Transmission bearing failures and causes explained

#1

Honda-Tech Member

Thread Starter

10/21/17 EDIT: Due to Photobucket stupidity, I am having issues with images missing or not loading on some of my threads. Please be patient as I work on correcting this issue.

Bearings and other load bearing surfaces fail for many reasons. Even though improper installation is and continues to be the number 1 cause of failed bearings and the shafts they support, there are multiple additional failure modes that can take much longer to propagate. Supporting a shaft is not as easy as throwing a bearing on it. The bearing used must the correct type and size to handle the loads the shaft will experience. In this post I will discuss many different types of bearings and apply this information to a typical Honda B, D or H series manual transmission. This information applies to pretty much any transmission or device that transmits power radially, but Honda manual transaxles and transmissions will be the primary focus of this post. The pictures I have chosen are representative of the style of bearings used, not the actual units themselves.

Let's start by comparing and contrasting helical cut gears to spur (or straight) gears, and why and where they are used.

The helical gear design has a lot of advantages when compared to other gear cuts. The most notable advantage of this design is the lack of noise produced while in mesh. Compare this to a typical reverse gear, which is spur cut. Spur gears produce significantly more noise during operation and when properly installed. Spur cut gears are also much cheaper to manufacture.

There are a few drawbacks to helical gear design. They are not as mechanically strong when compared to a spur cut gear. In addition to this, a set of helical gears will produce both axial and radial thrust while engaged and loaded. This problem must be corrected with adequate pre-load devices on the shafts for the gears to achieve long lasting operation. An ideally cut spur gear on the other hand, will only produce radial thrusts when loaded.

Having that said, let's start with the clutch and flywheel assembly, which is where the power enters the transmission. There are 3 major bearings that support the transmission mainshaft (or input shaft). From front to back, they are the pilot bearing, the input shaft bearing, and the rear input support (angular) bearing. Many technicians do not consider the pilot bearing to be a major support bearing, but this bearing has very a critical function as we will soon discover.

Pilot Bearing:

The role this bearing has is to precisely center the nose end of the input shaft and clutch disc with the flywheel on the engine. If this bearing were to fail, the nose end of the input shaft would be able to vibrate and/or thrust up and down as the clutch disc rotates. This clearance will allow the clutch disc to engage the flywheel at an axis that is no longer center-line to the crankshaft or power flow. This will cause the clutch disc to distort as it is applied onto the flywheel, and turn the nose end of the input shaft into a lever that increases the load born on the transmission input shaft bearing, destroying it in very short order. If the clutch disc is allowed to suffer this abuse long term, destruction of the disc, pressure plate, and release bearing can occur. Crankshaft bearings/seals are also known to be destroyed in these situations.

Input Shaft Bearing:

This bearing serves two primary purposes. The first is to provide the mainshaft with a bearing to pre-load against (with the aid of a cone pre-load washer and selective thrust shim). The second is to precisely locate the shaft in relation to the crankshaft of the engine with the use of alignment dowel pins. Because of it's ball bearing construction, this bearing is capable of handling both radial and axial thrusts from the shaft.

Rear Angular Bearing:

This bearing is an excellent design choice for helical cut gearsets, since the bearing allows for radial and axial support of the shaft. This bearing transmits the force to the transmission case at an angle proportional to how it came in. This design also utilizes a greater overall bearing surface area, allowing it to handle larger loads with the same physical size as a typical ball bearing.

There are also 3 major bearings that support the transmission countershaft.

Countershaft Clutch-Housing Bearing:

In the clutch housing side, we have a needle-type roller bearing, which is designed strictly for radial loads (since it has no provision to handle load in any other direction). This bearing in the D-series transaxles is prone to walkout, where the bearing will creep out of its housing due to axial thrusts. The B-series and other larger transaxles use a lock plate to prevent this bearing from walking out.

Countershaft Transmission-Housing Bearing:

This bearing is located on the countershaft itself and is held in place by a 32mm retaining nut. This is the bearing without the snap ring groove, and is also a radial type bearing. The outer bearing shell does have a slight provision to provide resistance to axial movements, but that is not the primary function of the bearing. Its goal is to precisely locate the countershaft within the transaxle housing assembly.

Countershaft Snap Ring Bearing:

This is a traditional caged ball bearing pressed in place above the previous bearing and retained by a 32mm retaining nut. It is similar to the input shaft bearing in design, as it allows for both axial and radial load support. This bearing is also responsible for locating and retaining the countershaft inside the case, since the countershaft would "float" and be free to move laterally if it was not held in place. This bearing keeps the countershaft in its place by way of a snap ring groove placed inside the transaxle housing and fits in this bearings' outer race.

As you can see, each of these bearings has an important role to fulfill. If one of these bearings were to fail, it can adversely affect the load distribution and operation of the other neighboring bearings (and parts) within the transaxle. Since the helix gear design creates both radial and axial thrust loads, keeping these shafts in the proper positions is paramount for long lasting operation of the gears and shafts.

I will address one bearing that tends to wear out very quickly when incorrectly installed and is often overlooked: The pilot bearing. This bearing is a small sealed ball bearing pressed into the crankshaft or flywheel on most manual transmission-equipped vehicles. This bearing can fail very quickly if shocked by the crankshaft and the input shaft such as when the transmission is mated without the dowel guides, the flywheel is not centered correctly on the crankshaft, or if there is excessive clearance in the input shaft bearing. When this bearing fails it will allow the input shaft to "wobble" or vibrate a small amount. If the clutch friction surface is unbalanced, or not center to and perpendicular to the flywheel, it will permit the clutch to engage the flywheel at an angle that is not center-line to power flow. This will destroy the pilot bearing, forcing the load onto the input shaft bearing.

Now the input shaft bearing has to take the load of this unbalanced clutch force at a mechanical advantage 6 inches away! If you know how a breaker bar works, you will know that the longer it is the more power you can exert on the business end. If the clutch disc is off center-line due to a failed pilot bearing, it will place this load on the input shaft bearing but at a mechanical advantage to the clutch disc since the clutch disc is where the force originates. This places significant strain on the input shaft bearing, and quickens its failure. Once this bearing fails, the rear angular bearing is the only bearing left on the mainshaft to handle the load correctly. This bearing is still to the task of supporting the input shaft from the back end due to its size and location from the input shaft bearing. The failure of the input shaft bearing though now allows a clearance to exist in the mainshaft pre-load, allowing the shaft to slam back and forth during acceleration and deceleration. This slamming is the result of the helical cut gear design. This is a problem that no bearing can handle very well for long.

The clearance that exists in the mainshaft will also cause the countershaft to thrust in the opposite direction, because of the helix gear design. Now if you remember, the only bearing on the countershaft that can effectively handle any axial thrust at all is the snap ring bearing. This bearing is usually the next to fail within the transmission, and a good portion of the B-series transmissions I see have this failure along with the input shaft bearing.

Once this snap ring bearing begins to fail (sometimes the thrusting of the shaft itself can exert enough force on the gear selected to also cause this) the countershaft needle bearing will begin to thrust of its hole in Honda D-series transmissions. In the B-series and other units this countershaft bearing is held in place by a locking tab. This bearing really has no effect on the shaft other than to keep it axially supported. But due to the helix gear design, it allows the countershaft to push on this bearing's housing radially, and pull/push it axially because of the helical gear cut and clearance that now exists in the mainshaft due to an input shaft bearing failure. This bearing will move out of its installed position until it makes contact with the differential, where it will leave a gear tooth pattern on the outer race.

Typical Tapered Roller Bearing

The differential bearings within a transaxle must also handle extreme loads. They are very strong and much large compared to other bearings found within a typical transaxle. There are two styles in common use: The tapered roller bearing and ball bearing. The tapered roller bearing is the strongest type because it rotates the rollers at an angle to fight both axial and radial movement due to the helical gear design used on most in and pinion gears. The setup of these bearings is more complex, and most differentials that use the tapered roller design require a torque-to-turn setting, which is a pre-load installation adjustment. Ball bearing units are preferred by most installers because of the ease of setup: There is no need to set a bearing pre-load adjustment, simply put a feeler gauge in the clearance, and get the right thrust shim for the application.

Defective bearings can also cause a lot of headaches, and not necessarily in sequence with what I have just spoke, which would be from the input to the output of the transaxle. Bearings also fail for many other reasons, such as lack of oil, improper bearing installation, wrong bearing altogether, etc.

Many issues can arise of the problems/clearances mentioned. Unable to maintain gear position and rapid wear of the slider and gear dogs are the primary victims of axial thrust and indicate a bearing pre-load problem. Shift forks can also be bent/broken by the axial and radial force caused by this lack of pre-load. In severe cases teeth could sheer off the gears due to interference. These performance issues, while maintaining some of the same basic roots, will be unique to every type of transmission. Understanding this information will allow you to make an educated guess as to what is causing the problem and where to start hunting for a problem.

Failing to shift into second gear seems to be the most common issue with most Honda B and D-series transaxles, so I will describe how this problem progresses, from start to finish. When a mainshaft clearance is allowed to exist, (eg failed input shaft bearing due to a bad pilot bearing, worn cone washer or shims, incorrect installation) shifting into second gear can be quite the challenge. The force exerted onto the countershaft for second gear will thrust the countershaft towards the passenger side of the vehicle due to the helical gear design, and the mainshaft will thrust towards the driver's side, towards the ISB. This makes shifter travel to second gear longer due to the countershaft repelling the mainshaft, which will shift in the opposite direction. This causes second gear synchronizer on the countershaft to grind and occasionally catch because the shaft has moved to a location that the shift fork cannot reach. On deceleration the shift fork tends to pop out of position because the shift fork detents cannot properly sit in their grooves due to the shaft's movement. Because this problem is not readily fixed, rapid shift fork wear or breakage will occur, making the problem worse with time.

The primary correction for this problem is to replace the snap ring bearing on the countershaft. This bearing is what holds the countershaft in place allowing the shift forks to reach each gear collar. The input shaft bearing would also require replacement due to the slamming effect which destroys the snap ring bearing. And of course, we cannot forget about the little pilot bearing and dowel pins, the start of this entire problem.

Bearings and other load bearing surfaces fail for many reasons. Even though improper installation is and continues to be the number 1 cause of failed bearings and the shafts they support, there are multiple additional failure modes that can take much longer to propagate. Supporting a shaft is not as easy as throwing a bearing on it. The bearing used must the correct type and size to handle the loads the shaft will experience. In this post I will discuss many different types of bearings and apply this information to a typical Honda B, D or H series manual transmission. This information applies to pretty much any transmission or device that transmits power radially, but Honda manual transaxles and transmissions will be the primary focus of this post. The pictures I have chosen are representative of the style of bearings used, not the actual units themselves.

Let's start by comparing and contrasting helical cut gears to spur (or straight) gears, and why and where they are used.

The helical gear design has a lot of advantages when compared to other gear cuts. The most notable advantage of this design is the lack of noise produced while in mesh. Compare this to a typical reverse gear, which is spur cut. Spur gears produce significantly more noise during operation and when properly installed. Spur cut gears are also much cheaper to manufacture.

There are a few drawbacks to helical gear design. They are not as mechanically strong when compared to a spur cut gear. In addition to this, a set of helical gears will produce both axial and radial thrust while engaged and loaded. This problem must be corrected with adequate pre-load devices on the shafts for the gears to achieve long lasting operation. An ideally cut spur gear on the other hand, will only produce radial thrusts when loaded.

Having that said, let's start with the clutch and flywheel assembly, which is where the power enters the transmission. There are 3 major bearings that support the transmission mainshaft (or input shaft). From front to back, they are the pilot bearing, the input shaft bearing, and the rear input support (angular) bearing. Many technicians do not consider the pilot bearing to be a major support bearing, but this bearing has very a critical function as we will soon discover.

Pilot Bearing:

The role this bearing has is to precisely center the nose end of the input shaft and clutch disc with the flywheel on the engine. If this bearing were to fail, the nose end of the input shaft would be able to vibrate and/or thrust up and down as the clutch disc rotates. This clearance will allow the clutch disc to engage the flywheel at an axis that is no longer center-line to the crankshaft or power flow. This will cause the clutch disc to distort as it is applied onto the flywheel, and turn the nose end of the input shaft into a lever that increases the load born on the transmission input shaft bearing, destroying it in very short order. If the clutch disc is allowed to suffer this abuse long term, destruction of the disc, pressure plate, and release bearing can occur. Crankshaft bearings/seals are also known to be destroyed in these situations.

Input Shaft Bearing:

This bearing serves two primary purposes. The first is to provide the mainshaft with a bearing to pre-load against (with the aid of a cone pre-load washer and selective thrust shim). The second is to precisely locate the shaft in relation to the crankshaft of the engine with the use of alignment dowel pins. Because of it's ball bearing construction, this bearing is capable of handling both radial and axial thrusts from the shaft.

Rear Angular Bearing:

This bearing is an excellent design choice for helical cut gearsets, since the bearing allows for radial and axial support of the shaft. This bearing transmits the force to the transmission case at an angle proportional to how it came in. This design also utilizes a greater overall bearing surface area, allowing it to handle larger loads with the same physical size as a typical ball bearing.

There are also 3 major bearings that support the transmission countershaft.

Countershaft Clutch-Housing Bearing:

In the clutch housing side, we have a needle-type roller bearing, which is designed strictly for radial loads (since it has no provision to handle load in any other direction). This bearing in the D-series transaxles is prone to walkout, where the bearing will creep out of its housing due to axial thrusts. The B-series and other larger transaxles use a lock plate to prevent this bearing from walking out.

Countershaft Transmission-Housing Bearing:

This bearing is located on the countershaft itself and is held in place by a 32mm retaining nut. This is the bearing without the snap ring groove, and is also a radial type bearing. The outer bearing shell does have a slight provision to provide resistance to axial movements, but that is not the primary function of the bearing. Its goal is to precisely locate the countershaft within the transaxle housing assembly.

Countershaft Snap Ring Bearing:

This is a traditional caged ball bearing pressed in place above the previous bearing and retained by a 32mm retaining nut. It is similar to the input shaft bearing in design, as it allows for both axial and radial load support. This bearing is also responsible for locating and retaining the countershaft inside the case, since the countershaft would "float" and be free to move laterally if it was not held in place. This bearing keeps the countershaft in its place by way of a snap ring groove placed inside the transaxle housing and fits in this bearings' outer race.

As you can see, each of these bearings has an important role to fulfill. If one of these bearings were to fail, it can adversely affect the load distribution and operation of the other neighboring bearings (and parts) within the transaxle. Since the helix gear design creates both radial and axial thrust loads, keeping these shafts in the proper positions is paramount for long lasting operation of the gears and shafts.

I will address one bearing that tends to wear out very quickly when incorrectly installed and is often overlooked: The pilot bearing. This bearing is a small sealed ball bearing pressed into the crankshaft or flywheel on most manual transmission-equipped vehicles. This bearing can fail very quickly if shocked by the crankshaft and the input shaft such as when the transmission is mated without the dowel guides, the flywheel is not centered correctly on the crankshaft, or if there is excessive clearance in the input shaft bearing. When this bearing fails it will allow the input shaft to "wobble" or vibrate a small amount. If the clutch friction surface is unbalanced, or not center to and perpendicular to the flywheel, it will permit the clutch to engage the flywheel at an angle that is not center-line to power flow. This will destroy the pilot bearing, forcing the load onto the input shaft bearing.

Now the input shaft bearing has to take the load of this unbalanced clutch force at a mechanical advantage 6 inches away! If you know how a breaker bar works, you will know that the longer it is the more power you can exert on the business end. If the clutch disc is off center-line due to a failed pilot bearing, it will place this load on the input shaft bearing but at a mechanical advantage to the clutch disc since the clutch disc is where the force originates. This places significant strain on the input shaft bearing, and quickens its failure. Once this bearing fails, the rear angular bearing is the only bearing left on the mainshaft to handle the load correctly. This bearing is still to the task of supporting the input shaft from the back end due to its size and location from the input shaft bearing. The failure of the input shaft bearing though now allows a clearance to exist in the mainshaft pre-load, allowing the shaft to slam back and forth during acceleration and deceleration. This slamming is the result of the helical cut gear design. This is a problem that no bearing can handle very well for long.

The clearance that exists in the mainshaft will also cause the countershaft to thrust in the opposite direction, because of the helix gear design. Now if you remember, the only bearing on the countershaft that can effectively handle any axial thrust at all is the snap ring bearing. This bearing is usually the next to fail within the transmission, and a good portion of the B-series transmissions I see have this failure along with the input shaft bearing.

Once this snap ring bearing begins to fail (sometimes the thrusting of the shaft itself can exert enough force on the gear selected to also cause this) the countershaft needle bearing will begin to thrust of its hole in Honda D-series transmissions. In the B-series and other units this countershaft bearing is held in place by a locking tab. This bearing really has no effect on the shaft other than to keep it axially supported. But due to the helix gear design, it allows the countershaft to push on this bearing's housing radially, and pull/push it axially because of the helical gear cut and clearance that now exists in the mainshaft due to an input shaft bearing failure. This bearing will move out of its installed position until it makes contact with the differential, where it will leave a gear tooth pattern on the outer race.

Typical Tapered Roller Bearing

The differential bearings within a transaxle must also handle extreme loads. They are very strong and much large compared to other bearings found within a typical transaxle. There are two styles in common use: The tapered roller bearing and ball bearing. The tapered roller bearing is the strongest type because it rotates the rollers at an angle to fight both axial and radial movement due to the helical gear design used on most in and pinion gears. The setup of these bearings is more complex, and most differentials that use the tapered roller design require a torque-to-turn setting, which is a pre-load installation adjustment. Ball bearing units are preferred by most installers because of the ease of setup: There is no need to set a bearing pre-load adjustment, simply put a feeler gauge in the clearance, and get the right thrust shim for the application.

Defective bearings can also cause a lot of headaches, and not necessarily in sequence with what I have just spoke, which would be from the input to the output of the transaxle. Bearings also fail for many other reasons, such as lack of oil, improper bearing installation, wrong bearing altogether, etc.

Many issues can arise of the problems/clearances mentioned. Unable to maintain gear position and rapid wear of the slider and gear dogs are the primary victims of axial thrust and indicate a bearing pre-load problem. Shift forks can also be bent/broken by the axial and radial force caused by this lack of pre-load. In severe cases teeth could sheer off the gears due to interference. These performance issues, while maintaining some of the same basic roots, will be unique to every type of transmission. Understanding this information will allow you to make an educated guess as to what is causing the problem and where to start hunting for a problem.

Failing to shift into second gear seems to be the most common issue with most Honda B and D-series transaxles, so I will describe how this problem progresses, from start to finish. When a mainshaft clearance is allowed to exist, (eg failed input shaft bearing due to a bad pilot bearing, worn cone washer or shims, incorrect installation) shifting into second gear can be quite the challenge. The force exerted onto the countershaft for second gear will thrust the countershaft towards the passenger side of the vehicle due to the helical gear design, and the mainshaft will thrust towards the driver's side, towards the ISB. This makes shifter travel to second gear longer due to the countershaft repelling the mainshaft, which will shift in the opposite direction. This causes second gear synchronizer on the countershaft to grind and occasionally catch because the shaft has moved to a location that the shift fork cannot reach. On deceleration the shift fork tends to pop out of position because the shift fork detents cannot properly sit in their grooves due to the shaft's movement. Because this problem is not readily fixed, rapid shift fork wear or breakage will occur, making the problem worse with time.

The primary correction for this problem is to replace the snap ring bearing on the countershaft. This bearing is what holds the countershaft in place allowing the shift forks to reach each gear collar. The input shaft bearing would also require replacement due to the slamming effect which destroys the snap ring bearing. And of course, we cannot forget about the little pilot bearing and dowel pins, the start of this entire problem.

Last edited by slowcivic2k; 11-09-2017 at 08:23 PM. Reason: Version 2.0

#3

Honda-Tech Member

Thread Starter

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by ToeJam »</TD></TR><TR><TD CLASS="quote">Thank you.</TD></TR></TABLE>

Your Welcome.

Your Welcome.

#5

Go Tigers!

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by slowcivic2k »</TD></TR><TR><TD CLASS="quote">In the clutch case, we have a needle bearing, which is designed for radial load. (since it has no provision to load axially) This bearing could walk out of its hole and would have little effect on transmission operation because of the 3rd bearing I will explain.</TD></TR></TABLE>

I wish this were true, sometimes these bearings can walk out of the casing and move the countershaft away from the clutch housing causing 2nd gear to never fully engage (grind).

I wish this were true, sometimes these bearings can walk out of the casing and move the countershaft away from the clutch housing causing 2nd gear to never fully engage (grind).

#7

B*a*n*n*e*d

iTrader: (1)

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by 4g hatch »</TD></TR><TR><TD CLASS="quote">this is great info and much appreciated. alot of people overlook the pilot bearing including myself</TD></TR></TABLE>

Very true...it happens.....Good write up

Very true...it happens.....Good write up

Trending Topics

#8

Honda-Tech Member

Thread Starter

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by Bense »</TD></TR><TR><TD CLASS="quote">

I wish this were true, sometimes these bearings can walk out of the casing and move the countershaft away from the clutch housing causing 2nd gear to never fully engage (grind).</TD></TR></TABLE>

Yea, I have measured a few cases where the shaft actually rubs on the bearing case, and puts a wear pattern on it, the thrust used to pull it out is never the same as the thrust on decel, since the tires don't really apply any power to push it back so it kinda rests on there. In some cases I don't see that happening, but it is a factor.

I wish this were true, sometimes these bearings can walk out of the casing and move the countershaft away from the clutch housing causing 2nd gear to never fully engage (grind).</TD></TR></TABLE>

Yea, I have measured a few cases where the shaft actually rubs on the bearing case, and puts a wear pattern on it, the thrust used to pull it out is never the same as the thrust on decel, since the tires don't really apply any power to push it back so it kinda rests on there. In some cases I don't see that happening, but it is a factor.

#9

D Tranny Guru

not the shaft, but the ring gear on the diff that causes the wear pattern on the CS bearing.

EVERY D series tranny I work on gets staked in 3 places, "performance" trannys get staked in 5-6 places, since I've seen them still walk out with only 3 "stakes".......

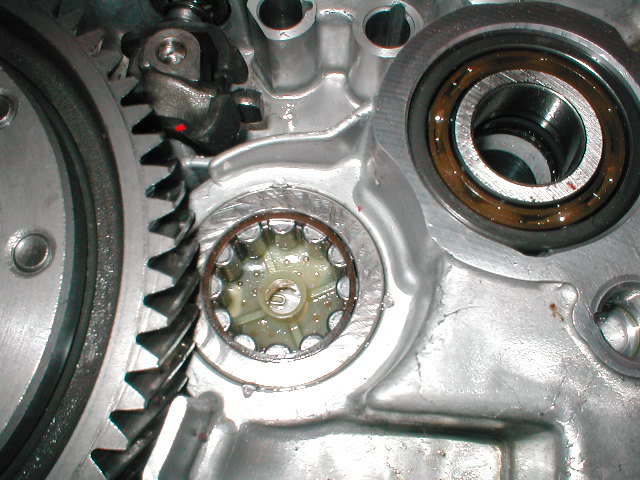

CS bearing that has walked out.......

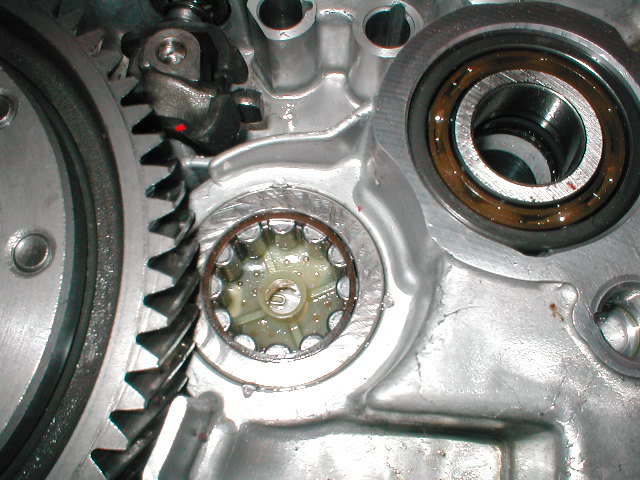

Tapped back into place......

The "staked" into place with a center punch.

As a respected tranny builder, I've only ever had ONE tranny that came back, it was my first build. I installed for a HT member, Todd Reid at Mid Ohio. Since that learning EVERY tranny gets staked.

BTW slowcivic2k, NICE WRITE-UP and explaining what causes the walking of the bearing.

EVERY D series tranny I work on gets staked in 3 places, "performance" trannys get staked in 5-6 places, since I've seen them still walk out with only 3 "stakes".......

CS bearing that has walked out.......

Tapped back into place......

The "staked" into place with a center punch.

As a respected tranny builder, I've only ever had ONE tranny that came back, it was my first build. I installed for a HT member, Todd Reid at Mid Ohio. Since that learning EVERY tranny gets staked.

BTW slowcivic2k, NICE WRITE-UP and explaining what causes the walking of the bearing.

#12

Honda-Tech Member

Thread Starter

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by GearSpeedEF7 »</TD></TR><TR><TD CLASS="quote">Stake those bearings!!  </TD></TR></TABLE>

</TD></TR></TABLE>

Yep, need to do the job that Honda neglected to... Why they didn't do that in the first place is beyond me...

</TD></TR></TABLE>

</TD></TR></TABLE>Yep, need to do the job that Honda neglected to... Why they didn't do that in the first place is beyond me...

#13

B*a*n*n*e*d

iTrader: (1)

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by slowcivic2k »</TD></TR><TR><TD CLASS="quote">

Yep, need to do the job that Honda neglected to... Why they didn't do that in the first place is beyond me...</TD></TR></TABLE>

SSSHHHHH! Keeps us busy

Yep, need to do the job that Honda neglected to... Why they didn't do that in the first place is beyond me...</TD></TR></TABLE>

SSSHHHHH! Keeps us busy

#14

D Tranny Guru

I've been swamped this year.

BTW, got my first SCCA Road Course win at a tranny builder.

SCCA ITA @ Gingerman this past weekend.....

GSEF7, might be calling you or sending a customer your way, typical GSR 3-4 grind and he wants carbon syncs.

BTW, got my first SCCA Road Course win at a tranny builder.

SCCA ITA @ Gingerman this past weekend.....

GSEF7, might be calling you or sending a customer your way, typical GSR 3-4 grind and he wants carbon syncs.

#15

Honda-Tech Member

Join Date: Sep 2004

Location: g town, nc, USA

Posts: 107

Likes: 0

Received 0 Likes

on

0 Posts

I think i Just broke my transmission, it feels like the rear mount on the engine is broke, but its fine, feels like it hesitates in all gears, started when i was in 5th gear going 45mph

Tranny feels hesitant, not motor

obd1 b16 oem lsd

It also had been making a knocking noise when first taking off in 1st gear only, unsure if it is related.

Tranny feels hesitant, not motor

obd1 b16 oem lsd

It also had been making a knocking noise when first taking off in 1st gear only, unsure if it is related.

#18

Honda-Tech Member

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by GearSpeedEF7 »</TD></TR><TR><TD CLASS="quote">Stake those bearings!!  </TD></TR></TABLE>

</TD></TR></TABLE>

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by slowcivic2k »</TD></TR><TR><TD CLASS="quote">

Why they didn't do that in the first place is beyond me...</TD></TR></TABLE>

A stock d-series driven normally as honda designed it have very few problems from it. On their higher power engine setups they retain the countershaft bearing with a bolted plate.

</TD></TR></TABLE>

</TD></TR></TABLE><TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by slowcivic2k »</TD></TR><TR><TD CLASS="quote">

Why they didn't do that in the first place is beyond me...</TD></TR></TABLE>

A stock d-series driven normally as honda designed it have very few problems from it. On their higher power engine setups they retain the countershaft bearing with a bolted plate.

#19

I have a b4ra transmission on a d16y8, what bearing would cause it to click or pop when driving forward and in reverse? Id like to replace it asap.

#20

http://www.youtube.com/watch?v=SKuLg...ature=youtu.be

thats the noise, any help would be amazing right about now.

thats the noise, any help would be amazing right about now.

#22

both axles are brand new. it doesn't click when turning, but clicks loudly in reverse. it clicks when driving but its not nearly as loud as it is in reverse.

my og transmission was clicking when i bought the car and we thought it was axles then.

I bought a parts civic and put that transmission in there and the sound dissapeared! but the tranny was slow so I rebuilt the old one. when i opened the case it was broken, so i figured that was the clicking. went on with the rebuild but didnt do any of the bearings. I used the bell housing from the parts civics transmission so those bearings were fine.

put it back together and click click click.

edit: I didnt do the bearings because the rebuild kit did not include them.

my og transmission was clicking when i bought the car and we thought it was axles then.

I bought a parts civic and put that transmission in there and the sound dissapeared! but the tranny was slow so I rebuilt the old one. when i opened the case it was broken, so i figured that was the clicking. went on with the rebuild but didnt do any of the bearings. I used the bell housing from the parts civics transmission so those bearings were fine.

put it back together and click click click.

edit: I didnt do the bearings because the rebuild kit did not include them.

#23

Honda-Tech Member

Thread Starter

Piecing together a housing is a very dumb idea, you have no idea if the machining between housings will match. Rebuild the unit correctly, then diagnose the noise.

#25

Honda-Tech Member

Thread Starter

It doesn't matter, if the bits that cut the housing were not the same, there will be a difference in clearances and fitment that will at the least, require adjustment.

Ask any NSX onwer of this folly, it does matter.

Ask any NSX onwer of this folly, it does matter.