Beginners blog: fabrication life progression

#101

Honda-Tech Member

Join Date: Apr 2012

Location: Hickory, NC

Posts: 626

Likes: 0

Received 0 Likes

on

0 Posts

good stuff man, makes me want to get a TIG and start learning.

But yes I know what you mean by the black boogers. It is a bit scary. sub'd!!!

But yes I know what you mean by the black boogers. It is a bit scary. sub'd!!!

#102

moderator emeritus

Thread Starter

been busy (thank you God!)

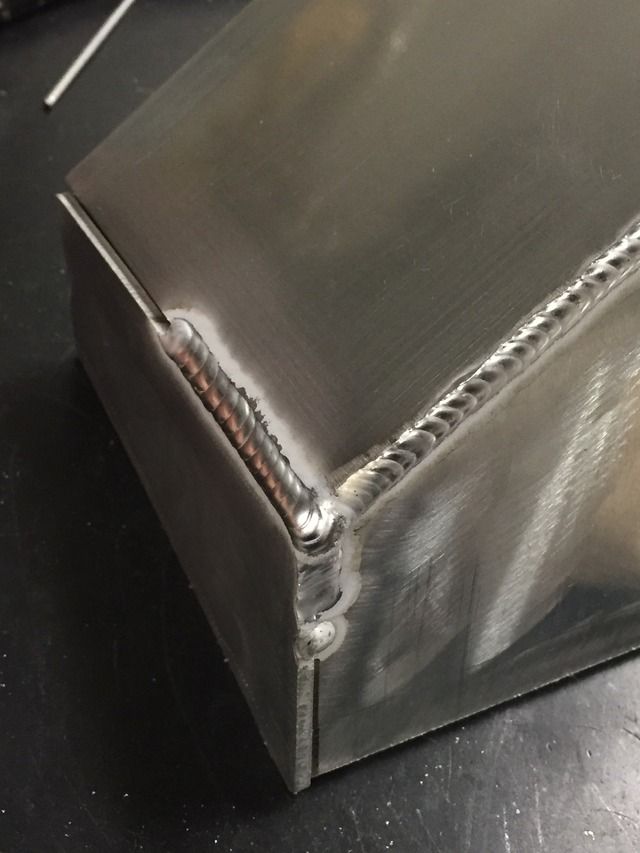

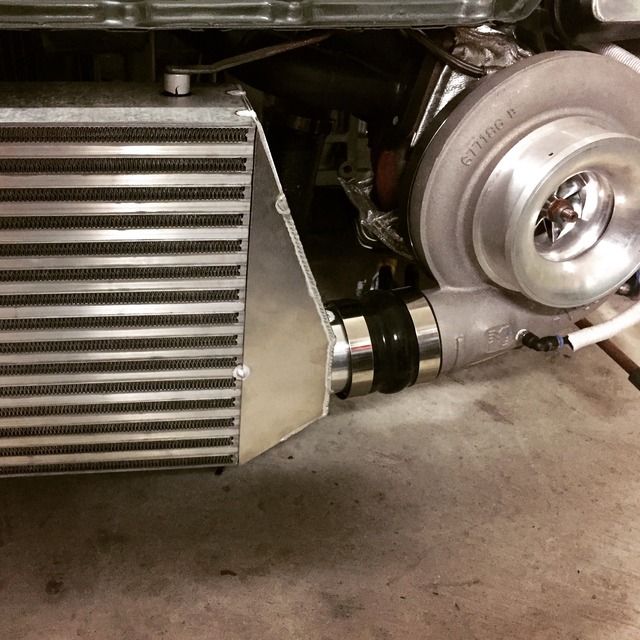

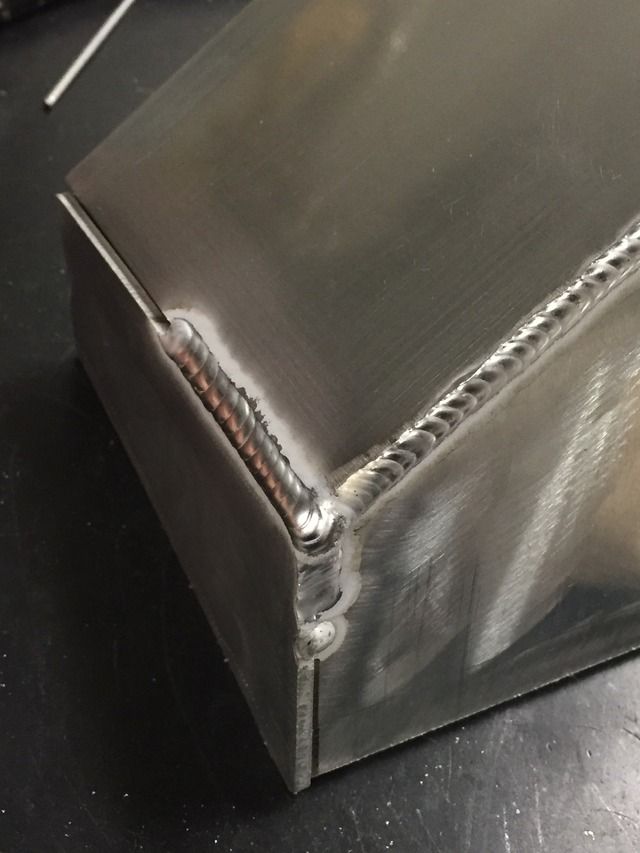

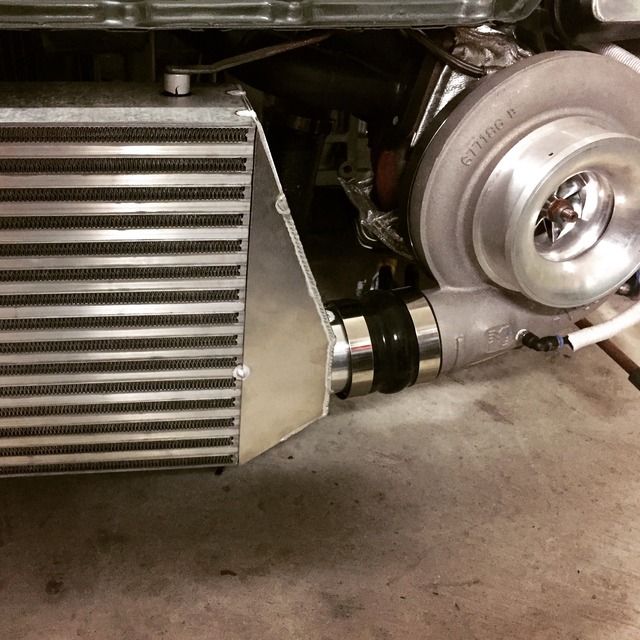

this is my first project as a "business". I am absolutely falling in love with doing aluminum work but this project has taught me to get the right tools to do the job. Using the bandsaw is fine for personal projects for the hobbyist but it simply takes too long and isnt quite as accurate as using a brake and shear. So with the money fromt his project, i will be purchasing a 3-in-1 brake/shear/roller but it will have to wait until hopefully we get the house we put an offer on.

This was my first time welding on a core and before i got this project i was very reluctant and anxious to start on it but after getting going, it was cake! It was a garrett core so it was pretty clean. I have been told the chinese cores are absolutely nasty and alot of care has to be taken.

With THAT be said, lol, we put an offer on a house with a 1200sqft shop with central AC on the back of the property with some fabrication equipment and a huge air compressor that is being left. I am praying everything goes smoothly (accepting prayers from anyone who prays!) as this would be a huge success in getting my "business" into a shop so i can actually call it a shop and not my garage lol. My garage is steadily getting packed with stuff and I am running out of room. Not having to pay for essentially a second mortgage to lease a building takes a lot of stress out of opening a shop so i can literally ease into doing it full-time once my day job consistently starts getting in the way of finishing projects in a timely manner.

and something I wanted to mention here for new guys or even up and running busy shops. I got setup with Kevin @ Home : My Shop Assist and I am doing a trial run with his software. About half way through this project, I realized I had no idea how much time I had into it and that plays a key role in knowing how much to quote for a job in the future to be accurate without scaring customers away and without selling myself short. Knowing approximately how much time a certain project should take is absolutely crucial as you can explain in fine detail why something is going to cost more or less than what the customer was expecting. It has a boat load of features which can effectively and efficiently help your shop run smoother, keep your clients informed as well as full job documentation along the way which is accessible by the customer. You can also keep in touch with outside jobs like your machinist given they run the same software. Anyway, just wanted to mention that as I am working hard at building my business properly with strong fundamentals IN THE BEGINNING! Being prepared is absolutely a requirement.

this is my first project as a "business". I am absolutely falling in love with doing aluminum work but this project has taught me to get the right tools to do the job. Using the bandsaw is fine for personal projects for the hobbyist but it simply takes too long and isnt quite as accurate as using a brake and shear. So with the money fromt his project, i will be purchasing a 3-in-1 brake/shear/roller but it will have to wait until hopefully we get the house we put an offer on.

This was my first time welding on a core and before i got this project i was very reluctant and anxious to start on it but after getting going, it was cake! It was a garrett core so it was pretty clean. I have been told the chinese cores are absolutely nasty and alot of care has to be taken.

With THAT be said, lol, we put an offer on a house with a 1200sqft shop with central AC on the back of the property with some fabrication equipment and a huge air compressor that is being left. I am praying everything goes smoothly (accepting prayers from anyone who prays!) as this would be a huge success in getting my "business" into a shop so i can actually call it a shop and not my garage lol. My garage is steadily getting packed with stuff and I am running out of room. Not having to pay for essentially a second mortgage to lease a building takes a lot of stress out of opening a shop so i can literally ease into doing it full-time once my day job consistently starts getting in the way of finishing projects in a timely manner.

and something I wanted to mention here for new guys or even up and running busy shops. I got setup with Kevin @ Home : My Shop Assist and I am doing a trial run with his software. About half way through this project, I realized I had no idea how much time I had into it and that plays a key role in knowing how much to quote for a job in the future to be accurate without scaring customers away and without selling myself short. Knowing approximately how much time a certain project should take is absolutely crucial as you can explain in fine detail why something is going to cost more or less than what the customer was expecting. It has a boat load of features which can effectively and efficiently help your shop run smoother, keep your clients informed as well as full job documentation along the way which is accessible by the customer. You can also keep in touch with outside jobs like your machinist given they run the same software. Anyway, just wanted to mention that as I am working hard at building my business properly with strong fundamentals IN THE BEGINNING! Being prepared is absolutely a requirement.

Last edited by 98vtec; 05-12-2015 at 06:58 AM.

#103

I'm really 2slow

Good stuff man!! Looks a whole lot better than how you started. All it takes is practice and more practice. Did you get those H-series head flanges from Columbia River as well? Are you looking at the harbor freight 3-1 machine? Good luck on that property. It is always nice to have something like that as work is just a few steps away and you only have 1 mortgage payment.

Last edited by 2fast4u831; 05-12-2015 at 11:08 AM.

#104

moderator emeritus

Thread Starter

Good stuff man!! Looks a whole lot better than how you started. All it takes is practice and more practice. Did you get those H-series head flanges from Columbia River as well? Are you looking at the harbor freight 3-1 machine? Good luck on that property. It is always nice to have something like that as work is just a few steps away and you only have 1 mortgage payment.

Thank you!

The head flanges came from PRL Motorsports. CRMB doesnt have a scan for a H22 exhaust gasket. next round of flanges, i am going to send them a gasket so they can scan it and make the flanges for me. I, however, liked the SPDexhaust flanges since they have options for primary tube diameter but we will see.

no, not Harbor freight. I was looking at Grizzly, Northern tool and JET. Although everywhere i read, it seems the guys that do it for a living dont ever see these machines living up to their ability. Also, lots of these sheet metal guys have advised spending the extra money and getting machines dedicated for a certain job instead of the combination machines. Their reasoning was strength and accuracy of a job.

We are riding on a lot of hope that everything goes our way. The house was not exactly what we were looking for but does have potential and has some nice features. the greatest part was that its on a private drive (no through traffic) surrounded by people who either do or used to race at the local circle tracks. Plus the fenced in 2 acres gives my dogs a whole lot of room. There is a machine shop at the beginning of the drive and there is a shop across from this property. I talked to the guy across the street and he gave me a bunch of information about their community which could be a shoe-in to getting involved in local race cars. Then there is a lake in walking distance which apparently is full of fish.

#105

-Intl Steve Krew

We are riding on a lot of hope that everything goes our way. The house was not exactly what we were looking for but does have potential and has some nice features. the greatest part was that its on a private drive (no through traffic) surrounded by people who either do or used to race at the local circle tracks. Plus the fenced in 2 acres gives my dogs a whole lot of room. There is a machine shop at the beginning of the drive and there is a shop across from this property. I talked to the guy across the street and he gave me a bunch of information about their community which could be a shoe-in to getting involved in local race cars. Then there is a lake in walking distance which apparently is full of fish.

#106

Very happy for you and your business!

I am glad to see you are getting work and that's a great looking project.

Also, very nice to see the (thank you God) above.

I am glad to see you are getting work and that's a great looking project.

Also, very nice to see the (thank you God) above.

#107

Honda-Tech Member

Join Date: Oct 2007

Location: dexter, mo., usa

Posts: 95

Likes: 0

Received 0 Likes

on

0 Posts

Looking good. Fyi, it takes a heck of a shear to do thicker aluminum. In the mean time get a skill saw with a carbide tip blade to cut it. Clamp a straight edge (square tubing or such)to the material for a guide. Very little prep work afterwards and cuts like butter.

#108

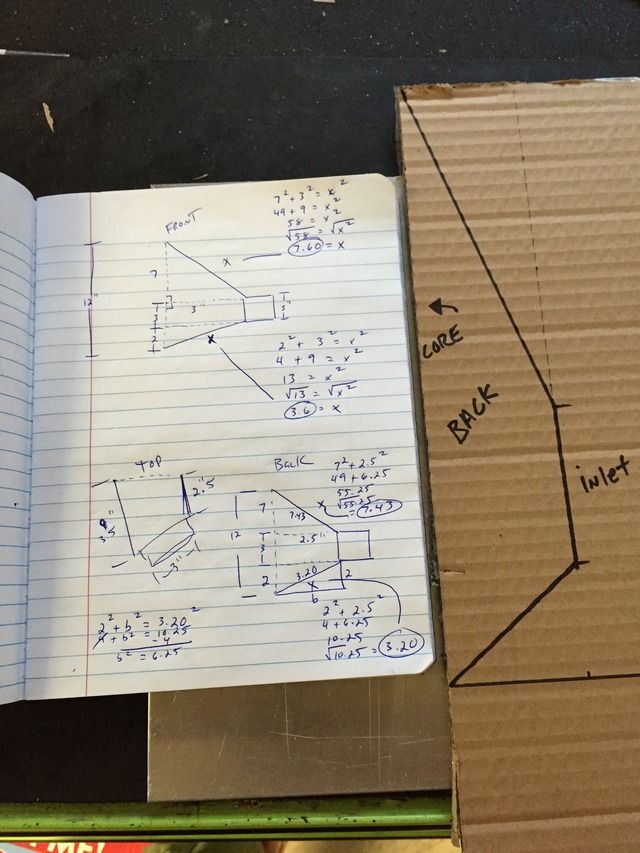

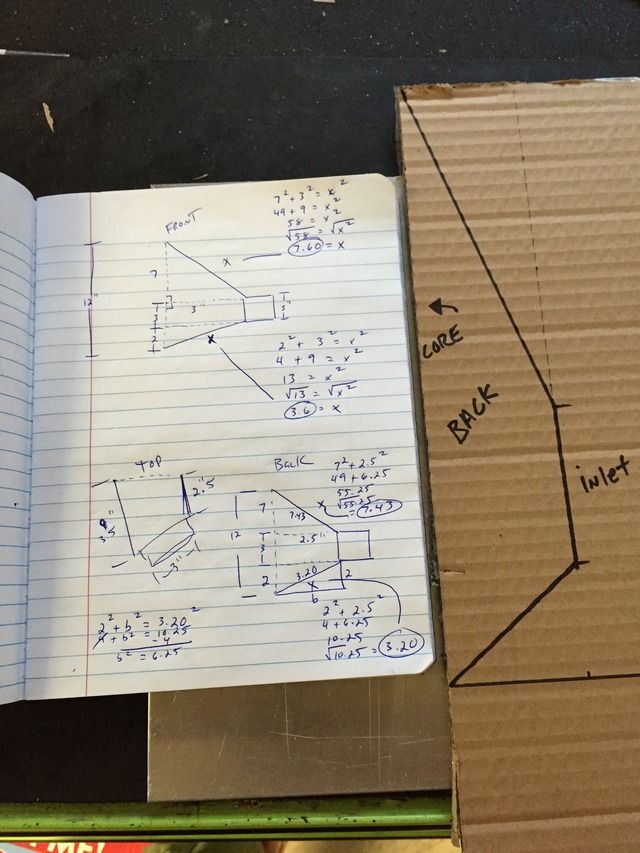

Can you explain all that math? i've never done math before on any of my projects. Well not that involved.

Which 3 in 1 will you get and how thick can it shear? i've been wanting one too. But want one that can do up to .100 aluminum

Which 3 in 1 will you get and how thick can it shear? i've been wanting one too. But want one that can do up to .100 aluminum

#109

I'm really 2slow

Thank you!

The head flanges came from PRL Motorsports. CRMB doesnt have a scan for a H22 exhaust gasket. next round of flanges, i am going to send them a gasket so they can scan it and make the flanges for me. I, however, liked the SPDexhaust flanges since they have options for primary tube diameter but we will see.

no, not Harbor freight. I was looking at Grizzly, Northern tool and JET. Although everywhere i read, it seems the guys that do it for a living dont ever see these machines living up to their ability. Also, lots of these sheet metal guys have advised spending the extra money and getting machines dedicated for a certain job instead of the combination machines. Their reasoning was strength and accuracy of a job.

We are riding on a lot of hope that everything goes our way. The house was not exactly what we were looking for but does have potential and has some nice features. the greatest part was that its on a private drive (no through traffic) surrounded by people who either do or used to race at the local circle tracks. Plus the fenced in 2 acres gives my dogs a whole lot of room. There is a machine shop at the beginning of the drive and there is a shop across from this property. I talked to the guy across the street and he gave me a bunch of information about their community which could be a shoe-in to getting involved in local race cars. Then there is a lake in walking distance which apparently is full of fish.

The head flanges came from PRL Motorsports. CRMB doesnt have a scan for a H22 exhaust gasket. next round of flanges, i am going to send them a gasket so they can scan it and make the flanges for me. I, however, liked the SPDexhaust flanges since they have options for primary tube diameter but we will see.

no, not Harbor freight. I was looking at Grizzly, Northern tool and JET. Although everywhere i read, it seems the guys that do it for a living dont ever see these machines living up to their ability. Also, lots of these sheet metal guys have advised spending the extra money and getting machines dedicated for a certain job instead of the combination machines. Their reasoning was strength and accuracy of a job.

We are riding on a lot of hope that everything goes our way. The house was not exactly what we were looking for but does have potential and has some nice features. the greatest part was that its on a private drive (no through traffic) surrounded by people who either do or used to race at the local circle tracks. Plus the fenced in 2 acres gives my dogs a whole lot of room. There is a machine shop at the beginning of the drive and there is a shop across from this property. I talked to the guy across the street and he gave me a bunch of information about their community which could be a shoe-in to getting involved in local race cars. Then there is a lake in walking distance which apparently is full of fish.

I wish you the best.

I wish you the best.

#110

moderator emeritus

Thread Starter

There are other ways to do it, but when you are just trying to come up with a design thats not to scale, this is easier than cutting and refining over and over until its right.

Grizzly.comŽ --

#112

moderator emeritus

Thread Starter

#116

Honda-Tech Member

Join Date: Aug 2001

Location: VA BEACH

Posts: 1,101

Likes: 0

Received 0 Likes

on

0 Posts

This thread is so inspiring mannn. I hope to be close to your skill provided the same amount of time. Keep it up!

#118

Looks like the makings of another great fabricator. Can I suggest something regarding the finish of the aluminum sheet on your boxes?

#119

moderator emeritus

Thread Starter

always!

and just as an update:

well it looks like I am going to be set back a little bit. I had my shop wiring inspected in prep for 220v and apparently the wiring (mostly the subpanel breaker) has been illegal for about 50 years and has to be removed and replaced. easier said that done affordably. I had two options. 1) run 200ft of 6ga wire from the house to a new 200amp panel or 2) give the shop its own meter and power supply from a neighboring transformer. We came to the conclusion that having its own power supply would be the best and most cost effective route for now and the future. After getting a quote to rewire the shop like I want, it is painfully obvious I will have to do a lot of the work myself. I had an estimate done a couple days ago and it was steep so I am getting a second opinion today. Hopefully this price works out better and I can find the time between everything to get it all done so I can get back to making some parts money.

#121

moderator emeritus

Thread Starter

both. it had a breaker with fuses that were screwed in with a lightbulb. he said they were outlawed because people would stick a penny in front of the fuse and put the fuse in place thus not allowing any control of the amperage and peoples structures caught fire.

I've ordered some new stuff though for my prelude build:

PRL Motorsports jig and purge fixture kit

CRMB 321 1.75" mandrel bends

CRMB 321 4-1 3" double slip collector

SPD 321 t4-3" tube form

SPD 1/2" head flange for 1.75" tube

SPD collector spring tabs

347 .035" filler

So I have made some moves but I have spent all I can spend on the car right now until I get the new shop powered and the welder buzzing again. We just moved into this new place and the shop that was there has been there since the 60's with the original wiring. its actually pretty nice and its concrete but the green house crap on the outside makes it look terrible but that will be getting fixed and it generally just needs a good cleaning. I had it fogged by my pest guy and sprayed so the bugs are a bit better under control but it needs a lot of work. it has a lot of potential though. There is an area without a door that would allow for one car and a lift eventually once I get the funds to raise the roof, then there is an area where I would be welding and I want all my cutting equipement setup outside so I don't have to sweep up all the time. then the garage door area can fit one car and I can use that for cars that do not need to be raised. Heres a couple pictures of what I am working with:

so my priority list is to get the shop re-powered and run the 220v outlets and then immediately add two 14" gable fans for some ventilation. it is really hot in there with all the doors shut. The windows are all Jalousie windows and need to be replaced with real windows and I would like to add a larger mobile AC unit but that's all kind of mute until I get power.

I've ordered some new stuff though for my prelude build:

PRL Motorsports jig and purge fixture kit

CRMB 321 1.75" mandrel bends

CRMB 321 4-1 3" double slip collector

SPD 321 t4-3" tube form

SPD 1/2" head flange for 1.75" tube

SPD collector spring tabs

347 .035" filler

So I have made some moves but I have spent all I can spend on the car right now until I get the new shop powered and the welder buzzing again. We just moved into this new place and the shop that was there has been there since the 60's with the original wiring. its actually pretty nice and its concrete but the green house crap on the outside makes it look terrible but that will be getting fixed and it generally just needs a good cleaning. I had it fogged by my pest guy and sprayed so the bugs are a bit better under control but it needs a lot of work. it has a lot of potential though. There is an area without a door that would allow for one car and a lift eventually once I get the funds to raise the roof, then there is an area where I would be welding and I want all my cutting equipement setup outside so I don't have to sweep up all the time. then the garage door area can fit one car and I can use that for cars that do not need to be raised. Heres a couple pictures of what I am working with:

so my priority list is to get the shop re-powered and run the 220v outlets and then immediately add two 14" gable fans for some ventilation. it is really hot in there with all the doors shut. The windows are all Jalousie windows and need to be replaced with real windows and I would like to add a larger mobile AC unit but that's all kind of mute until I get power.

#122

-Intl Steve Krew

Ahh gotcha. Yeah that is an OLD panel. I didn't know they were illegal, just thought they weren't up to code anymore.

#124

moderator emeritus

Thread Starter

#125

moderator emeritus

Thread Starter