DIY shock dyno

#26

Honda-Tech Member

Join Date: Oct 2004

Location: All over ATL

Posts: 2,088

Likes: 0

Received 0 Likes

on

0 Posts

Glagola,

Are you referring to the wire going to the pivotal point? I guess he could always change the units to radians/sec and then change that to in/sec based on the arm length. The distance the top of the shock is always the same distance away from the pivot and is providing a linear pressure to the shock though.

I haven't broken out a diagram and physics yet, but it seems to me this setup is probably close enough for 'government work'

Are you referring to the wire going to the pivotal point? I guess he could always change the units to radians/sec and then change that to in/sec based on the arm length. The distance the top of the shock is always the same distance away from the pivot and is providing a linear pressure to the shock though.

I haven't broken out a diagram and physics yet, but it seems to me this setup is probably close enough for 'government work'

#27

Honda-Tech Member

Join Date: Jul 2001

Location: atlanta, ga, usa

Posts: 721

Likes: 0

Received 0 Likes

on

0 Posts

Yo meng, it's definately close enough for gubment work. I just wouldn't use these numbers to compare with dyno plots that were done on typical linear dynos.

#30

Honda-Tech Member

Join Date: Jul 2002

Location: Peg City, 204

Posts: 812

Likes: 0

Received 0 Likes

on

0 Posts

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by blaze the chemi »</TD></TR><TR><TD CLASS="quote">I wonder what Penskes look like.</TD></TR></TABLE>

anything you want them to look like. with the selection of pistons avaialble, the sky's the limit basically. I'm putting some used Penskes on my Civic right now, probably going to use the high flow pistons i already have. On the dyno, they look somewhat similar to that Moton. Very linear.

with the selection of pistons avaialble, the sky's the limit basically. I'm putting some used Penskes on my Civic right now, probably going to use the high flow pistons i already have. On the dyno, they look somewhat similar to that Moton. Very linear.

anything you want them to look like.

with the selection of pistons avaialble, the sky's the limit basically. I'm putting some used Penskes on my Civic right now, probably going to use the high flow pistons i already have. On the dyno, they look somewhat similar to that Moton. Very linear.

with the selection of pistons avaialble, the sky's the limit basically. I'm putting some used Penskes on my Civic right now, probably going to use the high flow pistons i already have. On the dyno, they look somewhat similar to that Moton. Very linear.

#31

Honda-Tech Member

Thread Starter

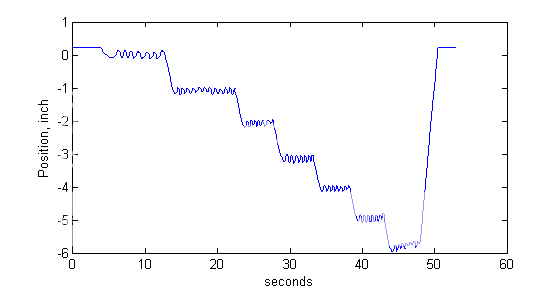

I usually actuate the shock near the middle of its travel, so the arm and piston are nearly perpendicular. Even so, I did a measurement of rotation vs shock displacement, and it was pretty linear anyway.

There are at least two sources of noise in the data that cause the spread. The first is that the velocity measurement is a little bit noisy. I can clean that up if I tweak the electronics a bit, or get a smoother pot, like conductive plastic.

Second, I can analyze out the spread due to shock hysteresis, i.e. turn-around effects. the plots I showed were near the middle of the stroke, but if I plot the full stroke, I can get that double nose feature near the origin, where you can see the difference between the start and end of the rebound stroke.

It's good to be able to do your own data analysis.

There are at least two sources of noise in the data that cause the spread. The first is that the velocity measurement is a little bit noisy. I can clean that up if I tweak the electronics a bit, or get a smoother pot, like conductive plastic.

Second, I can analyze out the spread due to shock hysteresis, i.e. turn-around effects. the plots I showed were near the middle of the stroke, but if I plot the full stroke, I can get that double nose feature near the origin, where you can see the difference between the start and end of the rebound stroke.

It's good to be able to do your own data analysis.

#32

Honda-Tech Member

Thread Starter

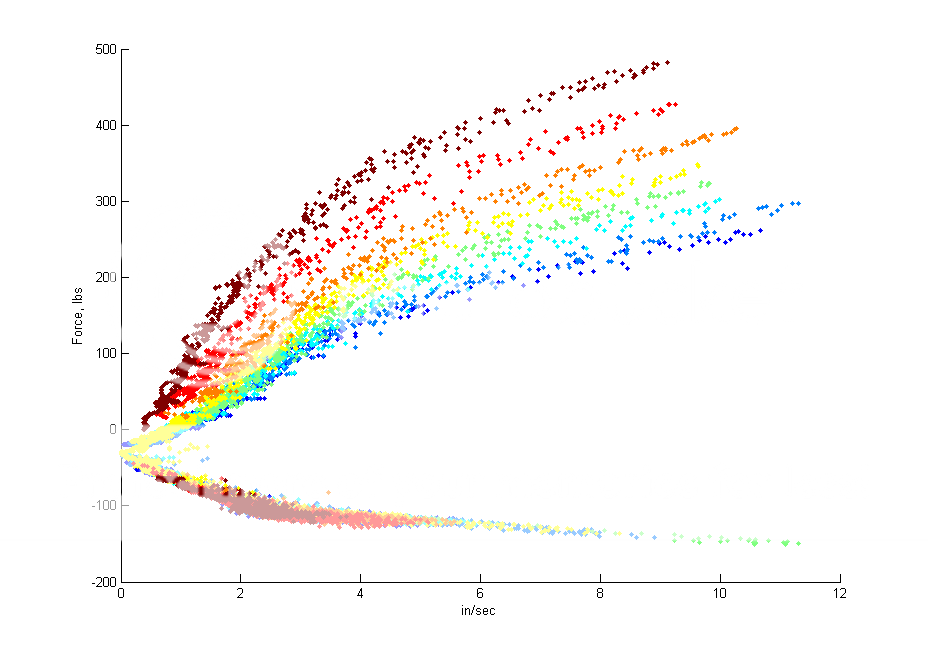

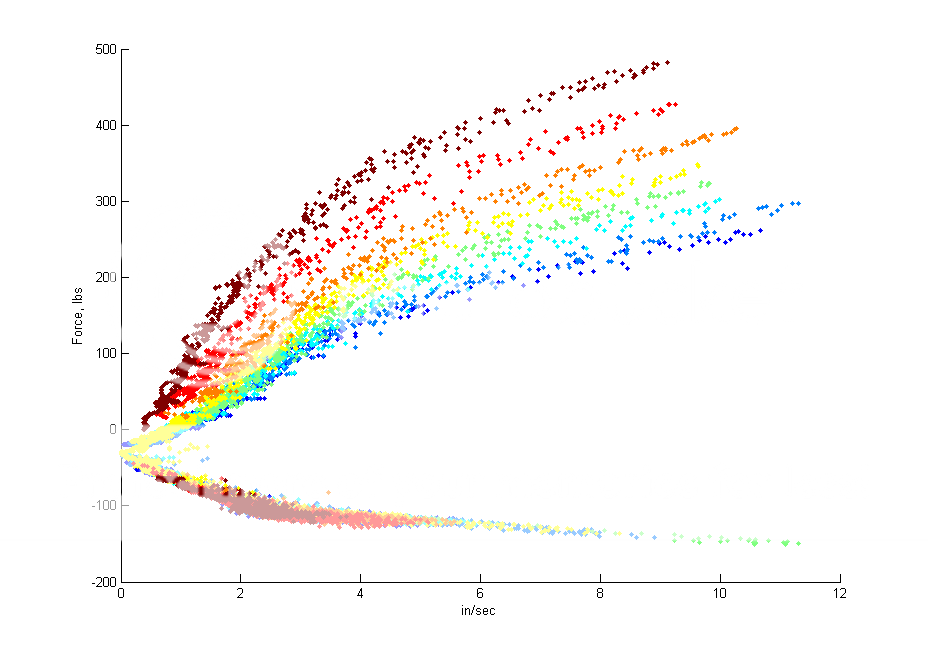

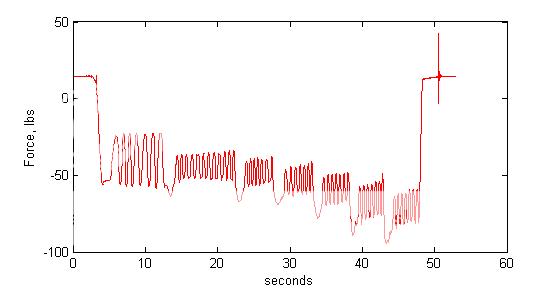

Koni Yellow rear shock 1153.

Looks like it has a much more reasonable compression damping curve than my 8211's. For some reason, the dyno data is a little bit noisier than usual. Maybe it has to do with the fact that I dyno'd this shock with a rubber bushing attached. Maybe because this shock has a skinny body so the hysteresis artifacts are larger? I'm going to drive around on these shocks for a while and see how the feel is compared to the 8211's.

Looks like it has a much more reasonable compression damping curve than my 8211's. For some reason, the dyno data is a little bit noisier than usual. Maybe it has to do with the fact that I dyno'd this shock with a rubber bushing attached. Maybe because this shock has a skinny body so the hysteresis artifacts are larger? I'm going to drive around on these shocks for a while and see how the feel is compared to the 8211's.

#33

Honda-Tech Member

Thread Starter

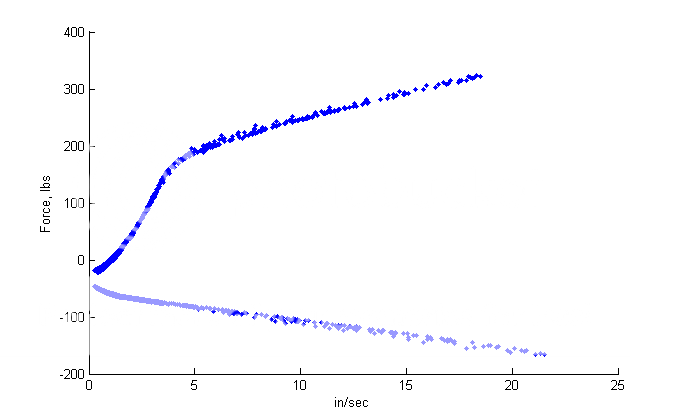

Got a Linear Velocity Transducer off Ebay, so now I can measure velocity directly. Since it's directly mounted to the shock, things like loose bearings, potentiometer noise, differentiation, etc. are a thing of the past.

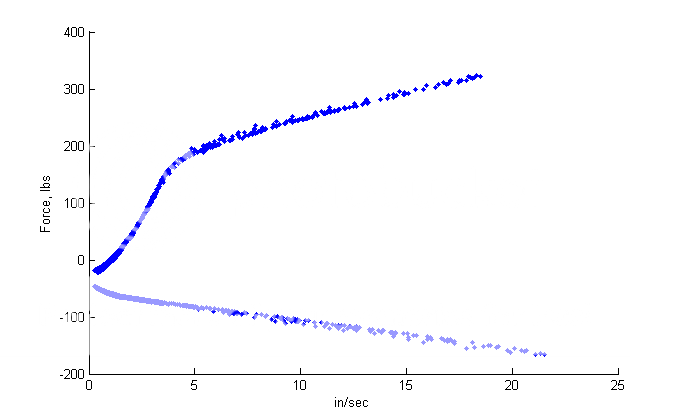

Look at this nice clean data off of a bilstein monotube:

Because of the progressive nature of the air space, I had to do a force vs position compensation.

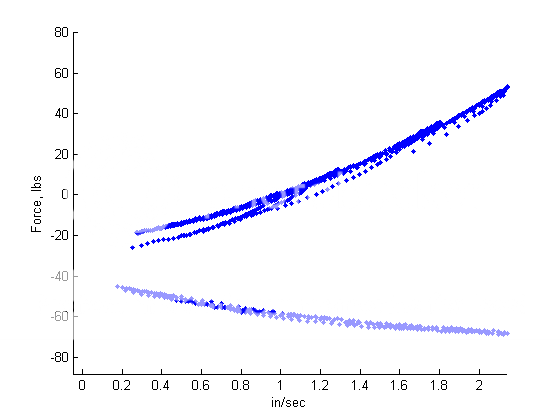

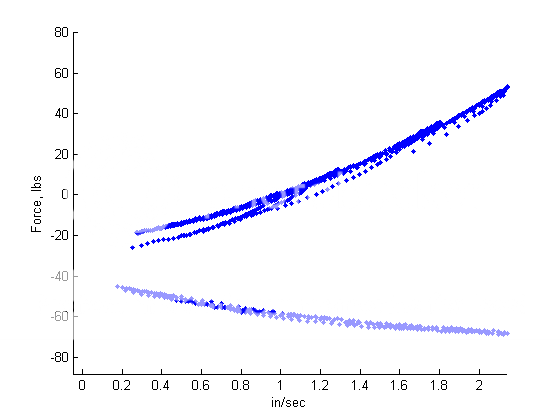

Next is a zoom in of the low speed portion.

Those little branches off of the rebound courve might be due to hysteresis, or maybe seal friction, or something else. I don't know yet.

Note that the rebound curve is progressive and the compression is digressive. That's coz I put a weird shimstack on the piston. This is one of Bilstein's older digressive pistons that has the same bleed for both rebound and compression. This might have to do with some people's complaints that Bilsteins might have too much low speed compression - because it's the same low speed damping as the rebound! Anyway, I put a bleed plate on the rebound side, and a "linear" stack on the compression side that has no "bleed" so to speak, except that I stacked the shims funny such that they would blow off easily.Maybe the slight digressive behavior is characteristic of a "bleedless" shim stack? I dunno. If anybody knows if progressive or digressive behavior at very low speeds is better, please let me know.

Modified by beanbag at 2:47 AM 10/20/2008

Look at this nice clean data off of a bilstein monotube:

Because of the progressive nature of the air space, I had to do a force vs position compensation.

Next is a zoom in of the low speed portion.

Those little branches off of the rebound courve might be due to hysteresis, or maybe seal friction, or something else. I don't know yet.

Note that the rebound curve is progressive and the compression is digressive. That's coz I put a weird shimstack on the piston. This is one of Bilstein's older digressive pistons that has the same bleed for both rebound and compression. This might have to do with some people's complaints that Bilsteins might have too much low speed compression - because it's the same low speed damping as the rebound! Anyway, I put a bleed plate on the rebound side, and a "linear" stack on the compression side that has no "bleed" so to speak, except that I stacked the shims funny such that they would blow off easily.Maybe the slight digressive behavior is characteristic of a "bleedless" shim stack? I dunno. If anybody knows if progressive or digressive behavior at very low speeds is better, please let me know.

Modified by beanbag at 2:47 AM 10/20/2008

#36

Honda-Tech Member

Thread Starter

The vi and m file are kind of application specific.

For the Vi, it just logs three channels on the ADC relating to position (Potentiometer), velocity (LVT), and force (load cell) and saves it to a file.

The M file simply plots force vs velocity and applies various calibration offsets like gas pressure, progressive nature of gas space, seal drag, etc.

For the Vi, it just logs three channels on the ADC relating to position (Potentiometer), velocity (LVT), and force (load cell) and saves it to a file.

The M file simply plots force vs velocity and applies various calibration offsets like gas pressure, progressive nature of gas space, seal drag, etc.

#37

Honda-Tech Member

Join Date: Aug 2002

Location: ashEVILle, NC, USSR

Posts: 4,417

Likes: 0

Received 0 Likes

on

0 Posts

Yah, I know. I have a USB-6009 is why I asked, I wanted to poke at what you'd done.

It'd be kind of nice to script a simple applet that uses the simple $25 DI-194RS for anyone trying to DIY, they're limited to using a transducer that uses analog voltages but that's not a terribly big deal. Also, I propose logging a fourth input of temperature like the Roehrig units do.

I had a local guy show me some dyno charts for his drag car's suspension a month or so ago and my hamster wheel has been spinning since. Thanks for the inspiration, sir, I intend to build one of these and geek out.

It'd be kind of nice to script a simple applet that uses the simple $25 DI-194RS for anyone trying to DIY, they're limited to using a transducer that uses analog voltages but that's not a terribly big deal. Also, I propose logging a fourth input of temperature like the Roehrig units do.

I had a local guy show me some dyno charts for his drag car's suspension a month or so ago and my hamster wheel has been spinning since. Thanks for the inspiration, sir, I intend to build one of these and geek out.

#38

Honda-Tech Member

Thread Starter

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by Joseph Davis »</TD></TR><TR><TD CLASS="quote">Yah, I know. I have a USB-6009 is why I asked, I wanted to poke at what you'd done.

It'd be kind of nice to script a simple applet that uses the simple $25 DI-194RS for anyone trying to DIY, they're limited to using a transducer that uses analog voltages but that's not a terribly big deal. Also, I propose logging a fourth input of temperature like the Roehrig units do.

I had a local guy show me some dyno charts for his drag car's suspension a month or so ago and my hamster wheel has been spinning since. Thanks for the inspiration, sir, I intend to build one of these and geek out.</TD></TR></TABLE>

If you have Labview 8, pm me your email address and I can send it to you.

The DI seems to be a very inexpensive device which would work fine for the dyno, but I also wanted to use a DAQ for my shock velocity datalogging, and the DI doesn't run very fast unless you pay extra for more software.

Logging temperature is also very easy to do, but I wouldn't be willing to put out enough effort to actually heat up the shock any significant amount.

It'd be kind of nice to script a simple applet that uses the simple $25 DI-194RS for anyone trying to DIY, they're limited to using a transducer that uses analog voltages but that's not a terribly big deal. Also, I propose logging a fourth input of temperature like the Roehrig units do.

I had a local guy show me some dyno charts for his drag car's suspension a month or so ago and my hamster wheel has been spinning since. Thanks for the inspiration, sir, I intend to build one of these and geek out.</TD></TR></TABLE>

If you have Labview 8, pm me your email address and I can send it to you.

The DI seems to be a very inexpensive device which would work fine for the dyno, but I also wanted to use a DAQ for my shock velocity datalogging, and the DI doesn't run very fast unless you pay extra for more software.

Logging temperature is also very easy to do, but I wouldn't be willing to put out enough effort to actually heat up the shock any significant amount.

#40

Honda-Tech Member

Thread Starter

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by SlobberGoat »</TD></TR><TR><TD CLASS="quote">Any chance of a youtube vid of it in action?

</TD></TR></TABLE>

</TD></TR></TABLE>

no way

</TD></TR></TABLE>

</TD></TR></TABLE>no way

#42

Honda-Tech Member

Join Date: Aug 2002

Location: ashEVILle, NC, USSR

Posts: 4,417

Likes: 0

Received 0 Likes

on

0 Posts

Are you using an electric motor to actuate the dyno, or...? I was considering using a ~2hp motor, controlled by an AB PowerFlex4; the 2hp flavors can be had for under a hundred on eBay, convert single phase 110 to three phase 220, and can control motor speed up to 400 Hz (6.6 times the plate rating @ 60 Hz). It's a no-brainer, I have one running my lathe as I was sick of fiddling the belt drive to change speeds.

Also, regarding the (inexpensive) DI-194RS from DataQ, it is not subject to needing the $ upgraded WinDaq software for full logging speed; that's the 148/158 series. It's rated at 240 samples/sec single channel and 60 samples/sec per channel when all four channels are utilized.

How fast are you actuating your dyno? I doubt you'd Nyquist a 194RS at that rate, but resolution is a valid concern; as you've noted 6 point graphs in the digital age is a joke.

Thanks for giving me a good idea to copy/run with.

Also, regarding the (inexpensive) DI-194RS from DataQ, it is not subject to needing the $ upgraded WinDaq software for full logging speed; that's the 148/158 series. It's rated at 240 samples/sec single channel and 60 samples/sec per channel when all four channels are utilized.

How fast are you actuating your dyno? I doubt you'd Nyquist a 194RS at that rate, but resolution is a valid concern; as you've noted 6 point graphs in the digital age is a joke.

Thanks for giving me a good idea to copy/run with.

#43

Honda-Tech Member

Thread Starter

Originally Posted by Joseph Davis

Are you using an electric motor to actuate the dyno, or...? I was considering using a ~2hp motor, controlled by an AB PowerFlex4; the 2hp flavors can be had for under a hundred on eBay, convert single phase 110 to three phase 220, and can control motor speed up to 400 Hz (6.6 times the plate rating @ 60 Hz). It's a no-brainer, I have one running my lathe as I was sick of fiddling the belt drive to change speeds.

Also, regarding the (inexpensive) DI-194RS from DataQ, it is not subject to needing the $ upgraded WinDaq software for full logging speed; that's the 148/158 series. It's rated at 240 samples/sec single channel and 60 samples/sec per channel when all four channels are utilized.

How fast are you actuating your dyno? I doubt you'd Nyquist a 194RS at that rate, but resolution is a valid concern; as you've noted 6 point graphs in the digital age is a joke.

Thanks for giving me a good idea to copy/run with.

Also, regarding the (inexpensive) DI-194RS from DataQ, it is not subject to needing the $ upgraded WinDaq software for full logging speed; that's the 148/158 series. It's rated at 240 samples/sec single channel and 60 samples/sec per channel when all four channels are utilized.

How fast are you actuating your dyno? I doubt you'd Nyquist a 194RS at that rate, but resolution is a valid concern; as you've noted 6 point graphs in the digital age is a joke.

Thanks for giving me a good idea to copy/run with.

There's a few benefits to hand actuation.

1. You can immediately tell if you valved a shock "wrong"

2. You can make very small amplitude oscillations to test seal drag and gas pressure

3. You can then make very large range sweeps to test the progressive nature of the gas space (in monotubes). This test is pretty useful to check if you have the dividing piston set at approx the right height. See below. If you can make your motor do this, then that would be good.

As for sampling speed, 60 Hz is fine for "smooth" dyno plots, but high frequency is better if you want to go to other waveforms. I actuate the dyno at most about 4 turn-arounds a second during a "normal" run and maybe up to 8 or more if I intentionally give it a jagged waveform.

Please post back if you ever get around to implementing the motor. That pretty much approaches a "real" dyno.

#44

Honda-Tech Member

Join Date: Apr 2004

Location: Ridgeland, MS, USA

Posts: 153

Likes: 0

Received 0 Likes

on

0 Posts

cool Post...

Never thought I'd see anybody using Labview on HT.

how much did you pay for that Load cell and what are the specs if you don't mind sharing?

I'm a PCB design Engineer by trade so PM me if you need a PCB for that circuit.

Morgan T

Never thought I'd see anybody using Labview on HT.

how much did you pay for that Load cell and what are the specs if you don't mind sharing?

I'm a PCB design Engineer by trade so PM me if you need a PCB for that circuit.

Morgan T

#48

Hi,

Great work, very interesting.

so much so that I fancy having a go myself

The electronics on your board, are they to convert the output from the sensor to a reading which the DAQ card can read properly? Am I right in thinking it needs to be a +/-10v signal?

Are you just using normal labview, or did you need to use the add-on signalexpress?

The metal side of it is no problem, but this is my first foray into datalogging like this.

Thanks in advance for any info

Chris

Great work, very interesting.

so much so that I fancy having a go myself

The electronics on your board, are they to convert the output from the sensor to a reading which the DAQ card can read properly? Am I right in thinking it needs to be a +/-10v signal?

Are you just using normal labview, or did you need to use the add-on signalexpress?

The metal side of it is no problem, but this is my first foray into datalogging like this.

Thanks in advance for any info

Chris

#49

Honda-Tech Member

Thread Starter

The electronics on your board, are they to convert the output from the sensor to a reading which the DAQ card can read properly? Am I right in thinking it needs to be a +/-10v signal?

Are you just using normal labview, or did you need to use the add-on signalexpress?

I am using "normal" labview. SignalExpress is a reduced functionality version of labview that came with the DAQ unit. I haven't used it, but as long as it can log data and output to a text file, it should be fine.

#50

Gotta bump this from the dead - too cool not to.

If I wanted to venture on such a project and copy you, how much would I need to spend on parts minus the frame & laptop. Basically all the bits you had to buy on e-bay, etc.

If I wanted to venture on such a project and copy you, how much would I need to spend on parts minus the frame & laptop. Basically all the bits you had to buy on e-bay, etc.