Took a stab at the coke can thing ....

#51

Honda-Tech Member

There are two tricks to razor blades.

1) Tack at both ends this keeps the gap consistent through out the weld, This is very similar to a number of cwb / aws tests.

2) if you are just doing it for a party trick, with no filler, have them butted right together, tack both ends, then use a touch more heat and move fast but consistent one end to the other. It will take a couple of tries to figure out speed vs amperage, but after you do, you can pretty much do it every time.

After 5 years of certified welding, keep in mind I haven't welded as a job for 4 years now, I can still do most of the party tricks I learned along the way: Welding beer cans together either halved or end to end, razor blade, spray transfer vertical up, 7024 vertical up. ect...

At one point I was doing 7024 vertical up so often, that when it came time to renew my cwb structural cert (can't remember the numbers anymore) I did it both with 7018 and 7024 all position. I kept those tested welding strips for years hanging on my wall. (Yeah, I know I am a super geek)

To make a longish post short, mostly they all just take practice, and they all have there tricks to make it easier.

1) Tack at both ends this keeps the gap consistent through out the weld, This is very similar to a number of cwb / aws tests.

2) if you are just doing it for a party trick, with no filler, have them butted right together, tack both ends, then use a touch more heat and move fast but consistent one end to the other. It will take a couple of tries to figure out speed vs amperage, but after you do, you can pretty much do it every time.

After 5 years of certified welding, keep in mind I haven't welded as a job for 4 years now, I can still do most of the party tricks I learned along the way: Welding beer cans together either halved or end to end, razor blade, spray transfer vertical up, 7024 vertical up. ect...

At one point I was doing 7024 vertical up so often, that when it came time to renew my cwb structural cert (can't remember the numbers anymore) I did it both with 7018 and 7024 all position. I kept those tested welding strips for years hanging on my wall. (Yeah, I know I am a super geek)

To make a longish post short, mostly they all just take practice, and they all have there tricks to make it easier.

I had to have mine legally destroyed by my inspector

I'm going to take a stab at the razor blade thing tomorrow

It was -38*C a few nights ago where I live...

#53

Junior Member

Join Date: May 2007

Location: Okotoks, AB

Posts: 40

Likes: 0

Received 0 Likes

on

0 Posts

#54

Junior Member

Join Date: Oct 2007

Location: Houston, TX, USA

Posts: 17

Likes: 0

Received 0 Likes

on

0 Posts

Anyone else going to try the center of the can so I can see how I did?

#57

Honda-Tech Member

Join Date: Mar 2007

Location: lower burrell, pa, usa

Posts: 306

Likes: 0

Received 0 Likes

on

0 Posts

cool.. For some reason I had problems with my high frequency start going haywire at that low of amperage. I had to start on the table, wait for it to balance it out, then jump onto the piece. I really should have taken the time to take out the 1/8 tungsten and replace it with something smaller lol but i didn't give a ****

#58

cool.. For some reason I had problems with my high frequency start going haywire at that low of amperage. I had to start on the table, wait for it to balance it out, then jump onto the piece. I really should have taken the time to take out the 1/8 tungsten and replace it with something smaller lol but i didn't give a ****

#59

Honda-Tech Member

Join Date: Oct 2002

Location: Houston, Texas, U.S.A.

Posts: 65

Likes: 0

Received 0 Likes

on

0 Posts

When I was welding the can in the center, I had a decent line going then I would blow a hole in it. Man i was yelling and screaming, made me pissed at my girlfriend cause she made me quit smoking, it would have been a perfect time for a cig....

Anyone else going to try the center of the can so I can see how I did?

Anyone else going to try the center of the can so I can see how I did?

#61

Honda-Tech Member

Join Date: Mar 2007

Location: lower burrell, pa, usa

Posts: 306

Likes: 0

Received 0 Likes

on

0 Posts

looks great for 18 days.. I think you're lying  and you obviously have a better camera than me.. along with fancy paper to lay parts on.. What filler did you use? I used .035 wire out of a mig, and I actually heated the wire right next to the blades so it dropped onto them once it formed a puddle. That seemed to help keep the part from melting away

and you obviously have a better camera than me.. along with fancy paper to lay parts on.. What filler did you use? I used .035 wire out of a mig, and I actually heated the wire right next to the blades so it dropped onto them once it formed a puddle. That seemed to help keep the part from melting away

and you obviously have a better camera than me.. along with fancy paper to lay parts on.. What filler did you use? I used .035 wire out of a mig, and I actually heated the wire right next to the blades so it dropped onto them once it formed a puddle. That seemed to help keep the part from melting away

and you obviously have a better camera than me.. along with fancy paper to lay parts on.. What filler did you use? I used .035 wire out of a mig, and I actually heated the wire right next to the blades so it dropped onto them once it formed a puddle. That seemed to help keep the part from melting away

Last edited by punkinbeck; 01-27-2009 at 05:45 PM. Reason: spelling

#62

looks great for 18 days.. I think you're lying  and you obviously have a better camera than me.. along with fancy paper to lay parts on.. What filler did you use? I used .035 wire out of a mig, and I actually heated the wire right next to the blades so it dropped onto them once it formed a puddle. That seemed to help keep the part from melting away

and you obviously have a better camera than me.. along with fancy paper to lay parts on.. What filler did you use? I used .035 wire out of a mig, and I actually heated the wire right next to the blades so it dropped onto them once it formed a puddle. That seemed to help keep the part from melting away

and you obviously have a better camera than me.. along with fancy paper to lay parts on.. What filler did you use? I used .035 wire out of a mig, and I actually heated the wire right next to the blades so it dropped onto them once it formed a puddle. That seemed to help keep the part from melting away

and you obviously have a better camera than me.. along with fancy paper to lay parts on.. What filler did you use? I used .035 wire out of a mig, and I actually heated the wire right next to the blades so it dropped onto them once it formed a puddle. That seemed to help keep the part from melting away

#63

Honda-Tech Member

Join Date: Jan 2005

Location: b00sting my D16s, SoWis, USA

Posts: 7,015

Likes: 0

Received 7 Likes

on

5 Posts

I envy you ppl with your HF start tig's. I'm having tough enough time with my cheap POS H-F toaster with scratch start. Not bad for 1/10 the price tho... I feel like a crippled genious who can't afford a wheel chair, lol.

#65

Honda-Tech Member

Join Date: Jun 2006

Location: Abbotsford, BC

Posts: 978

Likes: 0

Received 0 Likes

on

0 Posts

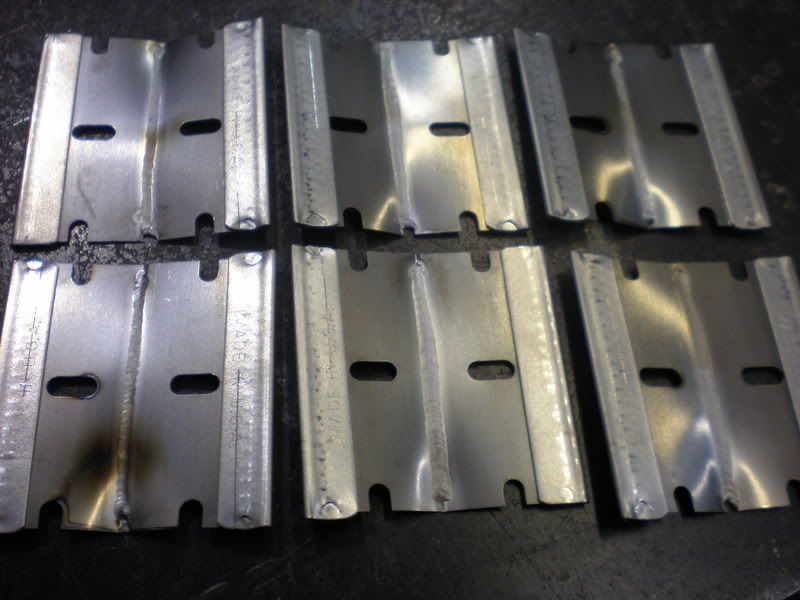

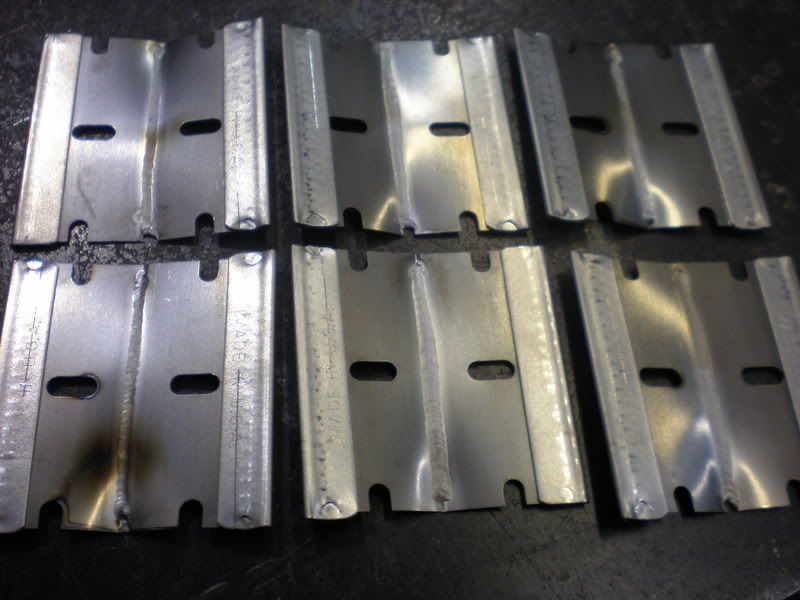

Pics from the days efforts. Done on my dynasty 300dx, its an older one, only goes down to 5 amps.

Coke cans, no pulsing, positioner etc.:

That was the best of 5 sets, I tried halving the can on one try, it was thin, about .004", didn't have any luck, I needed to go below 5 amps and my machine can't. Will have to see if the 200dx goes lower... I need to practice my Al welding, seem to only weld it every couple of months.

Razor blades, these were easy:

Parts from some production pieces I had to run:

Coke cans, no pulsing, positioner etc.:

That was the best of 5 sets, I tried halving the can on one try, it was thin, about .004", didn't have any luck, I needed to go below 5 amps and my machine can't. Will have to see if the 200dx goes lower... I need to practice my Al welding, seem to only weld it every couple of months.

Razor blades, these were easy:

Parts from some production pieces I had to run:

Last edited by dave@passenger; 02-22-2009 at 06:11 PM. Reason: Atrocious spelling.

#66

Honda-Tech Member

Join Date: Feb 2006

Location: Long Island, NY, USA

Posts: 1,514

Likes: 0

Received 0 Likes

on

0 Posts

wow good job! i tryed doing the razor blades i found liying around lol i got about half way and then i started blowing trhough it so i just jammed on the pedal and completly destroyed the razor blades out of frustration!!! ahaha

but i can seem to get the puddle starting on the al cans, it jsut starts the burn and then eventually it blows a hole in them

i just got my Miller Diversion and im still learning the machine... It welds great for small projects at home it goes down to 10 amps.

what are you guys setting your machines at for the Coke Cans? what size and type of tungsten are you guys using?

Keep em' coming guys

but i can seem to get the puddle starting on the al cans, it jsut starts the burn and then eventually it blows a hole in them

i just got my Miller Diversion and im still learning the machine... It welds great for small projects at home it goes down to 10 amps.

what are you guys setting your machines at for the Coke Cans? what size and type of tungsten are you guys using?

Keep em' coming guys

#68

Honda-Tech Member

Join Date: Mar 2007

Location: dayton, oh, usa

Posts: 433

Likes: 0

Received 0 Likes

on

0 Posts

are you guys serious about welding the cans with the beer/pop still in them? ive been thinking about trying it and kinda think the liquid might help with not blowing a hole through it but then again when the liquid gets hot its gonna build more pressure than its already under and then it would want to blow OUT of the weld spot. id really hate to clean pop out of my torch and wasting beer is just a no no.

#69

Honda-Tech Member

Join Date: Jun 2006

Location: Abbotsford, BC

Posts: 978

Likes: 0

Received 0 Likes

on

0 Posts

are you guys serious about welding the cans with the beer/pop still in them? ive been thinking about trying it and kinda think the liquid might help with not blowing a hole through it but then again when the liquid gets hot its gonna build more pressure than its already under and then it would want to blow OUT of the weld spot. id really hate to clean pop out of my torch and wasting beer is just a no no.

#71

Honda-Tech Member

Join Date: Sep 2006

Location: Mid-Michigan, USA

Posts: 1,235

Likes: 0

Received 0 Likes

on

0 Posts

When I tried re-joining the two halves of a Coke can I cut in half with my Oxy/Acetylene torch (with a tip that is WAY too big for .004" material) the plastic surface caught on fire and burnt up the can. It was comical. I may get a Meco Midget torch one of these days and try it again with the outer surface of the can wire brushed off. .004" is a tough one though. . .

Dave, those welds on that DP or whatever it is are INSANE! ! ! There are definitely some hot welders on this board!

Dave, those welds on that DP or whatever it is are INSANE! ! ! There are definitely some hot welders on this board!

#72

Honda-Tech Member

Join Date: Feb 2007

Location: trail, bc, canada

Posts: 188

Likes: 0

Received 0 Likes

on

0 Posts

Well, got bored at work, and found a few old Olfa "art knife" (scalpel) blades, and went to town.... Started out with just welding 2 together, and it just snowballed from there!! I ended up with what I'm calling "OLFA SURFER" made out of 6 blades.

Read 'em and weep, bitches!!

Put a penny in a couple of shots so you can get a grasp of the scale.

ENJOY!!

Read 'em and weep, bitches!!

Put a penny in a couple of shots so you can get a grasp of the scale.

ENJOY!!