smoke in high rpms

#1

Honda-Tech Member

Thread Starter

I have a turbo B16A w/ a garrett 57trim on about 10psi w/ the proper restricor. The car idles fine but smokes (blueish tint)at high rpms when doing hard pulls. I know it's oil but I am trying to find the source of the burning wether it be the turbo or the engine. I have found a very thin greasy consistency of oil in the inlet and I cleaned it out and drove DDing for a week and checked it again. The turbo was stil clean. I checked my plugs and cylinder 3 had the same thin greasy consistency on the threads (very little). I always wait for the engine to warm up properly before boosting and my tuner seems very competent too. I checked the oil and it seems to use oil a little more so just trying to see which is burning it.

#2

Honda-Tech Member

Thread Starter

oh yeah, btw the turbo was brand spankin' new when I bought it too so it seems odd that a garret would go out that quickly (I've had it on the car for about 7months now dding).

#3

Retired Moderator

iTrader: (8)

are you running a catch can and have lines hooked up correctly?

Positive Crankcase Ventilation System (PCV)

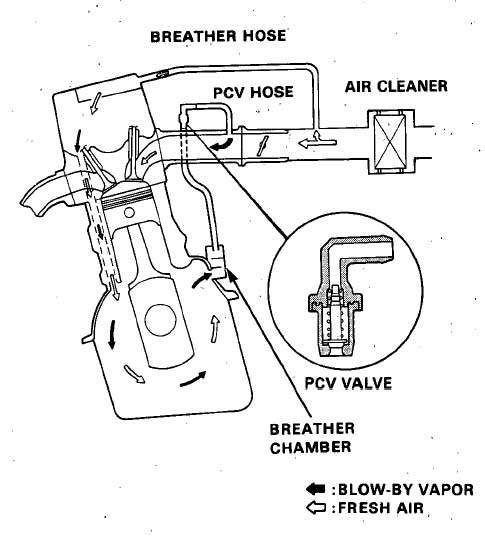

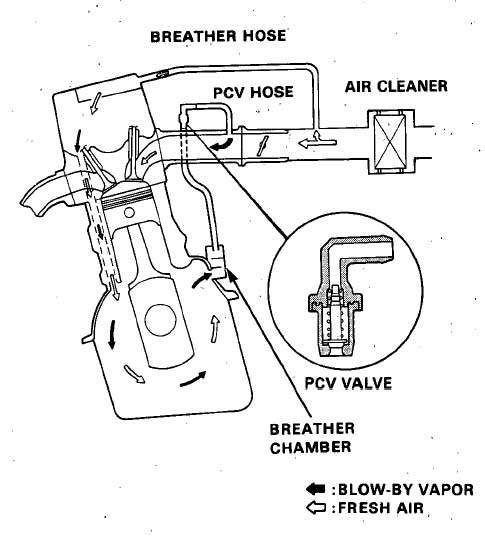

The positive crankcase ventilation system exists to relieve positive air pressure from the crankcase. Pressure in the crankcase is created by piston ring blow by and by the up and down motion of the pistons (just as the piston seals the top of the combustion chamber it seals the bottom of the cylinder, pulling air in on the compression and exhaust stroke, pushing air on the intake and power stroke). In order to relieve this pressure, a vacuum pressure sucks the pressure out of the crankcase through the PCV system. If the pressure is not vented piston ring and piston ring land damage can occur from the rings being jostled around as the piston is drawn down towards the crankcase, fighting against the pressure. In a turbo application this system must be modified or it will not work. Before figuring out how to modify the system it is a good idea to see how the stock system works. Below is a diagram of the stock PCV system:

As you can see the system begins in the intake pipe where air enters a hose that is attached to a barbed fitting on the valve cover. It is important to realize that the fitting on the valve cover is the PCV system inlet, air goes into the valve cover here. The air flows down through the head and into the crankcase. Once in the crankcase the air will pick up oil vapor from the oil being slung around at high velocity by the rotating assembly. The air then flows through the 'breather chamber' which is the black box you see on the back of the block under the intake manifold. The breather chamber has baffling in it that separates out some of the oil vapor and allows it to drain back into the crankcase. A hose connects the breather chamber to the PCV valve. The PCV valve is a one way valve that is open when a vacuum pressure is applied to the top of the valve. The PCV valve is connected to the intake manifold with a hose. The intake manifold exerts a vacuum pressure on the entire system. The PCV system is a closed vacuum circuit with pressure being exerted on one end and vacuum on the other. This allows any positive pressure in the crankcase to be vented.

The problem when a turbocharger is added is that the intake pipe and intake manifold become pressurized. If the fitting on the valve cover is still connected to the pressurized intake pipe it will pressurize the crankcase too. At the same time, the PCV valve will close when pressure is exerted on the top half of the valve, sealing the crankcase. If no modifications are made to the system a pressurized and sealed crankcase will occur when the boost kicks in, this is the worst possible time to have a sealed and pressurized crankcase.

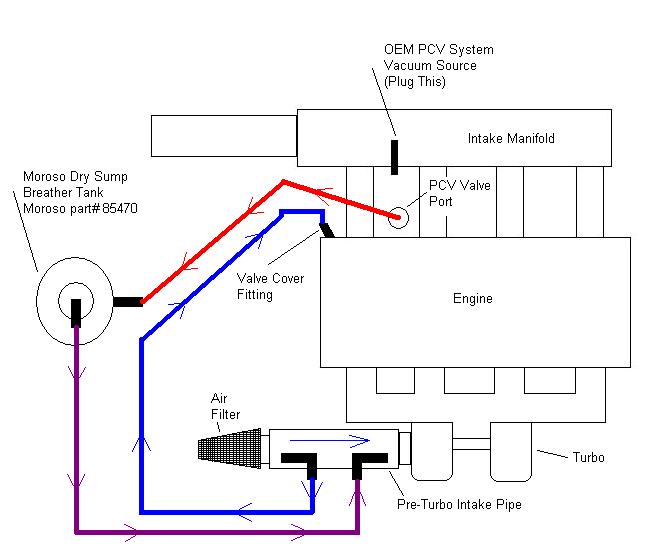

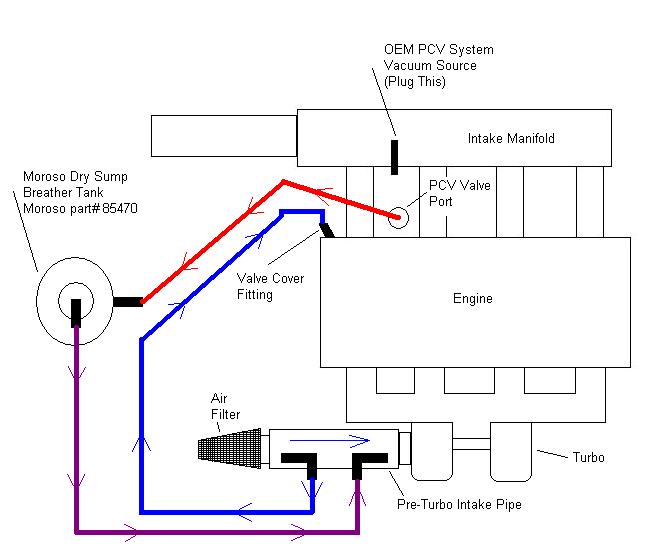

There are quite a few different opinions on how to plumb the PCV system for a turbo application. As long as the crankcase is not being pressurized by the intake charge pressure and the crankcase has some way to vent pressure you'll be in good shape. Probably the worst thing you can do is to add a valve cover breather filter to the fitting on the valve cover and retain the plumbing for the stock PCV valve. This would force the crankcase to vent through the valve cover breather filter. Many of the popular turbo PCV options include the use of a catch can. The catch can has internal baffling that separates out more oil vapor from the system. This is important because oil vapor effectively lowers the octane rating of the gas you are using, making detonation more likely. The catch can of choice is the Moroso Dry Sump Breather Tank Moroso part# 85470. The catch can needs to have 2 fittings on it. One is provided by way of a port on the side of the can. The other must be added by inserting a grommet into the top of the can (Help! PCV Grommet # 42048 for a Ford Econoline Van), and then a barbed fitting into the grommet. See picture below.

Below are a couple common turbo PCV plumbing options.

This setup mimics the stock setup PCV system. The inlet to the PCV system is in the pre-turbo intake pipe. A 90* fitting (a bulkhead fitting would work, or a bent piece of metal tube) with the opening facing towards the filter will allow incoming air to flow into the system. The air then flows into the valve cover, into the crankcase, and then out of the PCV valve port which now has a simple plastic 90* barbed fitting (no PCV valve). From the PCV port the air flows into the side of the catch can and out of the top of the can. Air then flows back to the pre-turbo intake pipe. For the PCV system outlet another 90* fitting is placed with its opening facing the turbo.

This routing sets up a closed circuit system with pressure being exerted on one end and vacuum on the other.

This routing is a little simpler than the one above. The valve cover fitting has a breather filter on it. Air flows through the crankcase and out of the PCV port which now has a plastic 90* barbed fitting in it (no PCV valve). From the PCV port, the air flows into the side of the catch can and out of the top of the can. Air then flows back to the pre-turbo intake pipe. A 90* fitting is not required here because air flowing across the opening of the fitting in the intake pipe will draw air out in the direction of air flow (the same reason water comes out the top of a straw when it is submerged in a glass of water and you blow across the top of it).

This routing is not a closed circuit system with the only drive for the system being provided by vacuum.

Thanks to xenocron from G2IC for this PCV plumbing option.

Positive Crankcase Ventilation System (PCV)

The positive crankcase ventilation system exists to relieve positive air pressure from the crankcase. Pressure in the crankcase is created by piston ring blow by and by the up and down motion of the pistons (just as the piston seals the top of the combustion chamber it seals the bottom of the cylinder, pulling air in on the compression and exhaust stroke, pushing air on the intake and power stroke). In order to relieve this pressure, a vacuum pressure sucks the pressure out of the crankcase through the PCV system. If the pressure is not vented piston ring and piston ring land damage can occur from the rings being jostled around as the piston is drawn down towards the crankcase, fighting against the pressure. In a turbo application this system must be modified or it will not work. Before figuring out how to modify the system it is a good idea to see how the stock system works. Below is a diagram of the stock PCV system:

As you can see the system begins in the intake pipe where air enters a hose that is attached to a barbed fitting on the valve cover. It is important to realize that the fitting on the valve cover is the PCV system inlet, air goes into the valve cover here. The air flows down through the head and into the crankcase. Once in the crankcase the air will pick up oil vapor from the oil being slung around at high velocity by the rotating assembly. The air then flows through the 'breather chamber' which is the black box you see on the back of the block under the intake manifold. The breather chamber has baffling in it that separates out some of the oil vapor and allows it to drain back into the crankcase. A hose connects the breather chamber to the PCV valve. The PCV valve is a one way valve that is open when a vacuum pressure is applied to the top of the valve. The PCV valve is connected to the intake manifold with a hose. The intake manifold exerts a vacuum pressure on the entire system. The PCV system is a closed vacuum circuit with pressure being exerted on one end and vacuum on the other. This allows any positive pressure in the crankcase to be vented.

The problem when a turbocharger is added is that the intake pipe and intake manifold become pressurized. If the fitting on the valve cover is still connected to the pressurized intake pipe it will pressurize the crankcase too. At the same time, the PCV valve will close when pressure is exerted on the top half of the valve, sealing the crankcase. If no modifications are made to the system a pressurized and sealed crankcase will occur when the boost kicks in, this is the worst possible time to have a sealed and pressurized crankcase.

There are quite a few different opinions on how to plumb the PCV system for a turbo application. As long as the crankcase is not being pressurized by the intake charge pressure and the crankcase has some way to vent pressure you'll be in good shape. Probably the worst thing you can do is to add a valve cover breather filter to the fitting on the valve cover and retain the plumbing for the stock PCV valve. This would force the crankcase to vent through the valve cover breather filter. Many of the popular turbo PCV options include the use of a catch can. The catch can has internal baffling that separates out more oil vapor from the system. This is important because oil vapor effectively lowers the octane rating of the gas you are using, making detonation more likely. The catch can of choice is the Moroso Dry Sump Breather Tank Moroso part# 85470. The catch can needs to have 2 fittings on it. One is provided by way of a port on the side of the can. The other must be added by inserting a grommet into the top of the can (Help! PCV Grommet # 42048 for a Ford Econoline Van), and then a barbed fitting into the grommet. See picture below.

Below are a couple common turbo PCV plumbing options.

This setup mimics the stock setup PCV system. The inlet to the PCV system is in the pre-turbo intake pipe. A 90* fitting (a bulkhead fitting would work, or a bent piece of metal tube) with the opening facing towards the filter will allow incoming air to flow into the system. The air then flows into the valve cover, into the crankcase, and then out of the PCV valve port which now has a simple plastic 90* barbed fitting (no PCV valve). From the PCV port the air flows into the side of the catch can and out of the top of the can. Air then flows back to the pre-turbo intake pipe. For the PCV system outlet another 90* fitting is placed with its opening facing the turbo.

This routing sets up a closed circuit system with pressure being exerted on one end and vacuum on the other.

This routing is a little simpler than the one above. The valve cover fitting has a breather filter on it. Air flows through the crankcase and out of the PCV port which now has a plastic 90* barbed fitting in it (no PCV valve). From the PCV port, the air flows into the side of the catch can and out of the top of the can. Air then flows back to the pre-turbo intake pipe. A 90* fitting is not required here because air flowing across the opening of the fitting in the intake pipe will draw air out in the direction of air flow (the same reason water comes out the top of a straw when it is submerged in a glass of water and you blow across the top of it).

This routing is not a closed circuit system with the only drive for the system being provided by vacuum.

Thanks to xenocron from G2IC for this PCV plumbing option.

Last edited by EsotericImage; 10-18-2010 at 12:50 PM.

#4

Honda-Tech Member

Thread Starter

Unfortunately, I wasn't using a catch can set-up. As a result, I found oil on the threads of my spark plugs so I'm guessing that either A) my rings are fried on 3 of the 4 cylinders, B) head gasket is done or C) valve seals are toast... shizzle... I know my trials and tribulations will help somebody else w/ these questions so any EDUCATED insight is much appreciated by myself and undoubtedly someone else going through this.

The following users liked this post:

Thread

Thread Starter

Forum

Replies

Last Post