fuse welding

#2

Honda-Tech Member

Join Date: May 2010

Location: akron, ohio

Posts: 56

Likes: 0

Received 0 Likes

on

0 Posts

It's when there is no filler rod used, just the two pieces of tubing or whatever. There is nothing that I know that needs this as it is more decorative and not as strong as with filler rod.

Some guys just like to do this because it looks cool.

Some guys just like to do this because it looks cool.

#4

Honda-Tech Member

Join Date: Sep 2004

Location: Lynnwood, WA, US

Posts: 444

Likes: 0

Received 0 Likes

on

0 Posts

My understanding is on thinner stuff you end up putting too much heat into the material to get the filler to melt, so fusing it is actually better on some stuff.

#6

Honda-Tech Member

Thread Starter

Join Date: Oct 2007

Posts: 661

Likes: 0

Received 0 Likes

on

0 Posts

so how is this done normally you are moving the torch and than dabing the filler rod with out filler rod are you just running the torch up and down the peice your trying to weld.

Trending Topics

#8

Honda-Tech Member

Join Date: Jan 2005

Location: Lower Right Hand Corner, PA

Posts: 5,643

Likes: 0

Received 0 Likes

on

0 Posts

From what I gather this is really only practice on stainless tubing, and the idea is to not get full penetration because it will sugar on the other side if it does. This way you don't have to purge the inside. The fit has to be perfect for this to work.

Doesn't work on aluminum very well.

Doesn't work on aluminum very well.

#9

OG Fabricator

Join Date: Dec 2006

Location: Calgary, Alberta, Canada

Posts: 1,342

Likes: 0

Received 0 Likes

on

0 Posts

Come on guys, geez...

It's an incorrect term to begin with. Autogenous denotes a lack of filler in a weld joint.

I hope all welds have fusion!!

It can be very strong, often as strong as the parent metal. The fit-up must be perfect, and the metal must be suited to welds that do not have a bunch of reinforcement, or convexity.

Mild steel, austenitic stainless, and titanium all do fine with quality fit-up and autogenous welds. Inconel, nickel alloys, aluminum, and magnesium are examples of materials not suited for autogenous welds due to the way the molten metal shrinks upon cooling. These metals prefer convex beads to help alleviate conditions such as crater cracking,etc. Filler is generally needed to satisfy this.

On good fit-up, of let's say 304L stainless tubing, an autogenous weld can be full thickness due to the shrinkage that occurs during the process. You can be flush inside and out without filler.

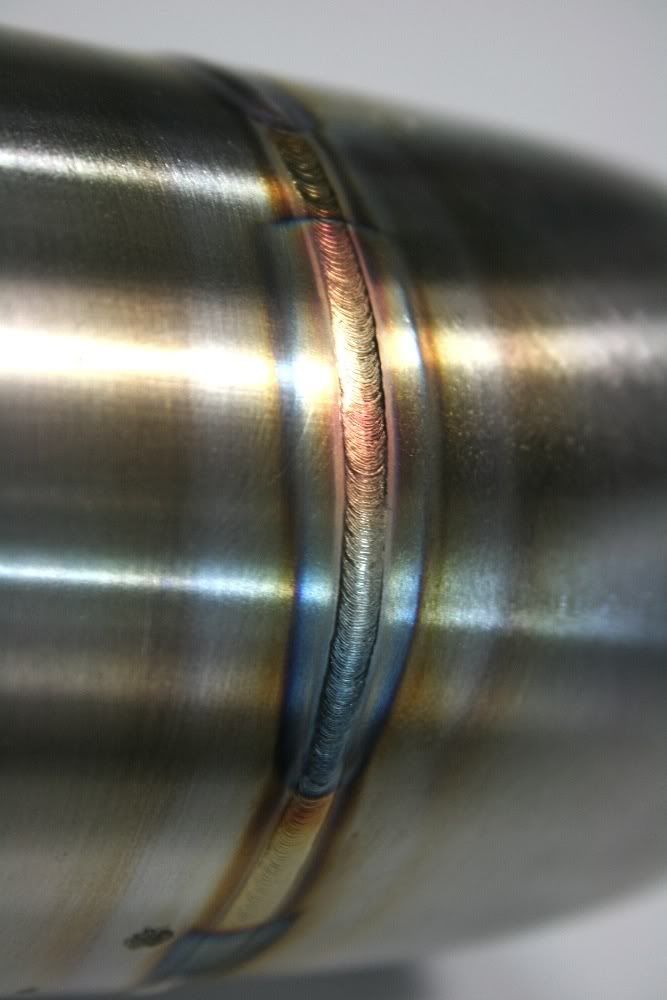

This is an example of a quality autogenous weld..

Inside..

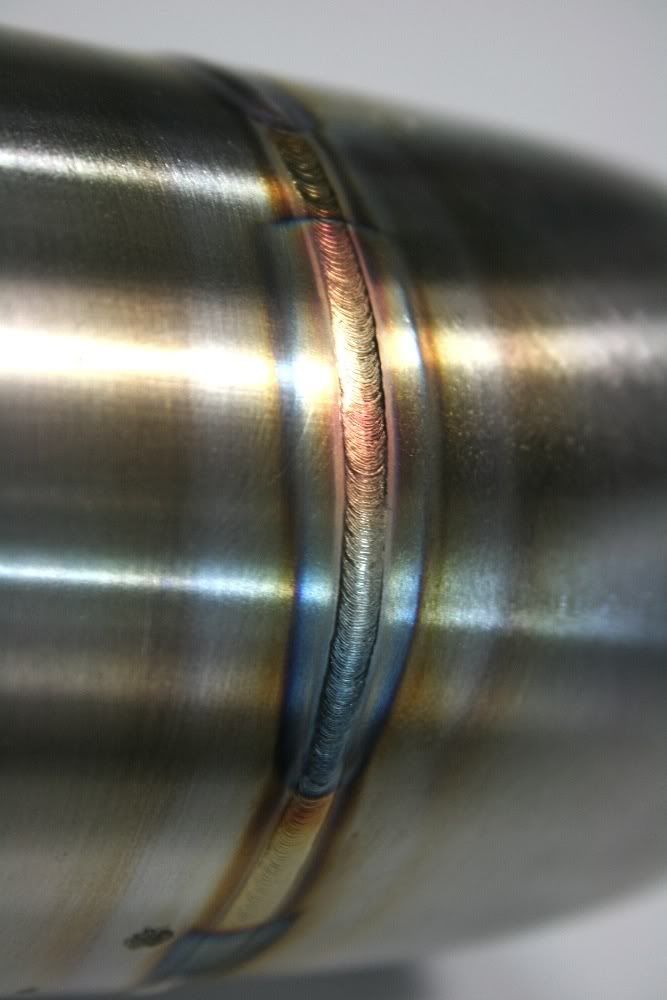

Now a weld with filler...

Inside...

So, more reinforcement on both sides of the material, but is it needed for exhaust?

How much stronger is it?

Both work just fine when done right on the right material and job.

It's an incorrect term to begin with. Autogenous denotes a lack of filler in a weld joint.

I hope all welds have fusion!!

It can be very strong, often as strong as the parent metal. The fit-up must be perfect, and the metal must be suited to welds that do not have a bunch of reinforcement, or convexity.

Mild steel, austenitic stainless, and titanium all do fine with quality fit-up and autogenous welds. Inconel, nickel alloys, aluminum, and magnesium are examples of materials not suited for autogenous welds due to the way the molten metal shrinks upon cooling. These metals prefer convex beads to help alleviate conditions such as crater cracking,etc. Filler is generally needed to satisfy this.

On good fit-up, of let's say 304L stainless tubing, an autogenous weld can be full thickness due to the shrinkage that occurs during the process. You can be flush inside and out without filler.

This is an example of a quality autogenous weld..

Inside..

Now a weld with filler...

Inside...

So, more reinforcement on both sides of the material, but is it needed for exhaust?

How much stronger is it?

Both work just fine when done right on the right material and job.

#12

Honda-Tech Member

Thread Starter

Join Date: Oct 2007

Posts: 661

Likes: 0

Received 0 Likes

on

0 Posts

Thanks a lot for all the people who replyed. I was wondering how dose the technique of the torch change when not useing filler. Whats involved in Autogenous welding

#13

Very nice pics. The rainbow shows proper argon shielding.

I weld without wire very often and wanted to mention some things.

When using the TIG process:

Basically when your tacking a piece together without wire your fusing(Autogenous weld).

Always hold the filler wire in your hand. As stated above the fit has to be exact/very tight. That being said you keep the wire in your hand in the event there is an area not tight. The puddle will split in two if the gap is to big. You will have a puddle on both pieces your trying to weld together. This is when you want to use that wire in your hand to reconnect the puddle.

On most materials there will be a loss of alloy. Your filler wire is compensating for the alloys you are burning out. This loss of alloy could cause oxidation, discoloration, or failure of the weld. If you have the luxury of a pulser you can limit this loss of alloy by keeping the pulses per second to an on/off or an on/verylow wave. Which would keep the material cooler and shielded longer.

Welding without wire can also produce an undercut weld which could get your welds rejected due to the loss of alloy and strength. Keep in mind when the architects calculate how many welds are required to make something strong enough, they aren't calculating autogenous welds.

I weld a lot of bronze and aluminum which in the thicker gauges requires some preheating. You can gauge when a material like bronze or aluminum is ready to weld by fusing. If the puddle connects to both pieces I'd say its hot enough to start adding wire.

Welding without wire is a great way to teach beginners how to control the puddle.

Also I would never fuse mild steel without scaling it first. The scale weakens the fuse drastically.

Just throwing my 2 cents in on top of what 9bells said.

I weld without wire very often and wanted to mention some things.

When using the TIG process:

Basically when your tacking a piece together without wire your fusing(Autogenous weld).

Always hold the filler wire in your hand. As stated above the fit has to be exact/very tight. That being said you keep the wire in your hand in the event there is an area not tight. The puddle will split in two if the gap is to big. You will have a puddle on both pieces your trying to weld together. This is when you want to use that wire in your hand to reconnect the puddle.

On most materials there will be a loss of alloy. Your filler wire is compensating for the alloys you are burning out. This loss of alloy could cause oxidation, discoloration, or failure of the weld. If you have the luxury of a pulser you can limit this loss of alloy by keeping the pulses per second to an on/off or an on/verylow wave. Which would keep the material cooler and shielded longer.

Welding without wire can also produce an undercut weld which could get your welds rejected due to the loss of alloy and strength. Keep in mind when the architects calculate how many welds are required to make something strong enough, they aren't calculating autogenous welds.

I weld a lot of bronze and aluminum which in the thicker gauges requires some preheating. You can gauge when a material like bronze or aluminum is ready to weld by fusing. If the puddle connects to both pieces I'd say its hot enough to start adding wire.

Welding without wire is a great way to teach beginners how to control the puddle.

Also I would never fuse mild steel without scaling it first. The scale weakens the fuse drastically.

Just throwing my 2 cents in on top of what 9bells said.

#14

I make high pressure radiators (1000's of psi). We do a ton of fusion (autogenous) welding. Butt welds can NOT be done autogenously (they can but it is a weak weld and hold no rating). Lap welds are really the only autogenous weld that can be made strong. Material really doesnt matter (with the exception of Al) I do carbon steel, 304, 316, al-6xn, and titanium autogenously on asme u and um certified pressure vessles.

Thread

Thread Starter

Forum

Replies

Last Post

duckmanEG

Honda CRX / EF Civic (1988 - 1991)

10

01-30-2009 08:08 PM