Some A/C expertise requested...

#1

Junior Member

Thread Starter

Join Date: Sep 2003

Location: Marietta, GA, USA

Posts: 364

Likes: 0

Received 0 Likes

on

0 Posts

I searched, but I didn't find any real concrete and thorough info from experienced AC technicians.

I finally acquired all the things I needed to reinstall AC on my 93 hatch, the P54 bracket, compressor, condensor, which were all gone after my car was stolen three years ago. I got a reman compressor built by XKINGX, which is, by the way, grrreat; let him know if you need one! New drier, new o-rings on compressor, drier and condensor connections.

I did 134a conversion.

I vacuumed it down for 1+ hours. I never got past 16 in. hg, but I think that's because the gauge is off (it was reading above zero when open to atmosphere). I forgot the purge the fill line when I began to put the first can in, so I know I put a little air in the system. Is this a really bad thing? The first can was about half full. I put another can in and did remember to purge the line.

One thing that alarmed me was that the compressor switched on, clutch engaged, when I started the car and turned the system on while still under vacuum. Is this ok? Isn't there a low pressure cutoff switch?

At about 70 deg at night, I was getting 30 psi low and 180 psi high at idle with about 18-20 oz in the system, and it seemingly blew nice & cold. During the heat of the day, about 90-95 deg ambient, I saw 40 psi, 210 psi at idle, and it doesn't blow cold, just kind of cool. I revved it and saw 25 low and 300 high. Is there a high pressure cutoff?

I notice the high pressure cap was busted, I think the valve core is leaking.. on a 134a conversion the original r12 high side core is used. Thus, I think it's leaking. It busted 2 different caps.

I'm thinking I might want to change the expansion valve since it sat open for 3 years. I almost want to do it for peace of mind.

I was driving tonight and it blew pretty cold.. I turned the fan down and noticed the compressor started to cycle like I thought they usually do.

SYNOPSIS:

-93 hatch stolen in 05, system open since.

-JUST converted to R134a, new compressor and drier, recharged.

-slight amount of air introduced (failed to purge line once), system was not flushed.

-AC cool but not cold, only 18-20 oz of the 22 req'd put in for fear of possible leaks (save the next can for later).

-questions insue...

QUESTIONS:

-What are normal and optimal pressures? What's too high?

-How do you diagnose a faulty thermal expansion valve?

-At what pressure does the switch shut off the compressor? The compressor cycling on and off is caused by the pressure switch, right?

-Do I really need to flush the system out?

-If I change the TXV, or open system to flush & clean, will I have to replace the drier again? When is drier replacement necessary (how long exposed to open air)?

I want to be 100% sure I won't fry the compressor with faulty fail-safes. I've worked on cars professionally for 5 years, but old British sports cars didn't have AC, PS, or AT.

Modified by DexterThEG at 1:21 AM 7/17/2008

I finally acquired all the things I needed to reinstall AC on my 93 hatch, the P54 bracket, compressor, condensor, which were all gone after my car was stolen three years ago. I got a reman compressor built by XKINGX, which is, by the way, grrreat; let him know if you need one! New drier, new o-rings on compressor, drier and condensor connections.

I did 134a conversion.

I vacuumed it down for 1+ hours. I never got past 16 in. hg, but I think that's because the gauge is off (it was reading above zero when open to atmosphere). I forgot the purge the fill line when I began to put the first can in, so I know I put a little air in the system. Is this a really bad thing? The first can was about half full. I put another can in and did remember to purge the line.

One thing that alarmed me was that the compressor switched on, clutch engaged, when I started the car and turned the system on while still under vacuum. Is this ok? Isn't there a low pressure cutoff switch?

At about 70 deg at night, I was getting 30 psi low and 180 psi high at idle with about 18-20 oz in the system, and it seemingly blew nice & cold. During the heat of the day, about 90-95 deg ambient, I saw 40 psi, 210 psi at idle, and it doesn't blow cold, just kind of cool. I revved it and saw 25 low and 300 high. Is there a high pressure cutoff?

I notice the high pressure cap was busted, I think the valve core is leaking.. on a 134a conversion the original r12 high side core is used. Thus, I think it's leaking. It busted 2 different caps.

I'm thinking I might want to change the expansion valve since it sat open for 3 years. I almost want to do it for peace of mind.

I was driving tonight and it blew pretty cold.. I turned the fan down and noticed the compressor started to cycle like I thought they usually do.

SYNOPSIS:

-93 hatch stolen in 05, system open since.

-JUST converted to R134a, new compressor and drier, recharged.

-slight amount of air introduced (failed to purge line once), system was not flushed.

-AC cool but not cold, only 18-20 oz of the 22 req'd put in for fear of possible leaks (save the next can for later).

-questions insue...

QUESTIONS:

-What are normal and optimal pressures? What's too high?

-How do you diagnose a faulty thermal expansion valve?

-At what pressure does the switch shut off the compressor? The compressor cycling on and off is caused by the pressure switch, right?

-Do I really need to flush the system out?

-If I change the TXV, or open system to flush & clean, will I have to replace the drier again? When is drier replacement necessary (how long exposed to open air)?

I want to be 100% sure I won't fry the compressor with faulty fail-safes. I've worked on cars professionally for 5 years, but old British sports cars didn't have AC, PS, or AT.

Modified by DexterThEG at 1:21 AM 7/17/2008

#2

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by DexterThEG »</TD></TR><TR><TD CLASS="quote">I searched, but I didn't find any real concrete and thorough info from experienced AC technicians.

I vacuumed it down for 1+ hours. I never got past 16 in. hg, but I think that's because the gauge is off (it was reading above zero when open to atmosphere). I forgot the purge the fill line when I began to put the first can in, so I know I put a little air in the system. Is this a really bad thing? The first can was about half full. I put another can in and did remember to purge the line.

</TD></TR></TABLE>

what size vacuum pump are you using...you should try to pull it down to 29"...if possible....sounds like you have non-condensibles in the system"air moisture"...if its ok at nite...and crappy during the day....its usually moisture in the system....as far as the TXV goes..it doesn't go bad to often..but if your system is charged correctly...and the low side is in a vac...then its stuck close....and if you change the TXV for peace of mind...you will have to change the drier..im not a car ac tech..i work on 5ton to 100ton commercial units...but its almost the same idea...LOL

Modified by dannydos at 6:56 PM 7/17/2008

I vacuumed it down for 1+ hours. I never got past 16 in. hg, but I think that's because the gauge is off (it was reading above zero when open to atmosphere). I forgot the purge the fill line when I began to put the first can in, so I know I put a little air in the system. Is this a really bad thing? The first can was about half full. I put another can in and did remember to purge the line.

</TD></TR></TABLE>

what size vacuum pump are you using...you should try to pull it down to 29"...if possible....sounds like you have non-condensibles in the system"air moisture"...if its ok at nite...and crappy during the day....its usually moisture in the system....as far as the TXV goes..it doesn't go bad to often..but if your system is charged correctly...and the low side is in a vac...then its stuck close....and if you change the TXV for peace of mind...you will have to change the drier..im not a car ac tech..i work on 5ton to 100ton commercial units...but its almost the same idea...LOL

Modified by dannydos at 6:56 PM 7/17/2008

#3

Junior Member

Thread Starter

Join Date: Sep 2003

Location: Marietta, GA, USA

Posts: 364

Likes: 0

Received 0 Likes

on

0 Posts

You know, based on that info I think the TXV is probably working fine. I'd hate to have to replace the drier again. I'm not a big fan of fixin that which is not broken.

The vac is rated at 1.5 cfm.. or is it cfm/hr.. whichever unit it is, it's 1.5. I'm going to get a gauge set from autozone when I recharge it, so I'll see if it's really getting down to close to 29".

I found that with my pryometer I have just the right kind of thermometer... I got around 61 deg at idle midday. The lowest I saw was 59deg moving, but it got up to 65 or so I believe. Once the sun started set it finally got down to 50-55 and I turned the fan down. When I turned the fan down, the compressor started to cycle.

I'm going to have to change the drier if I replace the TXV for sure, huh? I guess I might just change the high side valve core, suck it down for a couple hours and refill. I already bought the TXV from NAPA.. then I started to think "Made in China," hmmmm.

Thanks a lot for your input!

The vac is rated at 1.5 cfm.. or is it cfm/hr.. whichever unit it is, it's 1.5. I'm going to get a gauge set from autozone when I recharge it, so I'll see if it's really getting down to close to 29".

I found that with my pryometer I have just the right kind of thermometer... I got around 61 deg at idle midday. The lowest I saw was 59deg moving, but it got up to 65 or so I believe. Once the sun started set it finally got down to 50-55 and I turned the fan down. When I turned the fan down, the compressor started to cycle.

I'm going to have to change the drier if I replace the TXV for sure, huh? I guess I might just change the high side valve core, suck it down for a couple hours and refill. I already bought the TXV from NAPA.. then I started to think "Made in China," hmmmm.

Thanks a lot for your input!

#5

Honda-Tech Member

Um, that is a low pressure chiller, and the chiller barrel is supposed to operate in a vacuum. 15inHG low, 5psi high.

Your pressures are near spot on. Anything above 50 or below 15 (NORMALLY) is unacceptable and there will be little if any cooling.

A little air doesn't hurt, it really depends on the system size. C/K1500 Chevy's that have rear air are prone to leaking from the rear lines that are attached to the frame. Since they are costly, most customers just tell you to evac and fill it. And of course it sucks air into the system, but it still cools.

Find the plugs that came with your drier, and plug it up after your remove it. This is how most of them come into the shop I work at.

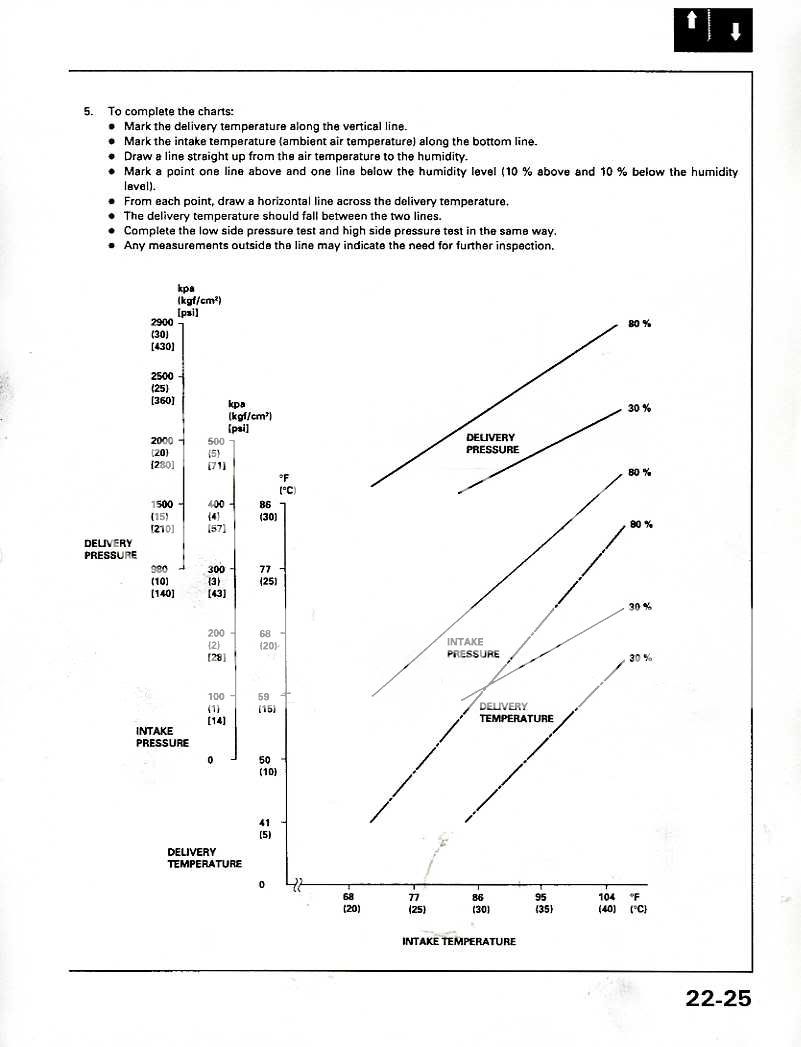

A 10-15 degree drop with near 100% humidity removal is in good working condition. Humid air is harder to cool due to its density, so don't be alarmed. 300psi is a little high, what was the outside temp that day? I would look at getting some faster fans. If the condenser cannot cool the refrigerant, it will cycle that heat into the evaporater, and result in less heat removal.

R134a is not as efficient as R12, keep that in mind, and did your compressor come with recharging instructions? Of the handful I have converted, they have different charge specs, as the weight and density of the two refrigerants differ. This may be a concern.

When diagnosing, note these things at that time:

Ambient Temperature

High Side Pressure

Low Side Pressure

Needle Fluttering

Cycling Point

Low Pressure Cutoff

Vent Temperature (Center vent only, full speed, recirc, windows closed)

Humidity

EDIT: When you replace the valve cores (use a tire valve tool) soak them in oil and operate them for a bit by hand before you install them. It helps seal them up better and makes it easier to see a valve leak after install.

Modified by slowcivic2k at 8:51 PM 7/17/2008

Your pressures are near spot on. Anything above 50 or below 15 (NORMALLY) is unacceptable and there will be little if any cooling.

A little air doesn't hurt, it really depends on the system size. C/K1500 Chevy's that have rear air are prone to leaking from the rear lines that are attached to the frame. Since they are costly, most customers just tell you to evac and fill it. And of course it sucks air into the system, but it still cools.

Find the plugs that came with your drier, and plug it up after your remove it. This is how most of them come into the shop I work at.

A 10-15 degree drop with near 100% humidity removal is in good working condition. Humid air is harder to cool due to its density, so don't be alarmed. 300psi is a little high, what was the outside temp that day? I would look at getting some faster fans. If the condenser cannot cool the refrigerant, it will cycle that heat into the evaporater, and result in less heat removal.

R134a is not as efficient as R12, keep that in mind, and did your compressor come with recharging instructions? Of the handful I have converted, they have different charge specs, as the weight and density of the two refrigerants differ. This may be a concern.

When diagnosing, note these things at that time:

Ambient Temperature

High Side Pressure

Low Side Pressure

Needle Fluttering

Cycling Point

Low Pressure Cutoff

Vent Temperature (Center vent only, full speed, recirc, windows closed)

Humidity

EDIT: When you replace the valve cores (use a tire valve tool) soak them in oil and operate them for a bit by hand before you install them. It helps seal them up better and makes it easier to see a valve leak after install.

Modified by slowcivic2k at 8:51 PM 7/17/2008

#6

Junior Member

Thread Starter

Join Date: Sep 2003

Location: Marietta, GA, USA

Posts: 364

Likes: 0

Received 0 Likes

on

0 Posts

Thanks a lot for the insight!!

I do have the plug for the drier if I need to open the system.

The outside temp was probably around 95 deg that day I saw 300 psi. I have noticed a very small amount of needle fluttering on the high gauge; I believe it was when I had the motor revved though.

Compressor didn't come with charging instructions.

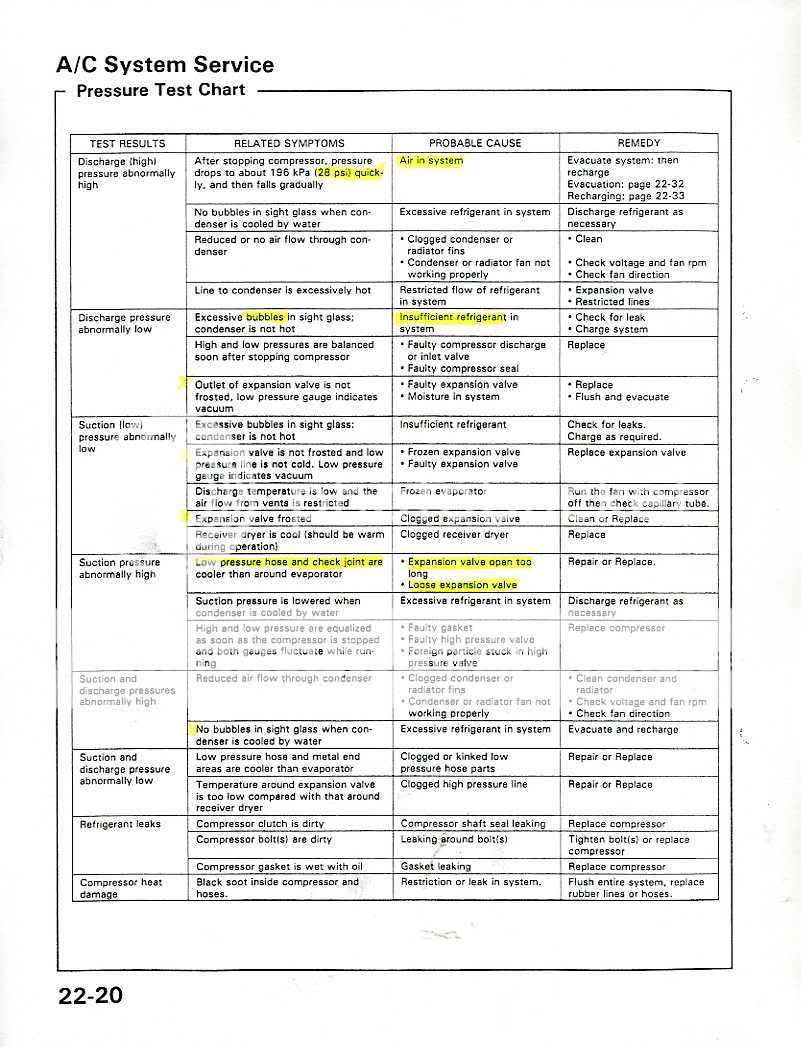

I found the Performance Test and Pressure Test Chart in the Helms and I got lot of ammo to go diagnosing later (after I sleep, hah). The one thing that bothers me is it doesn't say much about the "dual pressure switch." I'm guessing that means it's a high/low pressure cutoff. It doesn't specify what pressures will trip the switch.

I deduce 3 things that will cause the compressor to cycle. 1) over/undercharged, cutoff by the pressure switch. 2) cold temp, via thermo switch on evaporator, by way of ECU. 3) compressor overheats, cutoff via thermal protector.

I'm going to try to do what I can to make sure the TXV is functioning properly.. if it is, then a good vacuum and recharge should be all I need.

Thanks for the advice on the valve core, I will definitely use it.

I do have the plug for the drier if I need to open the system.

The outside temp was probably around 95 deg that day I saw 300 psi. I have noticed a very small amount of needle fluttering on the high gauge; I believe it was when I had the motor revved though.

Compressor didn't come with charging instructions.

I found the Performance Test and Pressure Test Chart in the Helms and I got lot of ammo to go diagnosing later (after I sleep, hah). The one thing that bothers me is it doesn't say much about the "dual pressure switch." I'm guessing that means it's a high/low pressure cutoff. It doesn't specify what pressures will trip the switch.

I deduce 3 things that will cause the compressor to cycle. 1) over/undercharged, cutoff by the pressure switch. 2) cold temp, via thermo switch on evaporator, by way of ECU. 3) compressor overheats, cutoff via thermal protector.

I'm going to try to do what I can to make sure the TXV is functioning properly.. if it is, then a good vacuum and recharge should be all I need.

Thanks for the advice on the valve core, I will definitely use it.

Trending Topics

#8

Junior Member

Thread Starter

Join Date: Sep 2003

Location: Marietta, GA, USA

Posts: 364

Likes: 0

Received 0 Likes

on

0 Posts

#9

Junior Member

Thread Starter

Join Date: Sep 2003

Location: Marietta, GA, USA

Posts: 364

Likes: 0

Received 0 Likes

on

0 Posts

OK, I ran Honda's performance test as shown above with all those factors in mind.

I know that the system is undercharged by probably no more than 5 oz. I underfilled it to begin with, expecting inevitable problems, and the high side valve core ended up leaking too.

Based on the chart, at around 40% humidity and 87 deg F, I should be seeing below 30 low and above 250 high. Under these circumstances, however, I saw 38 low and 215 high; vent temp 70 deg F. The high gauge fluttered about 15-20 psi rapidly. What does all of this mean? I would consider the low side too high and the high side too low. Could this possibly point to the TXV going out, or do I just need to fix the valve core, vac, fully recharge?

I am thinking about putting some dye in too.

I know that the system is undercharged by probably no more than 5 oz. I underfilled it to begin with, expecting inevitable problems, and the high side valve core ended up leaking too.

Based on the chart, at around 40% humidity and 87 deg F, I should be seeing below 30 low and above 250 high. Under these circumstances, however, I saw 38 low and 215 high; vent temp 70 deg F. The high gauge fluttered about 15-20 psi rapidly. What does all of this mean? I would consider the low side too high and the high side too low. Could this possibly point to the TXV going out, or do I just need to fix the valve core, vac, fully recharge?

I am thinking about putting some dye in too.

#10

Honda-Tech Member

Join Date: Oct 2005

Location: State College, Pa, US

Posts: 2,309

Likes: 0

Received 0 Likes

on

0 Posts

not to thread jack but I saw you ask the question about the the compressor cycling on and off and it being a bad switch. mine has done this since i installed it is it normal or do i also have a switch problem

#11

Junior Member

Thread Starter

Join Date: Sep 2003

Location: Marietta, GA, USA

Posts: 364

Likes: 0

Received 0 Likes

on

0 Posts

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by instructor74 »</TD></TR><TR><TD CLASS="quote">not to thread jack but I saw you ask the question about the the compressor cycling on and off and it being a bad switch. mine has done this since i installed it is it normal or do i also have a switch problem</TD></TR></TABLE>

Exactly, that's one of my last real questions. That along with the proper functionality of the TXV. The Helms doesn't even specify the press. switch cutof pressures.

Exactly, that's one of my last real questions. That along with the proper functionality of the TXV. The Helms doesn't even specify the press. switch cutof pressures.

#12

Honda-Tech Member

Join Date: Oct 2005

Location: State College, Pa, US

Posts: 2,309

Likes: 0

Received 0 Likes

on

0 Posts

I talked to a good friend of mine and found out some more info on the pressure switch. the way it sounds some switch's are adjustable and others need to be replaced due to the difference in pressure between the 2 coolants. As it turned out mine was low on r128 (had a leaky shrader valve) replaced that and recharged the system. It not cycling on and off like before.

#13

Honda-Tech Member

Most R134A systems have a high cutoff around 500psi, some higher than that, but thats the lowest I've seen.

Needle fluttering on the high side indicates that the reed valves in the compressor are not sealing all the way. Put some miles on it and that should diminish. If after around 2 months or so it continues, the compressor may be on the way to failure.

On most systems with a TXV, there are two switches, sometimes they are packaged as one piece with 4 wires or more, a low and high pressure cutoff. The high switch is obvious, its designed so the system doesn't blow up. The low side takes a little explanation.

That switch is designed to cut the compressor off if pressures dive below 20-30psi on most systems. This is in place for low speed A/C operation, since the TXV will be almost if not fully, closed. This prevents the evaporator from icing up due to lack of air flow (heat transfer). This switch should also inhibit operation while in vacuum.

The problem is, when a system is left open for an extended period of time, the diaphrams in the switches go bad, and can prohibit operation all together.

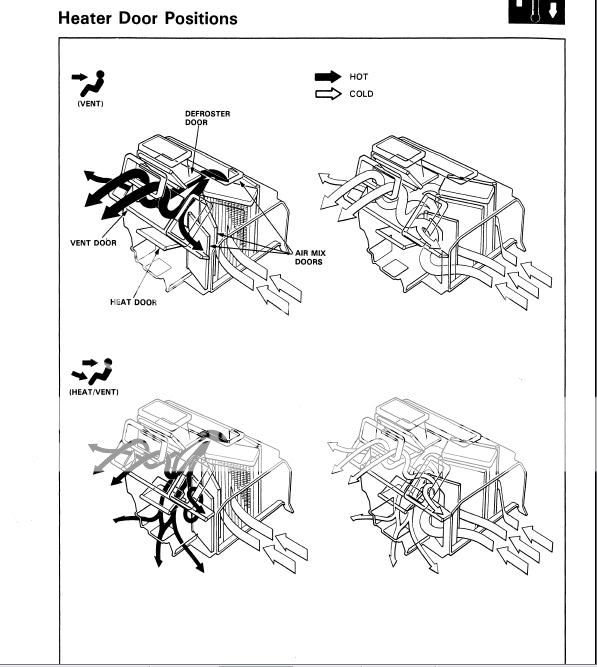

The TXV is working because the refrigerant pressure on the low side is "within" range, meaning it is restricting the flow like it is supposed to. I would look at the air blend doors in the dash and make sure they are not stuck, check the water valve under the hood as well, if that is open, that will nullify your A/C output. Also make sure the evaporator is cold. Given your readings, it should be cold.

Touch the lines running into the cab, one should be hot, the other cold.

Needle fluttering on the high side indicates that the reed valves in the compressor are not sealing all the way. Put some miles on it and that should diminish. If after around 2 months or so it continues, the compressor may be on the way to failure.

On most systems with a TXV, there are two switches, sometimes they are packaged as one piece with 4 wires or more, a low and high pressure cutoff. The high switch is obvious, its designed so the system doesn't blow up. The low side takes a little explanation.

That switch is designed to cut the compressor off if pressures dive below 20-30psi on most systems. This is in place for low speed A/C operation, since the TXV will be almost if not fully, closed. This prevents the evaporator from icing up due to lack of air flow (heat transfer). This switch should also inhibit operation while in vacuum.

The problem is, when a system is left open for an extended period of time, the diaphrams in the switches go bad, and can prohibit operation all together.

The TXV is working because the refrigerant pressure on the low side is "within" range, meaning it is restricting the flow like it is supposed to. I would look at the air blend doors in the dash and make sure they are not stuck, check the water valve under the hood as well, if that is open, that will nullify your A/C output. Also make sure the evaporator is cold. Given your readings, it should be cold.

Touch the lines running into the cab, one should be hot, the other cold.

#14

Junior Member

Thread Starter

Join Date: Sep 2003

Location: Marietta, GA, USA

Posts: 364

Likes: 0

Received 0 Likes

on

0 Posts

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by instructor74 »</TD></TR><TR><TD CLASS="quote">I talked to a good friend of mine and found out some more info on the pressure switch. the way it sounds some switch's are adjustable and others need to be replaced due to the difference in pressure between the 2 coolants. As it turned out mine was low on r128 (had a leaky shrader valve) replaced that and recharged the system. It not cycling on and off like before. </TD></TR></TABLE>

That brings up a good point. Technically since 134a is meant to operate at higher pressure differentials than R12, shouldn't a good retrofit job include the hi/lo pressure switch, and the TXV for a 134a system? The TXV I got from napa actually has R-134a stamped on it.

slowcivic2k, thanks for your help again, you are much appreciated! I sent you a PM, by the way.

I did notice that when I turned the fan down at night, the compressor did cycle off.. it must have hit the low pressure limit because I don't think it got below 35 deg F, where the Helms says the Thermo Switch will tell the ECU to cut off the system.

I'm going to look into the blend door tomorrow, but I did check the water valve and it is closed, the outlet hose cold. I infer from the name, but is the blend door's function to select between the heater core and evaporator?

Evaporator seems to be cold, low side lines are cold and condense water from the air. High side lines are pretty hot. I tried to get a good temp reading on the lines but I don't think my pyrometer liked all the hot air blowing around.

That brings up a good point. Technically since 134a is meant to operate at higher pressure differentials than R12, shouldn't a good retrofit job include the hi/lo pressure switch, and the TXV for a 134a system? The TXV I got from napa actually has R-134a stamped on it.

slowcivic2k, thanks for your help again, you are much appreciated! I sent you a PM, by the way.

I did notice that when I turned the fan down at night, the compressor did cycle off.. it must have hit the low pressure limit because I don't think it got below 35 deg F, where the Helms says the Thermo Switch will tell the ECU to cut off the system.

I'm going to look into the blend door tomorrow, but I did check the water valve and it is closed, the outlet hose cold. I infer from the name, but is the blend door's function to select between the heater core and evaporator?

Evaporator seems to be cold, low side lines are cold and condense water from the air. High side lines are pretty hot. I tried to get a good temp reading on the lines but I don't think my pyrometer liked all the hot air blowing around.

#16

Junior Member

Thread Starter

Join Date: Sep 2003

Location: Marietta, GA, USA

Posts: 364

Likes: 0

Received 0 Likes

on

0 Posts

I checked the air mix cable adjustment, per Helms manual, and it seemed to be just right. I'm going to have to discharge the system to replace the valve core, so I'm just going to install the 134a civic TXV and pressure switch. I want this next recharge to be the last one I have to do.

#17

Junior Member

Thread Starter

Join Date: Sep 2003

Location: Marietta, GA, USA

Posts: 364

Likes: 0

Received 0 Likes

on

0 Posts

I haven't even looked inside the heater box yet.

I blew 140 psi of air through it for 30 minutes and I don't think it'll ever come completely clean. Any recommendations? Thank you, Honda, for not using cabin air filters!!

The pressure switch reads continuity accross with zero pressure... bad right? What's worse is I cannot get one!!!

Modified by DexterThEG at 12:14 PM 7/20/2008

#18

Junior Member

Thread Starter

Join Date: Sep 2003

Location: Marietta, GA, USA

Posts: 364

Likes: 0

Received 0 Likes

on

0 Posts

What's with the aftermarket? This is the correct part from Napa. I guess you get what you pay for; it was only $25... made it China. It doesn't exactly fit properly (note the size difference), but I think I can make it fit. You can see that the valve action is directly opposite the OEM setup. Will this affect how the TXV operates in any way???

#19

Junior Member

Join Date: Jun 2008

Location: naples, fl, usa

Posts: 24

Likes: 0

Received 0 Likes

on

0 Posts

ok first off when you replaced the compressor and dryer did you install oil? second if so(and i hope you did) how much into each component? too much oil or lack there of will cause pressure inbalance.with that out of the way, do you have acess to an infared thermometer? if so check your in temp to your out temp from the evap.check your temp on the condenser both sides.you should be close on the evap test and a descent difference across the condenser.the blend door that they have posted is also a good suspect but i havent seen them go bad often in the honda product.your charge at factory spec was 22oz. of r-12 it will be the same for 134a.16 oz. in a pound so you need 1.6lb of 134a. and factory 5oz. of mineral oil.you should have flushed the system because you were going to convert to 134a witch uses a different oil than mineral. uses pag 46 or your preference in what honda makes for it. basically throw out your dryer because it is contaminated, flush the system, air dry it with a compressor, blow it all out, then install your oil, turn comp by hand.then vac down for at least 4 hours and charge system. you should have a couple ounces of oil in the comp, a couple in the condensor and one in the dryer. hopefully this helps. sorry for the long winded post...

#21

Junior Member

Thread Starter

Join Date: Sep 2003

Location: Marietta, GA, USA

Posts: 364

Likes: 0

Received 0 Likes

on

0 Posts

I didn't add any oil. The reman filled the compressor and specifically told me not to add oil to the system.

I have a pyrometer but it isn't giving me good surface temp readings with air blowing around. Fans are working great.

Part of the reason it wasn't working good is how clogged the evaporator was. I blew it out, put the new TXV in. Now I've replaced almost all the o-rings in the system.

I didn't want to go to the lengths of flushing the system out... probably because I was so anxious to get it working, so some patience went out the window. Plus, I figured since I replaced the drier and compressor, the majority of the oil will be the right stuff.

I cannot get the damn pressure switch. I tested the one on the system and it is faulty: showing continuity with no pressure on it. None of the parts stores have it, nor can they get it. Will check the stealership tomorrow.

I put everything back together, new high port valve, new TXV, old press. switch, and put the vacuum on it. It's getting into the high 20's now.

I have a pyrometer but it isn't giving me good surface temp readings with air blowing around. Fans are working great.

Part of the reason it wasn't working good is how clogged the evaporator was. I blew it out, put the new TXV in. Now I've replaced almost all the o-rings in the system.

I didn't want to go to the lengths of flushing the system out... probably because I was so anxious to get it working, so some patience went out the window. Plus, I figured since I replaced the drier and compressor, the majority of the oil will be the right stuff.

I cannot get the damn pressure switch. I tested the one on the system and it is faulty: showing continuity with no pressure on it. None of the parts stores have it, nor can they get it. Will check the stealership tomorrow.

I put everything back together, new high port valve, new TXV, old press. switch, and put the vacuum on it. It's getting into the high 20's now.

#23

Honda-Tech Member

Unless the compressor failed, there is little reason to flush it out. On accumulator system setups, flushing is almost required as the filter is after the evaporator, pushing debris through the whole system. Unless you had a line or major component fail, (anything other than an O-ring or valve core) there is no reason to flush it.

The refrigerant amount will vary from R12 to 134a, their density is different so the volume will vary, do not listen to "the honda king".

The dryer will be fine provided you plugged it back up when you opened the system. And even then, the vacuum procedure will remove most of the moisture from the system in the first place.

The clogging more than likely accounts for 99% of the system not working right. Again, Chevy 1500's, most notably the Astro, have problems sucking debris into the evaporator, yielding the same symptoms.

4 hours huh, really. There is no need to vac a system that long unless it has 20 evaporators and holds 50lbs of refrigerant. It takes 35 minutes to vacuum out vans with rear air, and it is substantially bigger than a Civic system. Yea yea, you cannot "overvacuum" a system, but why waste that much time. Would you tell that to a customer at your shop? Or don't you work at one.

There needs to be no oil put in anything but the compressor, Oil is placed in the low side service port only, and that one exception is valid for injecting dye. Oil sludges the metering device DOH!

The refrigerant amount will vary from R12 to 134a, their density is different so the volume will vary, do not listen to "the honda king".

The dryer will be fine provided you plugged it back up when you opened the system. And even then, the vacuum procedure will remove most of the moisture from the system in the first place.

The clogging more than likely accounts for 99% of the system not working right. Again, Chevy 1500's, most notably the Astro, have problems sucking debris into the evaporator, yielding the same symptoms.

4 hours huh, really. There is no need to vac a system that long unless it has 20 evaporators and holds 50lbs of refrigerant. It takes 35 minutes to vacuum out vans with rear air, and it is substantially bigger than a Civic system. Yea yea, you cannot "overvacuum" a system, but why waste that much time. Would you tell that to a customer at your shop? Or don't you work at one.

There needs to be no oil put in anything but the compressor, Oil is placed in the low side service port only, and that one exception is valid for injecting dye. Oil sludges the metering device DOH!

#24

Junior Member

Thread Starter

Join Date: Sep 2003

Location: Marietta, GA, USA

Posts: 364

Likes: 0

Received 0 Likes

on

0 Posts

slowcivic2k: you rock man, you confirmed exactly what I was thinking... no debris has been in this system and it's clean. I figured the drier would be ok, and I plugged it back up. I let the vacuum sit on for a couple hours (it's a rentel  ) and now it's time to see if it holds.

) and now it's time to see if it holds.

I had read somewhere to put a bit less 134, by volume, than R12 calls for. On the same note, I was looking at the A/C sticker on a 98 civic and it said 22 oz, just like my r12 system... or did the r12 system call for more than that?

) and now it's time to see if it holds.

) and now it's time to see if it holds.I had read somewhere to put a bit less 134, by volume, than R12 calls for. On the same note, I was looking at the A/C sticker on a 98 civic and it said 22 oz, just like my r12 system... or did the r12 system call for more than that?

#25

Honda-Tech Member

I have a 91 DX hatch with the original R12 system, and it calls for 32oz (2lbs) of R12. Most of the smaller cars call for around a pound and a half of R134a. I'd do a pound first, see where your pressures are, and add little by little until pressures are within spec for the ambient temp your in.

Most of the old R12 systems use much more refrigerant because of its efficiency/density. R134a condensers need to be much thinner (bar wise) with a lot of fins. By comparison, my condenser is so big it could pass for an interfooler. Then again, in 92 they went with the halfsize condenser and radiator. (Mine are full length full size.) So the amount will go down. This is because R12 is so much more efficient, that if the condenser gets too hot, it will completely ice the evaporator, the larger amount and reduced cooling form the condenser helps maintain a healthy temperature.

I will estimate 24oz will be all that is needed.

EDIT: With the TXV, make sure it is firmly heat-taped to the evap outlet. This is one component you don't want stray heat/cold getting on.

Modified by slowcivic2k at 10:33 PM 7/20/2008

Most of the old R12 systems use much more refrigerant because of its efficiency/density. R134a condensers need to be much thinner (bar wise) with a lot of fins. By comparison, my condenser is so big it could pass for an interfooler. Then again, in 92 they went with the halfsize condenser and radiator. (Mine are full length full size.) So the amount will go down. This is because R12 is so much more efficient, that if the condenser gets too hot, it will completely ice the evaporator, the larger amount and reduced cooling form the condenser helps maintain a healthy temperature.

I will estimate 24oz will be all that is needed.

EDIT: With the TXV, make sure it is firmly heat-taped to the evap outlet. This is one component you don't want stray heat/cold getting on.

Modified by slowcivic2k at 10:33 PM 7/20/2008