Harmonic damper. Use or not?

#1

Hi members.

How many of you have a turbo charged setup that is not using a crank damper?

I am busy with an engine build and I will not be able to replace the stock harmonic damper with another one and the stock one is scrap.

Will it be a no no to fit a normal light weight pulley?

How many of you have a turbo charged setup that is not using a crank damper?

I am busy with an engine build and I will not be able to replace the stock harmonic damper with another one and the stock one is scrap.

Will it be a no no to fit a normal light weight pulley?

#2

It depends on how high you plan to rev the engine. Most turbos dont rev that high, so unless your building something crazy you will be ok. I have had a light weight true jdm single belt pully for three years and no issues. 8250 rpm Though there are some people who are ocd as heck, and wont run any motor without it, Im also only all motor, and I do belive that high horesepower plays a part in it as well, though I dont know how much is too much for a lightweight pully

#3

Honda-Tech Member

^^^^^

The Danger of Power Pulleys &

Understanding the Harmonic Damper

BY STEVE DINAN OF DINAN BMW

I have been threatening for a long time to write a series of technical articles to educate consumers and to dispel misconceptions that exist about automotive after-market technology. Motivated by problems with customer's cars resulting from the installation of power pulleys, I wish to explain the potential dangers of these products and address the damage they cause to engines.

The theory behind the power pulley is that a reduction in the speed of the accessory drive will minimize the parasitic losses that rob power from the engine. Parasitic power losses are a result of the energy that the engine uses to turn accessory components such as the alternator and water pump, instead of producing power for acceleration. In an attempt to minimize this energy loss, many companies claim to produce additional power by removing the harmonic damper and replacing it with a lightweight assembly. While a small power gain can be realized, there are a significant number of potential problems associated with this modification, some that are small and one which is particularly large and damaging!

The popular method for making power pulleys on E36 engines is by removing the harmonic damper and replacing it with a lightweight alloy assembly. This is a very dangerous product because this damper is essential to the longevity of an engine. The substitution of this part often results in severe engine damage.

It is also important to understand that while the engine in a BMW is designed by a team of qualified engineers, these power pulleys are created and installed by people who do not understand some very important principles of physics. I would first like to give a brief explanation of these principles which are critical to the proper operation of an engine.

1) Elastic Deformation

Though it is common belief that large steel parts such as crankshafts are rigid and inflexible, this is not true. When a force acts on a crank it bends, flexes and twists just as a rubber band would. While this movement is often very small, it can have a significant impact on how an engine functions.

2) Natural Frequency

All objects have a natural frequency that they resonate (vibrate) at when struck with a hammer. An everyday example of this is a tuning fork. The sound that a particular fork makes is directly related to the frequency that it is vibrating at. This is its "natural frequency," that is dictated by the size, shape and material of the instrument. Just like a tuning fork, a crankshaft has a natural frequency that it vibrates at when struck. An important aspect of this principle is that when an object is exposed to a heavily amplified order of its own natural frequency, it will begin to resonate with increasing vigor until it vibrates itself to pieces (fatigue failure).

3) Fatigue Failure

Fatigue failure is when a material, metal in this case, breaks from repeated twisting or bending. A paper clip makes a great example. Take a paper clip and flex it back and forth 90° or so. After about 10 oscillations the paper clip will break of fatigue failure.

The explanation of the destructive nature of power pulleys begins with the two basic balance and vibration modes in an internal combustion engine. It is of great importance that these modes are understood as being separate and distinct.

1) The vibration of the engine and its rigid components caused by the imbalance of the rotating and reciprocating parts. This is why we have counterweights on the crankshaft to offset the mass of the piston and rod as well as the reason for balancing the components in the engine.

2) The vibration of the engine components due to their individual elastic deformations. These deformations are a result of the periodic combustion impulses that create torsional forces on the crankshaft and camshaft. These torques excite the shafts into sequential orders of vibration, and lateral oscillation. Engine vibration of this sort is counteracted by the harmonic damper and is the primary subject of this paper.

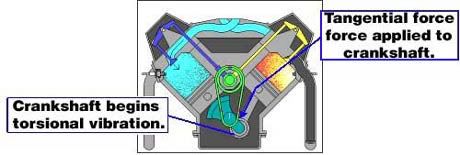

Torsional Vibration (Natural Frequency)

Every time a cylinder fires, the force twists the crankshaft. When the cylinder stops firing the force ceases to act and the crankshaft starts to return to the untwisted position. However, the crankshaft will overshoot and begin to twist in the opposite direction, and then back again. Though this back-and-forth twisting motion decays over a number of repetitions due to internal friction, the frequency of vibration remains unique to the particular crankshaft.

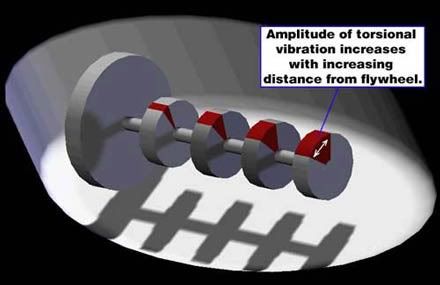

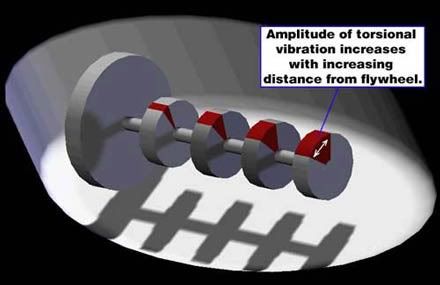

This motion is complicated in the case of a crankshaft because the amplitude of the vibration varies along the shaft. The crankshaft will experience torsional vibrations of the greatest amplitude at the point furthest from the flywheel or load.

Harmonic (sine wave) Torque Curves

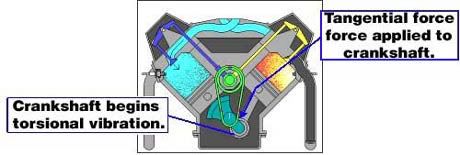

Each time a cylinder fires, force is translated through the piston and the connecting rod to the crankshaft pin. This force is then applied tangentially to, and causes the rotation of the crankshaft.

The sequence of forces that the crankshaft is subjected to is commonly organized into variable tangential torque curves that in turn can be resolved into either a constant mean torque curve or an infinite number of sine wave torque curves. These curves, known as harmonics, follow orders that depend on the number of complete vibrations (cylinder pulses) per revolution. Accordingly, the tangential crankshaft torque is comprised of many harmonics of varying amplitudes and frequencies. This is where the name "harmonic damper" originates.

Critical RPM's

When the crankshaft is revolving at an RPM such that the torque frequency, or one of the harmonic sine wave frequencies coincides with the natural frequency of the shaft, resonance occurs. Thus, the crankshaft RPM at which this resonance occurs is known a critical speed. A modern automobile engine will commonly pass through multiple critical speeds over the range of its possible RPM's. These speeds are categorized into either major or minor critical RPM's.

Major and Minor Critical RPM’s

Major and minor critical RPM's are different due to the fact that some harmonics assist one another in producing large vibrations, whereas other harmonics cancel each other out. Hence, the important critical RPM’s have harmonics that build on one another to amplify the torsional motion of the crankshaft. These critical RPM’s are know as the "major criticals". Conversely, the "minor criticals" exist at RPM's that tend to cancel and damp the oscillations of the crankshaft.

If the RPM remains at or near one of the major criticals for any length of time, fatigue failure of the crankshaft is probable. Major critical RPM’s are dangerous, and either must be avoided or properly damped. Additionally, smaller but still serious problems can result from an undamped crankshaft. The oscillation of the crankshaft at a major critical speed will commonly sheer the front crank pulley and the flywheel from the crankshaft. I have witnessed front pulley hub keys being sheered, flywheels coming loose, and clutch covers coming apart. These failures have often required crankshaft and/or gearbox replacement.

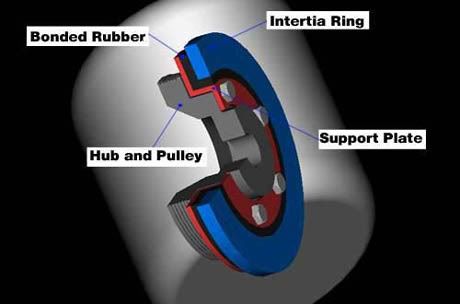

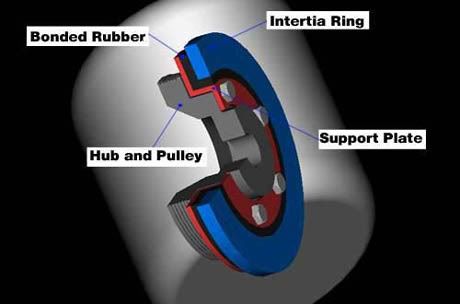

Harmonic Dampers

Crankshaft failure can be prevented by mounting some form of vibration damper at the front end of the crankshaft that is capable of absorbing and dissipating the majority of the vibratory energy. Once absorbed by the damper the energy is released in the form of heat, making adequate cooling a necessity. This heat dissipation was visibly essential in Tom Milner's PTG racing M3 which channeled air from the brake ducts to the harmonic damper, in order to keep the damper at optimal operating temperatures. While there are various types of torsional vibration dampers, BMW engines are primarily designed with "tuned rubber" dampers.

It is also important to note that while the large springs of a dual mass flywheel absorb some of the torsional impulses conveyed to the crankshaft, they are not harmonic dampers, and are only responsible for a small reduction in vibration.

In addition to the crankshaft issue, other problems can result from slowing down the accessories below their designed speeds, particularly at idle. Slowing the alternator down can result in reduced charging of the battery, dimming of the lights, and computer malfunctions. Slowing of the water pump and fan can result in warm running, while slowing of the power steering can cause stiff steering at idle and groaning noises. It is possible to implement design corrections and avoid these scenarios, but this would require additional components and/or software.

Our motto at Dinan is "Performance without sacrifice" We feel our customers expect ultra high performance along with the legendary comfort and reliability of a standard BMW.

While it is common that a Dinan BMW is the fastest BMW you can buy, performance is not our only goal. Dinan isn't just trying to make the fastest car. Instead a host of considerations go into the development of our products. Dinan puts much more effort into these other areas than does our competition.

These considerations are Performance, Reliability (Warranty), Driveability, Emissions, Value, Fit and Finish. We feel that the power pulley is a bad way to get extra power from and engine and the potential for serious engine damage is too great.

This is a simplified explanation meant to be comprehensible by those who are not automotive engineers. In trying to simplify an extremely complex topic some precision was sacrificed although we believe this explanation to be as accurate as possible. We encourage our customers to educate themselves and understand the automotive after-market because we believe that our products are the best researched, engineered, and fabricated products available.

For those interested in a more in depth and technical explanation of this topic, the reference book is Advanced Engine Technology, written by Heinz Heisler MSc,BSc,FIMI,MIRTE,MCIT. Heinz Heisler is the Head of Transportation Studies at The College of North West London. His book is distributed in this country by the SAE (Society of Automotive Engineers).

http://www.atiracing.com/products/da...mper_dinan.htm

The Danger of Power Pulleys &

Understanding the Harmonic Damper

BY STEVE DINAN OF DINAN BMW

I have been threatening for a long time to write a series of technical articles to educate consumers and to dispel misconceptions that exist about automotive after-market technology. Motivated by problems with customer's cars resulting from the installation of power pulleys, I wish to explain the potential dangers of these products and address the damage they cause to engines.

The theory behind the power pulley is that a reduction in the speed of the accessory drive will minimize the parasitic losses that rob power from the engine. Parasitic power losses are a result of the energy that the engine uses to turn accessory components such as the alternator and water pump, instead of producing power for acceleration. In an attempt to minimize this energy loss, many companies claim to produce additional power by removing the harmonic damper and replacing it with a lightweight assembly. While a small power gain can be realized, there are a significant number of potential problems associated with this modification, some that are small and one which is particularly large and damaging!

The popular method for making power pulleys on E36 engines is by removing the harmonic damper and replacing it with a lightweight alloy assembly. This is a very dangerous product because this damper is essential to the longevity of an engine. The substitution of this part often results in severe engine damage.

It is also important to understand that while the engine in a BMW is designed by a team of qualified engineers, these power pulleys are created and installed by people who do not understand some very important principles of physics. I would first like to give a brief explanation of these principles which are critical to the proper operation of an engine.

1) Elastic Deformation

Though it is common belief that large steel parts such as crankshafts are rigid and inflexible, this is not true. When a force acts on a crank it bends, flexes and twists just as a rubber band would. While this movement is often very small, it can have a significant impact on how an engine functions.

2) Natural Frequency

All objects have a natural frequency that they resonate (vibrate) at when struck with a hammer. An everyday example of this is a tuning fork. The sound that a particular fork makes is directly related to the frequency that it is vibrating at. This is its "natural frequency," that is dictated by the size, shape and material of the instrument. Just like a tuning fork, a crankshaft has a natural frequency that it vibrates at when struck. An important aspect of this principle is that when an object is exposed to a heavily amplified order of its own natural frequency, it will begin to resonate with increasing vigor until it vibrates itself to pieces (fatigue failure).

3) Fatigue Failure

Fatigue failure is when a material, metal in this case, breaks from repeated twisting or bending. A paper clip makes a great example. Take a paper clip and flex it back and forth 90° or so. After about 10 oscillations the paper clip will break of fatigue failure.

The explanation of the destructive nature of power pulleys begins with the two basic balance and vibration modes in an internal combustion engine. It is of great importance that these modes are understood as being separate and distinct.

1) The vibration of the engine and its rigid components caused by the imbalance of the rotating and reciprocating parts. This is why we have counterweights on the crankshaft to offset the mass of the piston and rod as well as the reason for balancing the components in the engine.

2) The vibration of the engine components due to their individual elastic deformations. These deformations are a result of the periodic combustion impulses that create torsional forces on the crankshaft and camshaft. These torques excite the shafts into sequential orders of vibration, and lateral oscillation. Engine vibration of this sort is counteracted by the harmonic damper and is the primary subject of this paper.

Torsional Vibration (Natural Frequency)

Every time a cylinder fires, the force twists the crankshaft. When the cylinder stops firing the force ceases to act and the crankshaft starts to return to the untwisted position. However, the crankshaft will overshoot and begin to twist in the opposite direction, and then back again. Though this back-and-forth twisting motion decays over a number of repetitions due to internal friction, the frequency of vibration remains unique to the particular crankshaft.

This motion is complicated in the case of a crankshaft because the amplitude of the vibration varies along the shaft. The crankshaft will experience torsional vibrations of the greatest amplitude at the point furthest from the flywheel or load.

Harmonic (sine wave) Torque Curves

Each time a cylinder fires, force is translated through the piston and the connecting rod to the crankshaft pin. This force is then applied tangentially to, and causes the rotation of the crankshaft.

The sequence of forces that the crankshaft is subjected to is commonly organized into variable tangential torque curves that in turn can be resolved into either a constant mean torque curve or an infinite number of sine wave torque curves. These curves, known as harmonics, follow orders that depend on the number of complete vibrations (cylinder pulses) per revolution. Accordingly, the tangential crankshaft torque is comprised of many harmonics of varying amplitudes and frequencies. This is where the name "harmonic damper" originates.

Critical RPM's

When the crankshaft is revolving at an RPM such that the torque frequency, or one of the harmonic sine wave frequencies coincides with the natural frequency of the shaft, resonance occurs. Thus, the crankshaft RPM at which this resonance occurs is known a critical speed. A modern automobile engine will commonly pass through multiple critical speeds over the range of its possible RPM's. These speeds are categorized into either major or minor critical RPM's.

Major and Minor Critical RPM’s

Major and minor critical RPM's are different due to the fact that some harmonics assist one another in producing large vibrations, whereas other harmonics cancel each other out. Hence, the important critical RPM’s have harmonics that build on one another to amplify the torsional motion of the crankshaft. These critical RPM’s are know as the "major criticals". Conversely, the "minor criticals" exist at RPM's that tend to cancel and damp the oscillations of the crankshaft.

If the RPM remains at or near one of the major criticals for any length of time, fatigue failure of the crankshaft is probable. Major critical RPM’s are dangerous, and either must be avoided or properly damped. Additionally, smaller but still serious problems can result from an undamped crankshaft. The oscillation of the crankshaft at a major critical speed will commonly sheer the front crank pulley and the flywheel from the crankshaft. I have witnessed front pulley hub keys being sheered, flywheels coming loose, and clutch covers coming apart. These failures have often required crankshaft and/or gearbox replacement.

Harmonic Dampers

Crankshaft failure can be prevented by mounting some form of vibration damper at the front end of the crankshaft that is capable of absorbing and dissipating the majority of the vibratory energy. Once absorbed by the damper the energy is released in the form of heat, making adequate cooling a necessity. This heat dissipation was visibly essential in Tom Milner's PTG racing M3 which channeled air from the brake ducts to the harmonic damper, in order to keep the damper at optimal operating temperatures. While there are various types of torsional vibration dampers, BMW engines are primarily designed with "tuned rubber" dampers.

It is also important to note that while the large springs of a dual mass flywheel absorb some of the torsional impulses conveyed to the crankshaft, they are not harmonic dampers, and are only responsible for a small reduction in vibration.

In addition to the crankshaft issue, other problems can result from slowing down the accessories below their designed speeds, particularly at idle. Slowing the alternator down can result in reduced charging of the battery, dimming of the lights, and computer malfunctions. Slowing of the water pump and fan can result in warm running, while slowing of the power steering can cause stiff steering at idle and groaning noises. It is possible to implement design corrections and avoid these scenarios, but this would require additional components and/or software.

Our motto at Dinan is "Performance without sacrifice" We feel our customers expect ultra high performance along with the legendary comfort and reliability of a standard BMW.

While it is common that a Dinan BMW is the fastest BMW you can buy, performance is not our only goal. Dinan isn't just trying to make the fastest car. Instead a host of considerations go into the development of our products. Dinan puts much more effort into these other areas than does our competition.

These considerations are Performance, Reliability (Warranty), Driveability, Emissions, Value, Fit and Finish. We feel that the power pulley is a bad way to get extra power from and engine and the potential for serious engine damage is too great.

This is a simplified explanation meant to be comprehensible by those who are not automotive engineers. In trying to simplify an extremely complex topic some precision was sacrificed although we believe this explanation to be as accurate as possible. We encourage our customers to educate themselves and understand the automotive after-market because we believe that our products are the best researched, engineered, and fabricated products available.

For those interested in a more in depth and technical explanation of this topic, the reference book is Advanced Engine Technology, written by Heinz Heisler MSc,BSc,FIMI,MIRTE,MCIT. Heinz Heisler is the Head of Transportation Studies at The College of North West London. His book is distributed in this country by the SAE (Society of Automotive Engineers).

http://www.atiracing.com/products/da...mper_dinan.htm

#4

Honda-Tech Member

iTrader: (1)

Join Date: Jun 2007

Location: newport news, VA, United States

Posts: 156

Likes: 0

Received 0 Likes

on

0 Posts

Definitely would never not run a harmonic. I use ATI Street damper and have had great luck. For the price, its a cheap security policy for your engine.

http://www.lightningmotorsports.com/.../i-269852.aspx

http://www.lightningmotorsports.com/.../i-269852.aspx

#5

Awesome stuff rich7777  thanks!

thanks!

Makes one wonder why a bearing knock jumps out of no ware sometimes!!

But what about the belt on the pulley connected the the alternator?

Does it maybe damp to some extent?

The damper should also help with "knocking"?

thanks!

thanks!Makes one wonder why a bearing knock jumps out of no ware sometimes!!

But what about the belt on the pulley connected the the alternator?

Does it maybe damp to some extent?

The damper should also help with "knocking"?

Trending Topics

#9

Who is Mr Robot?

iTrader: (2)

Join Date: Jul 2004

Location: ATL - Where the Pimps and Players dwell

Posts: 21,474

Likes: 0

Received 10 Likes

on

10 Posts

If there isn't one available get another stock one... Lightweight non dampened aluminum pullies will destroy an engine in a heartbeat... I've seen countless failures on numerous different motors that people ran with an aluminum lightweight pulley.. I've also seen a bunch of motors break that run ctr bullies.

#14

Honda-Tech Member

Join Date: Jun 2009

Location: New Zealand

Posts: 38

Likes: 0

Received 0 Likes

on

0 Posts

Definitely run a damper! I'm rebuilding my motor now after running a lightweight alloy crank pulley the first time round, shattered the oil pump gear into pieces.

Gone with ATI this time.

Gone with ATI this time.

#15

Honda-Tech Member

#16

Who is Mr Robot?

iTrader: (2)

Join Date: Jul 2004

Location: ATL - Where the Pimps and Players dwell

Posts: 21,474

Likes: 0

Received 10 Likes

on

10 Posts

Yea sounds about right.. The lightweight/undampened pulleys either shatter an oil pump gear or pound out a rod bearing, normally on #3 or #4... If life really hates you both happen simultaneously.

#17

Honda-Tech Member

Join Date: Jun 2009

Location: New Zealand

Posts: 38

Likes: 0

Received 0 Likes

on

0 Posts

Oil pump gave up at 250kmph down the back straight on the track. Wasn't the most ideal situation for it to bust. Such is life, definitely run a damper tho!

#18

Who is Mr Robot?

iTrader: (2)

Join Date: Jul 2004

Location: ATL - Where the Pimps and Players dwell

Posts: 21,474

Likes: 0

Received 10 Likes

on

10 Posts

I bet that did all sorts of horrific things to the motor. With anyone doing track days or along thet are a must

that's where harmonics are the worst since you tend to spend a lot of time higher in rhetorically rev range

that's where harmonics are the worst since you tend to spend a lot of time higher in rhetorically rev range

#19

Honda-Tech Member

On a friends B16 he used a CTR crank pulley against everyone's advice. Within 5k miles of putting the CTR pulley on, it locked up the oil pump gear, stripped the gear out, and spun 3 main bearings into the block. Think the loudest fingernail on chalkboard sounds you've ever heard. Luckily the head was salvageable and a proper LS/V was built... with a ATI dampner lol. Now... as to which is better Fluidampr or ATI, the answer is neither. Both have an intended use FLuidampr for a track only car and ATI for a street/race car. If a Fluidampr sits for a long time the "fluid" can actually harden in one side of the balancer, thus when you do eventually run the engine, the dampner will actually be hurting the motor.

#20

Honda-Tech Member

Join Date: Jul 2003

Location: Ontario & Alberta, Canada

Posts: 1,344

Likes: 0

Received 1 Like

on

1 Post

I run an ATI damper. Not a big fan of Nascar/Nextel/Sprint etc. racing, but according to the brochure that came with my pulley. ATI is sponsor and supplier for race engine dampers in these racing series. If team engineers choose to run an ATI pulley on engines that see a consistant 9000+RPM for 400-500 lap races with no issues. That is proof in itself that these work well enough for multimillion dollar race teams and will work just as well if not better on our little Honda engines, turbocharged or not.

#21

Honda-Tech Member

Join Date: Apr 2003

Location: Kona/V-town, HI

Posts: 2,776

Likes: 0

Received 0 Likes

on

0 Posts

my roomate revs his b16 constantly to 10k with a fluidampr, 2 year later check all the bearing while swapping pistons. Bearings looked fine, brand new looking

while many people run ATI problem free, the science behind fluidampr makes more sense to me

while many people run ATI problem free, the science behind fluidampr makes more sense to me

#22

Who is Mr Robot?

iTrader: (2)

Join Date: Jul 2004

Location: ATL - Where the Pimps and Players dwell

Posts: 21,474

Likes: 0

Received 10 Likes

on

10 Posts

The fluidampr constantly adjusts for New different vibrations but will solidify if it sits for a very very long time. I had one sit on a shelf for 4 years and it worked flawlessly

What i love is the op doesn't even come back to this thread.

What i love is the op doesn't even come back to this thread.

#24

Honda-Tech Member

Join Date: Aug 2007

Location: TN, US

Posts: 320

Likes: 0

Received 0 Likes

on

0 Posts

Are the benefits of an ATI/Fluidampr perceiveable in applications at or below 8000rpm?

I've been told the oem harmonic balancer is more than adequete for "factory" rpm range, and that the ATI/Fluidampr is overkill until you are revving to 9k+

BS?

I've been told the oem harmonic balancer is more than adequete for "factory" rpm range, and that the ATI/Fluidampr is overkill until you are revving to 9k+

BS?

#25

You are quite entertaining :D

You have your knife in for me?

Anyway thanks a lot for the replies members

I doubt that the engine I have needs to be known but it is a 4EFTE

I am building a frankenstein one now as spares for this engine is not available to SA at all and these engines with stock internals is pathetic.

and these engines with stock internals is pathetic.

Guess I will shop around and maybe make one

You have your knife in for me?

Anyway thanks a lot for the replies members

I doubt that the engine I have needs to be known but it is a 4EFTE

I am building a frankenstein one now as spares for this engine is not available to SA at all

and these engines with stock internals is pathetic.

and these engines with stock internals is pathetic.Guess I will shop around and maybe make one