f23 long block, k20 pistons,delta 272 grind

#226

wow im sorry guys i havent checked on this thread in some time. jdm thats crazy power on stock block. what size throttle body do you run and what intake manifold? i didnt change to 93 pump gas until i was experiencing major blow by. compression showed all cylinders under 180 with one at 130.i showed 60% loss during leakdown. when i first built it all cylinders were 290-300. with my motor like this i was generating major crankshaft pressure causing my dipstick to fly out on the dyno. i cant honestly say if the offset in the k20 pin is to blame. i daily drove this car onto some of the dryest dustiest construction site without a filter. stupid stupid on my part but oh well. you live and learn. i no longer daily it. as a matter of fact i tore the motor apart. i decided to put new pistons, rings and bearings. ill also be buying a big cam and experimenting with a few different manifolds next month.

#227

Honda-Tech Member

Thread Starter

Join Date: Jun 2007

Location: san antonio, TEXAS, UNITED STATES

Posts: 1,113

Likes: 0

Received 0 Likes

on

0 Posts

im not sure you read the thread but the motor/setup was completely unknown to me. i had no idea what i was doing or what the motor would do. i built it with a bunch of "junk" laying around the shop. pistons,header, h23 intake manifold,h23 fuel rail, head. you get the point. there was no budget to even consider a bisi 2 cam let alone new pistons. dizzy, plugs were out of the used /junk wire bin. i found the dizzy by chance just looking for one that didnt have external coil. who knew the obd1 nonvtec dizzy would bolt right up? not me. the 272 cam was the only thing i spent money on. best $98 i ever spent. my motor made good power for what it was. i destroyed every allmotor setup i ran except for an h2b 1500lb crx and an h23 h2b hatch with boltons. also my motor never failed. it was experiencing blow by from dirt/dust getting sucked into intake. i no longer had ring seal. the motor still put down 175hp 154 tq on a dynopack the week before. i dont know how you came to the conclusion my ringlands were cracked or that i was running very conservative timing? you are aware the k series pistons can handle good amounts of boost. i doubt my cr was high enough to even come close to cracking a ringland. and i am aware of the static cr of the rrc pistons. thats why i purchased them. i just mentioned i was putting a cam in it. im looking for 250+hp and 180tq. i get the feeling you didnt read the thread. if you did, thanks. if you didnt i suggest you read all 10 pages. lots of good tech talk in it.

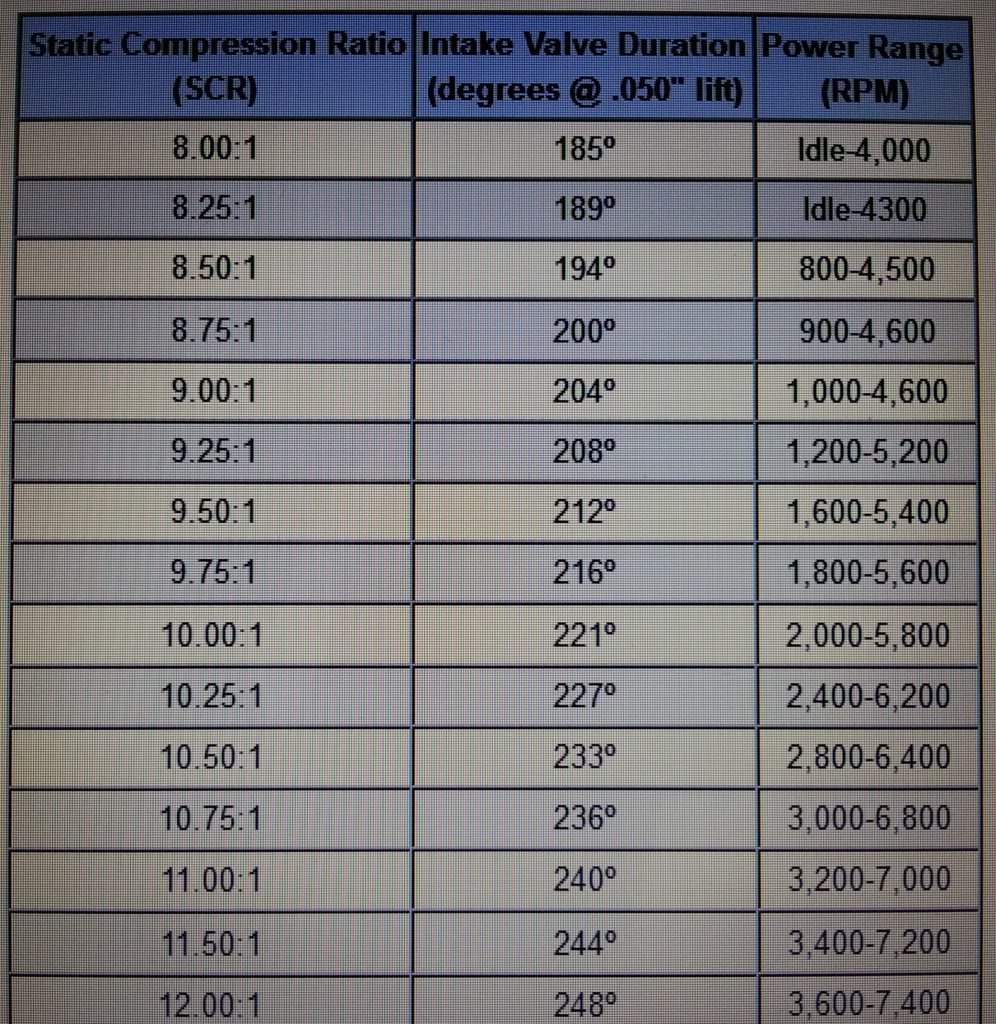

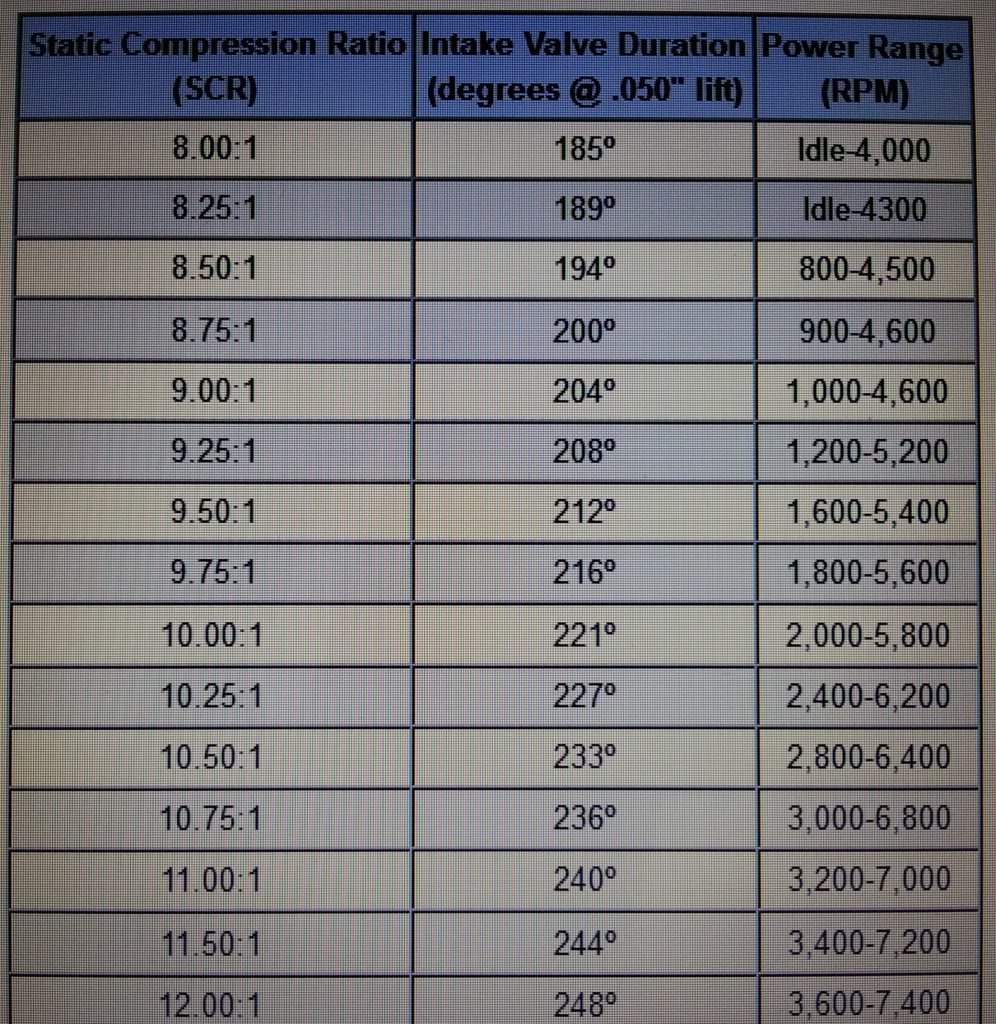

#228

i have read the whole article, the lack of torque your produce with the compression and bore/stroke of the engine on e85 and through a b-series trans at that ,which easily is 5% less parasitic drivetrain loss, is how i determined that the ingition timing was conservative. restrictions on intake or exhaust would have showed up as low peak hp not as much low torque and the fact that compression went from 300psi to 180psi and 130psi on a few means the rings had to fail quite badly, in my experience rings dont fail that bad without a failed ringland whether it be a small crack or a huge chunk of piston missing. im not knocking you for throwing spare parts together to have some fun with. if you had waited im sure you could have found used running f23 cheap, swapped your head and made over 200whp and still be driving it today. the experimenting is great, ive had many failures trying new endeavors to make more power. i think you'll do fine with the RRC pistons, you just need to make sure you get the proper camshaft for the compression. this chart is a good reference. you can go half a point up or down but anything more will cause you nothing but problems. ex good compression ratio for my cam (.415"/.391" 217*/222*) would be around 9.8:1 judging by the chart. my current compression is 9.7:1 so i can run an aggressive ignition curve which produces good power and torque. it's not recommended to go below 9.3:1 or above 10.3:1. now would 9:1 hurt it, no but it would be a little sluggish down low. would 10.5:1 hurt anything, no but the difference in power wouldn't be noticed between 10.3 and 10.5, but it's a hell of alot easier to find 10.5:1 pistons, lol. also @.040" duration is very similar to @.050", enough to determine the camshaft you want. if you do plan to go with a bisimoto level 3 i recommend, for the money, checking out DDtechcams.com derek and danny have been very helpful and will be making the cam for my 11.5:1 tsx piston build. i'll be looking to build 240-250whp and 180wtq range aswell, only difference is i got to make it happen with a T2W4 with a 4.64FD. good luck with the build, i look forward to the results.

#229

Honda-Tech Member

Join Date: Mar 2007

Location: Atlanta, Ga, USA

Posts: 199

Likes: 0

Received 0 Likes

on

0 Posts

Still a great thread. Has anything else on this build been solidified? I'm very interested to try this still.

#230

hey sorry for re flaming an old thread, but I am in process right now like right this second in build a f series f23a with k20a2 pistons but when i got to tighten the rod bolts the crankshaft will be stuck and wont turn over.. i am stumped, i did use acl race rod bearings that have a .25 marking on the box buy i thought its standard size rod bearings.. but that shouldn't be affecting the crank from getting stuck when fully torque down the rod bolts right?? I did install the pistons reverse like everyone has said to do. I installed the rods to pistons the same way as usual if 8nstalling f23 pistons on f23 rods.. I would assume the reverse will come in play when you go to install the piston right? Not reversing the rod while connecting them to the piston with the wrist pin no?? Sorry for all the questions also and I just have done countless hours of research but nobody has ever done a step by step k20 piston install on f23 block. But if you can help me that would be great and I would be in debt to you. Thanks

#231

Honda-Tech Member

hey sorry for re flaming an old thread, but I am in process right now like right this second in build a f series f23a with k20a2 pistons but when i got to tighten the rod bolts the crankshaft will be stuck and wont turn over.. i am stumped, i did use acl race rod bearings that have a .25 marking on the box buy i thought its standard size rod bearings.. but that shouldn't be affecting the crank from getting stuck when fully torque down the rod bolts right?? I did install the pistons reverse like everyone has said to do. I installed the rods to pistons the same way as usual if 8nstalling f23 pistons on f23 rods.. I would assume the reverse will come in play when you go to install the piston right? Not reversing the rod while connecting them to the piston with the wrist pin no?? Sorry for all the questions also and I just have done countless hours of research but nobody has ever done a step by step k20 piston install on f23 block. But if you can help me that would be great and I would be in debt to you. Thanks

#232

thanks for the reply brotha! Sorry for the late reply brotha! 😆 but Ive gotten it all figured out.. I was using oversized bearings and got the right size on and it spun freely, but I've been through 2 and now my third engine im building.. that f23a block with k20a2 shelf pistons didn't last but a week.. lol.. I was using a stock f22b1 ecu for one.. and it was my first time building a engine from top to bottom.. so I had my rods facing towards the intake side instead of exhaust side with the tangs.. I had oil pressure loss then I took it apart and all of the ringlands on all pistons were in the bottom of the oil pan... 😆 I'm not sure what caused this.. but the bearings were a bit worn out as well.. might of been too much compression or what ever.. but I rebuilt the block with f23a jdm spec pistons that have a slight higher compression than usdm ones.. not much but perfect for boost.. and put a stock f22a1 head on it and tuned it this time myself on 8lbs of boost. It ran really well for a car I built myself and tuned myself, not knowing what the hell I was doing.. 😆 🤣 I drove it for about 7 months but it always hd a oil leak well a couple of them.. and I decided to take it out and rebuild it again.. but I've gotten my hand on a fresh f23a1 block with brand new bearings that were color matched and measured.. the crank turns over by just breathing on it.. 😆 so the clearance is lovely!.. I'm thinking about using j35 or j32 pistons for a comp bump but I don't want to hit over 11.5:1 or keep it in the 10s and use this delta 272 I have already.. I've read jdm92_accorn posts day and night and follow his YouTube page. I love his build and he's done so well with the f22a head and stock f23a bottom end.. id like to just put new pistons in since I have the block already torn apart and a fresh hone on all the cylinder walls looking brand new with great cross hatching at 45 degree angles 👌 I would really like to break 200whp.. thats my ultimate goal.. but my chassis is heavy as ****.. going in a 95 accord ex cd5 sedan... was a auto but I've manual swapped it myself with a m2f4 I scorde from a junk accord I bought for 120 dollars! A whole car and whole manual swap i got lucky on.. 😆 I didn't know anything about f series and h series coming from a k series background.. but once I got on the highway and noticed it was at 3300 around 60mph.. I was like hmm seems kinda high.. but I looked it up and its a prelude si h23a1 non vtec trans... go figure 😆 I know its not the best trans.. but its what I have to work with.. if I can get 200whp and torque that will help pull this heavy *** boat to the finish line, it would make me happy. Plus, it seems like everyone on the road loves to pull up on a old 95 accord and test the waters.. no matter what type of car they have.. they know they'll have a 90 percent chance of gapping it 🤣 so it'll be fun to get some good reactions from time to time with a single cam.

#233

i have a ek hatch with H23a/gsr/4piston head/skunk 2 intake/1320 hood dump exhaust. i just bought a f23a engine. if i am wanting to run boost, which block would you start with?

#234

Honda-Tech Member

JDM H23A VTEC engine in the car now ??? If so, use that. It is a way better choice than the F23A engine.

The following users liked this post:

#235

Honda-Tech Member

H23's are God's gift of displacement to 90s Hondas.

Would not hesitate to use that, love those engines.

Would not hesitate to use that, love those engines.

The following users liked this post:

#236

@JRCivic1 Okay fair enough, i just watch a ton of utube videos and came across one stating the crank casing and the closed deck is better for boosted cars on the F23A. The reason why i bought it and was going to get hbeam rods and k20 pistons then use my (4piston) H head with different valves and cam.

Thank you, i will keep the F block for backup an spend my money on the H23A.

Thank you, i will keep the F block for backup an spend my money on the H23A.

#237

Honda-Tech Member

@JRCivic1 Okay fair enough, i just watch a ton of utube videos and came across one stating the crank casing and the closed deck is better for boosted cars on the F23A. The reason why i bought it and was going to get hbeam rods and k20 pistons then use my (4piston) H head with different valves and cam.

Thank you, i will keep the F block for backup an spend my money on the H23A.

Thank you, i will keep the F block for backup an spend my money on the H23A.

If you can, invest in sleeves for your H23 and never look back.

#238

The following users liked this post:

#239

some inspiration for the OP.

2point6 build it for his girl

dotted line: 282whp and 209wtq with euro-R intake mani and unequal length header

solid line: 292whp and 193wtq with heavily modified OBX intak mani and revised header (shorter primaries)

edit: oh uh and yeah it's on 93 octane

Attachment 447838

Attachment 447839

2point6 build it for his girl

dotted line: 282whp and 209wtq with euro-R intake mani and unequal length header

solid line: 292whp and 193wtq with heavily modified OBX intak mani and revised header (shorter primaries)

edit: oh uh and yeah it's on 93 octane

Attachment 447838

Attachment 447839

#240

@Ceedee5 Thank you for some inspiration! guess i just need to install the fueltech setup and get rid of crome out my hatch to get a good tune down for better E.T.'s I just bought this hatch a couple months ago, I do also need to tare it open and find out what pistons and rods i am running......maybe it could be as simple as pistons or a better intake (skunk2 now) and injectors to make this motor come alive. I feel the motor (H23A) is solid for sure but it also feels that i am lacking something. You said it best, Tune, Tune and Tune!

Thread

Thread Starter

Forum

Replies

Last Post

SwappedTURBOegg

Drag Racing

122

07-17-2015 11:32 AM

bauergold

All Motor / Naturally Aspirated

5

11-25-2009 11:30 AM