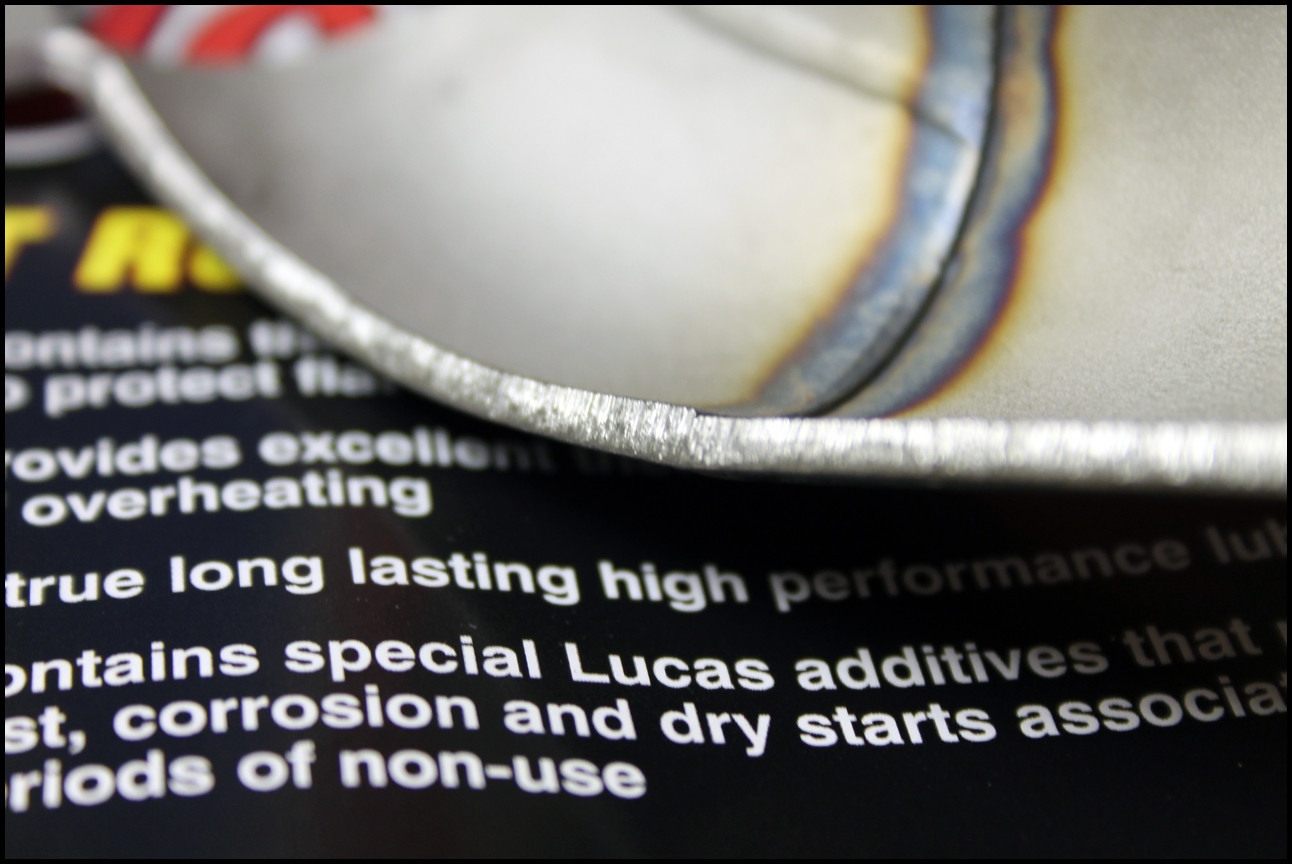

Here's one of my best passes on sch10.

Inside

I think most people consider full penetration to be an actual bead on the inside.

I dont have a hard time getting full penetration, i have a harder time filling the entire root. If my bevel is perfect, i can do it. If the fitment is off slightly, or the bevel is too large, i wont be able to fill the root unless i go colder and sacrifice penetration.

It is very difficult to fill the root and have full penetration all in one pass, with two passes, it takes so long to build a manifold its just a bitch.

Even if he dosnt penetrate all the way through, backpurging is still beneficial in that it does not weaken the weld on the inside. Whether or not there's a bead, it is still red hot and it would still sugar.

- That being said, i think people overestimate the requirements of a weld for the standard sch manifold. All his welds will hold just fine, its when you stop backpurging and really get too cold or overly too hot that you have anything to worry about. Thanks for the advice, i didnt realize all of the 90's were being cut in jigs, makes a lot of sense i suppose, shows how much time has to be put into producing a manifold! Then to have a jig fixture for every runner to be welded, sheesh lol. Would improve weld quality im sure though!

Here's one of my best passes on sch10.

Inside

I think most people consider full penetration to be an actual bead on the inside.

I dont have a hard time getting full penetration, i have a harder time filling the entire root. If my bevel is perfect, i can do it. If the fitment is off slightly, or the bevel is too large, i wont be able to fill the root unless i go colder and sacrifice penetration.

It is very difficult to fill the root and have full penetration all in one pass, with two passes, it takes so long to build a manifold its just a bitch.

Even if he dosnt penetrate all the way through, backpurging is still beneficial in that it does not weaken the weld on the inside. Whether or not there's a bead, it is still red hot and it would still sugar.

- That being said, i think people overestimate the requirements of a weld for the standard sch manifold. All his welds will hold just fine, its when you stop backpurging and really get too cold or overly too hot that you have anything to worry about. Thanks for the advice, i didnt realize all of the 90's were being cut in jigs, makes a lot of sense i suppose, shows how much time has to be put into producing a manifold! Then to have a jig fixture for every runner to be welded, sheesh lol. Would improve weld quality im sure though!

#20

Honda-Tech Member

Join Date: Jun 2004

Location: Kent, WA, USA

Posts: 426

Likes: 0

Received 0 Likes

on

0 Posts

Yes back purging will prevent the oxidation from forming on the inside if the material is in a molten state because of the fact that oxygen is present.

Looking at the welds itself, the HAZ and the amount of heat required to produce that weld in my opinion wouldn't need any purge at all since it's not sweating through if that makes sense. As far as the open root, purging is needed due to him leaving a 1/16 gap. I still would say its a strong weld none the less. But will it hold up to the abuse?

Looking at the welds itself, the HAZ and the amount of heat required to produce that weld in my opinion wouldn't need any purge at all since it's not sweating through if that makes sense. As far as the open root, purging is needed due to him leaving a 1/16 gap. I still would say its a strong weld none the less. But will it hold up to the abuse?

#23

Honda-Tech Member

Join Date: Feb 2004

Location: Tampa, FL

Posts: 438

Likes: 0

Received 0 Likes

on

0 Posts

I purge because I leave an open root on the collector, and I allow for a 1/16" open root on the runners. I just leave in the purging tubes and junk hooked up the whole time I am welding (I don't pay for argon out of my own pocket or anything heh).

I just do it the way I do because it works for me. Some people want a root and a cover pass, I'd rather just hammer it out in one pass and be done. I prefer to whip method MIG welding, some people prefer that circle business. Different strokes, I guess.

Also, yeah I fought that sch. 10 dump tube **** for a year before I could order some thinner material. Baby steps.

I just do it the way I do because it works for me. Some people want a root and a cover pass, I'd rather just hammer it out in one pass and be done. I prefer to whip method MIG welding, some people prefer that circle business. Different strokes, I guess.

Also, yeah I fought that sch. 10 dump tube **** for a year before I could order some thinner material. Baby steps.

I've see the actual pipe crack more times then the weld. People forget that materials that are commonly used for turbo manifolds really aren't suited for the conditions that they are subjected too. most guys blow their stuff up and move on before a manifold crack will ever happen.

Sch 10 for a dump tube = tuning fork, lol

your stuff looks awesome.

#24

do you always weld with only one glove? thats how i learned but i dont do it anymore. do you have any info on that torch setup? im still kinda new to tig but i could definatly use a nice small torch like that at work.

#25

Honda-Tech Member

Thread Starter

Join Date: May 2007

Location: Orlando, Fl, USA

Posts: 12

Likes: 0

Received 0 Likes

on

0 Posts

Thanks for the kind words and criticisms.

Because I cut my own 45s at work stuff like runner 2 happens. They are never exactly the same. One degree difference can make the angle a lot different. I also tried to place my tag further in the bend to make it easier to read and I don't like it.

Speaking of which, I have no idea where our tags come from. I don't do material orders directly, I just complain when I am running low. Sorry.

I usually don't wear a left glove doing stainless, but wear one when doing mild steel, MIG welding, and aluminum. I feel like I can't hold the rod correctly and it's a bad habit that I don't recommend.

I will have to write down the model number of the torch for you next week.

We make everything in house, check out the video I made earlier in the week.

Because I cut my own 45s at work stuff like runner 2 happens. They are never exactly the same. One degree difference can make the angle a lot different. I also tried to place my tag further in the bend to make it easier to read and I don't like it.

Speaking of which, I have no idea where our tags come from. I don't do material orders directly, I just complain when I am running low. Sorry.

I usually don't wear a left glove doing stainless, but wear one when doing mild steel, MIG welding, and aluminum. I feel like I can't hold the rod correctly and it's a bad habit that I don't recommend.

I will have to write down the model number of the torch for you next week.

We make everything in house, check out the video I made earlier in the week.