H23VTEC Turbo build with tech by ludesleep

#1

Honda-Tech Member

Thread Starter

Join Date: Feb 2003

Location: Texas ATM Aggie, Tx, 77840

Posts: 1,491

Likes: 0

Received 0 Likes

on

0 Posts

Well first off I wanna give a shout out to Satan, Firedrake, Boostless97lude and BEER30 especially for helping me build it and watching my back

<U>Head=h22a</U>

SuperTech valve train

custom valve job by me

custom port and chamber work by me

Golden Eagle cam gears

Custom Intake mani

1000cc injectors Delfi

Golden Eagle Rail

Stock Cams

Roller Rocker "coming soon"

<U>Block=H23a</U>

Golden Eagle sleeved

89mm bore

custom race hone by me

Endyn rollerwave pistons

Crower rods

Arp studs top and bottom, oil pan, flywheel

Golden Eagle sandwich

Moroso Pan

<U>Turbo Stuff</U>

Precision Pt-61

Aeromotive fuel

Lovefab SST

Tial 44mm wg

Tial bov

Intercooler

Cromepro or Neptune RTP**still waiting**

**Things I plan to fab myself or have already done so**

Solid aluminum 6061 motor mounts 30%

Vacuum manifold 100% complete

Traction bar 0%

Lots more to see in pics

I started this build three years ago and it just now coming to an end. I decided to go with a stationary engine(89mm bore 95mm stroke) which is a under-square piston-to-stroke configuration, meaning that the piston's diameter is smaller than the length of its stroke. Stationary engine produce generous amounts of low speed torque because of the long stroke. Remember Archimedes and his lever? Acrhimedes stated, "Give me a lever long enough and a place to stand and I will move the world" These engine are a good illustration of that lever's power.

Station ary engine have specific power output requirements because they are designed to run at a steady state, or within a defined rpm range.

Many shops have their "hone job"....I have mine. Many people over look the importance of a good hone. Having a good plateau finish is the key to every race hone. A plateau finish is essentially one where the tops of the peaks have been shaved off hence the "plateau" to provide a better surface for the rings. It has a controlled amount of texture remaining from both a course and fine grit honing process. Such a bore finish is equivalent to a broken in cylinder where the rough peaks, folded and torn metal left by conventional honing techniques have been shaved off by the rings, leaving a plateau like surface that provides adequate bearing area, yet retains its crosshatch for proper oil control and lubrication. This reduces ring wear when the engine is started for the first time, and allows the rings to seat within a few minutes. The result is longer ring and cylinder life, reduced blow-by and better oil control.

What Im about to tell you will solve the big mystery of "Is there really a such thing as a break in period" YES.....AND NO! Most shops try to stick by the Honda OEM hone which is basically for longer life. Honda uses a a very rough hone at finish that develop a plateau finish on its own as the rings scrub off the peaks left on the wall by honing. This ends up leaving alot of debris in the oil that can cause wear elsewhere in the engine. What's more, it wears the rings and cylinder unnecessarily. Almost all piston rings today come prelapped from the factory. Consequently, they do not have to scrub away at the cylinder bores to wear off the rough edges in order to create a gas tight seal between the combustion chamber and crankcase. The rings are essentially preseated and do not require a rough cylinder bore finish. In fact, a rough cylinder bore can be very detrimental to a new set of rings. If the surface finish is too rough, the rings will scuff and wear, giving a poor seal, resulting in reduced service life and high oil consumption. So why not produce the plateau finish in the beginning by using a special honing procedure that produces a prebroken in cylinder?

Improperly fitted bearings caused by runout in the connecting rod bores can cause recognizable failure itself. Problems can range from oil starvation and subsequent scoring of the cylinder walls, piston and rings, to excess oil throw off , leading to severe oil consumption of the engine. The connecting rod bores must be straight and square, onsize, maintain correct distance between each rod. To maintain all of these prerequisites, bearing housing and pin bores are reconditioned by boring or honing, or a combination of the two.

Next I wanna talk about align-honing and the importance of this process. I read on honda-tech and hear it alot that this process isn't that critical...well the truth is it is very crucial and is one of the most important considerations to make. I think alot of times people are confusing align-boring with the alighone process. The align-honing process is very different than the align-boring method because the housing bores are honed round and true with a mandrel, instead of bored to size with a tool bit which is normally only performed when new main caps are installed or spun main bearing repair. If the procedure is not performed it will lead to scuffed pistons, ineffective ring to cylinder wall sealing, cylinder head to block alignment, and uneven compression rations from one end to the block to the other. Imagine the rod trying to force its way along a straight path in the cylinder only to be pushed off center because the bore is not ninety degrees to the crank. Now.....some will say "I didn't align-hone my motor and it still runs great" and of course I would have to agree. At the same time I've seen and built alot of ....****...that will run. All motors are fighting the same battle "friction" and while your motor is over there running making your power...mine is over here one step ahead making more efficient power with a longer life.

****update****

Ok some of you have asked if I would share some info about my choice in Endyns pistons. For one I am a strong believer in the theory behind them and so does the other 90% of the industry...its been proven. The one thing thats very interesting about the piston is its shape. When at TDC it forms the same kidney shaped chamber that you can in the SBC. These very efficient chambers that make very efficient power.

These pistons are basically your 89mm(3.504) Endyn Roller Wave. Endyn for some reason doesnt list the dome/dishcc for any of the Hseries pistons. All they list is compression height. I called Larry and informed me that the pistons had a -10.2 dish volume.

So now we wanna find out what our true compression will be. We know that

CR=V1+v2+v3+v4+v5/V2+v3+v4+v5

V1(Swept volume)=Bore^2xStroke x .7854 x 16.39

V2(Chamber volume)=given or measured

V3(Head Gasket)=Bore^2 x compressed thickness x .7854 x 16.39

V4(deck)=Bore^2 x Deck x .7854 x 16.39

V5=valve relief cc dish or dome

Notice anything we don't have ?? Yes ..your deck! To find our deck we wanna use DH=S/.500+RL+CH+D, were as DH=Deck Height, S=Stroke, RL=Rod Length, CH=Compression Height, and D=Deck. So..

DH=8.643

S=3.740

CH=1.218

RL=5.580

DH=3.740/.5+5.580+1.218 which gives you 8.643-8.668=.025....Deck=-.025

Now that we have everything we need lets find our compression!

V1=3.504^2 x 3.740 x .7854 x16.39----**591.112cc**

V2=**53.8cc**

V3=3.504^2 x .030(gasket) x .7854 x 16.39---**4.742cc**

V4=3.504^2 x -.025(deck) x .7854 x 16.39---**-3.951**

V5=10.2

so 591+53.8+4.742+(-3.951)+10.2 / 53.8+4.742+(-3.951)+10.2=10.123CR

Update2/4/07

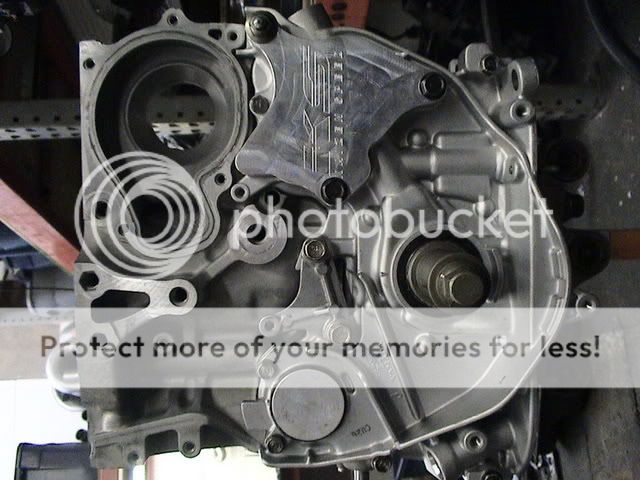

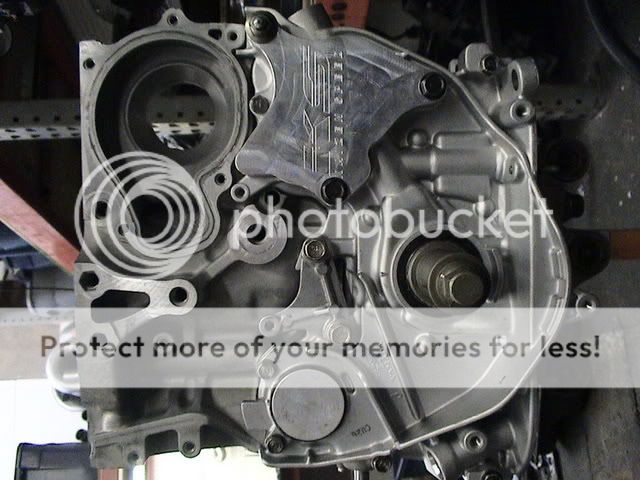

I had some time left at the end of the day on Fri and started and finished a project that needed to be done. For those who don't know what this is..it a block off plate for people who want to eliminate their balance shaft pump completely. Most people just pull the belt off but I wanted the weight out and off the motor.

Here is what the oil pump originally looks like(notice the plugs already installed from the shaft removal)

Here is the pump with the balance shaft oil pump installed(shaft and gear are already pressed out)

Now I first started off with a 4.000x4.000x.500 plate of 6061 aluminum. Both sides were fly-cut for machined surfaces for better seal. I then clamped the pump to the plate and scribed my line all the way around and transferred my clearance holes. Once holes were drilled I placed my plate onto the Bridgeport and got as close as possible to my scribe line. Next I bolted both parts together so I could use my grinder the clean up and blend in the sides of the plate with the original parts flange.

Finished product Total time 45mins

update 3/11/07 Valve spring compressor

the socket I used was a cheap 13/16 to be exact. I milled a portion of the side walls away...here is final product.

the socket I used was a cheap 13/16 to be exact. I milled a portion of the side walls away...here is final product.

JGS Precision 44mm wastegate

Modified by ludesleep at 4:49 PM 3/11/2007

<U>Head=h22a</U>

SuperTech valve train

custom valve job by me

custom port and chamber work by me

Golden Eagle cam gears

Custom Intake mani

1000cc injectors Delfi

Golden Eagle Rail

Stock Cams

Roller Rocker "coming soon"

<U>Block=H23a</U>

Golden Eagle sleeved

89mm bore

custom race hone by me

Endyn rollerwave pistons

Crower rods

Arp studs top and bottom, oil pan, flywheel

Golden Eagle sandwich

Moroso Pan

<U>Turbo Stuff</U>

Precision Pt-61

Aeromotive fuel

Lovefab SST

Tial 44mm wg

Tial bov

Intercooler

Cromepro or Neptune RTP**still waiting**

**Things I plan to fab myself or have already done so**

Solid aluminum 6061 motor mounts 30%

Vacuum manifold 100% complete

Traction bar 0%

Lots more to see in pics

I started this build three years ago and it just now coming to an end. I decided to go with a stationary engine(89mm bore 95mm stroke) which is a under-square piston-to-stroke configuration, meaning that the piston's diameter is smaller than the length of its stroke. Stationary engine produce generous amounts of low speed torque because of the long stroke. Remember Archimedes and his lever? Acrhimedes stated, "Give me a lever long enough and a place to stand and I will move the world" These engine are a good illustration of that lever's power.

Station ary engine have specific power output requirements because they are designed to run at a steady state, or within a defined rpm range.

Many shops have their "hone job"....I have mine. Many people over look the importance of a good hone. Having a good plateau finish is the key to every race hone. A plateau finish is essentially one where the tops of the peaks have been shaved off hence the "plateau" to provide a better surface for the rings. It has a controlled amount of texture remaining from both a course and fine grit honing process. Such a bore finish is equivalent to a broken in cylinder where the rough peaks, folded and torn metal left by conventional honing techniques have been shaved off by the rings, leaving a plateau like surface that provides adequate bearing area, yet retains its crosshatch for proper oil control and lubrication. This reduces ring wear when the engine is started for the first time, and allows the rings to seat within a few minutes. The result is longer ring and cylinder life, reduced blow-by and better oil control.

What Im about to tell you will solve the big mystery of "Is there really a such thing as a break in period" YES.....AND NO! Most shops try to stick by the Honda OEM hone which is basically for longer life. Honda uses a a very rough hone at finish that develop a plateau finish on its own as the rings scrub off the peaks left on the wall by honing. This ends up leaving alot of debris in the oil that can cause wear elsewhere in the engine. What's more, it wears the rings and cylinder unnecessarily. Almost all piston rings today come prelapped from the factory. Consequently, they do not have to scrub away at the cylinder bores to wear off the rough edges in order to create a gas tight seal between the combustion chamber and crankcase. The rings are essentially preseated and do not require a rough cylinder bore finish. In fact, a rough cylinder bore can be very detrimental to a new set of rings. If the surface finish is too rough, the rings will scuff and wear, giving a poor seal, resulting in reduced service life and high oil consumption. So why not produce the plateau finish in the beginning by using a special honing procedure that produces a prebroken in cylinder?

Improperly fitted bearings caused by runout in the connecting rod bores can cause recognizable failure itself. Problems can range from oil starvation and subsequent scoring of the cylinder walls, piston and rings, to excess oil throw off , leading to severe oil consumption of the engine. The connecting rod bores must be straight and square, onsize, maintain correct distance between each rod. To maintain all of these prerequisites, bearing housing and pin bores are reconditioned by boring or honing, or a combination of the two.

Next I wanna talk about align-honing and the importance of this process. I read on honda-tech and hear it alot that this process isn't that critical...well the truth is it is very crucial and is one of the most important considerations to make. I think alot of times people are confusing align-boring with the alighone process. The align-honing process is very different than the align-boring method because the housing bores are honed round and true with a mandrel, instead of bored to size with a tool bit which is normally only performed when new main caps are installed or spun main bearing repair. If the procedure is not performed it will lead to scuffed pistons, ineffective ring to cylinder wall sealing, cylinder head to block alignment, and uneven compression rations from one end to the block to the other. Imagine the rod trying to force its way along a straight path in the cylinder only to be pushed off center because the bore is not ninety degrees to the crank. Now.....some will say "I didn't align-hone my motor and it still runs great" and of course I would have to agree. At the same time I've seen and built alot of ....****...that will run. All motors are fighting the same battle "friction" and while your motor is over there running making your power...mine is over here one step ahead making more efficient power with a longer life.

****update****

Ok some of you have asked if I would share some info about my choice in Endyns pistons. For one I am a strong believer in the theory behind them and so does the other 90% of the industry...its been proven. The one thing thats very interesting about the piston is its shape. When at TDC it forms the same kidney shaped chamber that you can in the SBC. These very efficient chambers that make very efficient power.

These pistons are basically your 89mm(3.504) Endyn Roller Wave. Endyn for some reason doesnt list the dome/dishcc for any of the Hseries pistons. All they list is compression height. I called Larry and informed me that the pistons had a -10.2 dish volume.

So now we wanna find out what our true compression will be. We know that

CR=V1+v2+v3+v4+v5/V2+v3+v4+v5

V1(Swept volume)=Bore^2xStroke x .7854 x 16.39

V2(Chamber volume)=given or measured

V3(Head Gasket)=Bore^2 x compressed thickness x .7854 x 16.39

V4(deck)=Bore^2 x Deck x .7854 x 16.39

V5=valve relief cc dish or dome

Notice anything we don't have ?? Yes ..your deck! To find our deck we wanna use DH=S/.500+RL+CH+D, were as DH=Deck Height, S=Stroke, RL=Rod Length, CH=Compression Height, and D=Deck. So..

DH=8.643

S=3.740

CH=1.218

RL=5.580

DH=3.740/.5+5.580+1.218 which gives you 8.643-8.668=.025....Deck=-.025

Now that we have everything we need lets find our compression!

V1=3.504^2 x 3.740 x .7854 x16.39----**591.112cc**

V2=**53.8cc**

V3=3.504^2 x .030(gasket) x .7854 x 16.39---**4.742cc**

V4=3.504^2 x -.025(deck) x .7854 x 16.39---**-3.951**

V5=10.2

so 591+53.8+4.742+(-3.951)+10.2 / 53.8+4.742+(-3.951)+10.2=10.123CR

Update2/4/07

I had some time left at the end of the day on Fri and started and finished a project that needed to be done. For those who don't know what this is..it a block off plate for people who want to eliminate their balance shaft pump completely. Most people just pull the belt off but I wanted the weight out and off the motor.

Here is what the oil pump originally looks like(notice the plugs already installed from the shaft removal)

Here is the pump with the balance shaft oil pump installed(shaft and gear are already pressed out)

Now I first started off with a 4.000x4.000x.500 plate of 6061 aluminum. Both sides were fly-cut for machined surfaces for better seal. I then clamped the pump to the plate and scribed my line all the way around and transferred my clearance holes. Once holes were drilled I placed my plate onto the Bridgeport and got as close as possible to my scribe line. Next I bolted both parts together so I could use my grinder the clean up and blend in the sides of the plate with the original parts flange.

Finished product Total time 45mins

update 3/11/07 Valve spring compressor

the socket I used was a cheap 13/16 to be exact. I milled a portion of the side walls away...here is final product.

the socket I used was a cheap 13/16 to be exact. I milled a portion of the side walls away...here is final product.

JGS Precision 44mm wastegate

Modified by ludesleep at 4:49 PM 3/11/2007

#2

Honda-Tech Member

Join Date: Jul 2002

Location: Scottsdale, AZ, usa

Posts: 3,105

Likes: 0

Received 0 Likes

on

0 Posts

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by ludesleep »</TD></TR><TR><TD CLASS="quote">I started this post in the Prelude forum but thought it should also be shared with this one as well.

https://honda-tech.com/zero...90462</TD></TR></TABLE>

https://honda-tech.com/zerothread?id=1702889

Modified by tegasaurus at 4:04 PM 11/7/2006

https://honda-tech.com/zero...90462</TD></TR></TABLE>

https://honda-tech.com/zerothread?id=1702889

Modified by tegasaurus at 4:04 PM 11/7/2006

#3

Member

#4

Honda-Tech Member

Thread Starter

Join Date: Feb 2003

Location: Texas ATM Aggie, Tx, 77840

Posts: 1,491

Likes: 0

Received 0 Likes

on

0 Posts

nice but we shall see.....

Modified by ludesleep at 4:49 PM 3/11/2007

Modified by ludesleep at 4:49 PM 3/11/2007

#5

Honda-Tech Member

Thread Starter

Join Date: Feb 2003

Location: Texas ATM Aggie, Tx, 77840

Posts: 1,491

Likes: 0

Received 0 Likes

on

0 Posts

updated will post pics of the final product when honda sends in my new cam cap bolts.

#6

Junior Member

Join Date: Jan 2006

Location: Miramar, Florida, United States

Posts: 319

Likes: 0

Received 0 Likes

on

0 Posts

nice setup. i am deciding between building the h22 i have or trying this hybrid. keep us updated.

#7

Join Date: Apr 2001

Location: Northwest Tri Cities Kennewick, WA, USA

Posts: 2,090

Likes: 0

Received 0 Likes

on

0 Posts

I had some time left at the end of the day on Fri and started and finished a project that needed to be done. For those who don't know what this is..it a block off plate for people who want to eliminate their balance shaft pump completely.

Now I first started off with a 4.000x4.000x.500 plate of 6061 aluminum. Both sides were fly-cut for machined surfaces for better seal. I then clamped the pump to the plate and scribed my line all the way around and transferred my clearance holes. Once holes were drilled I placed my plate onto the Bridgeport and got as close as possible to my scribe line. Next I bolted both parts together so I could use my grinder the clean up and blend in the sides of the plate with the original parts flange.

Finished product Total time 45mins

at 4:49 PM 3/11/2007[/i][/QUOTE]

... We offer fully CNC'd blockoff plates for that rear gearcase... could've saved yourself 45 min. and you'd have a much nicer plate. Pretty good DIY though... and lots of good information

Now I first started off with a 4.000x4.000x.500 plate of 6061 aluminum. Both sides were fly-cut for machined surfaces for better seal. I then clamped the pump to the plate and scribed my line all the way around and transferred my clearance holes. Once holes were drilled I placed my plate onto the Bridgeport and got as close as possible to my scribe line. Next I bolted both parts together so I could use my grinder the clean up and blend in the sides of the plate with the original parts flange.

Finished product Total time 45mins

at 4:49 PM 3/11/2007[/i][/QUOTE]

... We offer fully CNC'd blockoff plates for that rear gearcase... could've saved yourself 45 min. and you'd have a much nicer plate. Pretty good DIY though... and lots of good information

Trending Topics

#9

Honda-Tech Member

Thread Starter

Join Date: Feb 2003

Location: Texas ATM Aggie, Tx, 77840

Posts: 1,491

Likes: 0

Received 0 Likes

on

0 Posts

I know I could have went with your kit but this is what makes it fun for me..knowing I did this or that. Thats why I build race motors...its my addiction!

Thread

Thread Starter

Forum

Replies

Last Post

ludesleep

Classifieds: Forced Induction

6

12-03-2009 12:22 PM

streetracer6rpt

Forced Induction

12

06-18-2007 07:12 PM

19sec beast

Forced Induction

33

02-25-2006 01:51 PM