bearings measuring what method you use?

#1

shops: which method do you use most to find correct bearing clearance for main/rod bearings?

do you just have used bearings that you use with plastigauge?

or do you use micrometer and dial bore gauge to measure the bore and and journal and then calculate the bearing thickness?

which one is more accurate from your experience?

I have digital micrometers btw. I know they are ebay but that's best I could afford. mitutoyo and other better quality ones is out of my budget.

do you just have used bearings that you use with plastigauge?

or do you use micrometer and dial bore gauge to measure the bore and and journal and then calculate the bearing thickness?

which one is more accurate from your experience?

I have digital micrometers btw. I know they are ebay but that's best I could afford. mitutoyo and other better quality ones is out of my budget.

Last edited by raverx3m; 11-30-2015 at 09:21 AM.

#2

Honda-Tech Member

Plastiguage is ONLY to be used as a double-check method.

The only way to properly measure bearing clearances is with inside and outside micrometers, preferably ones that read to the ten-thousandths.

The only way to properly measure bearing clearances is with inside and outside micrometers, preferably ones that read to the ten-thousandths.

#3

Honda-Tech Member

A set of dial bore gauge and outside mics.To be sure of the bearing thickness,i use a ball micrometer.

#4

Honda-Tech Member

I'm not a shop but this is how I do it...

Measure and record all crankshaft journal diameters at 3 points. Take several measurements to ensure accuracy.

Then set your Micrometer in your bore gauge and zero it out. This will now become your "standard".

Ten thousandths of an inch resolution is a must. That's .0001 inches.

Measure and record all crankshaft journal diameters at 3 points. Take several measurements to ensure accuracy.

Then set your Micrometer in your bore gauge and zero it out. This will now become your "standard".

Ten thousandths of an inch resolution is a must. That's .0001 inches.

#5

Honda-Tech Member

Then measure your rods with the bore gauge. Measure in 3 spots to ensure a perfectly round bore. Using some simple math, you now know the difference in size between the bore and the journal...

Factor in your desired bearing clearance, and now you know what thickness bearings you need.

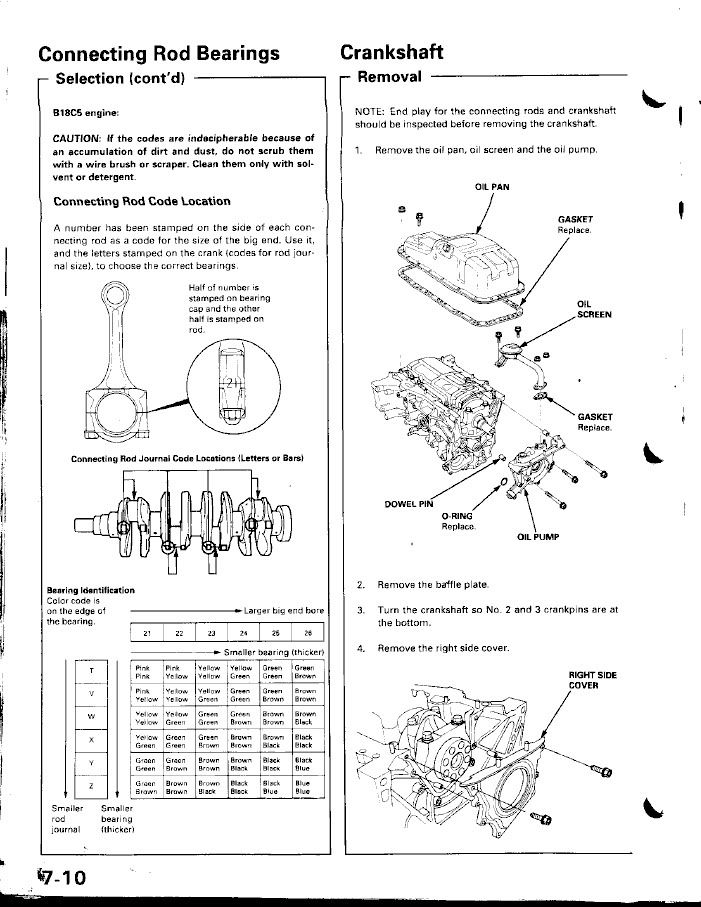

Earl (RIP) posted a factory bearing chart to determine which color bearings are which thickness...

Factor in your desired bearing clearance, and now you know what thickness bearings you need.

Earl (RIP) posted a factory bearing chart to determine which color bearings are which thickness...

#6

Honda-Tech Member

Measure your bearing thickness with a ball anvil micrometer. This should tell you exactly what your clearances will be. Take several measurements to verify accuracy. It's a very tedious process but it's necessary if you want to calculate your clearances perfectly.

Plastiguage should be used only to double check your measurements.

Hope all this makes sense.

Plastiguage should be used only to double check your measurements.

Hope all this makes sense.

#7

Honda-Tech Member

Summary...

Mic journals.

Set bore gauge to zero.

Measure bore housings.

Subtract desired bearing clearances.

Divide by 2 (2 bearing halves for each journal)

Select appropriate size bearing.

Verify bearing thickness.

Double check your measurements with plastigauge.

Rest easy knowing your clearances are set to where you want them to be ☺

Mic journals.

Set bore gauge to zero.

Measure bore housings.

Subtract desired bearing clearances.

Divide by 2 (2 bearing halves for each journal)

Select appropriate size bearing.

Verify bearing thickness.

Double check your measurements with plastigauge.

Rest easy knowing your clearances are set to where you want them to be ☺

Trending Topics

#8

do you still double check with plastigauge after you put new bearings in?

I asked few local shops and with one exception they said they do it anyway just to make sure.

I bought a digital caliper and dial bore gauge but dial bore gauge is too big and wont fit into the rod bore lol( didn't think about that when I bought it 2 years ago)

also has anyone ever measured the crank journal size in relation to the service manual letters/numbers? like they did with bearings

I have some inconsistencies with 2 of my type-r cranks what the letter says and what they measured.

I'm hoping its my mistake but I measured it like 10 times and every time it comes up same number/relationship depending on "room temperature"

I asked few local shops and with one exception they said they do it anyway just to make sure.

I bought a digital caliper and dial bore gauge but dial bore gauge is too big and wont fit into the rod bore lol( didn't think about that when I bought it 2 years ago)

also has anyone ever measured the crank journal size in relation to the service manual letters/numbers? like they did with bearings

I have some inconsistencies with 2 of my type-r cranks what the letter says and what they measured.

I'm hoping its my mistake but I measured it like 10 times and every time it comes up same number/relationship depending on "room temperature"

#9

crank1

main ---oem stamp--bearing color

1)54.975 #4 brown

2)54.974 #4 black

3)54.975 #4 blue

4)54.980 #3 green

5)54.979 #4 black

rod journals bearing color

1)44.981 *X br/blk

2)44.978 *Y blk/blk

3)44.980 *X br/blk

4)44.981 *X br/blk

crank2

main journals--- bearing color

1)54.983 #3 green

2)54.984 #2 green

3)54.984 #2 brown

4)54.980 #3 green

5)54.979 #3 brown

rod journals---color

1)44.981 *W brn/brn

2)44.983 *V grn/brn

3)44.982 *W brn/brn

4)44.983 *W brn/brn

block

1)B

2)C

3)D

4)B

5)C

ITR rods all marked #25

my problem is some numbers measured don't match the letters. cant tell if its my mistake or the crank is worn.

I see no major wear on the cranks.

one is perfectly clean I see no grooves its all smooth

other has the typical oil hole wear but I cant feel it with my fingernail.

I don't know the history of either crank so I cant say if either has been micropolished or worked on before I got it

is there a way to tell if crank was micropolished by looking at it compared to oem finish on journals?

should I be worried about 0.002mm inconsistencies between my measurement and what the letter stamp is?

main ---oem stamp--bearing color

1)54.975 #4 brown

2)54.974 #4 black

3)54.975 #4 blue

4)54.980 #3 green

5)54.979 #4 black

rod journals bearing color

1)44.981 *X br/blk

2)44.978 *Y blk/blk

3)44.980 *X br/blk

4)44.981 *X br/blk

crank2

main journals--- bearing color

1)54.983 #3 green

2)54.984 #2 green

3)54.984 #2 brown

4)54.980 #3 green

5)54.979 #3 brown

rod journals---color

1)44.981 *W brn/brn

2)44.983 *V grn/brn

3)44.982 *W brn/brn

4)44.983 *W brn/brn

block

1)B

2)C

3)D

4)B

5)C

ITR rods all marked #25

my problem is some numbers measured don't match the letters. cant tell if its my mistake or the crank is worn.

I see no major wear on the cranks.

one is perfectly clean I see no grooves its all smooth

other has the typical oil hole wear but I cant feel it with my fingernail.

I don't know the history of either crank so I cant say if either has been micropolished or worked on before I got it

is there a way to tell if crank was micropolished by looking at it compared to oem finish on journals?

should I be worried about 0.002mm inconsistencies between my measurement and what the letter stamp is?

#10

also I just realized another thing

crank#2 seems to fit much better in this block

should iuse that with aftermarket bearings?

I have 2 boxes of standard king bearings that people keep giving me with the block I purchase and I had no use for them yet.

if all the clearances are within specs would that be ok?

I looked and found mixed feelings about aftermarket bearings so I don't know if they are good or bad.

crank#2 seems to fit much better in this block

should iuse that with aftermarket bearings?

I have 2 boxes of standard king bearings that people keep giving me with the block I purchase and I had no use for them yet.

if all the clearances are within specs would that be ok?

I looked and found mixed feelings about aftermarket bearings so I don't know if they are good or bad.

#11

Honda-Tech Member

If your confident in your measurements, I could see an experienced machinist/builder skipping the plastigauge step, but personally I think it's a good idea. Just to be safe and to confirm your measurements. Plastigauge is cheap.

Depending on the bore guage you have, some have little extensions that you can use for the main bores and the rod. I have a mitutoyo I use for the mains and the rods, and another one I use to check the cylinders.

When I had cranks micropolished in the past, it just looks cleaner (polished and bright). I don't think you can visibly tell if it's ever been micropolished before.

Depending on the bore guage you have, some have little extensions that you can use for the main bores and the rod. I have a mitutoyo I use for the mains and the rods, and another one I use to check the cylinders.

When I had cranks micropolished in the past, it just looks cleaner (polished and bright). I don't think you can visibly tell if it's ever been micropolished before.

#12

Honda-Tech Member

I think .002 mm is so small I wouldn't worry about it.

Whatever bearings give you the clearance your after is what you should use. If Kings get you close enough, use them. If you want to fine tune your clearances even more, this is where oem bearings come handy.

Whatever bearings give you the clearance your after is what you should use. If Kings get you close enough, use them. If you want to fine tune your clearances even more, this is where oem bearings come handy.

#13

Just to give some perspective. .01mm measurements is considered about equal resolution as .0001" resolution.

If you notice in the helms manual their measurement specifications typically are .XXmm / .XXXX"

So .002mm should be more in range with 1/100,000th of an inch (.00001"). Way beyond most specs of cars. Now I think you are into aerospace domain.

If you notice in the helms manual their measurement specifications typically are .XXmm / .XXXX"

So .002mm should be more in range with 1/100,000th of an inch (.00001"). Way beyond most specs of cars. Now I think you are into aerospace domain.

#15

Honda-Tech Member

Just to give some perspective. .01mm measurements is considered about equal resolution as .0001" resolution.

If you notice in the helms manual their measurement specifications typically are .XXmm / .XXXX"

So .002mm should be more in range with 1/100,000th of an inch (.00001"). Way beyond most specs of cars. Now I think you are into aerospace domain.

If you notice in the helms manual their measurement specifications typically are .XXmm / .XXXX"

So .002mm should be more in range with 1/100,000th of an inch (.00001"). Way beyond most specs of cars. Now I think you are into aerospace domain.

#16

ok help me out here lol

I'm obviously not doing something right

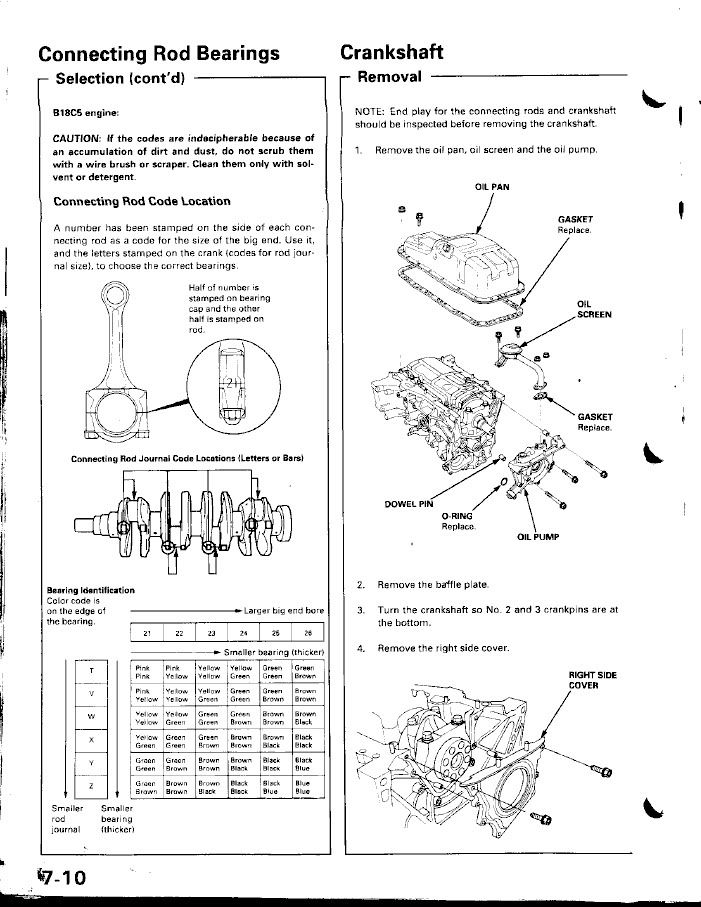

manual says this for itr rods

B18C5 engine:

Each rod falls into one of four tolerance ranges (from

+0.006 to + 0.024mm {+0.0002to + 0.0009in).

in 0.003mm (0.0001in l increments) depending on the size of its

big end bore. It's then stamped with a number (21, 22,

23,2 4,25o r 261i indicating the range.

You may find any combination of 21,2 2,2 3,2 4,2 5 or 26

in any engine.

Normal Bore Size: 48.0 mm {1.8!, in}

ok lets break down the sizes starting from 48.006mm? since that's what manual says

21 48.006

22 48.009

23 48.012

24 48.015

25 48.018

26 48.021

?? 48.024 ??

then I use my numbers I got from micrometer

and bearing thickness from the chart available here

plus required clearance from service manual

all my rods are stamped 25 which means they are somewhere in the range of 48.018 to 48.021mm bore according to the manual

adding up:

measured crank rod journal #2 44.978

black/black bearing total thickness range 3.014-3.008mm

total 47.992-47.986 range

adding required clearance of 0.038-0.050mm

48.030-48.036

so its adding up to more than the rod bore is supposed to be

meaning I'm off by .013-.020mm and if I work it backwards it whould be 44.964mm crank journal

I measured this for 3 days in a row recalibrated the micrometer every time just to make sure

got consistent numbers every time I measured it too

I'm obviously not doing something right

manual says this for itr rods

B18C5 engine:

Each rod falls into one of four tolerance ranges (from

+0.006 to + 0.024mm {+0.0002to + 0.0009in).

in 0.003mm (0.0001in l increments) depending on the size of its

big end bore. It's then stamped with a number (21, 22,

23,2 4,25o r 261i indicating the range.

You may find any combination of 21,2 2,2 3,2 4,2 5 or 26

in any engine.

Normal Bore Size: 48.0 mm {1.8!, in}

ok lets break down the sizes starting from 48.006mm? since that's what manual says

21 48.006

22 48.009

23 48.012

24 48.015

25 48.018

26 48.021

?? 48.024 ??

then I use my numbers I got from micrometer

and bearing thickness from the chart available here

plus required clearance from service manual

all my rods are stamped 25 which means they are somewhere in the range of 48.018 to 48.021mm bore according to the manual

adding up:

measured crank rod journal #2 44.978

black/black bearing total thickness range 3.014-3.008mm

total 47.992-47.986 range

adding required clearance of 0.038-0.050mm

48.030-48.036

so its adding up to more than the rod bore is supposed to be

meaning I'm off by .013-.020mm and if I work it backwards it whould be 44.964mm crank journal

I measured this for 3 days in a row recalibrated the micrometer every time just to make sure

got consistent numbers every time I measured it too

#17

What temperature is all the parts?

If I recall everything should be precisely 68° F when measuring if you want to have any hope of seeing factory specs.

It's part of the reason why I'm sort of on hold with my block. Workshop is too damn cold for spec measuring. Even with the little heater running in the room, the block is sitting just below 60° F.

If I recall everything should be precisely 68° F when measuring if you want to have any hope of seeing factory specs.

It's part of the reason why I'm sort of on hold with my block. Workshop is too damn cold for spec measuring. Even with the little heater running in the room, the block is sitting just below 60° F.

#18

My suggestion, get used starrett micrometers in good condition, and find a shop who will calibrate them for you. Good as new as long as threads all slip smooth.

All tools and parts should be same temperature. 65-75 deg f nominal. All parts and tools should be held at that temperature for a minimum of 12 hours before measuring.

All tools and parts should be same temperature. 65-75 deg f nominal. All parts and tools should be held at that temperature for a minimum of 12 hours before measuring.

#20

Temperature fluctuations in less than 12hr periods can throw you off. Large chunks of metal heat/cool slower than small ones. Hence you neeed to maintain temp for 12hrs before.

#23

Just use a properly calibrated mic and bore gauge, besides that its over kill. Also, could there be a possibility that the crank has some slight work before? Maybe work that you didn't know about that would have those measurements off?

Last edited by crazes; 12-03-2015 at 02:19 PM.

#24

I donno how. unless some aliens managed to add metal to the journals lol

I measured again and came up with same results when everything is at room temp

I have the 1 inch and 50mm calibration cylinders for the micrometers

and both of them measure dead on

im just trying to figure out how to use them I just bought the micrometers.

I set them up according to instructions etc. I used manual mics before.

its just strange that I have such a big error in the total

am I reading the service manual correctly?

for the rod big end diameter?

I measured again and came up with same results when everything is at room temp

I have the 1 inch and 50mm calibration cylinders for the micrometers

and both of them measure dead on

im just trying to figure out how to use them I just bought the micrometers.

I set them up according to instructions etc. I used manual mics before.

its just strange that I have such a big error in the total

am I reading the service manual correctly?

for the rod big end diameter?