Post your best welds!!!!!!!

#2952

Canuckian

Join Date: Nov 2009

Location: Ontario, Canada

Posts: 261

Likes: 0

Received 0 Likes

on

0 Posts

I do welds like these all day err'day with an orbital welder. My partner is almost at the point where his look nearly identical to what the machine does.

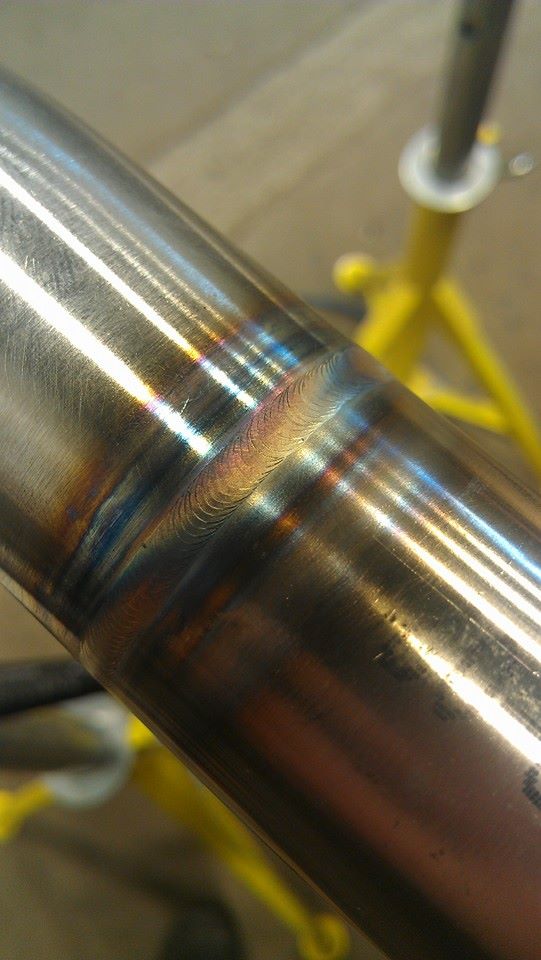

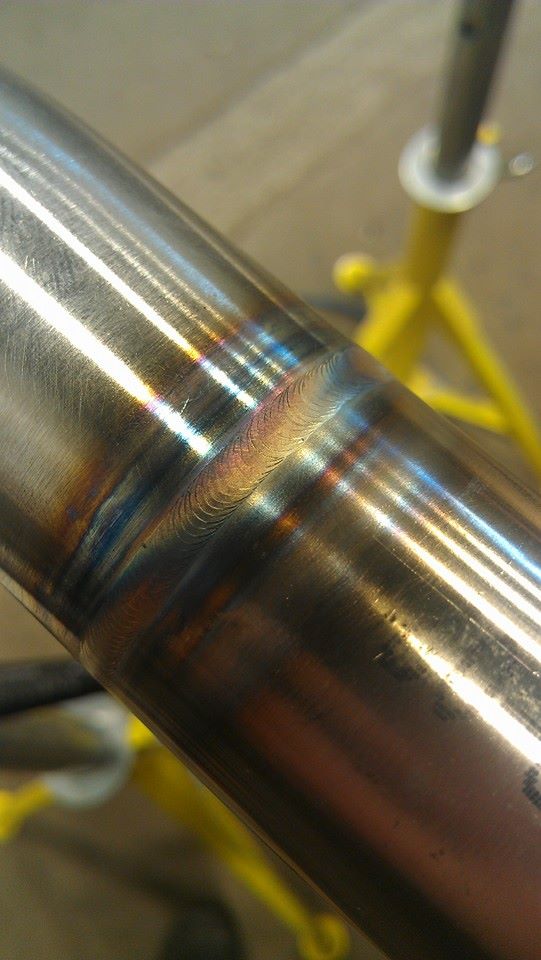

Second time picking up a tig torch and trying my hand at walking the cup. Trying to emulate buddys technique, he makes it seem so easy. Pardon the dirtiness.

Second time picking up a tig torch and trying my hand at walking the cup. Trying to emulate buddys technique, he makes it seem so easy. Pardon the dirtiness.

#2953

Honda-Tech Member

Join Date: Oct 2010

Location: Estonia

Posts: 12

Likes: 0

Received 0 Likes

on

0 Posts

60 amps. 1/16 308l wire 3/32 2% lanthanated electrode and #14 toxiccup

#2954

Honda-Tech Member

I do welds like these all day err'day with an orbital welder. My partner is almost at the point where his look nearly identical to what the machine does.

Attachment 388082

Second time picking up a tig torch and trying my hand at walking the cup. Trying to emulate buddys technique, he makes it seem so easy. Pardon the dirtiness.

Attachment 388083

Attachment 388082

Second time picking up a tig torch and trying my hand at walking the cup. Trying to emulate buddys technique, he makes it seem so easy. Pardon the dirtiness.

Attachment 388083

#2956

Canuckian

Join Date: Nov 2009

Location: Ontario, Canada

Posts: 261

Likes: 0

Received 0 Likes

on

0 Posts

Don't know why they didn't work.... Looks fine on my comp, on my phone it went all screwy. Anyways.. once again, first pic is done by with orbital welder, second one is a fusion weld on my second attempt ever using a tig torch after watching buddy.

Both done with 2"dia .065"wall sanitary 316L tubing

Both done with 2"dia .065"wall sanitary 316L tubing

#2958

Honda-Tech Member

#2959

Honda-Tech Member

Join Date: Feb 2008

Location: Orlando, FL

Posts: 123

Likes: 0

Received 0 Likes

on

0 Posts

Interesting about that black haze, a buddy of mine recently experienced that except much more pronounced. Not in the weld area, but just outside of it. Im starting to think a wire wheel is the way to for for schedule piping. It takes so much work with scotch brite, and ive seen some great finishes from a wire wheel on sch. Austin @ stm uses wire wheel and gets some really nice finishes out of it. Instagram

For thin wall stainless/ aluminum etc, i would still do scotch tho, since the pieces dont come to you as porous as the elbows do.

Here's a random out of practice tube weld.

For thin wall stainless/ aluminum etc, i would still do scotch tho, since the pieces dont come to you as porous as the elbows do.

Here's a random out of practice tube weld.

#2960

I do welds like these all day err'day with an orbital welder. My partner is almost at the point where his look nearly identical to what the machine does.

Attachment 388082

Second time picking up a tig torch and trying my hand at walking the cup. Trying to emulate buddys technique, he makes it seem so easy. Pardon the dirtiness.

Attachment 388083

Attachment 388082

Second time picking up a tig torch and trying my hand at walking the cup. Trying to emulate buddys technique, he makes it seem so easy. Pardon the dirtiness.

Attachment 388083

These are my orbital welds. Around one inch wide 7/8th deep. All hot wire tig (orbital) takes me 4 passes to weld all the out. Total weld time is about 16 hours straight.

#2961

These are just some random pics I have on my computer. most are from work. Thanks a lot guys. There are a lot of very impressive welds on this thread. Very nice to see the work of a skilled craftsman. keep up the good work. I will try to throw some pics up from the stuff I do at home.

#2962

These are just some random pics I have on my computer. most are from work. Thanks a lot guys. There are a lot of very impressive welds on this thread. Very nice to see the work of a skilled craftsman. keep up the good work. I will try to throw some pics up from the stuff I do at home.

#2963

Yeah its nuclear. I store the old fuel rods. Its a mock up of one of our units. Lids are 15 inches of stainless.

#2964

-Intl Steve Krew

#2965

I was close! I did 11 years in the navy working on nuclear subs and now I work at General Dynamics Electric Boat building them. Unfortunately, my trade is not welding. I'm in radcon.

#2966

I am a jack of all trades. I work for a lot of different companies so they keep me on my toes. I hold a bunch of TIG certs ranging from fusion welding to 6g to unlimited thickness. I have a bunch of Mig/flux core certs (stainless, hastalloy, Inconel etc......) I do a lot of SMAW (stick welding) pipe welding mostly. I also have some cool ones like my hot wore automatic TIG, SUB ARC (which I freakin hate) and laser beam welding.

#2967

lol yeah good call. I have worked with a lot of ex navy nuke guys. They work with us when we need under water construction done. They are the nuclear pool divers. They are also with me if I cant get my root pass in on time. They help get the canister back in the water as I hang my head in shame.

#2968

-Intl Steve Krew

I am a jack of all trades. I work for a lot of different companies so they keep me on my toes. I hold a bunch of TIG certs ranging from fusion welding to 6g to unlimited thickness. I have a bunch of Mig/flux core certs (stainless, hastalloy, Inconel etc......) I do a lot of SMAW (stick welding) pipe welding mostly. I also have some cool ones like my hot wore automatic TIG, SUB ARC (which I freakin hate) and laser beam welding.

#2969

I have been welding for the past seven years now. I am a contractor and I work for about 7 or 8 different companies a year. I worked full time in a shop for awhile along with working as a contractor at night. I currently am taking it easy and I am back in school pursuing my welding engineering degree.

#2973

B*a*n*n*e*d

iTrader: (15)

Join Date: Jul 2008

Location: montebello, ca, us

Posts: 6,632

Likes: 0

Received 15 Likes

on

10 Posts

Can i get some tips on welding 16 gauge stainless? The thick stuff i can weld no problem. This thin wall is a bitch.

I also have no foot pedal.

The pipe is only 2" . I can get good color on one 1" pass then i think the whole pipe heat soaks pretty fast and the next pass shows too much heat. Do i need to let it cool down for a few minutes?

I also have no foot pedal.

The pipe is only 2" . I can get good color on one 1" pass then i think the whole pipe heat soaks pretty fast and the next pass shows too much heat. Do i need to let it cool down for a few minutes?

#2974

moderator emeritus

Can i get some tips on welding 16 gauge stainless? The thick stuff i can weld no problem. This thin wall is a bitch.

I also have no foot pedal.

The pipe is only 2" . I can get good color on one 1" pass then i think the whole pipe heat soaks pretty fast and the next pass shows too much heat. Do i need to let it cool down for a few minutes?

I also have no foot pedal.

The pipe is only 2" . I can get good color on one 1" pass then i think the whole pipe heat soaks pretty fast and the next pass shows too much heat. Do i need to let it cool down for a few minutes?

Not being able to vary your amperage does not help

#2975

Can i get some tips on welding 16 gauge stainless? The thick stuff i can weld no problem. This thin wall is a bitch.

I also have no foot pedal.

The pipe is only 2" . I can get good color on one 1" pass then i think the whole pipe heat soaks pretty fast and the next pass shows too much heat. Do i need to let it cool down for a few minutes?

I also have no foot pedal.

The pipe is only 2" . I can get good color on one 1" pass then i think the whole pipe heat soaks pretty fast and the next pass shows too much heat. Do i need to let it cool down for a few minutes?