Crankshaft runout or Tunnels: Really in need of help here.

#1

Honda-Tech Member

Thread Starter

Over the summer my Oil pressure readings have been decreasing by the minute, and giving me second thoughts about tearing the motor back up apart for an unexpected discovery.

This is something I really didn't have planned beforehand because I was 100% certain

that this motor would last longer than one would think.

Picture of the bearings.

It's obvious to see that the main journal mirror finish is scorched on the third one.

Aside from all the others, one main bearing that I have independently put to rest is the

concave in grooved one because of excessive material, and finish loss as shown.

Then again, this is a perfect time for an in-experienced blueprinting individual such as myself to dial in an extra skill that will be well worth learning.

I've read more about crankshaft straightening online and enthusiasts have mentioned the following. Internal stresses, a fall from a work bench top, high end loads, and heat treating

are multiple factors that can cause crankshaft runout failure, resulting in a bent crank that is.

With that being said, can anybody please confirm my question ?

If I get this tool ...

http://www.earthchain.com/universal-arms.htm

Will it be necessary enough for identifying mis-aligned tunnels, out of shape, or if

the crank is ACTUALLY bent ?

I'm trying to find something off the shelf, but I am not getting anything that has good written reviews behind a well good known product.

This is something I really didn't have planned beforehand because I was 100% certain

that this motor would last longer than one would think.

Picture of the bearings.

It's obvious to see that the main journal mirror finish is scorched on the third one.

Aside from all the others, one main bearing that I have independently put to rest is the

concave in grooved one because of excessive material, and finish loss as shown.

Then again, this is a perfect time for an in-experienced blueprinting individual such as myself to dial in an extra skill that will be well worth learning.

I've read more about crankshaft straightening online and enthusiasts have mentioned the following. Internal stresses, a fall from a work bench top, high end loads, and heat treating

are multiple factors that can cause crankshaft runout failure, resulting in a bent crank that is.

With that being said, can anybody please confirm my question ?

If I get this tool ...

http://www.earthchain.com/universal-arms.htm

Will it be necessary enough for identifying mis-aligned tunnels, out of shape, or if

the crank is ACTUALLY bent ?

I'm trying to find something off the shelf, but I am not getting anything that has good written reviews behind a well good known product.

#3

DO IT ON ALL FOURS

More like improper clearancing... If there wasn't a massive vibration, the crank most likely wasn't bent.

None of the tools in the link will get you any measurements you are looking for.

None of the tools in the link will get you any measurements you are looking for.

#4

Honda-Tech Member

Join Date: Jul 2004

Location: nothing is real unless it is observed

Posts: 5,957

Likes: 0

Received 0 Likes

on

0 Posts

Top and bottom bearings look the same, Or more smashed on the bottoms?

#5

Honda-Tech Member

Thread Starter

crank journal measurements

#1 Main: 2.167"

#2 Main: 2.167"

#3 Main: 2.167"

#4 Main: 2.167"

#5 Main: 2.167"

#1 Main: 0.003"

#2 Main: 0.002"

#3 Main: 0.002"

#4 Main: 0.0025"

#5 Main: 0.002"

I also double checked my work with a plasti gauge.

The main journal that you see with the most wear, is the 3rd one. I will take a better picture today, addressing the journal proportion to each other, this way it'l be easier

to identify which one is which.

PS: The crank has NOT been balanced, and I've been boosting the living **** out of it. Can this serve a problem?

Don't ask me why, I just wanted to get this thing ready and done before the summer.

Before selling the setup here on H-T, I really want to validate a reasonable cause so the buyer knows the cranks/block current condition prior to machining.

#6

Honda-Tech Member

Join Date: Feb 2003

Location: Houston, TX

Posts: 1,171

Likes: 0

Received 0 Likes

on

0 Posts

What's the story on the setup? Were the main bores line honed?

I don't think balancing is the culprit. Your tightest clearance is supposed to be at 6 and 12 o'clock, so if the clearances were too tight, that's where the copper would show. In those pictures, the copper is showing at the parting line which is supposed to have the most clearance. I'm thinking either the main bores are out of round or there was trash behind the bearing when it was assembled.

I don't think balancing is the culprit. Your tightest clearance is supposed to be at 6 and 12 o'clock, so if the clearances were too tight, that's where the copper would show. In those pictures, the copper is showing at the parting line which is supposed to have the most clearance. I'm thinking either the main bores are out of round or there was trash behind the bearing when it was assembled.

#7

Honda-Tech Member

Thread Starter

What's the story on the setup? Were the main bores line honed?

I don't think balancing is the culprit. Your tightest clearance is supposed to be at 6 and 12 o'clock, so if the clearances were too tight, that's where the copper would show. In those pictures, the copper is showing at the parting line which is supposed to have the most clearance. I'm thinking either the main bores are out of round or there was trash behind the bearing when it was assembled.

I don't think balancing is the culprit. Your tightest clearance is supposed to be at 6 and 12 o'clock, so if the clearances were too tight, that's where the copper would show. In those pictures, the copper is showing at the parting line which is supposed to have the most clearance. I'm thinking either the main bores are out of round or there was trash behind the bearing when it was assembled.

Okay so let's get down to this problem!

Good thing you are interested in the background, and history involving this motor.

The Main Bores were NOT line honed.

Here is a quick rundown of me blueprinting the whole entire block this previous spring.

I have learned that I have left multiple variables out of display for proper inspection on what sadly resulted in rock bottom, a failure in my build technically speaking.

Such as run-out, being one for starters.

https://honda-tech.com/forums/drag-racing-36/ef9_trymes-journey-high-11s-race-build-3049141/

What exactly do you mean at the part line ? It having the most clearance ?

When you say part line, are you referring to the bottom bearings closer to the throat,

or the ones that are installed in the main caps ?

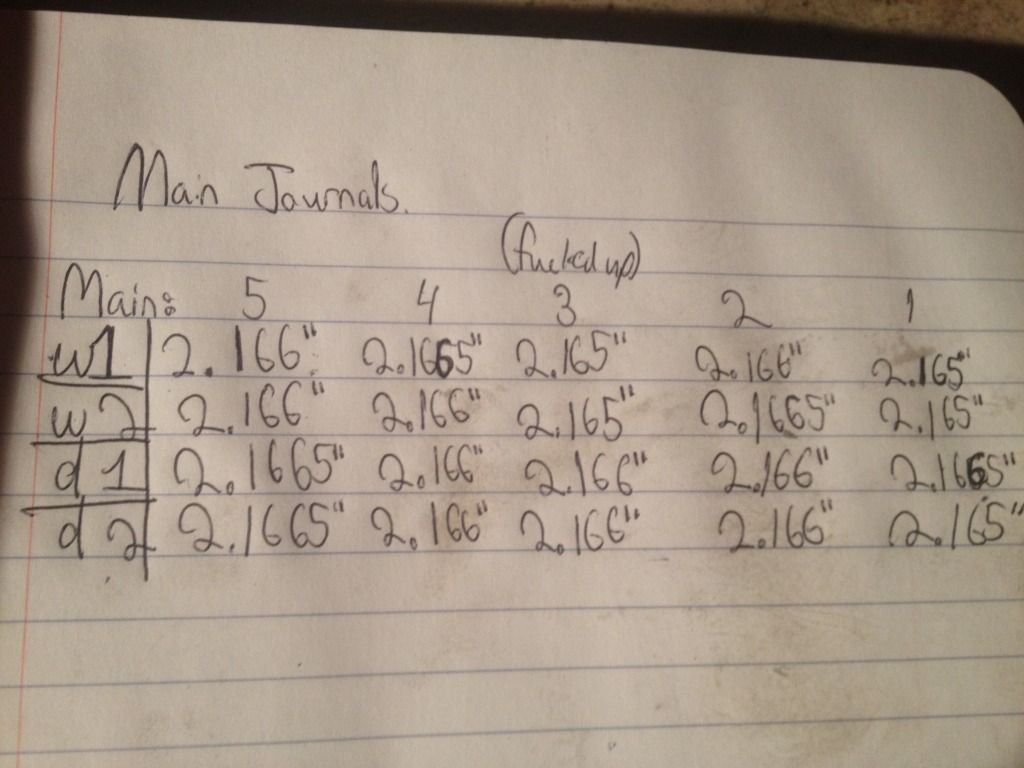

Regarding the Journals:

I just measured the cranks main's in various different aspects to confirm if it has been damaged, or if there was taper along these lines that I have missed prior to the previous

assembly.

This is the way I measure crankshaft main journals:

I set the crankshaft's rear on a wooden block, so it's stable and does not tip over.

Take something into perspective here on how my numbers are calculated based on my most formal technique that I'm left with.

For example, notice where the woodruff key slot is on the front of the crank shaft, and

then take a look at this chart that I have displayed.

W1: Is an indication how my micrometer is placed in reference to the location of the woodruff key, Closest to the front of the crank that is.

W2: Establishes the same exact micrometer location, except it's closer to the back of the crank.

Catch the drift .. ?

Okay. D1, and D2 has similarities to W1 and W2 except they are offset at about an 80-85* degree angle, away from the woodruff key slot. Here's a picture for a better illustration on

how to explain these kind of things. I'm pretty much measuring for taper here.

D1:

D2:

According to my chart, the numbers don't appear to be actually that far off even after the

beating that this vehicle has seen over the summer.

It really remains a mystery problem so far. The only tools within my possession that I have for actual measurements are these micrometers, and a dial bore gauge.

Anybody out there know of a reasonable method that experts use to check for the main bores being out of round ? I'm most likely thinking that this is the actual problem, but

I want to confirm before this B18c1 becomes a disposal. This way I have future reference

knowledge on my next upcoming K20 build that I'm looking to do next.

Trending Topics

#8

Honda-Tech Member

Join Date: Feb 2003

Location: Houston, TX

Posts: 1,171

Likes: 0

Received 0 Likes

on

0 Posts

By parting line, I mean where the two bearing shells meet, whether it be the main or rod bearings. For a bearing to function properly, the ID must be elliptical and not perfectly round or concentric. This is crucial to form the hydrodynamic wedge that keeps the bearings from making contact with the crankshaft journals.

If you had the correct instrumentation, you could see that the ID measured at the 6 and 12 o'clock position (parallel to the rod/main bolts) is smaller than the ID measured at or around the parting line where the two bearing shells meet. Aftermarket bearing manufacturers actually tailor this "eccentricity profile" to meet the needs of high performance engines.

If you had the correct instrumentation, you could see that the ID measured at the 6 and 12 o'clock position (parallel to the rod/main bolts) is smaller than the ID measured at or around the parting line where the two bearing shells meet. Aftermarket bearing manufacturers actually tailor this "eccentricity profile" to meet the needs of high performance engines.

#9

Honda-Tech Member

Thread Starter

This parting line that you speak of is an example that applied to my Y axis measurements, just in a different form of terminology that illustrated personal better understanding.

Now that you have caught my eye, presented me with the truth behind the actual meaning, I will consider obtaining your citation into account. It serves to be a lot more

professional let's say, lol.

Anyways, I was always told that the Y axis is supposed to have a bigger clearance than the X axis, but never given an actual in depth detail, acknowledging physics.

I do see what you mean by aftermarket bearing companies adjusting things here further in advance for a given high performance criteria.

However, from the parting lines, can't I have my current Dial Bore gauge display a wider measurement, and compare it to the 6-12 o'clock positions. Correct ?

Wouldn't this give me a slight idea if a line bore needs to be performed ?

Now that you have caught my eye, presented me with the truth behind the actual meaning, I will consider obtaining your citation into account. It serves to be a lot more

professional let's say, lol.

Anyways, I was always told that the Y axis is supposed to have a bigger clearance than the X axis, but never given an actual in depth detail, acknowledging physics.

I do see what you mean by aftermarket bearing companies adjusting things here further in advance for a given high performance criteria.

However, from the parting lines, can't I have my current Dial Bore gauge display a wider measurement, and compare it to the 6-12 o'clock positions. Correct ?

Wouldn't this give me a slight idea if a line bore needs to be performed ?

#10

DO IT ON ALL FOURS

So again, improper clearancing... why does everyone here default to plastigauge / the 6 and 12 o'clock positions? It is a circle there are MANY more measurements to take into account...

One of the easiest "half-assed" ways of doing things is to check for binding on each main individually. This isn't a tell all process, but should have picked up on this problem.

The proper way is a dial bore gauge and micrometer, easy enough. I find it interesting though that it lasted that long. What kind of bearings were you using?

What are you trying to sell the block for?

One of the easiest "half-assed" ways of doing things is to check for binding on each main individually. This isn't a tell all process, but should have picked up on this problem.

The proper way is a dial bore gauge and micrometer, easy enough. I find it interesting though that it lasted that long. What kind of bearings were you using?

What are you trying to sell the block for?

#11

Honda-Tech Member

Thread Starter

I don't understand how all this trouble can result into improper clearance.

Have you even checked my main bearing clearance ?

Don't take things overboard because I'm definitely not addressing your answers the wrong way, I'm just trying to prevent this from happening in the future. Because this is

some straight up bulls*!t man. You have no idea how bad it feels collecting parts annually, and then fail after 5-6 months of driving. It sucks man!

I wish it lasted at least for about a Year until things started going to hell.

When you say "half-assed" way of checking the mains individually for binding, are you referring to turning the crank while one main cap is tight, torqued to spec ?

Also binding usually comes from the bore being more close to round then football shaped, off entered, or sometimes both, correct ?

I used ACL Bearings. For both Main's and Rods.

Standard size. The 6-12 O' clock measurements were double checked over and over, for ultimate verification.

Even plasti gauge was taken into account, after Dial Bore gauge measuring was complete.

I did take a bit of 3-9 O' Clock measurements as well. They were only like [+0.0015 - +0.002"] wider than the primary

6-12 O' clock measurements.

Dude, just guide me in the right path man.

I noticed you're a lot more talented in these things than I am.

I'm really trying to learn from my mistakes here, inhibiting future failures especially on a

motor where the value will be a lot higher compared to a B series. I'm not made out of Benjamin Franklins, ya know.

If we can track this issue down, I'll definitely consider making a reasonable deal with you if you're interested in the block. I see you're in Indiana, so travel won't be that bad.

Have you even checked my main bearing clearance ?

Don't take things overboard because I'm definitely not addressing your answers the wrong way, I'm just trying to prevent this from happening in the future. Because this is

some straight up bulls*!t man. You have no idea how bad it feels collecting parts annually, and then fail after 5-6 months of driving. It sucks man!

I wish it lasted at least for about a Year until things started going to hell.

When you say "half-assed" way of checking the mains individually for binding, are you referring to turning the crank while one main cap is tight, torqued to spec ?

Also binding usually comes from the bore being more close to round then football shaped, off entered, or sometimes both, correct ?

I used ACL Bearings. For both Main's and Rods.

Standard size. The 6-12 O' clock measurements were double checked over and over, for ultimate verification.

Even plasti gauge was taken into account, after Dial Bore gauge measuring was complete.

I did take a bit of 3-9 O' Clock measurements as well. They were only like [+0.0015 - +0.002"] wider than the primary

6-12 O' clock measurements.

Dude, just guide me in the right path man.

I noticed you're a lot more talented in these things than I am.

I'm really trying to learn from my mistakes here, inhibiting future failures especially on a

motor where the value will be a lot higher compared to a B series. I'm not made out of Benjamin Franklins, ya know.

If we can track this issue down, I'll definitely consider making a reasonable deal with you if you're interested in the block. I see you're in Indiana, so travel won't be that bad.

Last edited by EF9_TryMe; 10-13-2012 at 11:55 AM.

#13

Honda-Tech Member

Thread Starter

No I did not. That's what I was trying to refer to.

Maybe I need to go back into doing this, to see how the measurements differ.

When applying this method for a single main journal ...

I should take two, 6-12 O' Clock measurements from front to back, and then two, 3-9 O' Clock measurements from front to back, correct ?

Maybe I need to go back into doing this, to see how the measurements differ.

When applying this method for a single main journal ...

I should take two, 6-12 O' Clock measurements from front to back, and then two, 3-9 O' Clock measurements from front to back, correct ?

Last edited by EF9_TryMe; 10-13-2012 at 03:01 PM.

#14

DO IT ON ALL FOURS

I have typed 4 responses now for each of them to be wiped out while getting links that YOU could easily search for. So, long story short. Read my response for EXACTLY for what it is. You guys are obsessed with only ONE measurement. It is a circle, there are many measurements. The bores should be round, the eccentric is built into the bearing. Your CLEARANCE at the parting line wasn't correct. This COULD HAVE been measured for. I am actually not being mean, just pissed at my phone!

http://www.substech.com/dokuwiki/dok...ngine_bearings

http://www.enginebuildermag.com/Arti...gs_go_bad.aspx

Oh, and I just wanted to point out that if your micrometer only goes down to reading 0.0005" I would throw them away and purchase ones that can read at least 0.0001" - you will be surprised how much the variance matters.

http://www.substech.com/dokuwiki/dok...ngine_bearings

http://www.enginebuildermag.com/Arti...gs_go_bad.aspx

Oh, and I just wanted to point out that if your micrometer only goes down to reading 0.0005" I would throw them away and purchase ones that can read at least 0.0001" - you will be surprised how much the variance matters.

#15

Honda-Tech Member

Thread Starter

^Most impressive.

Those two links made a lot of sense!

One last question.

Just for confirming things.

Crush:

Once the main bearing is in place with the tang side completely flat, consider the other side of the

bearing for proper measuring from the parting line to the top of it's end if it's sticking out.

What is a good tool that should be put to use for finding this final value ?

Eccentricity:

From the parting line, move up to a certain height specified in a service manual related for that particular motor.

In the meantime you are neighboring the end of Y Axis, stop at that certain location ?

Those two links made a lot of sense!

One last question.

Just for confirming things.

Crush:

Once the main bearing is in place with the tang side completely flat, consider the other side of the

bearing for proper measuring from the parting line to the top of it's end if it's sticking out.

What is a good tool that should be put to use for finding this final value ?

Eccentricity:

From the parting line, move up to a certain height specified in a service manual related for that particular motor.

In the meantime you are neighboring the end of Y Axis, stop at that certain location ?

Last edited by EF9_TryMe; 10-14-2012 at 08:56 PM.

#16

DO IT ON ALL FOURS

Crush - Whatever you like really. Something as simple as a machinist caliper or even a accurate dial indicator would work. The largest factor to this being sure that the bearings and block are cleaned extremely well (as everything should always be) before you take your measurments.

Eccentricity - Yes, basically you are concerned with the difference between the X and Y axis. Although in rare circumstances the bore could be egg shaped at a 45* angle if that makes sense.

Between the two, I would worry about the bore first before anything else. If this is off, it will in fact effect crush readings. The crush measurement is also built into the bearing so to speak, and will vary with different manufactures and types of bearings. Basicly quality versus the cheapest ones you can find.

Eccentricity - Yes, basically you are concerned with the difference between the X and Y axis. Although in rare circumstances the bore could be egg shaped at a 45* angle if that makes sense.

Between the two, I would worry about the bore first before anything else. If this is off, it will in fact effect crush readings. The crush measurement is also built into the bearing so to speak, and will vary with different manufactures and types of bearings. Basicly quality versus the cheapest ones you can find.

#17

Honda-Tech Member

Thread Starter

Cool.

While we're still on the same topic, Got anymore useful links or books that you recommend

reading ?

While we're still on the same topic, Got anymore useful links or books that you recommend

reading ?

#18

Honda-Tech Member

Join Date: Apr 2005

Location: ruckersville, va, usa

Posts: 1,220

Likes: 0

Received 0 Likes

on

0 Posts

Why didn’t you plastigauge going the opposite direction than below, laying it the other direction you could of seen a discrepancy in the plastigauge clearance across the whole face of the bearing vs only in one spot? I always lay the plastigauge across the whole surface area of the bearing face...

I also double checked my work with a plasti gauge.

The main journal that you see with the most wear, is the 3rd one. I will take a better picture today, addressing the journal proportion to each other, this way it'l be easier

to identify which one is which.

PS: The crank has NOT been balanced, and I've been boosting the living **** out of it. Can this serve a problem?

Don't ask me why, I just wanted to get this thing ready and done before the summer.

Before selling the setup here on H-T, I really want to validate a reasonable cause so the buyer knows the cranks/block current condition prior to machining.[/QUOTE]

I also double checked my work with a plasti gauge.

The main journal that you see with the most wear, is the 3rd one. I will take a better picture today, addressing the journal proportion to each other, this way it'l be easier

to identify which one is which.

PS: The crank has NOT been balanced, and I've been boosting the living **** out of it. Can this serve a problem?

Don't ask me why, I just wanted to get this thing ready and done before the summer.

Before selling the setup here on H-T, I really want to validate a reasonable cause so the buyer knows the cranks/block current condition prior to machining.[/QUOTE]

#19

DO IT ON ALL FOURS

I just smacked my self on the forehead. I can't believe I missed that in the pictures... that is absolutely the WRONG way to plastigauge...

#20

Honda-Tech Member

Thread Starter

Sleepencivic - you live and you learn.

Nevaevasatisfied - lol.

So as of right now, how the block sits...measuring JUST the bores WITHOUT the bearings installed won't symbolize anything related to how straight and proportional each bore is, correct ?

The eg-mun mentioned something about measuring them without the bearings ?

Just to confirm things once again...when you meant to say eg shaped at a 45* angle

for ie: you mean it starts off at the top left and ends down at the bottom right. Instead of

Starting and ending at the parting line, correct ?

Nevaevasatisfied - lol.

So as of right now, how the block sits...measuring JUST the bores WITHOUT the bearings installed won't symbolize anything related to how straight and proportional each bore is, correct ?

The eg-mun mentioned something about measuring them without the bearings ?

Just to confirm things once again...when you meant to say eg shaped at a 45* angle

for ie: you mean it starts off at the top left and ends down at the bottom right. Instead of

Starting and ending at the parting line, correct ?

#21

Honda-Tech Member

lay a straight edge aross the main and see if it rocks or u can put .001 shim under the straight edge.

#22

Honda-Tech Member

#23

DO IT ON ALL FOURS

Sleepencivic - you live and you learn.

Nevaevasatisfied - lol.

So as of right now, how the block sits...measuring JUST the bores WITHOUT the bearings installed won't symbolize anything related to how straight and proportional each bore is, correct ?

The eg-mun mentioned something about measuring them without the bearings ?

Just to confirm things once again...when you meant to say eg shaped at a 45* angle

for ie: you mean it starts off at the top left and ends down at the bottom right. Instead of

Starting and ending at the parting line, correct ?

Nevaevasatisfied - lol.

So as of right now, how the block sits...measuring JUST the bores WITHOUT the bearings installed won't symbolize anything related to how straight and proportional each bore is, correct ?

The eg-mun mentioned something about measuring them without the bearings ?

Just to confirm things once again...when you meant to say eg shaped at a 45* angle

for ie: you mean it starts off at the top left and ends down at the bottom right. Instead of

Starting and ending at the parting line, correct ?

X-axis = Parting Line

Y-axis = 90* away from parting line...

45* = The middle of the parting line and 90* away.

If a circle is 360* and you divide it in half that is 180*. Divide that in half and it is 90*. Divide that in half and it is 45*... See the trend?

Again, the ONLY way to measure the bores is to torque to spec, and use a dial bore gauge and micrometer. Obviously to measue the bore you absolutely can NOT have bearings in them. They are eccentric... see what's going on here? There are WAY too many write-ups and videos on the YouTube for me to honestly be repeating all of this. Even EvansTuning did segments on this...

#24

Honda-Tech Member

Join Date: Apr 2005

Location: ruckersville, va, usa

Posts: 1,220

Likes: 0

Received 0 Likes

on

0 Posts

Keep it simple before you go spending hours measuring do the plastigauge the proper way and post the pics of the variances....

#25

Honda-Tech Member

Join Date: Aug 2009

Location: Barbados, Caribbean

Posts: 158

Likes: 0

Received 0 Likes

on

0 Posts

Hey EF9 Try me, what sort of oil were you using? I've built about 15+ b series engines, and whilst that is not a big number, i have used similar methods to yours. Fortunately I've never had bearing failure, but I tend to use vr1 20-50 and advise the owners to use preferably 20-50 or10-40 in their boosted hondas. I am by no means an expert, but your method looks ok to me. It might have been something else.

1. What sort of oil were you using?

2. Did the motor have oil pump problems?

3. Was this a new or reused oil pump?

4.Any possibility of foreign debris into the engine?

Very sorry about your build.

1. What sort of oil were you using?

2. Did the motor have oil pump problems?

3. Was this a new or reused oil pump?

4.Any possibility of foreign debris into the engine?

Very sorry about your build.