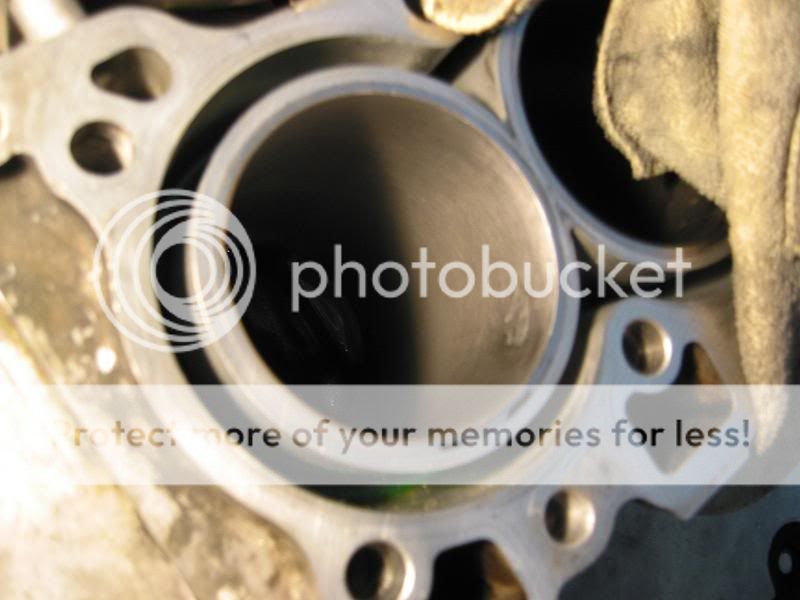

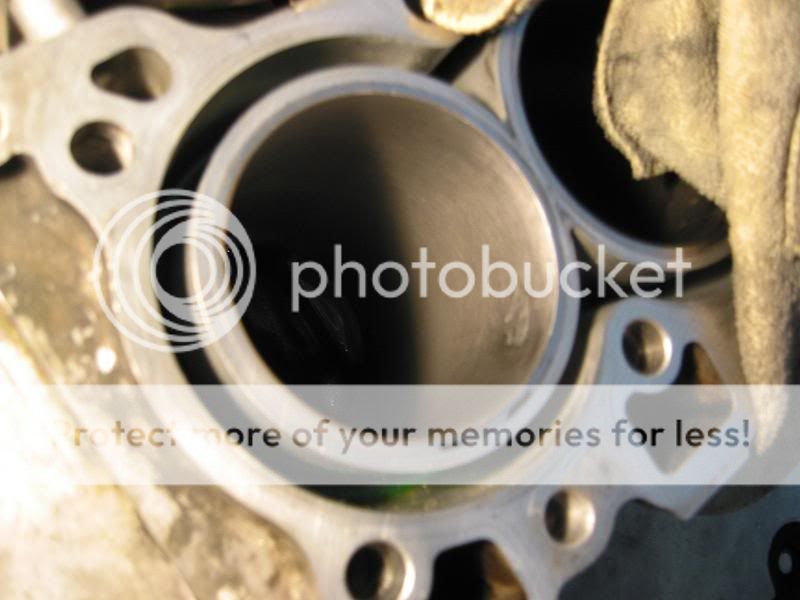

Honing the cylinder walls

#1

Honda-Tech Member

Thread Starter

Join Date: Dec 2003

Location: Oakland, CA, USA

Posts: 2,979

Likes: 0

Received 0 Likes

on

0 Posts

I just finish honing my cylinder walls, i can't seem to get my crosshair to angle at a 45 degree angle. It seem very flat, would that give me any problems later on? I also got VERY little thin layer of left over alumium from my previous piston left on the wall but i got most of it off, would that cause problems? thx..

#2

Honda-Tech Member

you need to move the hone up and down pretty fast/quick to get a decent cross hatch hone. if the hone marks are flat/straight your not moving it up and down fast enough.

use some wd40 or transmission fluid to lubricate the cylinders while honing to help make a decent smooth finish.

if you have aluminum stuck to the cylinder wall from the previous piston you might have some serious cylinder damage. you should remove the block and take it to a machine shop so they can properly measure/bore/hone the cylinders.

use some wd40 or transmission fluid to lubricate the cylinders while honing to help make a decent smooth finish.

if you have aluminum stuck to the cylinder wall from the previous piston you might have some serious cylinder damage. you should remove the block and take it to a machine shop so they can properly measure/bore/hone the cylinders.

#3

Honda-Tech Member

Thread Starter

Join Date: Dec 2003

Location: Oakland, CA, USA

Posts: 2,979

Likes: 0

Received 0 Likes

on

0 Posts

The alumium that's left on there is VERY THIN...by feeling it and eyeing it looks like it's going to get burned off instantly when i start the motor, it's also at the top of the cylinder wall not on the mid or bottome of it. I did manage to remove most of the alumium off the wall by the honer.I did use wd40 and move the honer up and down pretty quickly, seem like it didn't help do the crossline..

#4

Join Date: May 2006

Location: California, United States

Posts: 961

Likes: 0

Received 0 Likes

on

0 Posts

If you start your motor with that aluminium still on the cylinder wall, you're going to be re-rebuilding. Have you taken a look at how tight Honda's clearances are?

#5

Honda-Tech Member

Thread Starter

Join Date: Dec 2003

Location: Oakland, CA, USA

Posts: 2,979

Likes: 0

Received 0 Likes

on

0 Posts

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by 91SiZ6 »</TD></TR><TR><TD CLASS="quote">If you start your motor with that aluminium still on the cylinder wall, you're going to be re-rebuilding. Have you taken a look at how tight Honda's clearances are?</TD></TR></TABLE>

yes i have, that's why i didn't want to hone too much away from my cylinder wall, before it start boring it out...i got it to the point where it was so thin that you can't even feel it, i'm just more worried about if my crosshair was not at the right angles what will it effect..

yes i have, that's why i didn't want to hone too much away from my cylinder wall, before it start boring it out...i got it to the point where it was so thin that you can't even feel it, i'm just more worried about if my crosshair was not at the right angles what will it effect..

#7

Mad Scientist

wow....some people should not be building engines until they have enough knowledge....

for how long did you hone? if you ''honed'' the aluminum scraps off the walls that means you also honed the part with no aluminum; now you have uneven surfaces andc learances. .0001 is not a lot....

also are you using any kind of measurements in order to see where your PTWC is?

checked for egg shaping?

for how long did you hone? if you ''honed'' the aluminum scraps off the walls that means you also honed the part with no aluminum; now you have uneven surfaces andc learances. .0001 is not a lot....

also are you using any kind of measurements in order to see where your PTWC is?

checked for egg shaping?

Trending Topics

#8

Honda-Tech Member

Thread Starter

Join Date: Dec 2003

Location: Oakland, CA, USA

Posts: 2,979

Likes: 0

Received 0 Likes

on

0 Posts

yah...i got most of the alumium...But i found out after that i have a DENT!! in the damn cylinder wall...so now i'm stuck deciding to sell my GSR block for a b20b and go b20 vtec...or should i machine the GSR block to 2L..

#9

Join Date: May 2006

Location: California, United States

Posts: 961

Likes: 0

Received 0 Likes

on

0 Posts

You're doing machine work with the motor in the car? DOH!!!

Pull it and take it to a machine shop. Let a professional decide if the block is usable any more. You might be able to over-bore by .020" and get a usable motor back. There's also the option of having it resleeved.

Pull it and take it to a machine shop. Let a professional decide if the block is usable any more. You might be able to over-bore by .020" and get a usable motor back. There's also the option of having it resleeved.

#12

Honda-Tech Member

bore and hone from a machine shop should not cost that much. couple hundred bucks at the most. you will need to buy oversized pistons for sure.

#13

Join Date: May 2006

Location: California, United States

Posts: 961

Likes: 0

Received 0 Likes

on

0 Posts

It should be around $200 depending on your shop of choice. Here's the thing though, it's very easy to have a very large paper weight if you screw the cylinders up.

The best thing to do is take it to them to see if it's salvagable, then buy pistons, then have the block bored to fit the pistons perfectly. They'll measure the pistons with a mic', add the piston to wall clearance, and then bore the cylinder that size instead of just .020" over.

The best thing to do is take it to them to see if it's salvagable, then buy pistons, then have the block bored to fit the pistons perfectly. They'll measure the pistons with a mic', add the piston to wall clearance, and then bore the cylinder that size instead of just .020" over.

#14

Honda-Tech Member

Join Date: Jul 2004

Location: VA, USA

Posts: 9,846

Likes: 0

Received 0 Likes

on

0 Posts

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by 91SiZ6 »</TD></TR><TR><TD CLASS="quote">It should be around $200 depending on your shop of choice. Here's the thing though, it's very easy to have a very large paper weight if you screw the cylinders up.

The best thing to do is take it to them to see if it's salvagable, then buy pistons, then have the block bored to fit the pistons perfectly. They'll measure the pistons with a mic', add the piston to wall clearance, and then bore the cylinder that size instead of just .020" over.</TD></TR></TABLE>

The best thing to do is take it to them to see if it's salvagable, then buy pistons, then have the block bored to fit the pistons perfectly. They'll measure the pistons with a mic', add the piston to wall clearance, and then bore the cylinder that size instead of just .020" over.</TD></TR></TABLE>

#16

Honda-Tech Member

Thread Starter

Join Date: Dec 2003

Location: Oakland, CA, USA

Posts: 2,979

Likes: 0

Received 0 Likes

on

0 Posts

Arite, im bringing the block to the machine shop, and i know it has to be bore out, but what's a good safe size to bore it out to? 82mm?

#17

Honda-Tech Member

Join Date: May 2003

Location: Portland, Oregon

Posts: 5,735

Likes: 0

Received 0 Likes

on

0 Posts

Haha... back yard hone job

I've actually done that a time or two. Pulled the slugs out, replaced with new pistons (the reason for the rebuild was broken ring lands), honed the **** out of the cylinders, cleaned it up, and tossed it back together. lol

Rebuild took about 5 hours from pulling the car in, to pulling it back out.

Not recommended, but when you are poor like me, you do what you gotta do.

I've actually done that a time or two. Pulled the slugs out, replaced with new pistons (the reason for the rebuild was broken ring lands), honed the **** out of the cylinders, cleaned it up, and tossed it back together. lol

Rebuild took about 5 hours from pulling the car in, to pulling it back out.

Not recommended, but when you are poor like me, you do what you gotta do.

#19

Member

Join Date: Apr 2005

Location: MN, United States

Posts: 1,402

Likes: 0

Received 0 Likes

on

0 Posts

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by 91SiZ6 »</TD></TR><TR><TD CLASS="quote">

The best thing to do is take it to them to see if it's salvagable, then buy pistons, then have the block bored to fit the pistons perfectly. They'll measure the pistons with a mic', add the piston to wall clearance, and then bore the cylinder that size instead of just .020" over.</TD></TR></TABLE>

your supposed to get the pistons before honing a block? um i was thinking you get the block honed first, to get the exact bore size for the pistons and then order the pistons. If not couldnt you just give the machinest the measurement specs of the piston for the deck size and all that other ****?

The best thing to do is take it to them to see if it's salvagable, then buy pistons, then have the block bored to fit the pistons perfectly. They'll measure the pistons with a mic', add the piston to wall clearance, and then bore the cylinder that size instead of just .020" over.</TD></TR></TABLE>

your supposed to get the pistons before honing a block? um i was thinking you get the block honed first, to get the exact bore size for the pistons and then order the pistons. If not couldnt you just give the machinest the measurement specs of the piston for the deck size and all that other ****?

#21

Member

Join Date: Apr 2005

Location: MN, United States

Posts: 1,402

Likes: 0

Received 0 Likes

on

0 Posts

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by 91SiZ6 »</TD></TR><TR><TD CLASS="quote">That's what I've always been told by machinsts. You get a perfect fit if you match the bore to the pistons instead of matching the pistons to the bore.</TD></TR></TABLE>

is a hone ALWAYS .5 over? say you have an ls block. Stock bore is 81mm, but the motor also has 240k miles on it, so theres probably going to be some wear in the cylinders, making that bore diamater different from 81mm correct? and if thats different, how can i be certain the final hone will be 81.5mm ? Thats why i havent ordered pistons yet. Unless im just thinking too hard, the final bore will be 81.5 then?

is a hone ALWAYS .5 over? say you have an ls block. Stock bore is 81mm, but the motor also has 240k miles on it, so theres probably going to be some wear in the cylinders, making that bore diamater different from 81mm correct? and if thats different, how can i be certain the final hone will be 81.5mm ? Thats why i havent ordered pistons yet. Unless im just thinking too hard, the final bore will be 81.5 then?

#22

Join Date: May 2006

Location: California, United States

Posts: 961

Likes: 0

Received 0 Likes

on

0 Posts

Well first, a bore and a hone are two different things. You're talking about overboring which is making the cylinder physically larger in diameter. A hone is just to put file-like marks called a "crosshatch" on the cylinder walls to break the rings in.

No, a bore doesn't always have to be .5mm over, it can also be .25mm over or even larger than .5mm. You need a dial bore gauge to check the roundness of the cylinders, which machine shops have. Generally speaking though, you get perfectly round cylinders with a .5mm overbore. So what you'd do is buy .020"/.5mm over pistons, take them to the machine shop with your block and tell them that you want the block bored to match the pistons. Have the piston to wall clearance handy in case they ask. And the ring gap if you want to have them do that for you as well. It would also be a good time to have the pistons pressed onto their rods. Along with anything else you'd rather have the machine shop do for you.

No, a bore doesn't always have to be .5mm over, it can also be .25mm over or even larger than .5mm. You need a dial bore gauge to check the roundness of the cylinders, which machine shops have. Generally speaking though, you get perfectly round cylinders with a .5mm overbore. So what you'd do is buy .020"/.5mm over pistons, take them to the machine shop with your block and tell them that you want the block bored to match the pistons. Have the piston to wall clearance handy in case they ask. And the ring gap if you want to have them do that for you as well. It would also be a good time to have the pistons pressed onto their rods. Along with anything else you'd rather have the machine shop do for you.

#23

Member

Join Date: Apr 2005

Location: MN, United States

Posts: 1,402

Likes: 0

Received 0 Likes

on

0 Posts

well as of now the cylinders are probably egg shaped. So is the actual .5mm cutting "boring" and the "hone" is just a final touchup cut for the rings? If a typical .5mm bore is plenty to turn the egg shape into an actual circle than yea that is fine.

Was just wondering if it would take more than .5mm to get perfectly round cylinders, and then later find out that the cylinders have a larger diamater than what i expected and the 81.5mm pistons in the ups truck wont fit. Pretty much just want to get it done the first time and not have to reship parts because i ordered them for the wrong specs.

Was just wondering if it would take more than .5mm to get perfectly round cylinders, and then later find out that the cylinders have a larger diamater than what i expected and the 81.5mm pistons in the ups truck wont fit. Pretty much just want to get it done the first time and not have to reship parts because i ordered them for the wrong specs.

#24

Mad Scientist

NO, you get the pistons FIRST; then they get measured at a certain spot and assigned each to a cylinder

PTWC = piston to wall clearance

THEn from there you can measure the cylinder walls wich at 240k are going to be egg shaped a lot.

from there you can bore.

Oem honda has only 81.25 overbore, in the aftermarket you can get 81.5 up to 82 wich would be the biggest i would go with stock sleeves.

DEEDEEDEEE

PTWC = piston to wall clearance

THEn from there you can measure the cylinder walls wich at 240k are going to be egg shaped a lot.

from there you can bore.

Oem honda has only 81.25 overbore, in the aftermarket you can get 81.5 up to 82 wich would be the biggest i would go with stock sleeves.

DEEDEEDEEE

#25

Member

Join Date: Apr 2005

Location: MN, United States

Posts: 1,402

Likes: 0

Received 0 Likes

on

0 Posts

for the compression ratio of the pistons, that all has to do with the gap of the piston to cylinder wall clearance right?

cuz on this site for wiseco pistons, it sais 9:3-9:8 c/r, and i was looking into a 9:5 or 9:6, http://www.nolimitmotorsport.c....html thats the site if that helps

scroll down to b18a1/b1 and the part number K542M815, just wondering how i obtain that 9:6 c/r

thanks

cuz on this site for wiseco pistons, it sais 9:3-9:8 c/r, and i was looking into a 9:5 or 9:6, http://www.nolimitmotorsport.c....html thats the site if that helps

scroll down to b18a1/b1 and the part number K542M815, just wondering how i obtain that 9:6 c/r

thanks