Help with merge collectors - SolidWorks

#1

Honda-Tech Member

Thread Starter

Join Date: Jul 2009

Posts: 534

Likes: 0

Received 0 Likes

on

0 Posts

Hallo everyone, I have a situation, I'm trying to help my friend building his first headers, one for his d16z6 mild all motor setup and one for his stock turbo d16 project, we are trying to make them both eqval lenght so we are trying to design them in solidworks, and the thing is, I'm no expert, I havent studied designing or anything, so I'm pretty noob, I already did D16 exhaust/head flange, t3 turbine inlet flange,

one guy explaind to me, that he builds his manifolds in solidworks just making up 90/45/30/60 degree pipes, as he will use, and making few lenght straights, as parts, and then mocking everything up in assambly, and then checking for eqval lenghts, but the only thing he didnt explain to me is how to make t3 flange with 4 merge pipes as collector, and for all motor header, how to make 2-1 merge collector...

So, I would be really glad if someone could take me step by step, how to make turbine inlet flange with 4 merge pipes together as part, so I could use it in my assambly when I will be mocking up my manifold, and if I'm getting everything right, I need that merge collector be the way I could really make it in real world application, cause I will be positioning head flange, that merge collector, and then putting runners between them... so I need that collector to be real size like it will be in real world application.

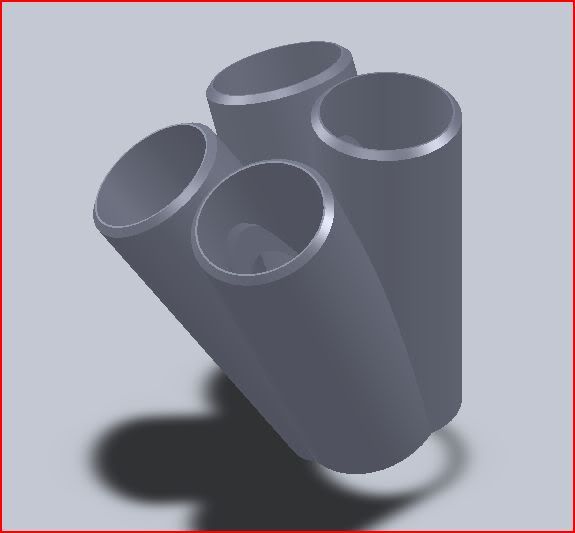

the merge collector I'm talking is like this in picture:

Ok, thanks already for all the help, I hope my english is well enough to understand what I'm saying.

P.S. I'm really glad that we have this great forum here on HT, this has been great insperation for me to start buying my own equipment and trying to work with solidworks and so on.

one guy explaind to me, that he builds his manifolds in solidworks just making up 90/45/30/60 degree pipes, as he will use, and making few lenght straights, as parts, and then mocking everything up in assambly, and then checking for eqval lenghts, but the only thing he didnt explain to me is how to make t3 flange with 4 merge pipes as collector, and for all motor header, how to make 2-1 merge collector...

So, I would be really glad if someone could take me step by step, how to make turbine inlet flange with 4 merge pipes together as part, so I could use it in my assambly when I will be mocking up my manifold, and if I'm getting everything right, I need that merge collector be the way I could really make it in real world application, cause I will be positioning head flange, that merge collector, and then putting runners between them... so I need that collector to be real size like it will be in real world application.

the merge collector I'm talking is like this in picture:

Ok, thanks already for all the help, I hope my english is well enough to understand what I'm saying.

P.S. I'm really glad that we have this great forum here on HT, this has been great insperation for me to start buying my own equipment and trying to work with solidworks and so on.

#2

Honda-Tech Member

Join Date: Jun 2004

Location: Rockford, IL

Posts: 566

Likes: 0

Received 0 Likes

on

0 Posts

i would try to sketch this part http://www.verociousmotorsports.com/...et-Flange-2451 using the plain command because you have to set each circle in different degree. after sketching the part extrude then to length then assemble it to the flange. the rest i would sketch the 90/45/30/60 pipes then assemble them to the manifold. hopefully that helps.

#3

Honda-Tech Member

Join Date: Apr 2003

Location: Montreal, Quebec, Canada

Posts: 988

Likes: 0

Received 0 Likes

on

0 Posts

For your information, you can use assemblies within assemblies. So your collector does not necessarily need to be a part. (Though it is easier to just model it as a whole).

The way I model collectors is I start by sketching a rectangle (in 3DSKetch mode), then from each corner I run center lines downwards at approx 15deg from y ... Draw it like Yo would see it and then dimension the angles. Once you're done that, create a sketch plane based on each of those lines. Then it's a matter of extruding round tubes back upwards.

Tip: extrude 4 solid round bars the extrude cut the centers out. Cut off the top of the collector and draw the flange last.

You can then adjust angles and the original rectangle until everything lines up where you want it to.

I typed this on my phone so I may have left out some details.

Maybe I can find some time to show an example later.

Hope that helps!

The way I model collectors is I start by sketching a rectangle (in 3DSKetch mode), then from each corner I run center lines downwards at approx 15deg from y ... Draw it like Yo would see it and then dimension the angles. Once you're done that, create a sketch plane based on each of those lines. Then it's a matter of extruding round tubes back upwards.

Tip: extrude 4 solid round bars the extrude cut the centers out. Cut off the top of the collector and draw the flange last.

You can then adjust angles and the original rectangle until everything lines up where you want it to.

I typed this on my phone so I may have left out some details.

Maybe I can find some time to show an example later.

Hope that helps!

#4

Honda-Tech Member

Join Date: Apr 2009

Location: Tempe, AZ

Posts: 71

Likes: 0

Received 0 Likes

on

0 Posts

I modeled a collector in solidworks a few months ago.

If your looking for something like this, let me know...I'll send the file over.

If your looking for something like this, let me know...I'll send the file over.

#5

Honda-Tech Member

Thread Starter

Join Date: Jul 2009

Posts: 534

Likes: 0

Received 0 Likes

on

0 Posts

For your information, you can use assemblies within assemblies. So your collector does not necessarily need to be a part. (Though it is easier to just model it as a whole).

The way I model collectors is I start by sketching a rectangle (in 3DSKetch mode), then from each corner I run center lines downwards at approx 15deg from y ... Draw it like Yo would see it and then dimension the angles. Once you're done that, create a sketch plane based on each of those lines. Then it's a matter of extruding round tubes back upwards.

Tip: extrude 4 solid round bars the extrude cut the centers out. Cut off the top of the collector and draw the flange last.

You can then adjust angles and the original rectangle until everything lines up where you want it to.

I typed this on my phone so I may have left out some details.

Maybe I can find some time to show an example later.

Hope that helps!

The way I model collectors is I start by sketching a rectangle (in 3DSKetch mode), then from each corner I run center lines downwards at approx 15deg from y ... Draw it like Yo would see it and then dimension the angles. Once you're done that, create a sketch plane based on each of those lines. Then it's a matter of extruding round tubes back upwards.

Tip: extrude 4 solid round bars the extrude cut the centers out. Cut off the top of the collector and draw the flange last.

You can then adjust angles and the original rectangle until everything lines up where you want it to.

I typed this on my phone so I may have left out some details.

Maybe I can find some time to show an example later.

Hope that helps!

and of course, if you could find a time to show an example, it would be awsome

and of course, if you could find a time to show an example, it would be awsome

Trending Topics

#8

Honda-Tech Member

Thread Starter

Join Date: Jul 2009

Posts: 534

Likes: 0

Received 0 Likes

on

0 Posts

yes, and with flange  I just cant understand, how can I draw it, to later be able to reproduce it using chop saw

I just cant understand, how can I draw it, to later be able to reproduce it using chop saw

P.S. I dont have chop saw, my friend has one, and this will be our first attempt cutting pipes for this collector, so I'm just thinking, when I draw it, how I do it, to be able later take the same messurements on real pipe, and cut it with chop saw

I just cant understand, how can I draw it, to later be able to reproduce it using chop saw

I just cant understand, how can I draw it, to later be able to reproduce it using chop saw

P.S. I dont have chop saw, my friend has one, and this will be our first attempt cutting pipes for this collector, so I'm just thinking, when I draw it, how I do it, to be able later take the same messurements on real pipe, and cut it with chop saw

#9

Honda-Tech Member

Join Date: Apr 2009

Location: Tempe, AZ

Posts: 71

Likes: 0

Received 0 Likes

on

0 Posts

Cutting a collector w/ a chop saw

https://honda-tech.com/forums/welding-fabrication-53/merge-collector-fabrication-101-a-2787713/

https://honda-tech.com/forums/welding-fabrication-53/merge-collector-fabrication-101-a-2787713/

#10

Honda-Tech Member

Thread Starter

Join Date: Jul 2009

Posts: 534

Likes: 0

Received 0 Likes

on

0 Posts

Cutting a collector w/ a chop saw

https://honda-tech.com/forums/showthread.php?t=2787713

https://honda-tech.com/forums/showthread.php?t=2787713

#11

Honda-Tech Member

Join Date: Oct 2008

Location: Rotherham, S Yorks, UK

Posts: 357

Likes: 0

Received 0 Likes

on

0 Posts

I don't use my solidworks as a means to cut the collector. I think it would be pretty diffucult. For what its worth, as a one off i'd just buy a premade collector.

#12

Honda-Tech Member

Thread Starter

Join Date: Jul 2009

Posts: 534

Likes: 0

Received 0 Likes

on

0 Posts

#13

Honda-Tech Member

Thread Starter

Join Date: Jul 2009

Posts: 534

Likes: 0

Received 0 Likes

on

0 Posts

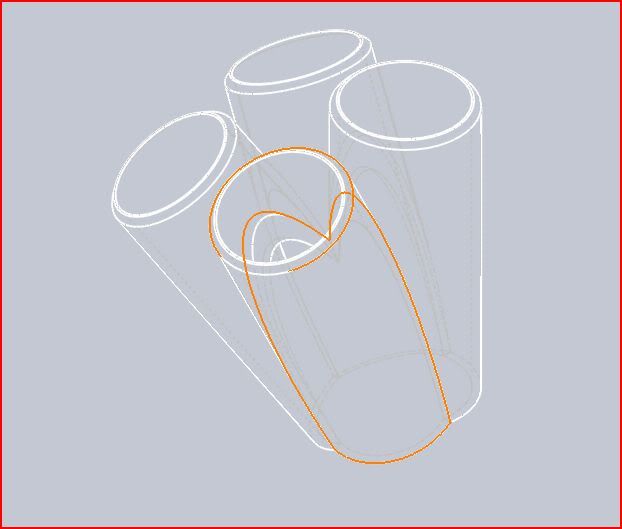

Ok, I think, I've made some progress  I've drawn that collector! I'm not sure is it the right way, the way I did it, but thats a way

I've drawn that collector! I'm not sure is it the right way, the way I did it, but thats a way  So, I'll just post up the step by step guide as I did it, and I hope all SolidWorks pro guys will chime in, and will give approval to my way of doing it, so that way, everyone of other guys out there, wanting to know how to do it, will be able to use this topic as a guide.

So, I'll just post up the step by step guide as I did it, and I hope all SolidWorks pro guys will chime in, and will give approval to my way of doing it, so that way, everyone of other guys out there, wanting to know how to do it, will be able to use this topic as a guide.

(I'm happy I made it, but I really dont know how I will reproduce it in real world, but I think it's doable)

So, ok, I'll try

1) The first thing I did, I drew a sketch of a turbine inlet flange I will be using on the top plain(this is GT28R flange with a bit modified dimensions). [If you need flange dimensions that are used on new Garrett turbochargers, you can get them at Garrett's webpage].

2) Then I used extruded boss/base feature to extrude that sketch to the thickness I will be making my flange(Extrude flange to down side)[I had part file of that flange made already, so I just copied that file, opened in SW, and worked from there].

3) Then I started new 3Dsketch, I drew a square on the same plane as I drew sketch of my flange(Dimension it as you need yours, as far as I understand, it depends on what flange you will be using).

4) Then I drew centerline from the origin point upwards(90 degrees to that square), dimension it as you need, I dimensioned it almost 4".

5) Then I sketched new plain, as reference I used face of flange and upper point of that centerline.

6) Then double clicking on that new plain your created, I sketched square parallel to the square we drew on top plain. Dimension it as you need, as I found it, I used diameter of pipe I will use + few mm(In my example - 45mm, cause I was using 42.4mm OD pipe).

7) Then I drew centerline from one corner of lower square to that upper square[hope you can understand from picture].

8) Repeated for all other corners.

9) Then I drew line from corner of lower square to corner of upper square.

10) Repeated for all other corners.

11) The next thing I did was dimensioned angle from that centerline of one corner, to that line from the same corner(hope you can understand from picture)[I used 15 degrees, dont know if its right or not, I just used that].

12) Then I exited sketch mode, and used weldment tools, with premade profile of that pipe I will be using. weldment tool works really great

13) Made all 4 pipes with weldment tools.

Ok, so, if you only want to use this collector to assemble your manifold, then this is as far as you need to go(at least I think so :D ). But if you want to finish it further, then read on

14) If you make that flange invisible, you can see you have some unwanted edges left.

15) To cut them away, I made a new 3Dsketch, drew circle on that top plain, the main thing is, it has to be bigger than those 4 pipes.

16) Then I exited that previous circle sketch and entered new 3Dsketch, were I drew vertical line from origin, which is 90 degrees to top plain(The main thing here is that it needs to be taller then those unwanted edges if looking from side view).

17) Then I exited sketch mode, used Sweep Cut feature, as profile I selected that big circle we drew, as path, that line we drew.

18) As you can see, it did great

19) If you look inside those pipes, you can see some stuff going on there we really dont need all that :D so we will cut that out.

we really dont need all that :D so we will cut that out.

20) Once more, you sketch a new plain, this time as reference you use upper face of one of those pipes, distance from face to plain set to 0.

21) Next thing you do, you double click on that plain, and sketch a circle, the same size the inner diameter of your pipe is.

22) Once again, you use Sweep Cut feature, as profile you select that circle you just drew, as path, the line which is axis of your pipe.

23) You repeat steps 20/21/22 for other three pipes as well(when you will try to sweep cut next pipe, you wont see path lines, you need to find sweep cut of first pipe in feature manager, under that, you need to find your sketch with those lines, and make it visable[right click, show]). When you will be finished sweep cutting all pipes, it should look like this:

24) You're done. Save this part. It should look like this:

First off all, I hope all this ir correct, and it is possible to reproduce collector that has been designed this way.

Second, I really hope this helps someone, cause I've put some time into this :D

Ok, waiting for some replays

I've drawn that collector! I'm not sure is it the right way, the way I did it, but thats a way

I've drawn that collector! I'm not sure is it the right way, the way I did it, but thats a way  So, I'll just post up the step by step guide as I did it, and I hope all SolidWorks pro guys will chime in, and will give approval to my way of doing it, so that way, everyone of other guys out there, wanting to know how to do it, will be able to use this topic as a guide.

So, I'll just post up the step by step guide as I did it, and I hope all SolidWorks pro guys will chime in, and will give approval to my way of doing it, so that way, everyone of other guys out there, wanting to know how to do it, will be able to use this topic as a guide.(I'm happy I made it, but I really dont know how I will reproduce it in real world, but I think it's doable)

So, ok, I'll try

1) The first thing I did, I drew a sketch of a turbine inlet flange I will be using on the top plain(this is GT28R flange with a bit modified dimensions). [If you need flange dimensions that are used on new Garrett turbochargers, you can get them at Garrett's webpage].

2) Then I used extruded boss/base feature to extrude that sketch to the thickness I will be making my flange(Extrude flange to down side)[I had part file of that flange made already, so I just copied that file, opened in SW, and worked from there].

3) Then I started new 3Dsketch, I drew a square on the same plane as I drew sketch of my flange(Dimension it as you need yours, as far as I understand, it depends on what flange you will be using).

4) Then I drew centerline from the origin point upwards(90 degrees to that square), dimension it as you need, I dimensioned it almost 4".

5) Then I sketched new plain, as reference I used face of flange and upper point of that centerline.

6) Then double clicking on that new plain your created, I sketched square parallel to the square we drew on top plain. Dimension it as you need, as I found it, I used diameter of pipe I will use + few mm(In my example - 45mm, cause I was using 42.4mm OD pipe).

7) Then I drew centerline from one corner of lower square to that upper square[hope you can understand from picture].

8) Repeated for all other corners.

9) Then I drew line from corner of lower square to corner of upper square.

10) Repeated for all other corners.

11) The next thing I did was dimensioned angle from that centerline of one corner, to that line from the same corner(hope you can understand from picture)[I used 15 degrees, dont know if its right or not, I just used that].

12) Then I exited sketch mode, and used weldment tools, with premade profile of that pipe I will be using. weldment tool works really great

13) Made all 4 pipes with weldment tools.

Ok, so, if you only want to use this collector to assemble your manifold, then this is as far as you need to go(at least I think so :D ). But if you want to finish it further, then read on

14) If you make that flange invisible, you can see you have some unwanted edges left.

15) To cut them away, I made a new 3Dsketch, drew circle on that top plain, the main thing is, it has to be bigger than those 4 pipes.

16) Then I exited that previous circle sketch and entered new 3Dsketch, were I drew vertical line from origin, which is 90 degrees to top plain(The main thing here is that it needs to be taller then those unwanted edges if looking from side view).

17) Then I exited sketch mode, used Sweep Cut feature, as profile I selected that big circle we drew, as path, that line we drew.

18) As you can see, it did great

19) If you look inside those pipes, you can see some stuff going on there

we really dont need all that :D so we will cut that out.

we really dont need all that :D so we will cut that out.

20) Once more, you sketch a new plain, this time as reference you use upper face of one of those pipes, distance from face to plain set to 0.

21) Next thing you do, you double click on that plain, and sketch a circle, the same size the inner diameter of your pipe is.

22) Once again, you use Sweep Cut feature, as profile you select that circle you just drew, as path, the line which is axis of your pipe.

23) You repeat steps 20/21/22 for other three pipes as well(when you will try to sweep cut next pipe, you wont see path lines, you need to find sweep cut of first pipe in feature manager, under that, you need to find your sketch with those lines, and make it visable[right click, show]). When you will be finished sweep cutting all pipes, it should look like this:

24) You're done. Save this part. It should look like this:

First off all, I hope all this ir correct, and it is possible to reproduce collector that has been designed this way.

Second, I really hope this helps someone, cause I've put some time into this :D

Ok, waiting for some replays

Last edited by RadekSkylark; 05-16-2011 at 01:09 PM.

#14

Looks fine to me but you could have done a few things differently and finished much quicker. You had a few redundant construction lines ect. that could have been left out but the way you did the part will keep it all in check well should you modify it later.

#15

simpler way to cut your pipes: use the Split command. it's very easy with 4 pipes, simply use the pipe, front plane, and right plane as the Trim Tools, press the Cut Part button, and choose which piece of the cut pipe that you want to keep, and check the box marked "consume cut bodies" to get rid of the bits you don't want. Repeat for the 3 other pipes.

you can also use the top plane of the flange as another Trim Tool, that way you have one feature that controls all of the cuts on your pipe.

you can also use the top plane of the flange as another Trim Tool, that way you have one feature that controls all of the cuts on your pipe.

#16

if engineers would just stop being little women and get their hands dirty threads like this wouldnt exist.

paper doesnt equal the real world

paper doesnt equal the real world

#17

solidworks, or any CAD for that matter, is a great way to prove a design before material is cut. it also let's you try several different designs and see which is the best for your application, whether it's the most visually appealing, etc.

#18

Honda-Tech Member

real engineers get their hands dirty. [most of the time] it saves time and materials to work it out on paper first. no offense to the OP, but if he were an engineer he wouldn't be asking how, he would know how to do it.

#19

Honda-Tech Member

Join Date: Sep 2006

Location: walnut, ca, usa

Posts: 570

Likes: 0

Received 0 Likes

on

0 Posts

LOL, bingo! It's a lot cheaper to mess up your design on the computer than the real thing. Engineers love getting their hands dirty believe me, but you have to plan it out first.

#20

Honda-Tech Member

Thread Starter

Join Date: Jul 2009

Posts: 534

Likes: 0

Received 0 Likes

on

0 Posts

simpler way to cut your pipes: use the Split command. it's very easy with 4 pipes, simply use the pipe, front plane, and right plane as the Trim Tools, press the Cut Part button, and choose which piece of the cut pipe that you want to keep, and check the box marked "consume cut bodies" to get rid of the bits you don't want. Repeat for the 3 other pipes.

you can also use the top plane of the flange as another Trim Tool, that way you have one feature that controls all of the cuts on your pipe.

you can also use the top plane of the flange as another Trim Tool, that way you have one feature that controls all of the cuts on your pipe.

#21

Hi, i did this, but when i have to cut it, how do i measure angles from the draw i did with solidworks? i dont know if you know what i means.

thanks.

thanks.

#22

Honda-Tech Member

Such a typical blue collar response. You guys like to do nothing but bitch about engineers. It is obvious the OP is not an engineer. The proper way to do this in the engineering world is to make each tube a separate part then assemble them into an assembly. You would then have to draft a drawing for the tube, flange, and assembled collector.

#23

Honda-Tech Member

Join Date: Jan 2005

Location: Lower Right Hand Corner, PA

Posts: 5,643

Likes: 0

Received 0 Likes

on

0 Posts

^ Yep. Unfortunately without the ability to break it down into individual parts the entire point of making it a 3D drawing on a computer is pretty much useless unless you are planning to machine the part as a whole.

#24

Honda-Tech Member

Join Date: Oct 2005

Location: greeley, co, usa

Posts: 1,132

Likes: 0

Received 0 Likes

on

0 Posts

1 1/2" schedule 10 pvc + super glue is a great way to learn and a whole hell of a lot cheaper than stainless. I suggest this to anyone setting up a fixture for a chop saw.

#25

you're right, i was looking design for this and finally found a good one, i will try to make it this week, also ordered a digital angle finder..

?

?