Skunk2 Pro-series camgear failure

#1

Honda-Tech Member

Thread Starter

Order of events

1.Notice the car ran rather crappy one day. Then it wouldn't idle at all without holding the gas down

2.Checked spark plugs= fouled then replaced with new = fouled again

3.Checked wires = all were within /resistance ohm specs

4.Checked distributor coil and icm I ended up buying a new distributor

5.Hooked up laptop, Hondata was showing 5-9mm/hg when I held revs at 1k = super low vacuum

6. Checked all areas for leaks, none found

7. Compression test resulted cylinder 1-4 (250-280-280-280)

8. Maybe a loose or tight valve so I decide to take off valve cover and found images below

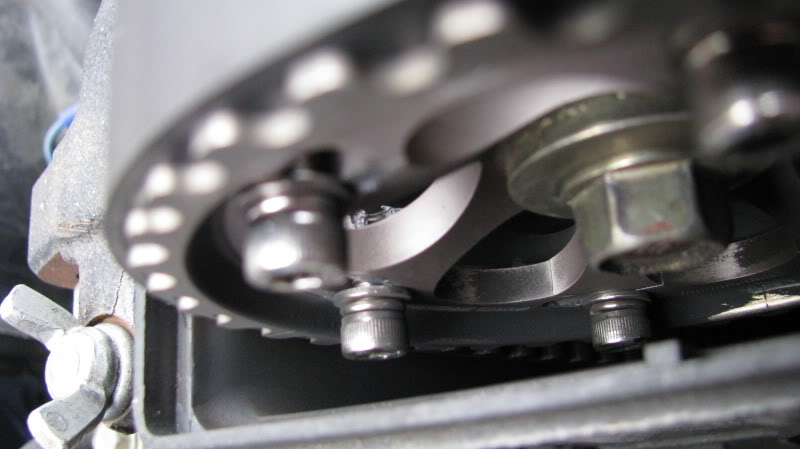

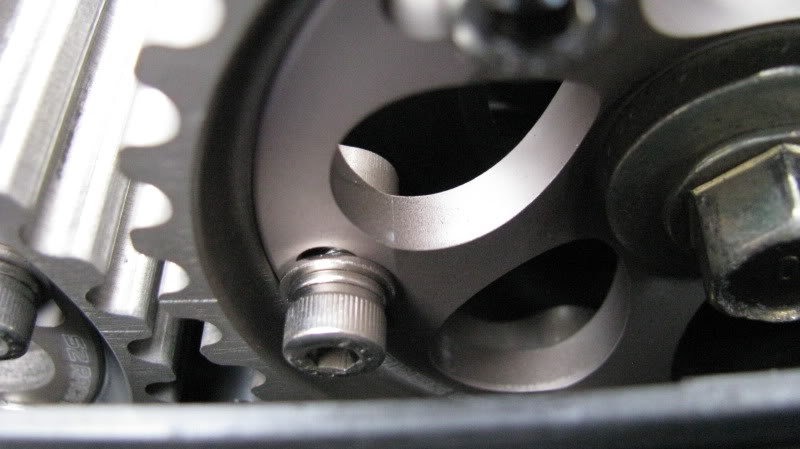

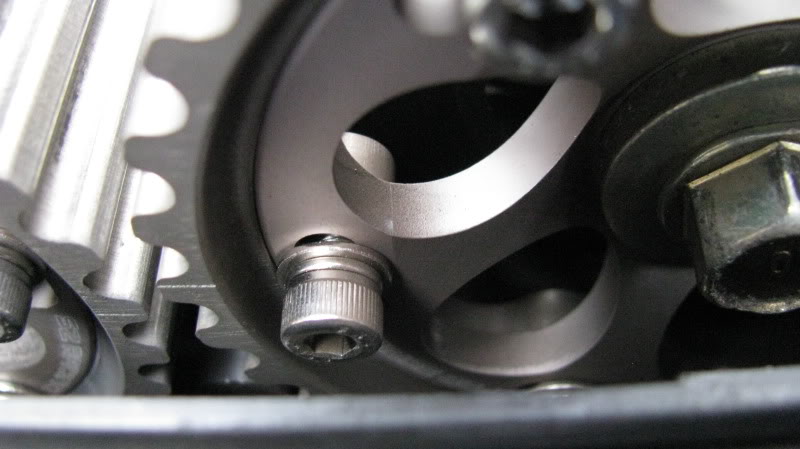

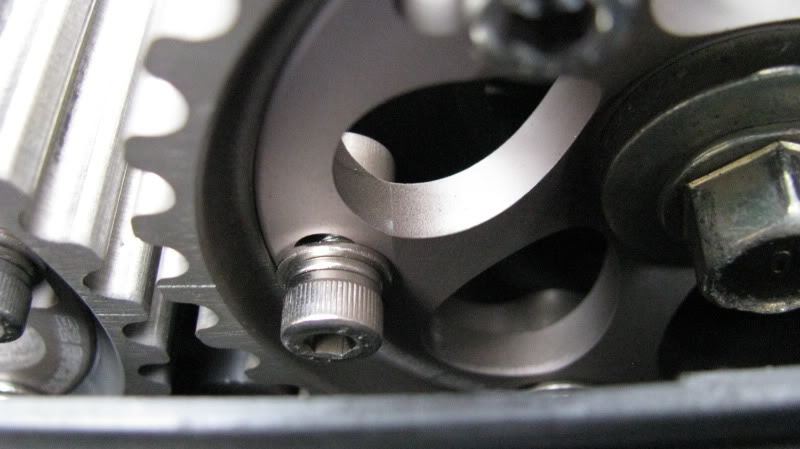

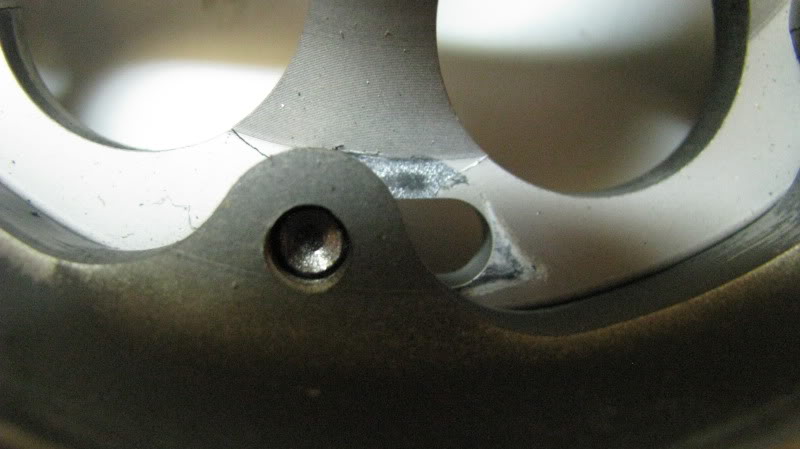

As we can see from the pictures the exhaust gear cracked(notice the chuck missing where is allen bolt threads in), rotated from +5(original settings) to -5 effectively ~20degrees resulting in valve to valve or piston contact (I have yet to pull the head) causing the huge vac leak

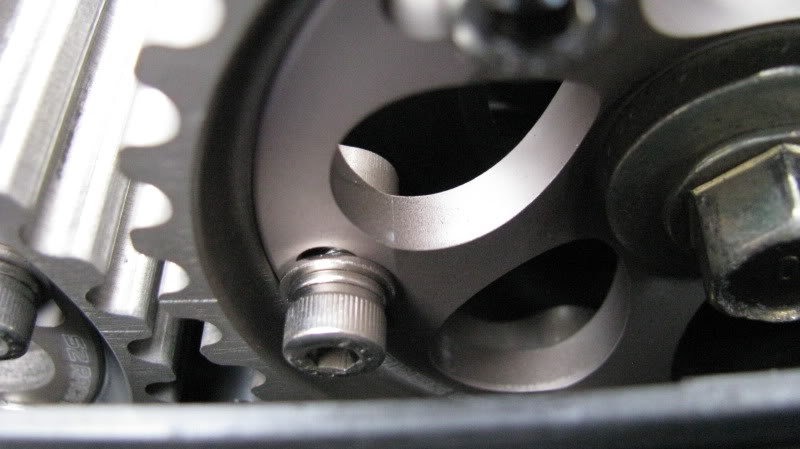

Also take notice the intake gear....a hairline fracture can be seen and is developing where the exhaust gear failed.......

These allen bolts were never torqued down using brute force just hand tight with allen key so I didn't go beyond their limits or else they would have broken off like some have done.

I have all timing covers, and don't have a mooncut or camgear adjustment cutout so no foreign object can enter or exit to cause this.

I will be contacting Skunk2 first thing Monday morning to resolve this issue clearly a manufacture defect.

1.Notice the car ran rather crappy one day. Then it wouldn't idle at all without holding the gas down

2.Checked spark plugs= fouled then replaced with new = fouled again

3.Checked wires = all were within /resistance ohm specs

4.Checked distributor coil and icm I ended up buying a new distributor

5.Hooked up laptop, Hondata was showing 5-9mm/hg when I held revs at 1k = super low vacuum

6. Checked all areas for leaks, none found

7. Compression test resulted cylinder 1-4 (250-280-280-280)

8. Maybe a loose or tight valve so I decide to take off valve cover and found images below

As we can see from the pictures the exhaust gear cracked(notice the chuck missing where is allen bolt threads in), rotated from +5(original settings) to -5 effectively ~20degrees resulting in valve to valve or piston contact (I have yet to pull the head) causing the huge vac leak

Also take notice the intake gear....a hairline fracture can be seen and is developing where the exhaust gear failed.......

These allen bolts were never torqued down using brute force just hand tight with allen key so I didn't go beyond their limits or else they would have broken off like some have done.

I have all timing covers, and don't have a mooncut or camgear adjustment cutout so no foreign object can enter or exit to cause this.

I will be contacting Skunk2 first thing Monday morning to resolve this issue clearly a manufacture defect.

Last edited by 00b18b; 10-10-2009 at 02:37 PM.

#2

All Motor Mentor

Join Date: Aug 2004

Location: 902, Nova Scotia, Canada

Posts: 6,987

Likes: 0

Received 1 Like

on

1 Post

One of the first things they're going to ask you is what you torqued those bolts to. If you don't know because you didn't use a torque wrench and went by feel, doing it "hand tight", they're probably going to say installer error. The good thing about Skunk is their customer service these days and you may get lucky.

Just FYI, those bolts typically strip before they break when their torque rating is exceeded so hand tight doesn't mean it cant be too tight.

Just FYI, those bolts typically strip before they break when their torque rating is exceeded so hand tight doesn't mean it cant be too tight.

#3

Honda-Tech Member

Join Date: Feb 2002

Location: South Bay, CA

Posts: 1,700

Likes: 0

Received 0 Likes

on

0 Posts

One of the first things they're going to ask you is what you torqued those bolts to. If you don't know because you didn't use a torque wrench and went by feel, doing it "hand tight", they're probably going to say installer error. The good thing about Skunk is their customer service these days and you may get lucky.

Just FYI, those bolts typically strip before they break when their torque rating is exceeded so hand tight doesn't mean it cant be too tight.

Just FYI, those bolts typically strip before they break when their torque rating is exceeded so hand tight doesn't mean it cant be too tight.

Years ago with my Toda gears I think we torqued them by hand and I am SOOOO glad this didnt happen to me.

Best of luck man, sorry this happened....could be worse though so while that may not be fun at least you didnt get any piston/valve contact....bright side

#4

Honda-Tech Member

Thread Starter

One of the first things they're going to ask you is what you torqued those bolts to. If you don't know because you didn't use a torque wrench and went by feel, doing it "hand tight", they're probably going to say installer error. The good thing about Skunk is their customer service these days and you may get lucky.

Just FYI, those bolts typically strip before they break when their torque rating is exceeded so hand tight doesn't mean it cant be too tight.

Just FYI, those bolts typically strip before they break when their torque rating is exceeded so hand tight doesn't mean it cant be too tight.

1st and fore most I would ask to please show a set of instructions that say a torque number requirement

why?....they did not furnish one inside the package nor do they have one listed on the site

2nd the failure can be seen not due to bolt failure but design.... look at intake gear

I can if needed unscrew the bolts to show no signs of stripping threads, if they ask.

3rd these allen bolts uses a spring loaded lock washer. This applies the necessary force so torquing is not required. Hand snug with key for something this small is more than enough. I would like to see someone apply a torque of 10 -15lb and watch it pop

#5

Honda-Tech Member

im sorry to see this happen to anybody. that really sucks man. but if i received them with no torque specification i would have contacted them before installing the gears. but thats just me. its hard to believe they wouldnt come with instructions. hopefully skunk2 will send you a new set free of charge.

#6

Honda-Tech Member

Thread Starter

A new set wouldn't help the situation really. My valves and piston are damaged due to the event...and thinking of running the new set again, not a chance.

im looking at....

new valves

new piston

machine work

-new seats cut

-possible the guide has cracked

new headgasket

new timing belt

new arp headstuds

im looking at....

new valves

new piston

machine work

-new seats cut

-possible the guide has cracked

new headgasket

new timing belt

new arp headstuds

#7

Member

So, what torque/ tightening numbers did you use? ALL cam gears come un-torqued or loose, so you can set them to the desired degrees and tighten them. What did you set and torque yours to? Or did you just take them out of the box and install them? Seeing as the cam timing is WAY off, that would be my guess.

Trending Topics

#8

Honda-Tech Member

yeah i know its too late. sorry bro, and i dont blame you for not wanting to take a second chance on those pro series gears. i was considering those same cam gears a few months back. i think this is the second time someone here on HT that i know of, has had Skunk2 cam gears fail on them. im considering BDL gears just because their bolts are larger and i havent heard any complaints about them yet.

#9

Honda-Tech Member

Thread Starter

So, what torque/ tightening numbers did you use? ALL cam gears come un-torqued or loose, so you can set them to the desired degrees and tighten them. What did you set and torque yours to? Or did you just take them out of the box and install them? Seeing as the cam timing is WAY off, that would be my guess.

The fractures on the gear and three chunks that broke off where the threads are the culprit. This dislocation allowed for movement where the bolt and spring washer applies pressure against. Since this area was non-existent, it caused for easy backing out. so then we have easy gear slippage.

I mean disregard the exhaust gear pictures...look at the intake gear which is still fine no slippage/damage.. How do you explain the developing fracture shown? Does that not look like failure going to happen? notice the similarities how the exhaust gears have cracks in the same area?

#10

Honda-Tech Member

i'm with him on this. i have skunks original gears and i was paranoid about those things but i've had no problems. i also looked for a torque number and there is no spec to be found.

i just used an allen wrench, gobbed some loctite on them and went by feel with the experience i have.

it's like doing new spark plugs. it spins until the washer touches, then it is tighter while the washer crushes, then it stops and you are done.

but adjustable gear by nature of what they are do freak me out.

they really should make an assortment of inserts that can go in the slot next to the bolt so even if it does slip, it can only go so far.

i just used an allen wrench, gobbed some loctite on them and went by feel with the experience i have.

it's like doing new spark plugs. it spins until the washer touches, then it is tighter while the washer crushes, then it stops and you are done.

but adjustable gear by nature of what they are do freak me out.

they really should make an assortment of inserts that can go in the slot next to the bolt so even if it does slip, it can only go so far.

#12

Honda-Tech Member

Join Date: Sep 2008

Location: East Side

Posts: 103

Likes: 0

Received 0 Likes

on

0 Posts

Sorry to see this. But on the lighter side Why dont you put the stock gears on and redo your compression test and measure your vacuum with a guage at idle. Your compression acually doesnt look waisted. im sure you know that since the timing was off compression and vacuum will be low. Just a thought before you spend all that money that could be spent on other things.

#13

Honda-Tech Member

FYI- The rule of thumb for aircraft structural sheetmetal is 1.5 Edge Distance...This means if you have a fastener hole that is .250" in diameter, the closest it should be to any edge or other hole is .375". That is the MINIMUM allowed for all the aluminum alloys used. I personally dont care for that design...

#14

Honda-Tech Member

Join Date: Jun 2000

Location: Crazy Canuck, Everywhere

Posts: 1,637

Likes: 0

Received 0 Likes

on

0 Posts

This truly sucks and I am very sorry to see this happen.

My objective opinion is this:

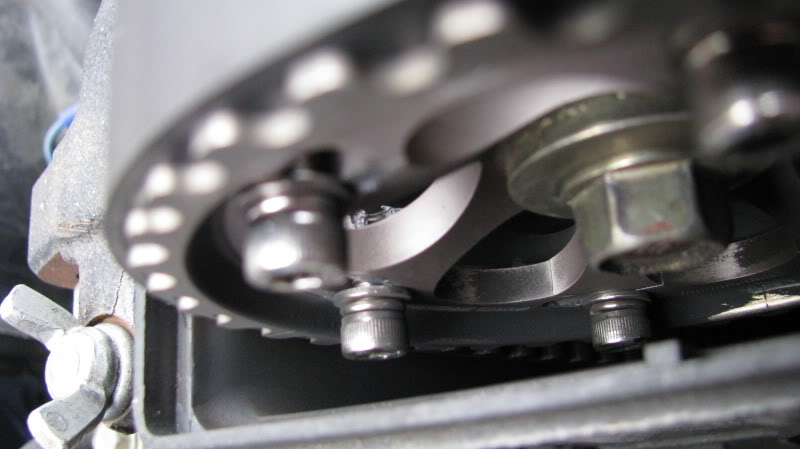

The first thing that struck me when I saw this picture was how it seems the slip scares on the left of the gear are so much greater then on the right (which almost seem non-existent). From this I draw a conclusion that the bolts where not all clamping with the same force when this event occurred. Clearly this would suggest that some of the bolts had backed out enough such that they were no longer holding the gear in place adequately. While I do fault Skunk2 for not providing a guideline for setting these up I do believe that ultimately this was installer error. Relying on the lock washer to maintain sufficient force under such operating conditions I think was a little optimistic, applying Lock-tight here is a no-brainier considering the obvious consequences if these things slip.

I'm not sure much conclusion can be drawn from the actual fractures and missing bits themselves. During such an event the gears are clearly subject to forces they were not designed to handle. Even the intake stress fractures could have been induced by the mechanical collisions that were happening.

Again... I think this sucks and I am in agreement with you that Skunk2 (and other suppliers of like products) should be more clear on how to tighten these guys down. I'm not sure if Skunk2 is alone here in not providing this information, nor do I think they are alone in having their products involved in such misfortunes.

Doug

My objective opinion is this:

The first thing that struck me when I saw this picture was how it seems the slip scares on the left of the gear are so much greater then on the right (which almost seem non-existent). From this I draw a conclusion that the bolts where not all clamping with the same force when this event occurred. Clearly this would suggest that some of the bolts had backed out enough such that they were no longer holding the gear in place adequately. While I do fault Skunk2 for not providing a guideline for setting these up I do believe that ultimately this was installer error. Relying on the lock washer to maintain sufficient force under such operating conditions I think was a little optimistic, applying Lock-tight here is a no-brainier considering the obvious consequences if these things slip.

I'm not sure much conclusion can be drawn from the actual fractures and missing bits themselves. During such an event the gears are clearly subject to forces they were not designed to handle. Even the intake stress fractures could have been induced by the mechanical collisions that were happening.

Again... I think this sucks and I am in agreement with you that Skunk2 (and other suppliers of like products) should be more clear on how to tighten these guys down. I'm not sure if Skunk2 is alone here in not providing this information, nor do I think they are alone in having their products involved in such misfortunes.

Doug

#15

Honda-Tech Member

very good observation babynsx. i should go back on what i said about saying skunk2 cam gears failing. i did mention i seen this happen before on two other occasions but i am no place to say that the problem lies on behalf of skunk2's engineering. like i mentioned before i wouldnt personally install some cam gears on my car if i didnt know what they were to be torqued to. to me, it wouldnt be the wisest thing to do even though you can guess the torque it could handle based on the size of the bolts.

Last edited by BigBlock22; 10-12-2009 at 10:58 PM.

#16

Honda-Tech Member

Join Date: Feb 2008

Location: Boston, Ma

Posts: 43

Likes: 0

Received 0 Likes

on

0 Posts

The 6 Allen bolts on the Cam Gear use a star pattern and are supposed to be Torqued to 6-7ft lbs. using a 1/4” drive torque wrench.

skunk2 is just going to tell you its your own fault for not torquing them down and hand tighting them

skunk2 is just going to tell you its your own fault for not torquing them down and hand tighting them

#17

Honda-Tech Member

Join Date: Oct 2007

Location: Oregon City, OR, USA

Posts: 1,745

Likes: 0

Received 2 Likes

on

2 Posts

^ Just saw that today as well.

http://www.skunk2.com/installation/304-05-5225.pdf

These are for the H22 gears, but I imagine the other applications would be the same specs. Sorry to hear, though, that sucks.

http://www.skunk2.com/installation/304-05-5225.pdf

These are for the H22 gears, but I imagine the other applications would be the same specs. Sorry to hear, though, that sucks.

#18

Honda-Tech Member

Join Date: Feb 2008

Location: Boston, Ma

Posts: 43

Likes: 0

Received 0 Likes

on

0 Posts

^ Just saw that today as well.

http://www.skunk2.com/installation/304-05-5225.pdf

These are for the H22 gears, but I imagine the other applications would be the same specs. Sorry to hear, though, that sucks.

http://www.skunk2.com/installation/304-05-5225.pdf

These are for the H22 gears, but I imagine the other applications would be the same specs. Sorry to hear, though, that sucks.

for h and b series and they were the same.

so im pretty sure the pros are too

#19

Honda-Tech Member

Thread Starter

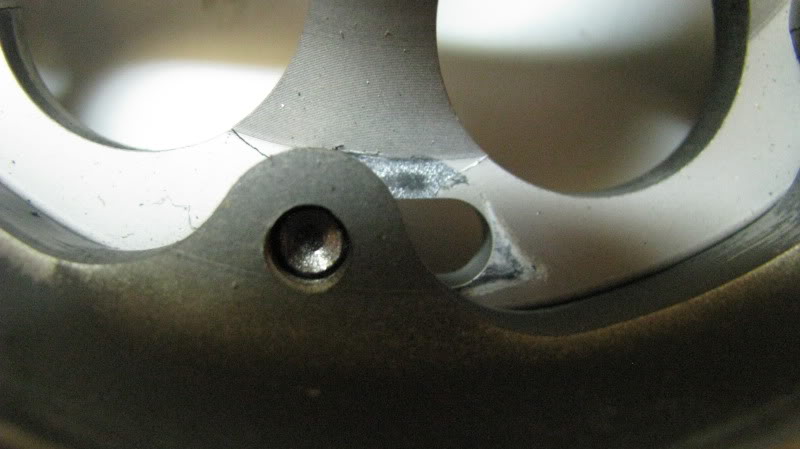

Decided to take off gears and do some investigation.....

back of the exhaust gear we see 2 chunks missing

the "SLOPE" or rise I speak of below

ok lets examine........

1st bolt missing chunk

Look at both mating surfaces outline and paint removal

Note: edge of the slope where the arch tip was pressing against

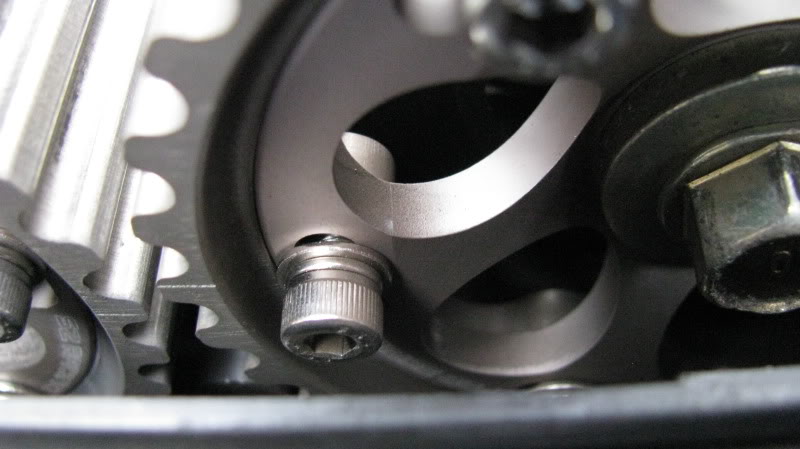

2nd bolt missing chunk

Look at the dark spot where you can see where the mating surfaces made actual contact

Note the tip was again riding on the "slope" edge.....think of where the pressure is placed in relation to breakage....

3rd bolt bolt

Notice when the gear spun look at the gouge marks the dragging along the tip

I'm surprised it didn't break like the others... maybe with more time?

4th

here we can see nice flat full paint removal meaning both mating surfaces were sitting properly and most importantly snug/tight would you say?

5th

Here we see the same issue of the tip being dragged and gouging along the "slope"

6th

We an see how nice and tight the bolt was by the paint removal and this was not riding the "slope"

CONCLUSION

I can conclude the arched tips that broke, did so before spinning. We can see no sliding gouge marks. What we see here is an example of someone laying a board on a street to a curb and applying pressure in the middle. This resulting for the leading tip to fracture and break off loosing all resistance the bolt had applied.

also

I can conclude that the the design is flawed...We can see that the gear does not always sit on a true surface

also

I can conclude the issue was not due to over or under tightening the bolt....gouge marks, paint removal say the pressure that was applied was sufficient the reason for slippage was due to the two bolts no longer having threads to hold on too causing an unbalanced rotation. As this happened stress fractures developed in multiple areas, ending with what we see here.

I'm done proving my points

back of the exhaust gear we see 2 chunks missing

the "SLOPE" or rise I speak of below

ok lets examine........

1st bolt missing chunk

Look at both mating surfaces outline and paint removal

Note: edge of the slope where the arch tip was pressing against

2nd bolt missing chunk

Look at the dark spot where you can see where the mating surfaces made actual contact

Note the tip was again riding on the "slope" edge.....think of where the pressure is placed in relation to breakage....

3rd bolt bolt

Notice when the gear spun look at the gouge marks the dragging along the tip

I'm surprised it didn't break like the others... maybe with more time?

4th

here we can see nice flat full paint removal meaning both mating surfaces were sitting properly and most importantly snug/tight would you say?

5th

Here we see the same issue of the tip being dragged and gouging along the "slope"

6th

We an see how nice and tight the bolt was by the paint removal and this was not riding the "slope"

CONCLUSION

I can conclude the arched tips that broke, did so before spinning. We can see no sliding gouge marks. What we see here is an example of someone laying a board on a street to a curb and applying pressure in the middle. This resulting for the leading tip to fracture and break off loosing all resistance the bolt had applied.

also

I can conclude that the the design is flawed...We can see that the gear does not always sit on a true surface

also

I can conclude the issue was not due to over or under tightening the bolt....gouge marks, paint removal say the pressure that was applied was sufficient the reason for slippage was due to the two bolts no longer having threads to hold on too causing an unbalanced rotation. As this happened stress fractures developed in multiple areas, ending with what we see here.

I'm done proving my points

#20

Honda-Tech Member

Join Date: Aug 2009

Location: Baton Rouge,Louisiana

Posts: 7,635

Likes: 0

Received 3 Likes

on

3 Posts

its obvious it was tight.. it wouldn't have taken paint off like that if it wasn't tight to a good extent.. goodluck with your claim vs skunk2.

#21

Honda-Tech Member

maybe it was an engineering flaw after all... sorry you had to be the guy that learned the lesson. weird how they would have used bolts that dont thread all the way into the back plate. perhaps you could make another thread warning people about your experience with their cam gears. who knows how many people this will end up affecting.

Last edited by BigBlock22; 10-11-2009 at 07:39 PM.

#22

Honda-Tech Member

yeah, from what i can remember most metals will crack or stretch when they are over torqued. at the same time the gears are not perfect in design.

#23

Honda-Tech Member

Join Date: Jun 2000

Location: Crazy Canuck, Everywhere

Posts: 1,637

Likes: 0

Received 0 Likes

on

0 Posts

CONCLUSION

I can conclude the arched tips that broke, did so before spinning. We can see no sliding gouge marks. What we see here is an example of someone laying a board on a street to a curb and applying pressure in the middle. This resulting for the leading tip to fracture and break off loosing all resistance the bolt had applied.

I can conclude the arched tips that broke, did so before spinning. We can see no sliding gouge marks. What we see here is an example of someone laying a board on a street to a curb and applying pressure in the middle. This resulting for the leading tip to fracture and break off loosing all resistance the bolt had applied.

I would also say that during such an event (where there is also piston/valve contact) that a lot of slapping around is likely occurring within the cam gear causing it to slam against its end stops. For this reason I find it entirely plausible (and more likely) that all mechanical failures occurred after this event started. Continuing from this logic it is also likely that much of the deep scaring also occurred during this period which would make drawing any conclusions on a design flaw difficult.

I may be wrong, but I can bet that Skunk2 will feel they can draw similar conclusions and on a reasonable basis not assume any responsibility for this. If my comments help prepare you for your discussions with them then I have helped you!

Doug

#24

Honda-Tech Member

Thread Starter

Not trying to **** in your Cheerios but I'm not sure I reach the same conclusion... your photos seem to clearly show that the gear was intact when the initial slip occurred, and for some time afterwords. I reach this conclusion because the slide scares in all the photos show the full outline of the material that was originally there (and subsequently broke off).

I would also say that during such an event (where there is also piston/valve contact) that a lot of slapping around is likely occurring within the cam gear causing it to slam against its end stops. For this reason I find it entirely plausible (and more likely) that all mechanical failures occurred after this event started. Continuing from this logic it is also likely that much of the deep scaring also occurred during this period which would make drawing any conclusions on a design flaw difficult.

I may be wrong, but I can bet that Skunk2 will feel they can draw similar conclusions and on a reasonable basis not assume any responsibility for this. If my comments help prepare you for your discussions with them then I have helped you!

Doug

I would also say that during such an event (where there is also piston/valve contact) that a lot of slapping around is likely occurring within the cam gear causing it to slam against its end stops. For this reason I find it entirely plausible (and more likely) that all mechanical failures occurred after this event started. Continuing from this logic it is also likely that much of the deep scaring also occurred during this period which would make drawing any conclusions on a design flaw difficult.

I may be wrong, but I can bet that Skunk2 will feel they can draw similar conclusions and on a reasonable basis not assume any responsibility for this. If my comments help prepare you for your discussions with them then I have helped you!

Doug

Ok let's focus on the broken tips... If they were still intact during the spin. Why isn't there a mark or gouge outline of it? We see it on the others but not on the broken ones..I don't see any so CLEARLY this means they were broken off before the spin. The pictures tell the story not me.

btw....when a gear slips its heading to full advance and that's it. Its just one direction no slapping around or movement....From my judgment I can clearly say that it made one swoop across and touched the intake valve during the opening and closing event of cylinder one....why? because my compression is still great for the other three cylinders or else they would show a low number? am I not correct?

#25

Honda-Tech Member

Join Date: Oct 2007

Location: Tampa, FL

Posts: 1,248

Likes: 0

Received 0 Likes

on

0 Posts

Its obvious that there is a design flaw relating to how the two pieces fit together. It does not look like the bolts were tightened enough to ensure both pieces fit flush. IMO, if they were flush and tight together, it wouldn't look like the pieces were galled. Looks like they were loose for a while and the last remaining places that were tight broke from having all the stress on them.

<-- Goes outside to double-check camgear bolts

<-- Goes outside to double-check camgear bolts