B-Evo B20 Build thread

#1

Honda-Tech Member

Thread Starter

My ongoing project, The goal for this setup is response first and anywere in the neighborhood of 350hp and 350ft/lbs of torque.

I enjoy making things work that are not designed to. Engineering solutions is fun. I Didnt want any no-name bits and want close to oem reliability so most of it is recycled oem parts. Everything you see done is with basic tools a recip saw and a eastwood welder.

My setup is/will be:

Stock bottom end B20B Low compression

P8R Stock port head

Rocket Motorsports 24/22 Camshafts

Rocket Motorsports single valve springs and spring seats

Rocket motorsports Viton valve seals

ARP Head Studs

Skunk2 First Gen intake manifold

Skunk2 Alpha 70mm throttle body

Evo X OEM ev14 fuel injectors (~650cc/min @ 55psi)

Ktuned Injector top hats

Sumitomo/Denso injector pigtails

Warlboro 255lph HP fuel pump

Adjustable fuel pressure regulator

Evo 8 15g w/ 9.8 hotside

Custom manifold and downpipe elbow

We will start with today and work backwards!

Today I installed my Evo x Injectors, very impressed with them especially going from OEM 20+ year old injectors. They idle incredibly smooth in comparison. and the spray patter is very efficient while setting my fuel pressure the car was idling leaner than my wideband could monitor and it was still smoother than the factory injectors. K-tuned injector top hats dropped right onto the injectors with the evo x (blue) upper o rings and the length is 48mm. They are bosch injectors with a Sumitomo-Denso connector. an ID style connector will not work.

The Green O rings are indeed for A/c but I wanted some extra insurance that there was a good seal between the lower injector seals and the injector body.

Soldered in the injector pig tails and repairing the IAT pigtail correctly.

Set fuel pressure and Injector dead times (thanks PSI performance) and she fired right up first crank.

TurboFlanges.Com supplied the Evo turbo flange and PRL Motorsports supplied the B series exhaust manifold flange both in mild steel. the tubing is 1.5in 10GA mild steel. I only have a Gas Mig so stainless wasnt really an option.

Turbo manifold? close enough

Excuse the second pass, I couldnt really muster much more amperage out of my welder!

The collector is welded inside and out. picked up a 1/4 inch die grinder and these puppies (for way too much money) from the matco guy this week

Here is my marvelous **** box! 313,000 Miles on the body

here she is waiting to go cone killing

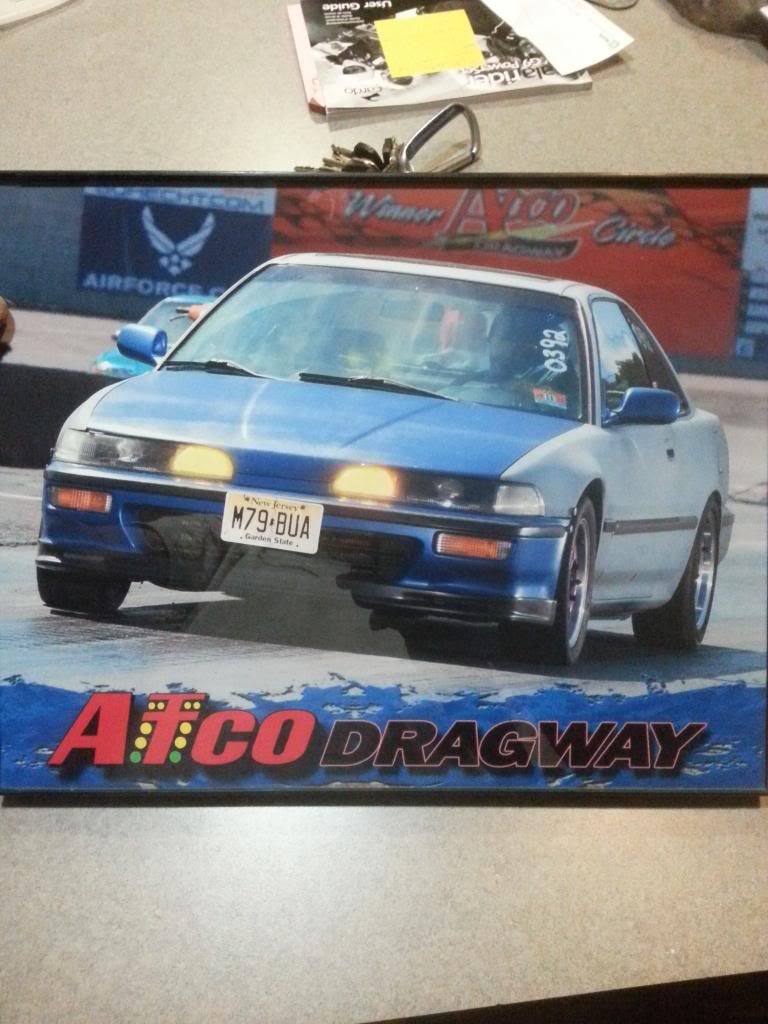

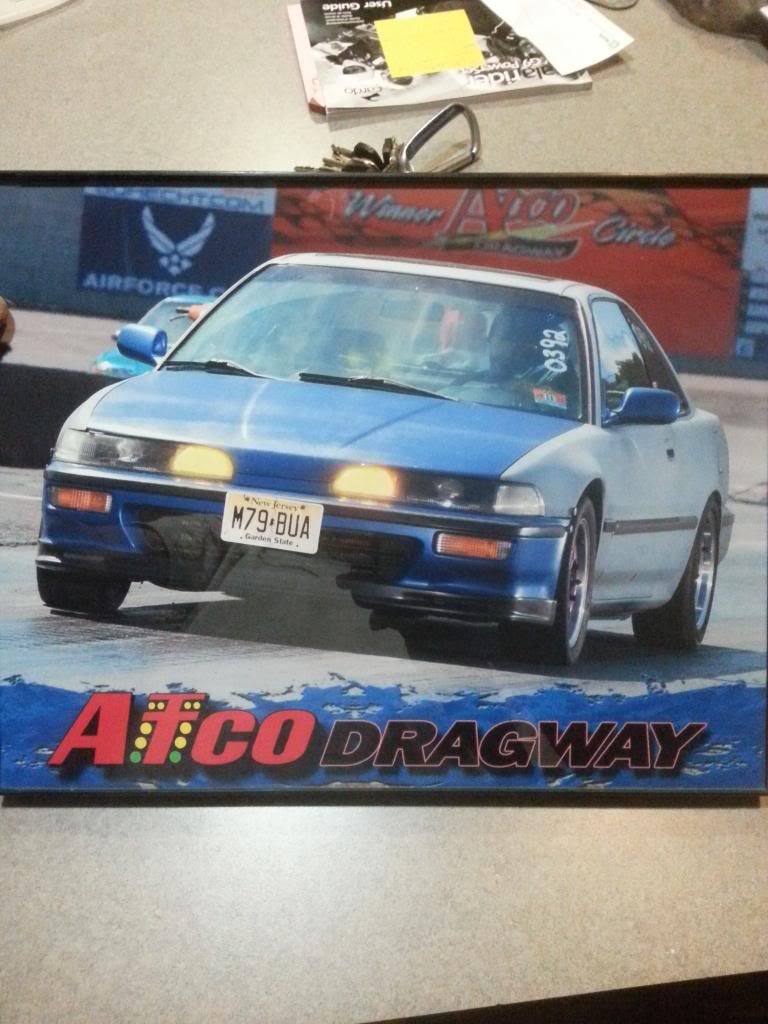

And drag racing!

Note my projector retrofits!

I enjoy making things work that are not designed to. Engineering solutions is fun. I Didnt want any no-name bits and want close to oem reliability so most of it is recycled oem parts. Everything you see done is with basic tools a recip saw and a eastwood welder.

My setup is/will be:

Stock bottom end B20B Low compression

P8R Stock port head

Rocket Motorsports 24/22 Camshafts

Rocket Motorsports single valve springs and spring seats

Rocket motorsports Viton valve seals

ARP Head Studs

Skunk2 First Gen intake manifold

Skunk2 Alpha 70mm throttle body

Evo X OEM ev14 fuel injectors (~650cc/min @ 55psi)

Ktuned Injector top hats

Sumitomo/Denso injector pigtails

Warlboro 255lph HP fuel pump

Adjustable fuel pressure regulator

Evo 8 15g w/ 9.8 hotside

Custom manifold and downpipe elbow

We will start with today and work backwards!

Today I installed my Evo x Injectors, very impressed with them especially going from OEM 20+ year old injectors. They idle incredibly smooth in comparison. and the spray patter is very efficient while setting my fuel pressure the car was idling leaner than my wideband could monitor and it was still smoother than the factory injectors. K-tuned injector top hats dropped right onto the injectors with the evo x (blue) upper o rings and the length is 48mm. They are bosch injectors with a Sumitomo-Denso connector. an ID style connector will not work.

The Green O rings are indeed for A/c but I wanted some extra insurance that there was a good seal between the lower injector seals and the injector body.

Soldered in the injector pig tails and repairing the IAT pigtail correctly.

Set fuel pressure and Injector dead times (thanks PSI performance) and she fired right up first crank.

TurboFlanges.Com supplied the Evo turbo flange and PRL Motorsports supplied the B series exhaust manifold flange both in mild steel. the tubing is 1.5in 10GA mild steel. I only have a Gas Mig so stainless wasnt really an option.

Turbo manifold? close enough

Excuse the second pass, I couldnt really muster much more amperage out of my welder!

The collector is welded inside and out. picked up a 1/4 inch die grinder and these puppies (for way too much money) from the matco guy this week

Here is my marvelous **** box! 313,000 Miles on the body

here she is waiting to go cone killing

And drag racing!

Note my projector retrofits!

#2

Honda-Tech Member

Thread Starter

Also painted the Turbo housings with VHT high temp exhaust paint on the turbine side and wrinkle black 300* on the compressor side. Not sure how the hotside will fare.

Considering fabricating an o2 dump and tubular downpipe to let the turbo breath a little more on the hot side.

Kinguwa Banjo to -4 An oil feed, and drain plate adapter.

Will retain Factory water cooled center section

Cam idle and rev before the tune was improved (thank you RM)

Now idling at 1000rpm @ 34 degrees of timing. (where it pulled highest vacuum @ 11in/hg)

Considering fabricating an o2 dump and tubular downpipe to let the turbo breath a little more on the hot side.

Kinguwa Banjo to -4 An oil feed, and drain plate adapter.

Will retain Factory water cooled center section

Cam idle and rev before the tune was improved (thank you RM)

Now idling at 1000rpm @ 34 degrees of timing. (where it pulled highest vacuum @ 11in/hg)

#3

Honda-Tech Member

Join Date: Feb 2007

Location: up north, wa

Posts: 554

Likes: 0

Received 0 Likes

on

0 Posts

Bump for a b20, I'm putting together a stock b20vtec turbo setup right now. Hoping to get tuned in about 3 weeks. Who's tuning your setup?

#5

Honda-Tech Member

Thread Starter

#6

Honda-Tech Member

Thread Starter

Before:

After:

Also Cleaned up the turbine housing, radiused the waste gate port exits, smoothed the entries and brought them out about another 1-2mm in diameter. there was a noticable lip just past the turbine in the hot side, took it down and blended it into the housing, should help alot

only have pre porting pictures

After:

Also Cleaned up the turbine housing, radiused the waste gate port exits, smoothed the entries and brought them out about another 1-2mm in diameter. there was a noticable lip just past the turbine in the hot side, took it down and blended it into the housing, should help alot

only have pre porting pictures

Trending Topics

#8

Who is Mr Robot?

iTrader: (2)

Join Date: Jul 2004

Location: ATL - Where the Pimps and Players dwell

Posts: 21,474

Likes: 0

Received 10 Likes

on

10 Posts

I have a 10.5 single flapper turbine housing and it needs some serious die grinder love... some of the transitions and casting flaws are absurd.

#9

Honda-Tech Member

Thread Starter

thank you (cant tell if your comment was sarcasm or not- i know the manifold is no show piece)

Do you want to sell it lol?

Do you want to sell it lol?

#10

Who is Mr Robot?

iTrader: (2)

Join Date: Jul 2004

Location: ATL - Where the Pimps and Players dwell

Posts: 21,474

Likes: 0

Received 10 Likes

on

10 Posts

not sure, it currently has a 34mm inlet restrictor compressor housing since it came off a rally car so I might be putting a billet 16g replacement wheel in.

if I pick up an EVO 9 CHRA then I'll go with an 11.5 turbine housing, a td06sl2r turbine wheel, and a larger ported shroud compressor housing and billet 20g or 25g wheel.

I kinda want to see what torque numbers the 16g will produce with the restrictor. they limit power to about 300-350 but cause a massive increase in torque.

if I pick up an EVO 9 CHRA then I'll go with an 11.5 turbine housing, a td06sl2r turbine wheel, and a larger ported shroud compressor housing and billet 20g or 25g wheel.

I kinda want to see what torque numbers the 16g will produce with the restrictor. they limit power to about 300-350 but cause a massive increase in torque.

#11

Honda-Tech Member

Thread Starter

Finally finished my Manifold port matched the turbo and manifold to the gasket. Cleaned up the turbo entry.

Set my wastegate actuator arm 1/2 turn tiger than slip onto the post of the flapper arm.

Set my wastegate actuator arm 1/2 turn tiger than slip onto the post of the flapper arm.

#12

Honda-Tech Member

Thread Starter

Got the setup up and running, tuned by Rated R tuning of Millville NJ.

Made 240hp and 185ftlbs on 7lbs. later found that my manifold had cracked during its first heat cycle. Re welded my manifold and in cool weather it will level off at about 9-10 lbs of boost. Occasionally it will spike to 10 then fall back down to 7 psi. not sure why as of yet. Switched from an ApexI SpecII BOV, to a Tial q. Seller was incorrect on what spring was in it, so I get mild part throttle surge and a little flutter from the compressor below 5psi. Torque is great and sees 10psi (plus whatever the spike is, usually 11psi) by 3000rpm. very fun street car.

pics coming soon along with a EBC

Made 240hp and 185ftlbs on 7lbs. later found that my manifold had cracked during its first heat cycle. Re welded my manifold and in cool weather it will level off at about 9-10 lbs of boost. Occasionally it will spike to 10 then fall back down to 7 psi. not sure why as of yet. Switched from an ApexI SpecII BOV, to a Tial q. Seller was incorrect on what spring was in it, so I get mild part throttle surge and a little flutter from the compressor below 5psi. Torque is great and sees 10psi (plus whatever the spike is, usually 11psi) by 3000rpm. very fun street car.

pics coming soon along with a EBC

#14

Honda-Tech Member

Thread Starter

I ran a t3/t4 b series integra (not sure what the setup was) But the guys' "posse" walked up and huddled around my car at some meet because someone said the car was turbocharged and were looking under the bumper etc etc trying to decipher what the deal with my car was, Mind you Intercooler is black and I have my downpipe connected to my 60mm exhaust with a open wastegate dump.

Come to find out his car was making right around 300 to the wheels, But his setup was very very laggy in comparison to mine. He beeped and jumped on his second beep, by the third beep I left and still hit full boost before him and it was a dead even race to the top of 5th. I was very impressed.

Did a boost leak test and found one of my injector seals was leaking along with 2 couplers, fixed that and the car is running pretty well boost is pretty consistent spikes to about 11psi and settles down at 9psi up till rev limit. Glad to see my wastegate porting and dump are working and able to vent that much volume of exhaust gasses and keep boost low

All in all I am more impressed that All the parts I hand made are holding up as well as they are. manifold and downpipe/dump are holding up great and my porting and cleanup work is showing its worth.

Picture dump:

Porting:

bay shots

oil drain, my AN line was 1/2in too short, have to cut another length of hose

#16

Premium Member

I like this car. I've always had a thing for these Integras. Also I can respect the fact that you actually made a custom setup and did the work yourself instead of just buying entirely cookie cutter off-the-shelf parts that most people go with. Seems like it's a fun street car. Well done.

#17

Honda-Tech Member

Thread Starter

I like this car. I've always had a thing for these Integras. Also I can respect the fact that you actually made a custom setup and did the work yourself instead of just buying entirely cookie cutter off-the-shelf parts that most people go with. Seems like it's a fun street car. Well done.

#18

Who is Mr Robot?

iTrader: (2)

Join Date: Jul 2004

Location: ATL - Where the Pimps and Players dwell

Posts: 21,474

Likes: 0

Received 10 Likes

on

10 Posts

Good numbers for 7psi.. you and I both know once you get around the 1BAR mark the turbo will be much happier lol. the spiking is only happening because you're running such low pressure.

given the current spring inside the wastegate the flapper is only opening a marginal amount because you aren't near the base pressure of the spring. even though you aren't reaching that pressure the gate still creeps open with no boost controller, hence the creep since the flapper is only open probably a few mm or so. if you hadn't ported the flapper I'm sure you'd see more creep at higher rpm. I don't think an ebc will solve the creep since you aren't trying to go over the base spring pressure. the only thing the ebc will do is hold the gate closed longer so it builds boost quicker. since the ebc won't force the flapper to open more than it already is you'll still have a creep problem

if you can find or have an internal wastegate with a lower spring pressure then you can cut the arm off of each (measure distances of both in regards to where the end of the lower psi gate is in relation to the OEM evo one) thread both ends, put a threaded splice piece in and boom.

although given the OEM wastegate mounting location and the bend in the arm you'd either have to make a new bracket to bolt the actuator on to the turbo at an angle (so each rod meets straight on) and cut the evo rod at the straight section in the middle or bend the new actuator rod to match the angle of the evo rod.

you have a low psi gate that actually works. since the spring rate is lower the gate will open more for a given pressure level, eliminating creep.

Turbosmart makes an upgraded actuator for the evo turbos that come with multiple springs so you can play with base pressures. it wouldn't be as cheap as the first method but it would be quicker and easier. TheShodan is a stocking Turbosmart dealer if you're interested.

not sure exactly how much power it should make, especially with the 9.8 turbine housing but I don't see 300 being an issue. it should only take a couple hundred more rpm to make 14-15psi and the torque gain alone will be killer.

I've been debating about trying my 10.5 evo 8 16g on my non vtec f22a1 in my accord but given how well the cylinder head flows from the factory I'm afraid it won't carry power above the midrange much but should have a beastly area under the curve lol, especially with the torque enhancing inlet restrictor.

given the current spring inside the wastegate the flapper is only opening a marginal amount because you aren't near the base pressure of the spring. even though you aren't reaching that pressure the gate still creeps open with no boost controller, hence the creep since the flapper is only open probably a few mm or so. if you hadn't ported the flapper I'm sure you'd see more creep at higher rpm. I don't think an ebc will solve the creep since you aren't trying to go over the base spring pressure. the only thing the ebc will do is hold the gate closed longer so it builds boost quicker. since the ebc won't force the flapper to open more than it already is you'll still have a creep problem

if you can find or have an internal wastegate with a lower spring pressure then you can cut the arm off of each (measure distances of both in regards to where the end of the lower psi gate is in relation to the OEM evo one) thread both ends, put a threaded splice piece in and boom.

although given the OEM wastegate mounting location and the bend in the arm you'd either have to make a new bracket to bolt the actuator on to the turbo at an angle (so each rod meets straight on) and cut the evo rod at the straight section in the middle or bend the new actuator rod to match the angle of the evo rod.

you have a low psi gate that actually works. since the spring rate is lower the gate will open more for a given pressure level, eliminating creep.

Turbosmart makes an upgraded actuator for the evo turbos that come with multiple springs so you can play with base pressures. it wouldn't be as cheap as the first method but it would be quicker and easier. TheShodan is a stocking Turbosmart dealer if you're interested.

not sure exactly how much power it should make, especially with the 9.8 turbine housing but I don't see 300 being an issue. it should only take a couple hundred more rpm to make 14-15psi and the torque gain alone will be killer.

I've been debating about trying my 10.5 evo 8 16g on my non vtec f22a1 in my accord but given how well the cylinder head flows from the factory I'm afraid it won't carry power above the midrange much but should have a beastly area under the curve lol, especially with the torque enhancing inlet restrictor.

#19

Honda-Tech Member

Thread Starter

Good numbers for 7psi.. you and I both know once you get around the 1BAR mark the turbo will be much happier lol. the spiking is only happening because you're running such low pressure.

given the current spring inside the wastegate the flapper is only opening a marginal amount because you aren't near the base pressure of the spring. even though you aren't reaching that pressure the gate still creeps open with no boost controller, hence the creep since the flapper is only open probably a few mm or so. if you hadn't ported the flapper I'm sure you'd see more creep at higher rpm. I don't think an ebc will solve the creep since you aren't trying to go over the base spring pressure. the only thing the ebc will do is hold the gate closed longer so it builds boost quicker. since the ebc won't force the flapper to open more than it already is you'll still have a creep problem

if you can find or have an internal wastegate with a lower spring pressure then you can cut the arm off of each (measure distances of both in regards to where the end of the lower psi gate is in relation to the OEM evo one) thread both ends, put a threaded splice piece in and boom.

although given the OEM wastegate mounting location and the bend in the arm you'd either have to make a new bracket to bolt the actuator on to the turbo at an angle (so each rod meets straight on) and cut the evo rod at the straight section in the middle or bend the new actuator rod to match the angle of the evo rod.

you have a low psi gate that actually works. since the spring rate is lower the gate will open more for a given pressure level, eliminating creep.

Turbosmart makes an upgraded actuator for the evo turbos that come with multiple springs so you can play with base pressures. it wouldn't be as cheap as the first method but it would be quicker and easier. TheShodan is a stocking Turbosmart dealer if you're interested.

not sure exactly how much power it should make, especially with the 9.8 turbine housing but I don't see 300 being an issue. it should only take a couple hundred more rpm to make 14-15psi and the torque gain alone will be killer.

I've been debating about trying my 10.5 evo 8 16g on my non vtec f22a1 in my accord but given how well the cylinder head flows from the factory I'm afraid it won't carry power above the midrange much but should have a beastly area under the curve lol, especially with the torque enhancing inlet restrictor.

given the current spring inside the wastegate the flapper is only opening a marginal amount because you aren't near the base pressure of the spring. even though you aren't reaching that pressure the gate still creeps open with no boost controller, hence the creep since the flapper is only open probably a few mm or so. if you hadn't ported the flapper I'm sure you'd see more creep at higher rpm. I don't think an ebc will solve the creep since you aren't trying to go over the base spring pressure. the only thing the ebc will do is hold the gate closed longer so it builds boost quicker. since the ebc won't force the flapper to open more than it already is you'll still have a creep problem

if you can find or have an internal wastegate with a lower spring pressure then you can cut the arm off of each (measure distances of both in regards to where the end of the lower psi gate is in relation to the OEM evo one) thread both ends, put a threaded splice piece in and boom.

although given the OEM wastegate mounting location and the bend in the arm you'd either have to make a new bracket to bolt the actuator on to the turbo at an angle (so each rod meets straight on) and cut the evo rod at the straight section in the middle or bend the new actuator rod to match the angle of the evo rod.

you have a low psi gate that actually works. since the spring rate is lower the gate will open more for a given pressure level, eliminating creep.

Turbosmart makes an upgraded actuator for the evo turbos that come with multiple springs so you can play with base pressures. it wouldn't be as cheap as the first method but it would be quicker and easier. TheShodan is a stocking Turbosmart dealer if you're interested.

not sure exactly how much power it should make, especially with the 9.8 turbine housing but I don't see 300 being an issue. it should only take a couple hundred more rpm to make 14-15psi and the torque gain alone will be killer.

I've been debating about trying my 10.5 evo 8 16g on my non vtec f22a1 in my accord but given how well the cylinder head flows from the factory I'm afraid it won't carry power above the midrange much but should have a beastly area under the curve lol, especially with the torque enhancing inlet restrictor.

Im guessing that the angle in which they interact determines how fast/ the motion ratio of the wastegate flapper opening. The closer to 90 degrees the angle the the quicker it will respond to low boost conditions with limited wastegate movement. Between my wg arm angle, porting of my housing, and open wastegate dump it makes for a relatively good boost control setup for such a low boost pressure. Im working on an arduino based open source boost controller with one of my Computer Engineering buddies to control a mac solenoid, for a <$100 User definable boost control system.

Im going to slap together a quick and dirty MBC and take it to the track tonight and see what she does. Hoping for mid-high 12's since it was running 13.9-14.3 on the motor alone.

Cant wait to get the turbo into its happy place at higher pressure ratios should maintain its responsiveness and make a good amount of power.

Also considering going to an aftermarket 11.5cm Hotside housing... or a 9 turbo.

#20

Honda-Tech Member

Thread Starter

She ran 13.194 @103.941hp

R/t .287

60' 1.902

330' 5.497

1/8 8.468 @82.8 mph

1000' 11.015

1/4 13.194 @103.94

Track was jumk, slicks were down to 11.5lbs, and I have to shift into 5th . Upping the Rev limiter should eliminate one shift and hopefully put me on my first 12 second pass.

R/t .287

60' 1.902

330' 5.497

1/8 8.468 @82.8 mph

1000' 11.015

1/4 13.194 @103.94

Track was jumk, slicks were down to 11.5lbs, and I have to shift into 5th . Upping the Rev limiter should eliminate one shift and hopefully put me on my first 12 second pass.

#21

Who is Mr Robot?

iTrader: (2)

Join Date: Jul 2004

Location: ATL - Where the Pimps and Players dwell

Posts: 21,474

Likes: 0

Received 10 Likes

on

10 Posts

The angle of the arm isn't terribly important, at least not as important as you're making it out to be. you have to remember that the diaphragm and spring inside the canister will deflect a good bit (hold the canister, grab the end of the rod and wiggle it around)

Shie an extreme angle can affect how much effort it takes to open the flapper (the angle can be so extreme that it binds but that's it) which can cause problems, but again, you haven't reached the base pressure of the current spring so the gate isn't opening as far as it should... and there's no way to remedy that except for running more boost or get one with a softer spring.

remember that with the softer/lower rate spring that the flapper will open further at the same pressure than the stiffer spring did.

I'm super tired at the moment so this post might not make complete sense lol

Shie an extreme angle can affect how much effort it takes to open the flapper (the angle can be so extreme that it binds but that's it) which can cause problems, but again, you haven't reached the base pressure of the current spring so the gate isn't opening as far as it should... and there's no way to remedy that except for running more boost or get one with a softer spring.

remember that with the softer/lower rate spring that the flapper will open further at the same pressure than the stiffer spring did.

I'm super tired at the moment so this post might not make complete sense lol

#22

Honda-Tech Member

Join Date: May 2001

Location: NC

Posts: 3,073

Likes: 0

Received 0 Likes

on

0 Posts

She ran 13.194 @103.941hp

R/t .287

60' 1.902

330' 5.497

1/8 8.468 @82.8 mph

1000' 11.015

1/4 13.194 @103.94

Track was jumk, slicks were down to 11.5lbs, and I have to shift into 5th . Upping the Rev limiter should eliminate one shift and hopefully put me on my first 12 second pass.

R/t .287

60' 1.902

330' 5.497

1/8 8.468 @82.8 mph

1000' 11.015

1/4 13.194 @103.94

Track was jumk, slicks were down to 11.5lbs, and I have to shift into 5th . Upping the Rev limiter should eliminate one shift and hopefully put me on my first 12 second pass.

What size slicks