Pre Turbo + Post Turbo Water Injection / Flow Rates

#1

Ok. So I am having a hard time making up my mind on whether or not to inject post turbo along with pre turbo, or just pre turbo, and how much to inject where.

Please, let’s keep all talk of potential wheel wear blah blah blah out of here. Every case I have seen with wheel wear has been from a system that was not installed properly. If you want to do it right, you need to spray DIRECTLY at the wheel, not into the intake piping. This will ensure that the atomized water goes through the wheel and doesn’t puddle up and get sucked through the walls of the inlet(thus the wheel wear @ the edges). Granted this will happen regardless, but on a much smaller scale if done right.

From my understanding, I want approx. 5-7 GPH(350-450cc) pre turbo, although I am not sure how this will affect my post turbo injection. Do I need to cut back based on the pre turbo injection?

For example:

4gph pre turbo

2gph post

I want the pre turbo to boost the efficiency range of my turbo, and post turbo injection to lower IAT. From my research, pre turbo will lower IAT although not as good.

I have a feeling the answer here is going to be test the system out with different nozzles, but was hoping someone would know.

Thanks for the help!

Here is a good read on a guy who tested the two out individually, but not together: http://www.rx7club.com/auxiliary-inj...esults-987107/

Please, let’s keep all talk of potential wheel wear blah blah blah out of here. Every case I have seen with wheel wear has been from a system that was not installed properly. If you want to do it right, you need to spray DIRECTLY at the wheel, not into the intake piping. This will ensure that the atomized water goes through the wheel and doesn’t puddle up and get sucked through the walls of the inlet(thus the wheel wear @ the edges). Granted this will happen regardless, but on a much smaller scale if done right.

From my understanding, I want approx. 5-7 GPH(350-450cc) pre turbo, although I am not sure how this will affect my post turbo injection. Do I need to cut back based on the pre turbo injection?

For example:

4gph pre turbo

2gph post

I want the pre turbo to boost the efficiency range of my turbo, and post turbo injection to lower IAT. From my research, pre turbo will lower IAT although not as good.

I have a feeling the answer here is going to be test the system out with different nozzles, but was hoping someone would know.

Thanks for the help!

Here is a good read on a guy who tested the two out individually, but not together: http://www.rx7club.com/auxiliary-inj...esults-987107/

#2

Who is Mr Robot?

iTrader: (2)

Join Date: Jul 2004

Location: ATL - Where the Pimps and Players dwell

Posts: 21,474

Likes: 0

Received 10 Likes

on

10 Posts

Pre turbo is a horrible idea. It's heavily documented that pre turbo water injection erodes the compressor wheel away quickly with cast wheels, billet wheels are a little more resilient but will still erode.

if you have a high pressure, high atomization nozzle pointed directly at the center of the wheel/shaft then the erosion is basically elminated. with the wheel tips spinning faster than the speed of sound and with a poor quality nozzle/ poor placement/ too much methanol the droplets hit the wheel and literally dissolve the blades.

think if it like driving through a sand storm with no air filter

4gph is way too much methanol regardless of pre or post turbo.

if you have a high pressure, high atomization nozzle pointed directly at the center of the wheel/shaft then the erosion is basically elminated. with the wheel tips spinning faster than the speed of sound and with a poor quality nozzle/ poor placement/ too much methanol the droplets hit the wheel and literally dissolve the blades.

think if it like driving through a sand storm with no air filter

4gph is way too much methanol regardless of pre or post turbo.

#3

if you have a high pressure, high atomization nozzle pointed directly at the center of the wheel/shaft then the erosion is basically elminated. with the wheel tips spinning faster than the speed of sound and with a poor quality nozzle/ poor placement/ too much methanol the droplets hit the wheel and literally dissolve the blades.

think if it like driving through a sand storm with no air filter

4gph is way too much methanol regardless of pre or post turbo.

4gph is way too much methanol regardless of pre or post turbo.

#4

Who is Mr Robot?

iTrader: (2)

Join Date: Jul 2004

Location: ATL - Where the Pimps and Players dwell

Posts: 21,474

Likes: 0

Received 10 Likes

on

10 Posts

I have experience with it. running high amounts of water after the turbo is fine, before the turbo you can actually inject too much to the point where it starts to pool in the compressor cover.

the nozzle must be centered in relation to the turbine shaft and requires the use of a finely atomizing nozzle. this way the larger droplets hit the shaft nut and hub of the wheel breaking them up.

if you have the nozzle to one side of the wheel the large droplets, whether pure water or not, will erode the wheel.

I'm on my phone right now but when I get home I'll post my pics of eroded compressor wheels from improper nozzle placement (distance from the wheel, relative position within the compressor inlet)/poorly atomized mixture.

I'll also show you the proper setup for pre-turbo injection. aquamist specifically makes a nozzle fixture that places the nozzle in the center of the wheel and is far enough away to allow total atomization. It's actually a really cool piece, I think you'll like it and it could help you visualize proper nozzle height from the wheel and proper placement in relation to the compressor wheel.

like I said the erosion is more profound on cast wheels due to the soft, brittle nature of the material. forged billet wheels are much stronger and they don't suffer erosion as bad

I would start off slow doing pre turbo. maybe 2gph-3gph and see what the atomization pattern is like then go from there and here's why.

injection rate vs shaft speed is also important. you can't dump 3gph+ into the compressor housing at low boost/shaft speeds, it will pool in the housing. you need to have the injection amount slowly increase in relation to shaft speed. so basically have your ecu or pump controller start injecting at whatever psi you designate and set the maximum injection rate for whatever boost level your maximum would be.

I wouldn't run your maximum injection amount until the turbo reaches full boost, that way you're making sure the injection mixture properly atomizes and doesn't pool within the housing.

the nozzle must be centered in relation to the turbine shaft and requires the use of a finely atomizing nozzle. this way the larger droplets hit the shaft nut and hub of the wheel breaking them up.

if you have the nozzle to one side of the wheel the large droplets, whether pure water or not, will erode the wheel.

I'm on my phone right now but when I get home I'll post my pics of eroded compressor wheels from improper nozzle placement (distance from the wheel, relative position within the compressor inlet)/poorly atomized mixture.

I'll also show you the proper setup for pre-turbo injection. aquamist specifically makes a nozzle fixture that places the nozzle in the center of the wheel and is far enough away to allow total atomization. It's actually a really cool piece, I think you'll like it and it could help you visualize proper nozzle height from the wheel and proper placement in relation to the compressor wheel.

like I said the erosion is more profound on cast wheels due to the soft, brittle nature of the material. forged billet wheels are much stronger and they don't suffer erosion as bad

I would start off slow doing pre turbo. maybe 2gph-3gph and see what the atomization pattern is like then go from there and here's why.

injection rate vs shaft speed is also important. you can't dump 3gph+ into the compressor housing at low boost/shaft speeds, it will pool in the housing. you need to have the injection amount slowly increase in relation to shaft speed. so basically have your ecu or pump controller start injecting at whatever psi you designate and set the maximum injection rate for whatever boost level your maximum would be.

I wouldn't run your maximum injection amount until the turbo reaches full boost, that way you're making sure the injection mixture properly atomizes and doesn't pool within the housing.

#5

Thanks for the info. I think i know what mount you are talking about.

This one? http://www.aquamist.co.uk/forum/gall...ecooler/14.jpg

I reached out to alcohol-injection.com(Devils own) and was advised ideal flow would be 4gph total, and to break it up so total injection does not surpass 4gph~.

I think i will buy a few nozzles and play with it, i guess there is no other real way to do it.

Most likely will start with 2-3gph pre and 1-2gph post intercooler.

and yes post them pics! but just goes to show if its done right, you should be good.

This one? http://www.aquamist.co.uk/forum/gall...ecooler/14.jpg

I reached out to alcohol-injection.com(Devils own) and was advised ideal flow would be 4gph total, and to break it up so total injection does not surpass 4gph~.

I think i will buy a few nozzles and play with it, i guess there is no other real way to do it.

Most likely will start with 2-3gph pre and 1-2gph post intercooler.

and yes post them pics! but just goes to show if its done right, you should be good.

#6

Who is Mr Robot?

iTrader: (2)

Join Date: Jul 2004

Location: ATL - Where the Pimps and Players dwell

Posts: 21,474

Likes: 0

Received 10 Likes

on

10 Posts

Yea that's the one. it really is a nice piece and the airfoil design of the three legs shpuldnt interfere with overall flow.

there's another one a company makes for 4" inlet turbos (or it was 5" to sit in the airbox elbow to the turbo) on diesel applications. it has the nozzle cone physically machined into center and braces, I think a total of 8.

there's a few videos of it, it atomizes the water mixture so finely it looks like fog, seriously lol. I think they said they are using injection pressures of 800-1000psi maximum. I'm not sure how they get pressure that high unless they are using some sort of engine driven pump (maybe a modified injection pump?) but I would imagine that much pressure, while good for atomization, probably kills flow.

I've been meaning to email them to see if they can make it for smaller inlet turbos. it installs just like the aquamist piece. also to verify the pressure at which it will still atomize well and to find out how they get pressures that high lol

I'll post the videos if I can find them, it's absurd how much it atomizes the mixture.

there's another one a company makes for 4" inlet turbos (or it was 5" to sit in the airbox elbow to the turbo) on diesel applications. it has the nozzle cone physically machined into center and braces, I think a total of 8.

there's a few videos of it, it atomizes the water mixture so finely it looks like fog, seriously lol. I think they said they are using injection pressures of 800-1000psi maximum. I'm not sure how they get pressure that high unless they are using some sort of engine driven pump (maybe a modified injection pump?) but I would imagine that much pressure, while good for atomization, probably kills flow.

I've been meaning to email them to see if they can make it for smaller inlet turbos. it installs just like the aquamist piece. also to verify the pressure at which it will still atomize well and to find out how they get pressures that high lol

I'll post the videos if I can find them, it's absurd how much it atomizes the mixture.

#7

Moderator

iTrader: (14)

Excellent article to consider as you both discuss this.

http://www.alcoholinjectionsystems.c...icle_info.html

Devil's Own

http://www.alcohol-injection.com/en/...jection-nozzle

http://www.alcoholinjectionsystems.c...icle_info.html

Devil's Own

http://www.alcohol-injection.com/en/...jection-nozzle

Last edited by TheShodan; 05-14-2014 at 07:13 PM.

Trending Topics

#9

Thanks TheShodan for the links.

For the record, DevilsOwn recomends 4gph TOTAL for 50/50 water/meth.

so whether its broken up pre/post or just post, 4gph total injection.

building my kit. mcmaster has most of the parts i need minus the pump, also have a friend who works there so can you say discount!?

only thing i need to figure out is pre turbo mounting of the nozzle. whats the size of your inlet? maybe we can do a 2 piece order and get a discount...

For the record, DevilsOwn recomends 4gph TOTAL for 50/50 water/meth.

so whether its broken up pre/post or just post, 4gph total injection.

building my kit. mcmaster has most of the parts i need minus the pump, also have a friend who works there so can you say discount!?

only thing i need to figure out is pre turbo mounting of the nozzle. whats the size of your inlet? maybe we can do a 2 piece order and get a discount...

#10

Who is Mr Robot?

iTrader: (2)

Join Date: Jul 2004

Location: ATL - Where the Pimps and Players dwell

Posts: 21,474

Likes: 0

Received 10 Likes

on

10 Posts

Sorry today was a clusterfuck. when i get home I'll dig out the super awesome pre turbo water/meth injection literature lol.

I should end up running an 8374 or 9180 EFR, both have a 4" ported shroud inlet. I will be using methanol though so I might have the compressor housing hard coat anodized to protect it (or ceramic coating more than likely). I would anodize the compressor wheel but taking apart a super expensive brand new turbo apart and voiding what little warranty it had doesn't sound like fun.

I should end up running an 8374 or 9180 EFR, both have a 4" ported shroud inlet. I will be using methanol though so I might have the compressor housing hard coat anodized to protect it (or ceramic coating more than likely). I would anodize the compressor wheel but taking apart a super expensive brand new turbo apart and voiding what little warranty it had doesn't sound like fun.

#12

Who is Mr Robot?

iTrader: (2)

Join Date: Jul 2004

Location: ATL - Where the Pimps and Players dwell

Posts: 21,474

Likes: 0

Received 10 Likes

on

10 Posts

Yea I'm compiling all of it right now... what I'm noticing is more people are using the aquamist ring or machining something similar on their own. I've found really good examples of what not to do and how to properly setup pre and post turbo injection, whether it's at the inlet, in the volute (possibly better than the inlet because there's no risk of wheel erosion and it still cools down the compressed air in the housing) to how to properly setup direct port runner injection.

it's going to take me a few hours to get it together but just a heads up, it's going to be one stupidly long post, I may break it down into smaller individual posts. I don't think people want to read a single post that's three pages long lol. hell HT might limit the size.

I'll basically start with what not to do and the results, how to do it that's proven, and how people are coming up with new ideas that could work better with little to no component wear.

I also found that 8 nozzle ifog thing for the duramax I was talking about. it's designed for a 4" inlet and they place it over the turbo inlet or in the intake elbow. you could still use this piece, which is less than 300$ and simply run a 4" air filter on an intake arm and utilize it. I still need to ask them how they are producing 1000psi at the nozzle.. maybe they are staging pumps one in front of the other like we do with inline fuel pumps. that's the only way I see high pressure, by each pump multiplying the pressure it receives. I still don't know how they get around the internal pressure bypass valve the typical pump has, maybe they block it off.

it's going to take me a few hours to get it together but just a heads up, it's going to be one stupidly long post, I may break it down into smaller individual posts. I don't think people want to read a single post that's three pages long lol. hell HT might limit the size.

I'll basically start with what not to do and the results, how to do it that's proven, and how people are coming up with new ideas that could work better with little to no component wear.

I also found that 8 nozzle ifog thing for the duramax I was talking about. it's designed for a 4" inlet and they place it over the turbo inlet or in the intake elbow. you could still use this piece, which is less than 300$ and simply run a 4" air filter on an intake arm and utilize it. I still need to ask them how they are producing 1000psi at the nozzle.. maybe they are staging pumps one in front of the other like we do with inline fuel pumps. that's the only way I see high pressure, by each pump multiplying the pressure it receives. I still don't know how they get around the internal pressure bypass valve the typical pump has, maybe they block it off.

#13

Sounds good man, i love researching this stuff.

Here is another great read, and i think this is the same system you are talking about, atlhough only 4 nozzles not 8. (after watching the video, i see that the nozzles are double sided= same as 8)

http://killerbeeperformance.com/indu...cooling/i-fog/

http://killerbeeperformance.com/download/ifog/i-fog.pdf

I have an idea for a mount. Create a mold and build an aluminum furnace, melt, pour, and thats that! Wonder how well this would work out

Here is another great read, and i think this is the same system you are talking about, atlhough only 4 nozzles not 8. (after watching the video, i see that the nozzles are double sided= same as 8)

http://killerbeeperformance.com/indu...cooling/i-fog/

http://killerbeeperformance.com/download/ifog/i-fog.pdf

I have an idea for a mount. Create a mold and build an aluminum furnace, melt, pour, and thats that! Wonder how well this would work out

#14

Who is Mr Robot?

iTrader: (2)

Join Date: Jul 2004

Location: ATL - Where the Pimps and Players dwell

Posts: 21,474

Likes: 0

Received 10 Likes

on

10 Posts

Yea that's what I was talking about.

I've decided to make a more detailed write up on pre turbo, post turbo, and intake manifold injection. so it's taking a little longer to get done

I've decided to make a more detailed write up on pre turbo, post turbo, and intake manifold injection. so it's taking a little longer to get done

#15

Who is Mr Robot?

iTrader: (2)

Join Date: Jul 2004

Location: ATL - Where the Pimps and Players dwell

Posts: 21,474

Likes: 0

Received 10 Likes

on

10 Posts

Ok, so after lots of internet trolling for images of certain examples I think I've finally gotten a good representation of what to do and what not to do for various water water/methanol injection systems

PRE TURBO INJECTION

Pre-turbo injection is basically anything injected within the intake tract before the compressor wheel of the turbocharger.

Typically you want to use an atomization nozzle positioned in the center of the intake and at least 10" from the compressor wheel itself. This allows the water or water/methanol mixture plenty of time to atomize evenly, reducing the erosion effects that we've all seen on cast compressor wheels.

Now in regards to compressor wheel erosion, it only seems to be prolific on turbochargers that have cast compressor wheels. Forged billet wheels are much stronger and traditionally don't show the same kind of erosion that cast wheels do.

That being said, even a properly installed pre-turbo injection system will still cause some erosion. it is normal very minimal. I'll show you examples later on.

Also it is worth noting that you cannot use a fuel pump nor a fuel injector for water injection... Yes people have asked and tried... and failed.

Gasoline as a liquid (and any other hydrocarbon chain fuel) is not electrically conductive. If you notice that the fuel pump connections and fuel sender connections are not insulated from fuel. Also in a typical tank or inline mounted fuel pump the fuel is used to both lubricate and cool the pump. This means the fuel physically flows around and through the armature and brushes of the pump. Despite electrical current passing from the brush to the armature and causing a spark the fuel doesn't ignite.

Using water will seize up a fuel pump and injector with a quickness.

That being said people have used fuel pumps and fuel injectors for various styles of injection utilizing pure methanol. I have examples of this as well.

WHAT NOT TO DO

so this should be pretty self explanatory

Don't have the nozzle offset to one side of the compressor wheel

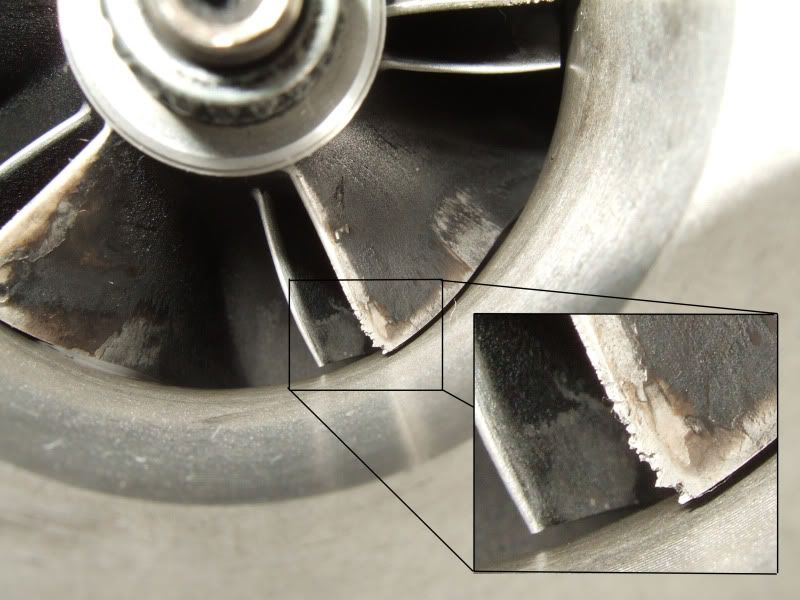

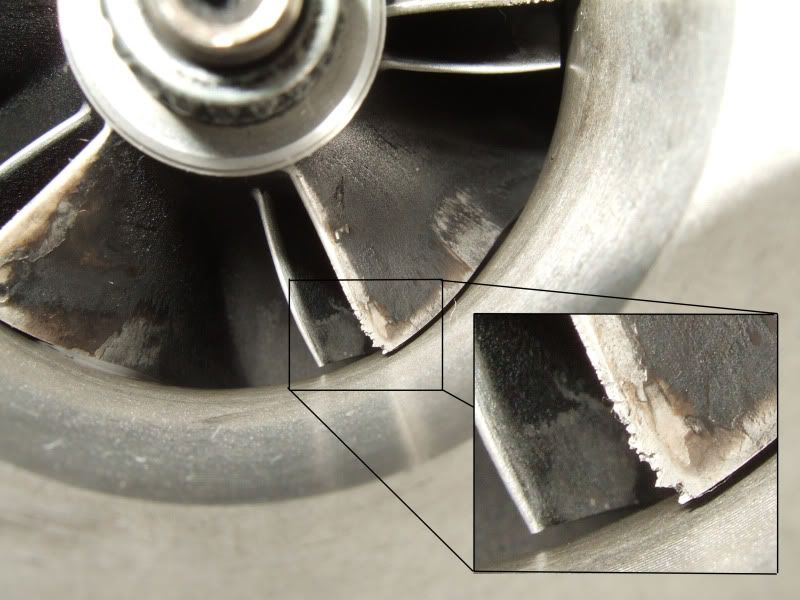

If you run the nozzle like these examples then in a very short period of time this will happen

or this

or at worst, this.

This is where he had his nozzle

this kind of compressor wheel erosion is due to either

A) improper nozzle placement in relation to the compressor wheel

B) running the wrong nozzle style and size for a given location and power level

C) over injection

D) improper system pressure resulting in poor atomization, large droplets sandblast compressor wheels

E) a combination of the above.

PROPER EXAMPLES OF PRE TURBO INJECTION

This is how it should be done, either with the nozzle centered with the compressor wheel, or having a nozzle a minimum of 8-10 inches from the compressor wheel or having a nozzle within the air filter itself

examples

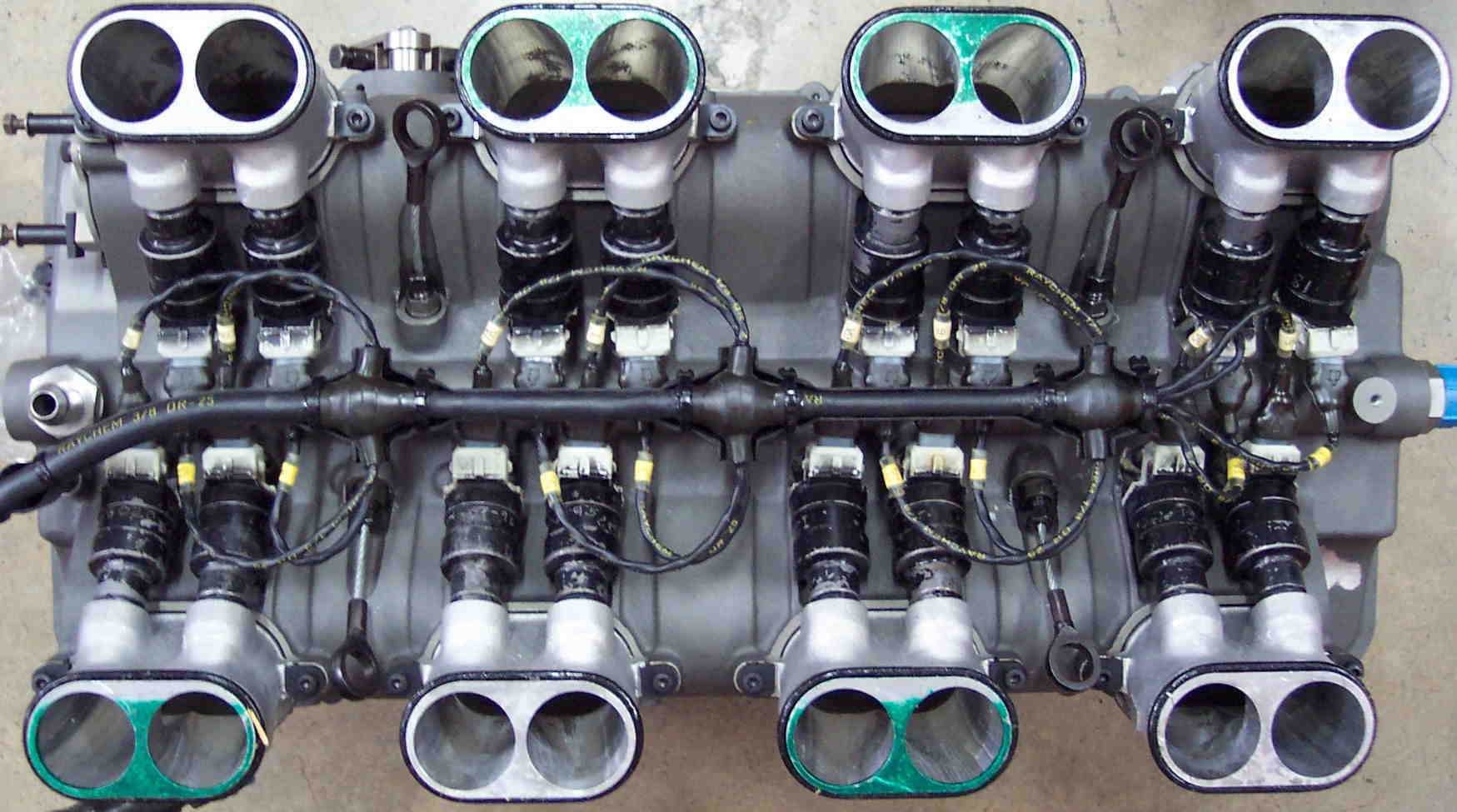

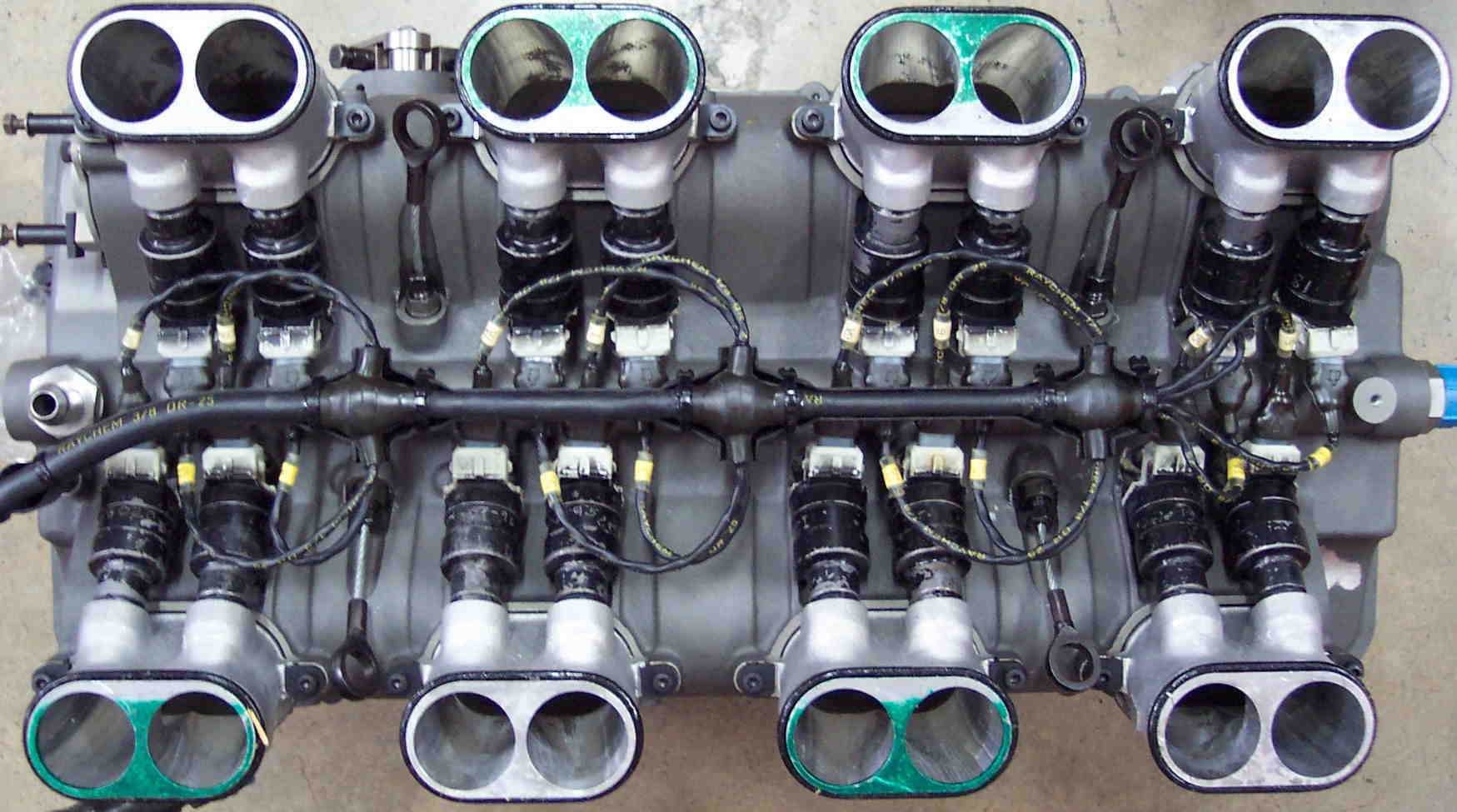

Here's the setup used on LOLA's Cosworth XB powered Champ car running pure methanol. They use a ring of side-feed injectors to inject a finely atomized mist of pure methanol into the compressor wheel. I have a turbo like this with a forged Titanium, teflon coated compressor wheel, I really want to try a setup like this.

The XB intake manifold with pure methanol port injection (the little black and silver things between each set of injectors

QUESTIONABLE METHOD

I stumbled across this image on a diesel performance website

While running a billet compressor wheel does eliminate most of the erosion issues, having this nozzle facing away from the wheel can have serious consequences. While I can understand pointing the nozzle away from the wheel gives more time for the mixture to atomize, when running at high boost/airflow levels air can be moving so fast past the nozzle that it sucks it backwards before it can atomize, causing huge droplets to hit the weakest part of the compressor wheel, the edge

COMPRESSOR WHEEL EROSION

Here are examples of what you can expect to see as far as compressor wheel wear with proper pre-turbo injection systems. The photos show roughly 2 years of pre-turbo injection use.

PRE TURBO INJECTION

Pre-turbo injection is basically anything injected within the intake tract before the compressor wheel of the turbocharger.

Typically you want to use an atomization nozzle positioned in the center of the intake and at least 10" from the compressor wheel itself. This allows the water or water/methanol mixture plenty of time to atomize evenly, reducing the erosion effects that we've all seen on cast compressor wheels.

Now in regards to compressor wheel erosion, it only seems to be prolific on turbochargers that have cast compressor wheels. Forged billet wheels are much stronger and traditionally don't show the same kind of erosion that cast wheels do.

That being said, even a properly installed pre-turbo injection system will still cause some erosion. it is normal very minimal. I'll show you examples later on.

Also it is worth noting that you cannot use a fuel pump nor a fuel injector for water injection... Yes people have asked and tried... and failed.

Gasoline as a liquid (and any other hydrocarbon chain fuel) is not electrically conductive. If you notice that the fuel pump connections and fuel sender connections are not insulated from fuel. Also in a typical tank or inline mounted fuel pump the fuel is used to both lubricate and cool the pump. This means the fuel physically flows around and through the armature and brushes of the pump. Despite electrical current passing from the brush to the armature and causing a spark the fuel doesn't ignite.

Using water will seize up a fuel pump and injector with a quickness.

That being said people have used fuel pumps and fuel injectors for various styles of injection utilizing pure methanol. I have examples of this as well.

WHAT NOT TO DO

so this should be pretty self explanatory

Don't have the nozzle offset to one side of the compressor wheel

If you run the nozzle like these examples then in a very short period of time this will happen

or this

or at worst, this.

This is where he had his nozzle

this kind of compressor wheel erosion is due to either

A) improper nozzle placement in relation to the compressor wheel

B) running the wrong nozzle style and size for a given location and power level

C) over injection

D) improper system pressure resulting in poor atomization, large droplets sandblast compressor wheels

E) a combination of the above.

PROPER EXAMPLES OF PRE TURBO INJECTION

This is how it should be done, either with the nozzle centered with the compressor wheel, or having a nozzle a minimum of 8-10 inches from the compressor wheel or having a nozzle within the air filter itself

examples

Here's the setup used on LOLA's Cosworth XB powered Champ car running pure methanol. They use a ring of side-feed injectors to inject a finely atomized mist of pure methanol into the compressor wheel. I have a turbo like this with a forged Titanium, teflon coated compressor wheel, I really want to try a setup like this.

The XB intake manifold with pure methanol port injection (the little black and silver things between each set of injectors

QUESTIONABLE METHOD

I stumbled across this image on a diesel performance website

While running a billet compressor wheel does eliminate most of the erosion issues, having this nozzle facing away from the wheel can have serious consequences. While I can understand pointing the nozzle away from the wheel gives more time for the mixture to atomize, when running at high boost/airflow levels air can be moving so fast past the nozzle that it sucks it backwards before it can atomize, causing huge droplets to hit the weakest part of the compressor wheel, the edge

COMPRESSOR WHEEL EROSION

Here are examples of what you can expect to see as far as compressor wheel wear with proper pre-turbo injection systems. The photos show roughly 2 years of pre-turbo injection use.

#16

Who is Mr Robot?

iTrader: (2)

Join Date: Jul 2004

Location: ATL - Where the Pimps and Players dwell

Posts: 21,474

Likes: 0

Received 10 Likes

on

10 Posts

One thing to keep in mind:

Anytime you inject methanol before the throttle body and you have a blow off valve that vents to atmosphere you will be venting methanol vapor laden air out of the valve...

be sure that the valve doesn't point towards any potential heat or ignition source or could have a severe fire hazard

Anytime you inject methanol before the throttle body and you have a blow off valve that vents to atmosphere you will be venting methanol vapor laden air out of the valve...

be sure that the valve doesn't point towards any potential heat or ignition source or could have a severe fire hazard

#18

Who is Mr Robot?

iTrader: (2)

Join Date: Jul 2004

Location: ATL - Where the Pimps and Players dwell

Posts: 21,474

Likes: 0

Received 10 Likes

on

10 Posts

I'm going to finish up the rest of this tonight when I'm done at the other house.

I'm going to do a post for each injection location with what not to do/what to do photos and result photos. I figure that will help everyone grasp the different concepts behind injecting in each spot.

I will then do a text post that gets into more detail regarding the theory behind each method, what fluids to inject where, the molecular chemistry and physics behind what happens, as well as debunk some popular myths around water, water/methanol, and pure methanol injection.

I've also emailed Richard with Aquamist in the UK to see if he can help provide reasoning and a formula for pre turbo injection flow rates based on turbo size, horsepower/airflow, and boost levels.

Aquamists injection standard for pre throttle body/intake manifold direct port injection is 1cc-2cc per minute for every brake horsepower or approximately .02-.03 gallons per hour.

so for a 400bhp car you would inject a minimum of 400cc (6.34gph) and a maximum of 800cc (12.68gph)

However there has to be some practical limit because over injection will saturate the intake charge and the fluid being injected will no longer atomize and evaporate, it would stay in a liquid state. this can lead to puddling within the intake tract and having liquid stick to the walls of the charge piping and the intake manifold.

this is dangerous.. it can lead to hydrolocking an engine, bending valves, and if there's a backfire using methanol then it will blow the intake manifold apart and cause severe damage or even injury or death. I have a photo of a mk4 supra that was running a lot of methanol injection and the motor backfired and it ripped the plenum apart.

the explosion is similar to a nitrous backfire.

I'm going to do a post for each injection location with what not to do/what to do photos and result photos. I figure that will help everyone grasp the different concepts behind injecting in each spot.

I will then do a text post that gets into more detail regarding the theory behind each method, what fluids to inject where, the molecular chemistry and physics behind what happens, as well as debunk some popular myths around water, water/methanol, and pure methanol injection.

I've also emailed Richard with Aquamist in the UK to see if he can help provide reasoning and a formula for pre turbo injection flow rates based on turbo size, horsepower/airflow, and boost levels.

Aquamists injection standard for pre throttle body/intake manifold direct port injection is 1cc-2cc per minute for every brake horsepower or approximately .02-.03 gallons per hour.

so for a 400bhp car you would inject a minimum of 400cc (6.34gph) and a maximum of 800cc (12.68gph)

However there has to be some practical limit because over injection will saturate the intake charge and the fluid being injected will no longer atomize and evaporate, it would stay in a liquid state. this can lead to puddling within the intake tract and having liquid stick to the walls of the charge piping and the intake manifold.

this is dangerous.. it can lead to hydrolocking an engine, bending valves, and if there's a backfire using methanol then it will blow the intake manifold apart and cause severe damage or even injury or death. I have a photo of a mk4 supra that was running a lot of methanol injection and the motor backfired and it ripped the plenum apart.

the explosion is similar to a nitrous backfire.

#21

Who is Mr Robot?

iTrader: (2)

Join Date: Jul 2004

Location: ATL - Where the Pimps and Players dwell

Posts: 21,474

Likes: 0

Received 10 Likes

on

10 Posts

Thanks.

I try to share my knowledge and experience with others in the hopes it helps at least one person lol

I'm finding it hard, at least for me (genius iq can be a bitch lol), to simplify the theory, principles, and concepts of methanol injection.

I'm afraid if I don't put it in layman's terms just just right then the uninitiated will get lost in a huge mess of chemistry, physics, and technical terms. I need to get to the point where most people can read this thread and hopefully grasp some of the content.

I try to share my knowledge and experience with others in the hopes it helps at least one person lol

I'm finding it hard, at least for me (genius iq can be a bitch lol), to simplify the theory, principles, and concepts of methanol injection.

I'm afraid if I don't put it in layman's terms just just right then the uninitiated will get lost in a huge mess of chemistry, physics, and technical terms. I need to get to the point where most people can read this thread and hopefully grasp some of the content.

#23

Who is Mr Robot?

iTrader: (2)

Join Date: Jul 2004

Location: ATL - Where the Pimps and Players dwell

Posts: 21,474

Likes: 0

Received 10 Likes

on

10 Posts

Yea sorry for the delays.

I'm having to invest way too much time in our house fire repairs drama (fire was April 6 2012) and the house still isn't done... we are trying to get the house on the market but we can't find ccontractors who will actually do what the say they will.

and it looks like I've caught my 2nd case of food poisoning ever... last time was a good 10 years ago, this time it was apparently bad Yellowfin sashimi. FML

I'm having to invest way too much time in our house fire repairs drama (fire was April 6 2012) and the house still isn't done... we are trying to get the house on the market but we can't find ccontractors who will actually do what the say they will.

and it looks like I've caught my 2nd case of food poisoning ever... last time was a good 10 years ago, this time it was apparently bad Yellowfin sashimi. FML

#25

Who is Mr Robot?

iTrader: (2)

Join Date: Jul 2004

Location: ATL - Where the Pimps and Players dwell

Posts: 21,474

Likes: 0

Received 10 Likes

on

10 Posts

Honestly I'm debating about letting it burn again lol. the house didn't even burn down and it still isn't done. the irony of the whole thing is had the house burned to foundation they could have rebuilt the whole house twice by now.

I've been having to babysit the contractors doing the repairs and the guys the realtor has doing cosmetic stuff. I shouldn't have to watch everyone to make sure they are doing their job. the outside of our house just got painted and it looks like a cheetahs fur... thin spots and splotches all over where I can see the old paint, they dug up all of our plants when they mulched our beds... plants we imported from the UK, Japan, Australia, etc. that I've kept alive for the last 10+ years, just mowed down over 10k in plants. then he fucked up laying sod

blah blah blah.

I've been there for the last week everyday. today I was there from like noon to 8pm and i have to go back tomorrow too. hopefully by mid Monday I won't have to deal with the house for a while so I can finish this.

I've been working on it here and there when I can but not enough to make any real progress.

soon hopefully.

I've been having to babysit the contractors doing the repairs and the guys the realtor has doing cosmetic stuff. I shouldn't have to watch everyone to make sure they are doing their job. the outside of our house just got painted and it looks like a cheetahs fur... thin spots and splotches all over where I can see the old paint, they dug up all of our plants when they mulched our beds... plants we imported from the UK, Japan, Australia, etc. that I've kept alive for the last 10+ years, just mowed down over 10k in plants. then he fucked up laying sod

blah blah blah.

I've been there for the last week everyday. today I was there from like noon to 8pm and i have to go back tomorrow too. hopefully by mid Monday I won't have to deal with the house for a while so I can finish this.

I've been working on it here and there when I can but not enough to make any real progress.

soon hopefully.