Degreeing Cams

#1

Honda-Tech Member

Thread Starter

I degreed some cams for the first time this weekend and I'd like some feedback. I did it on a dummy motor (stock B16) that I put together out of spare parts for practice; when I'm sure I'm doing everything right I'll do it on my running motor. Here's what I did:

Removed the cams/rockers, removed the springs for an intake and an exhaust valve, replaced them with lighter springs, replaced those two rockers and locked the VTEC rockers to them, replaced cams, and set valve clearances to 0".

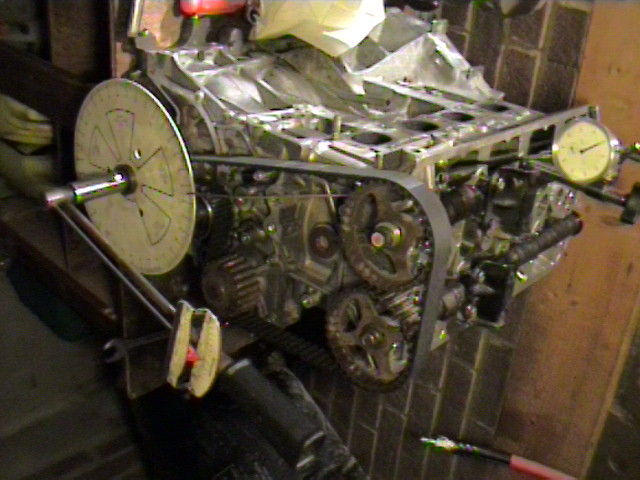

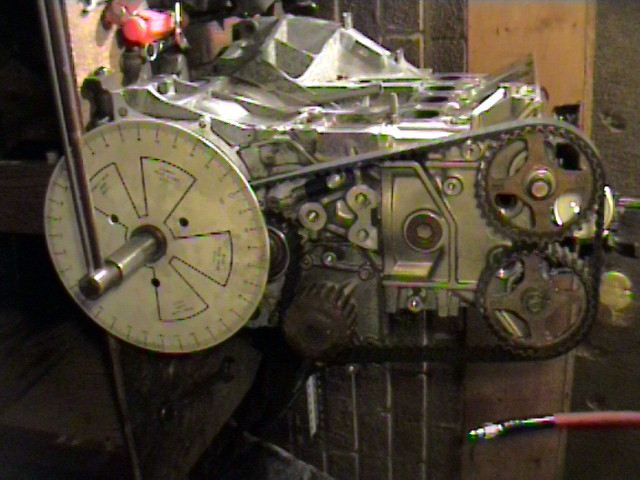

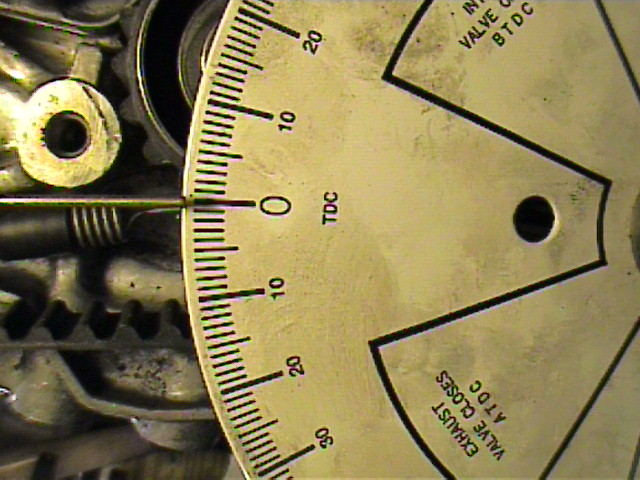

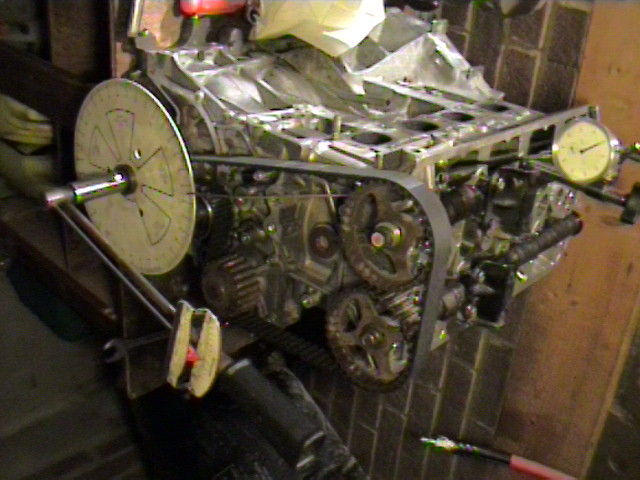

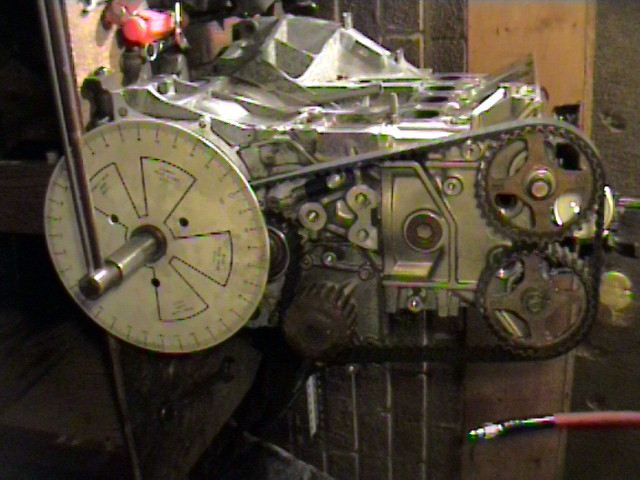

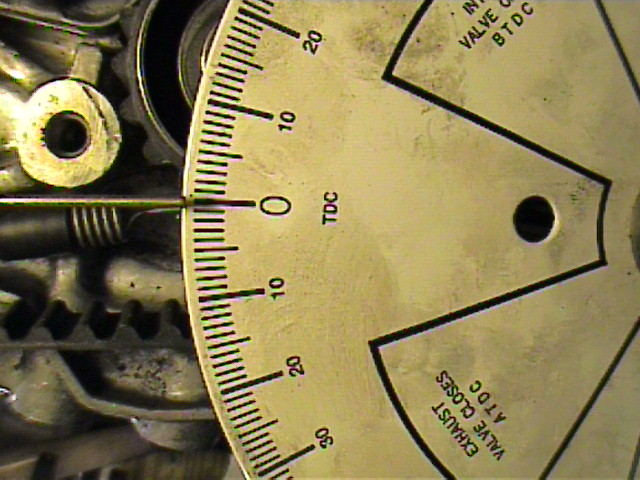

Bolted the degree wheel to the crankshaft and the pointer to the head.

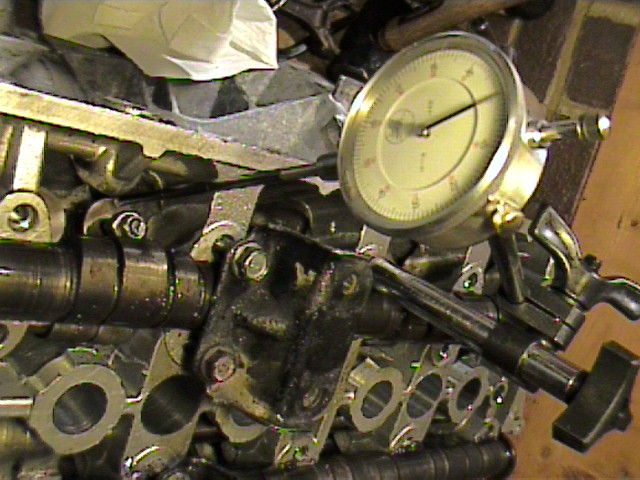

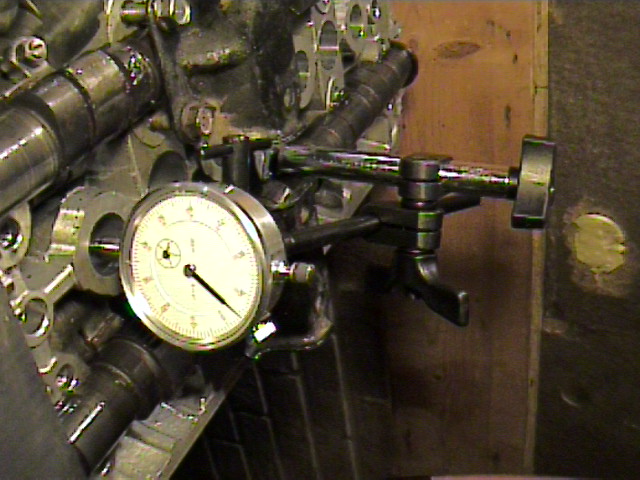

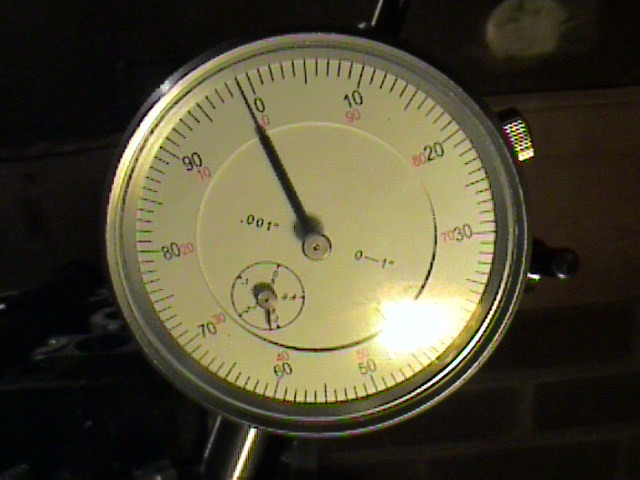

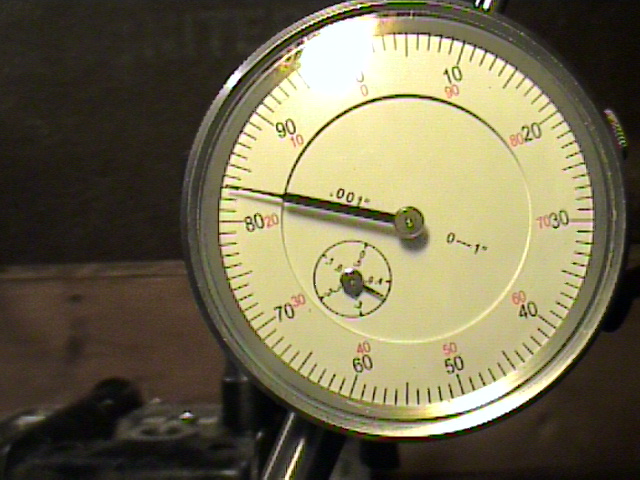

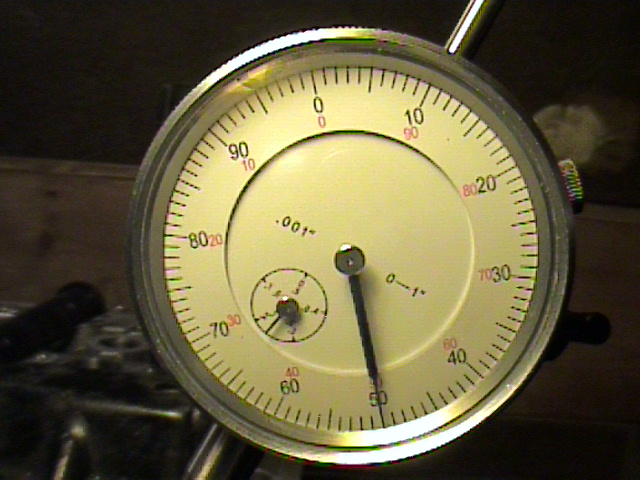

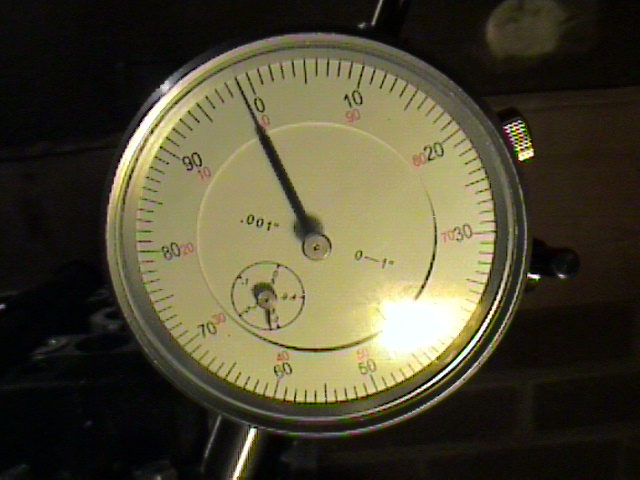

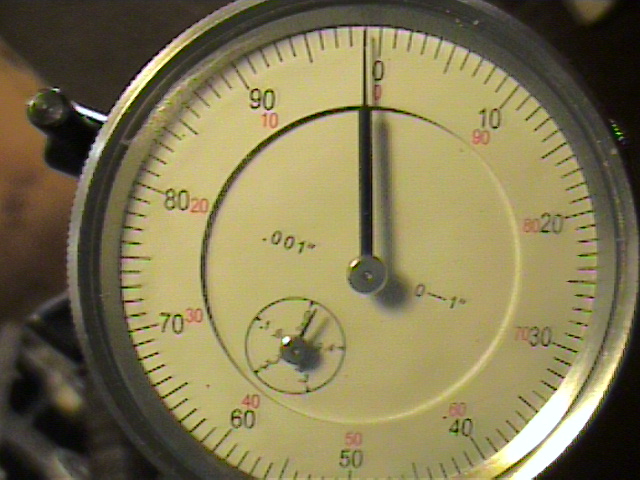

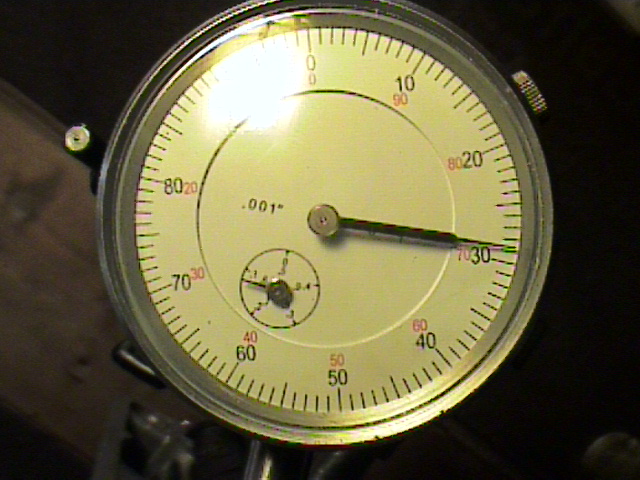

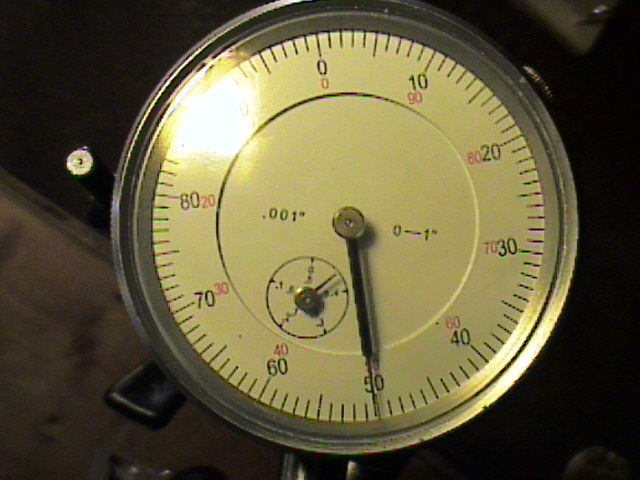

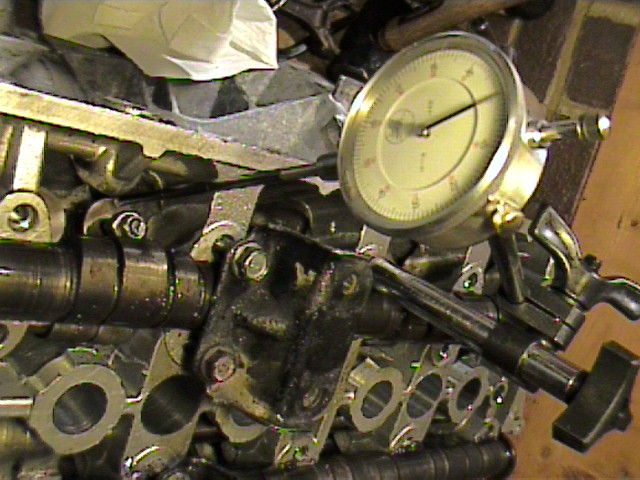

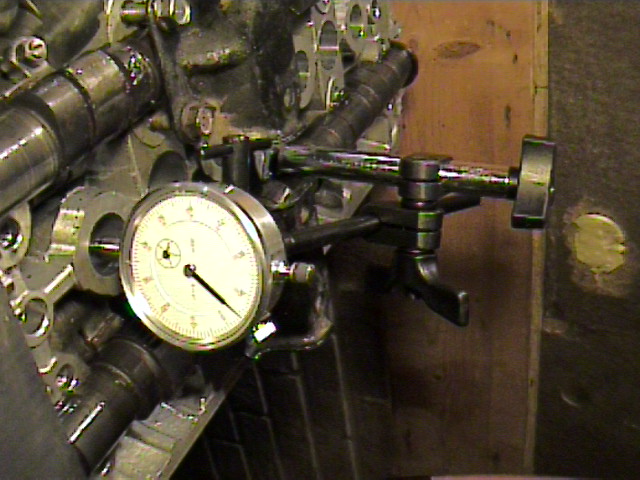

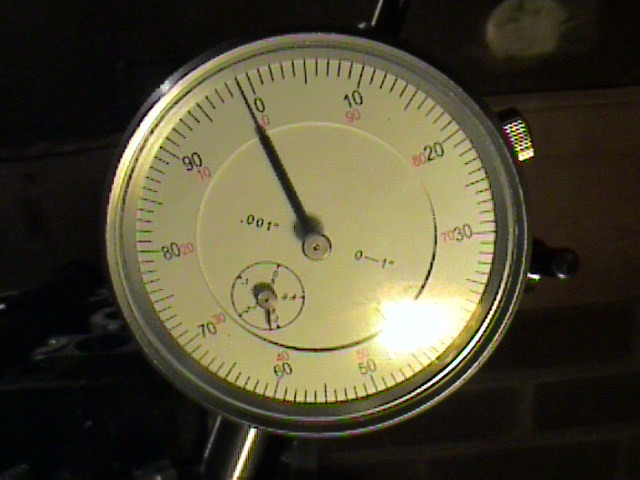

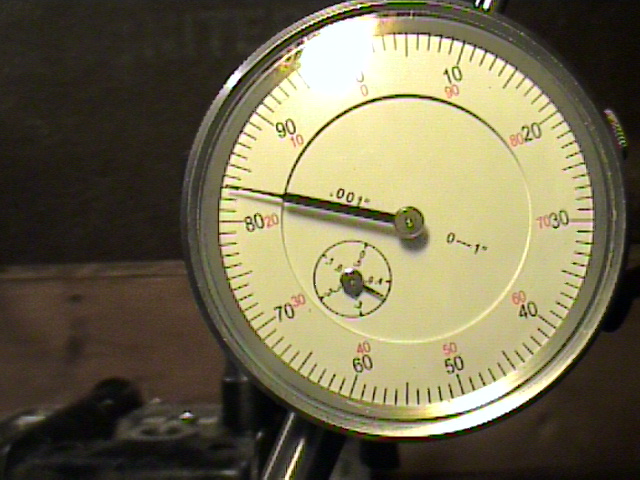

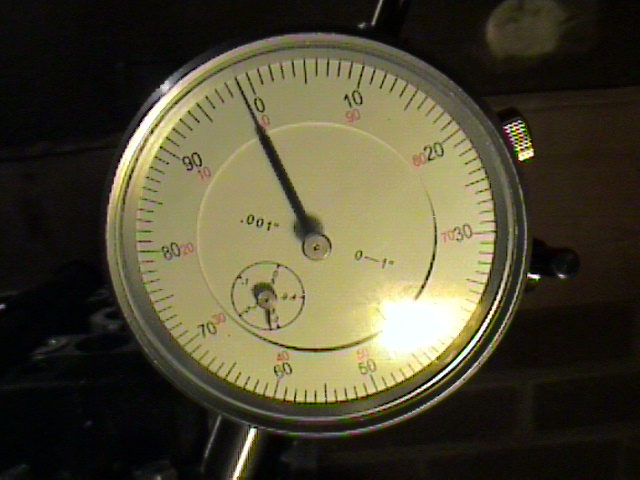

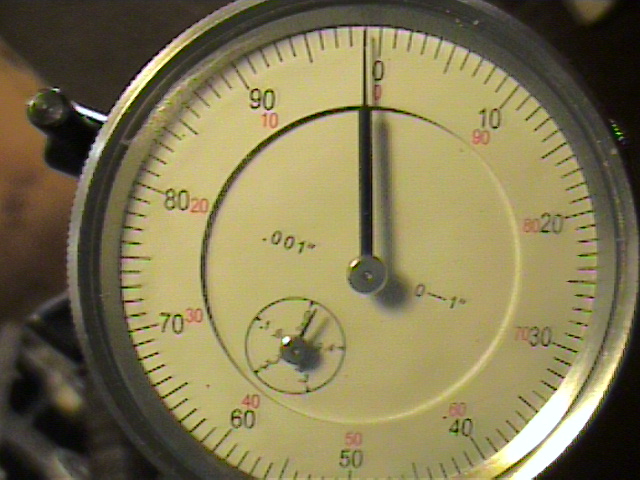

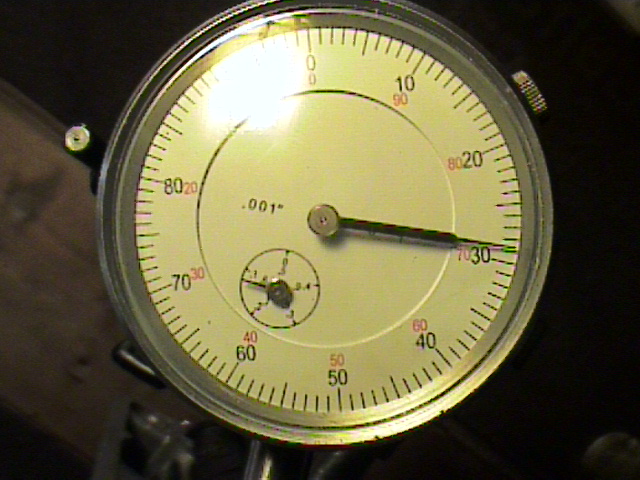

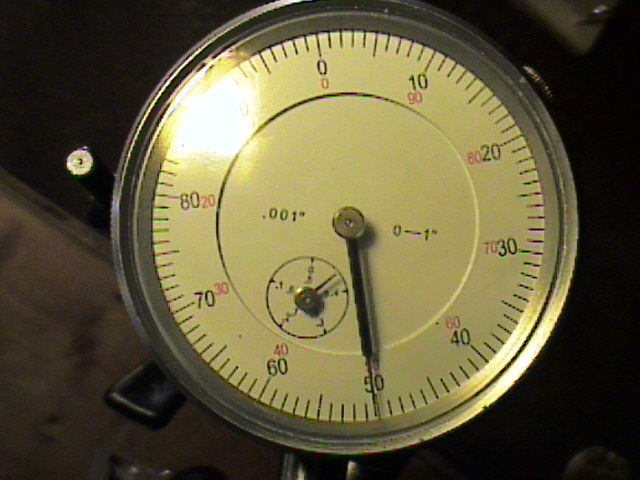

Secured the micrometer assembly to the head.

Here's pics of the setup:

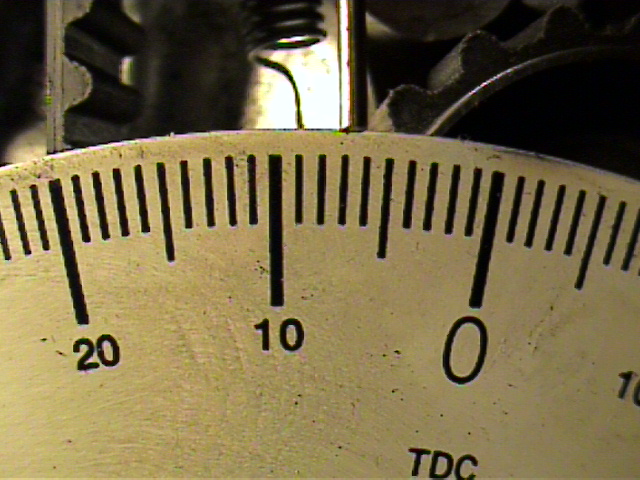

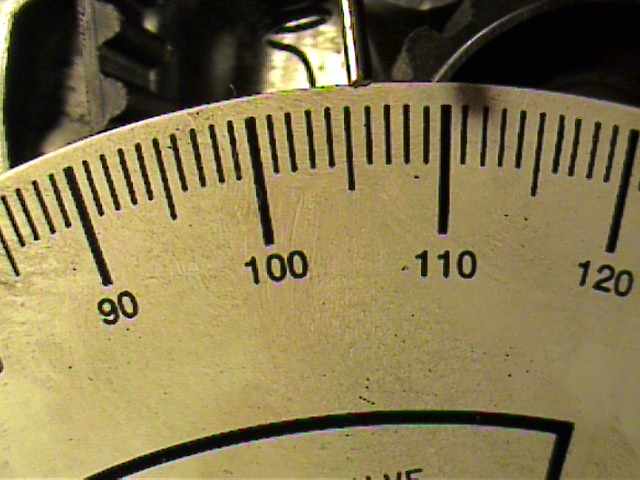

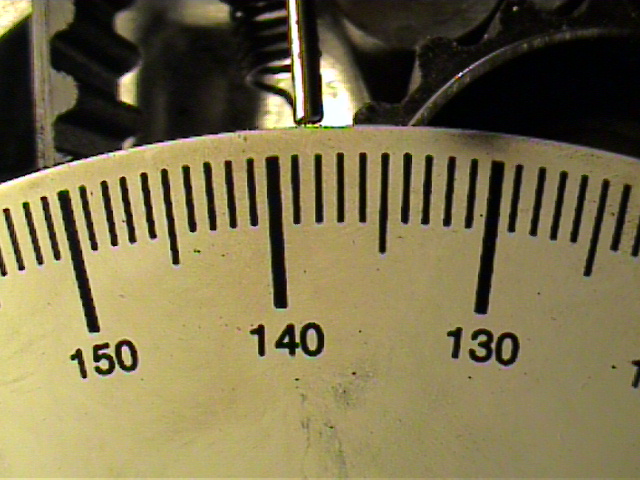

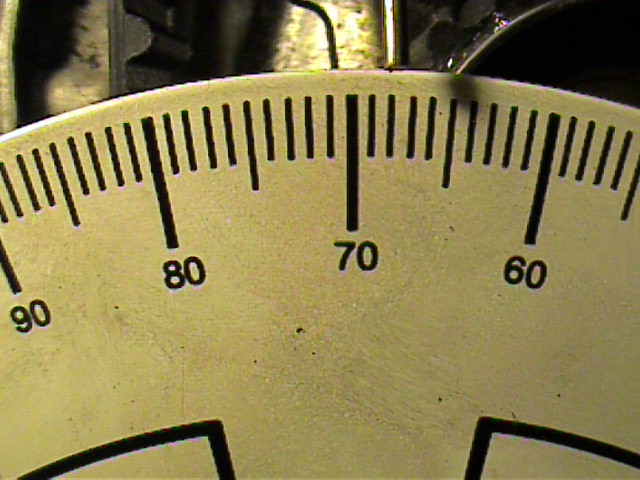

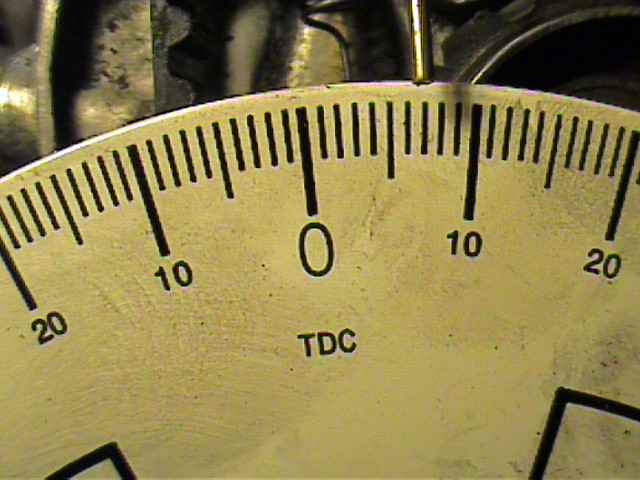

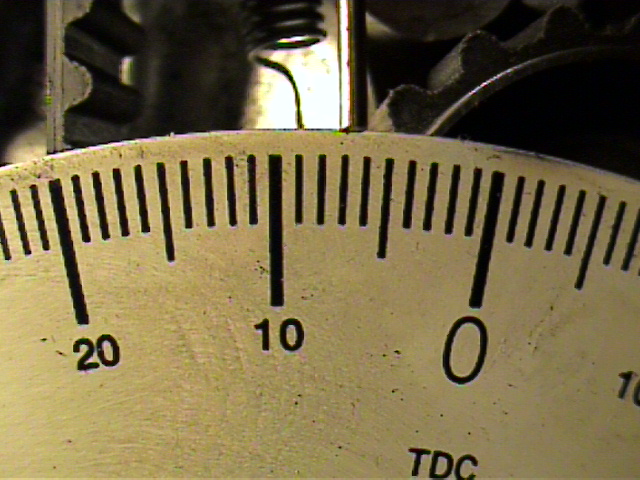

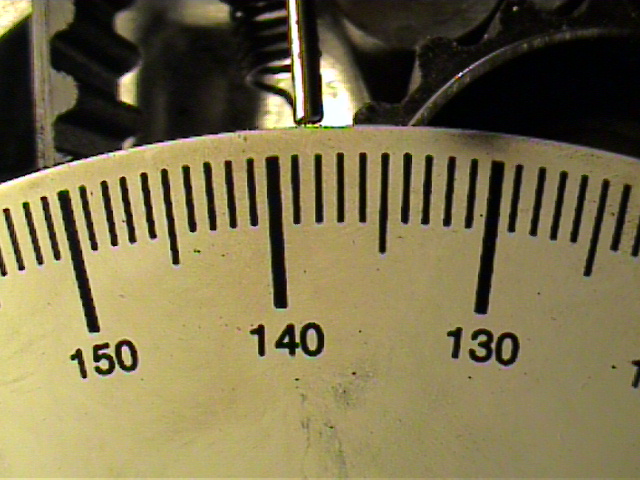

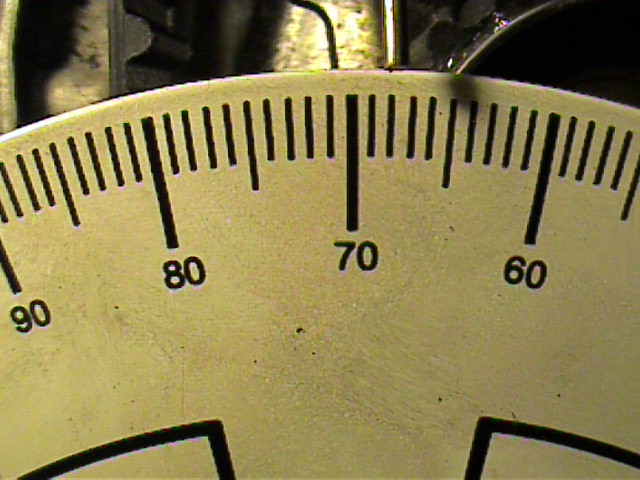

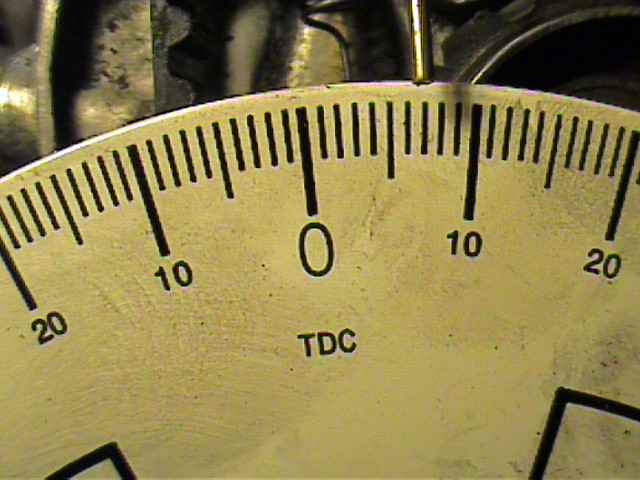

Next I used the micrometer to find TDC and set my pointer on TDC on the degree wheel:

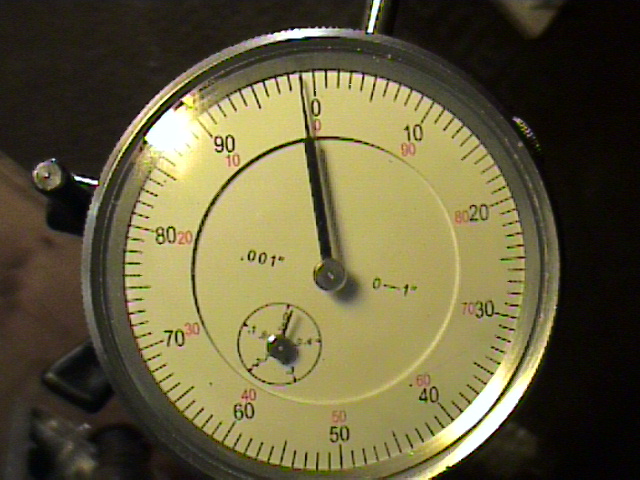

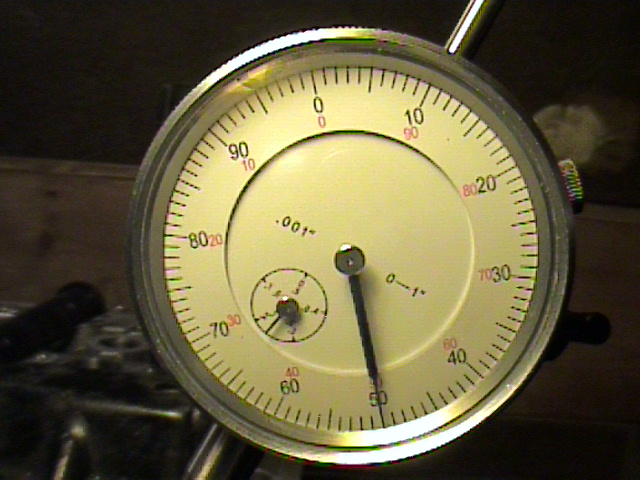

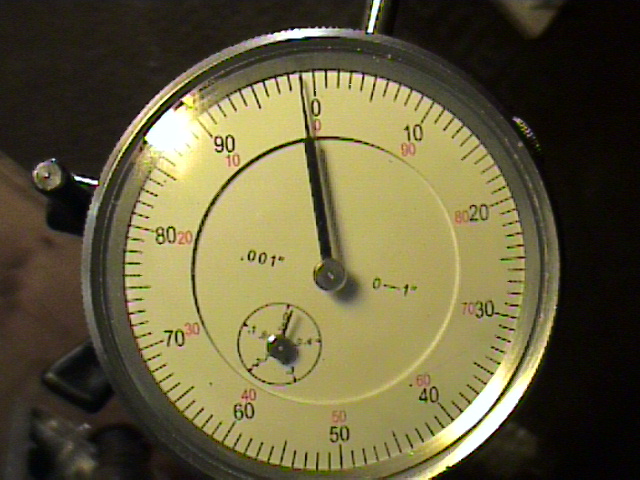

Next I put the micrometer on the intake valve spring retainer to check the intake cam lobe:

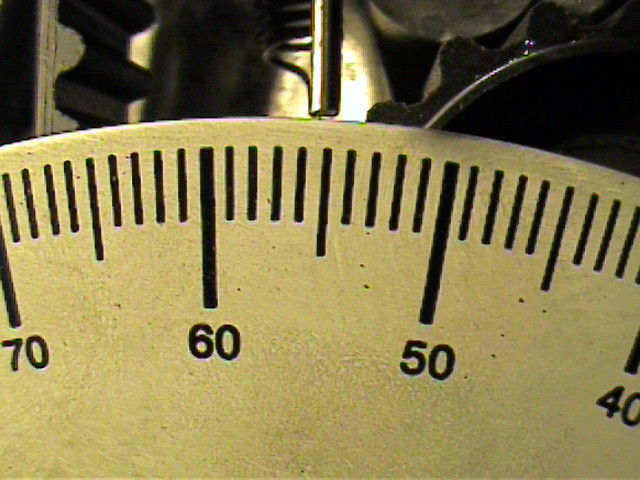

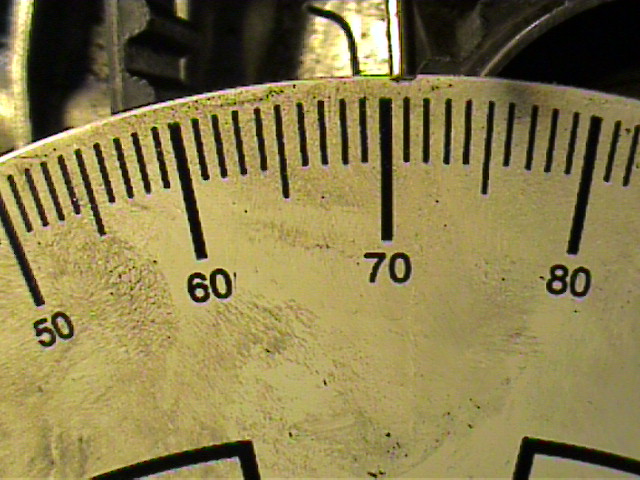

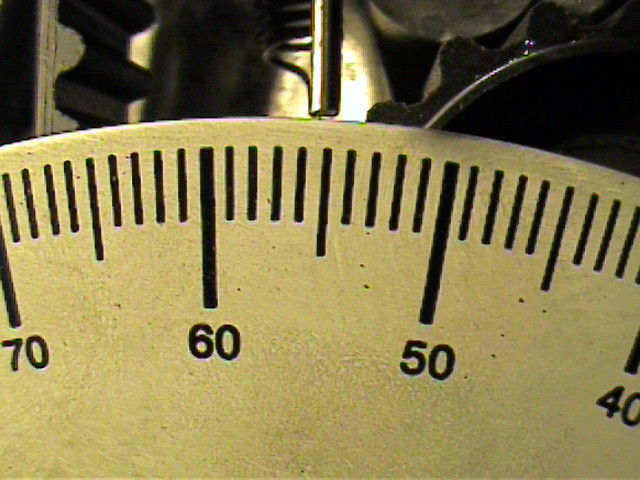

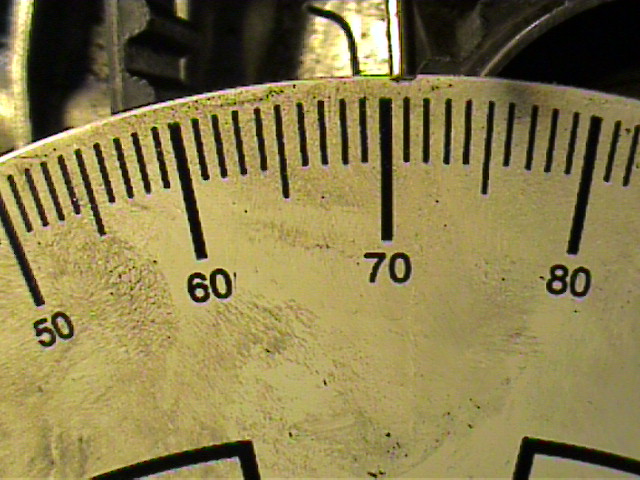

It starts opening the valve (.001 degree at 55 degrees BTDC)

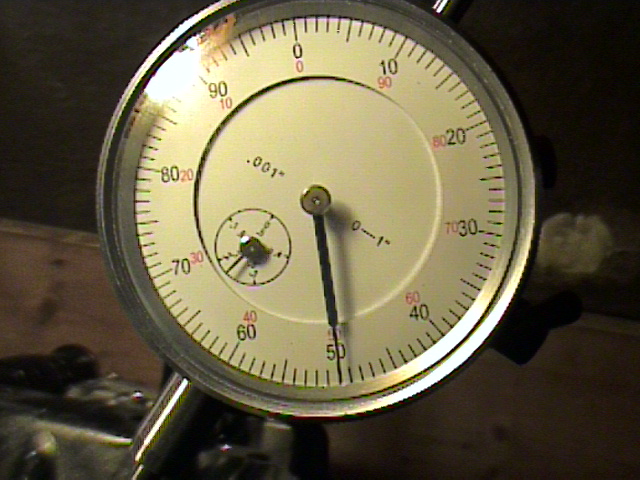

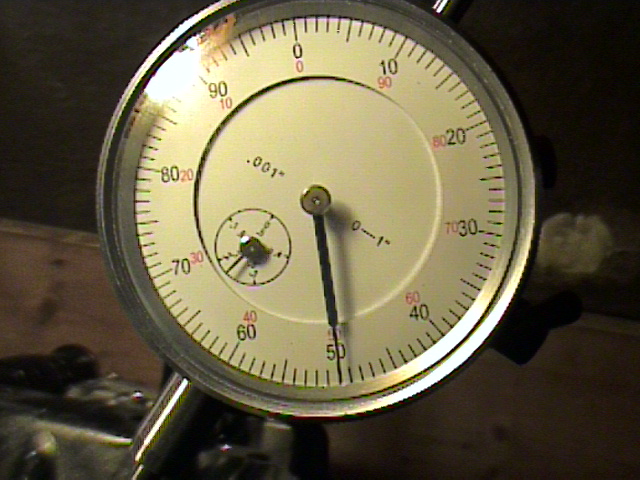

Opening to .050" at 7 degrees BTDC:

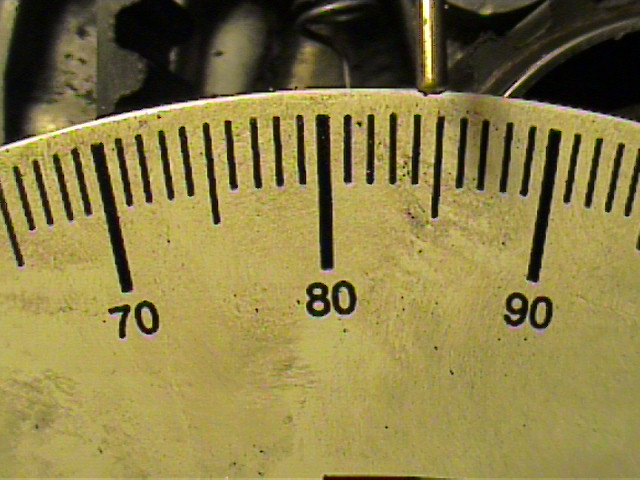

Max lift of .417" @ 106 degrees ATDC

Closing (.050" @ 138 degrees BTDC)

About closed (.001" @ 68 degrees BTDC)

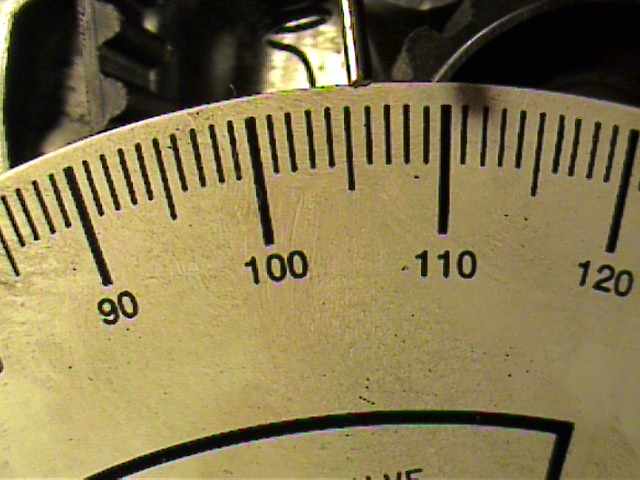

<U>Now for the exhaust:</U>

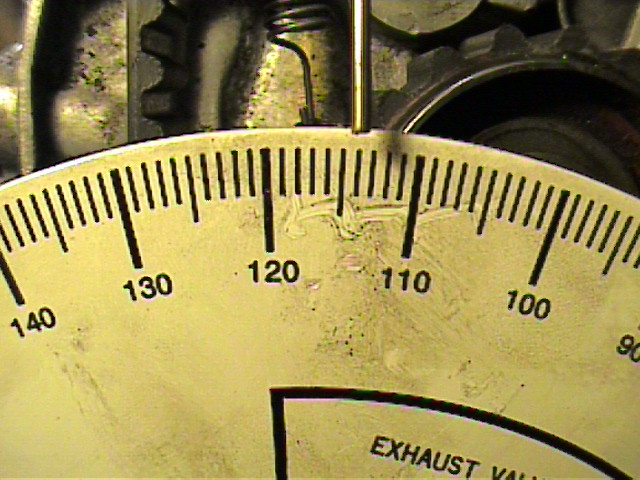

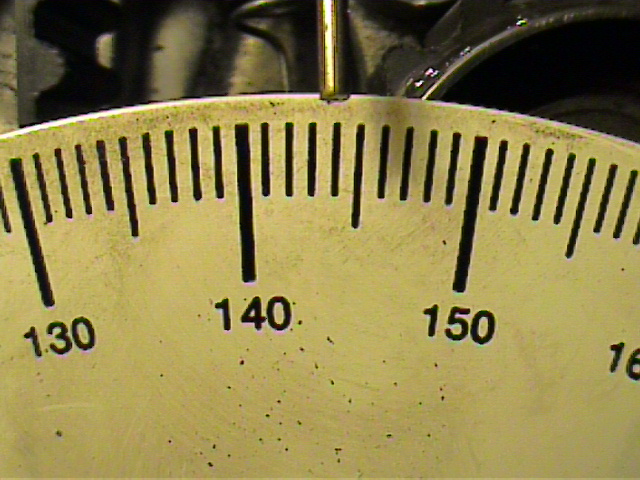

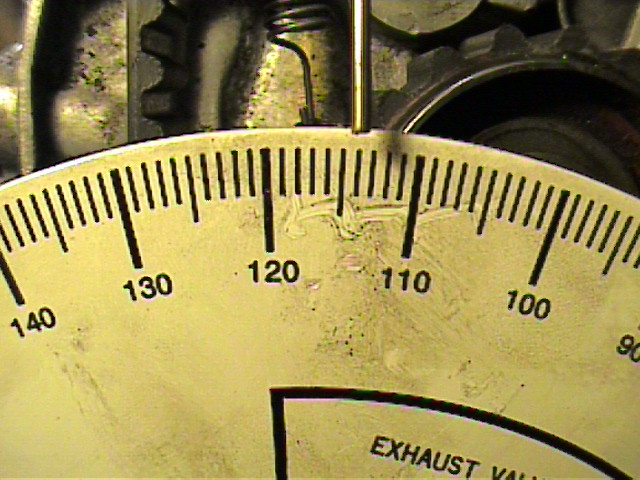

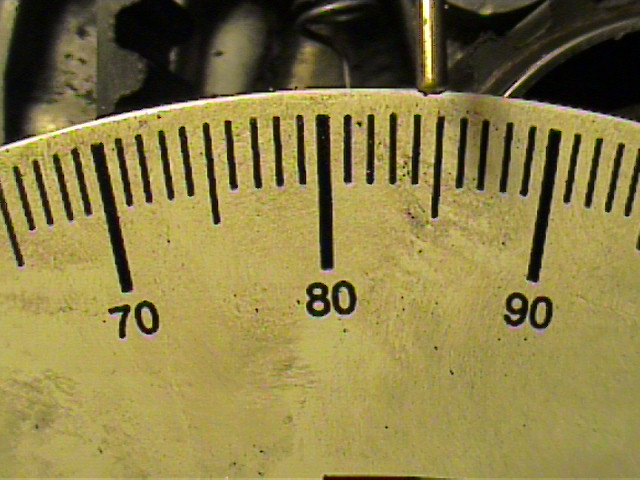

Starting to open (.001 degree at 71 degrees ATDC)

Opening (.050" @ 144 degrees ATDC)

Max lift (.371" @ 114 degrees BTDC):

Closing (.050" @ 7 degrees ATDC)

About closed (.001" @ 85 degrees ATDC)

That's all I got, please let me know if I'm doing anything wrong. I still need to figure where to get the information about where the valves are supposed to be opening. Once I get it all figured out I will try it on the motor in my car. Brad from RLZ gave me some numbers a while back, but they don't seem to be anywhere near what I'm seeing here, I'm guessing I don't understand what I'm doing yet.

Thanks to Hung and Danny at Phantasm in Raleigh, NC, for invaluable assistance with getting this setup together.

Removed the cams/rockers, removed the springs for an intake and an exhaust valve, replaced them with lighter springs, replaced those two rockers and locked the VTEC rockers to them, replaced cams, and set valve clearances to 0".

Bolted the degree wheel to the crankshaft and the pointer to the head.

Secured the micrometer assembly to the head.

Here's pics of the setup:

Next I used the micrometer to find TDC and set my pointer on TDC on the degree wheel:

Next I put the micrometer on the intake valve spring retainer to check the intake cam lobe:

It starts opening the valve (.001 degree at 55 degrees BTDC)

Opening to .050" at 7 degrees BTDC:

Max lift of .417" @ 106 degrees ATDC

Closing (.050" @ 138 degrees BTDC)

About closed (.001" @ 68 degrees BTDC)

<U>Now for the exhaust:</U>

Starting to open (.001 degree at 71 degrees ATDC)

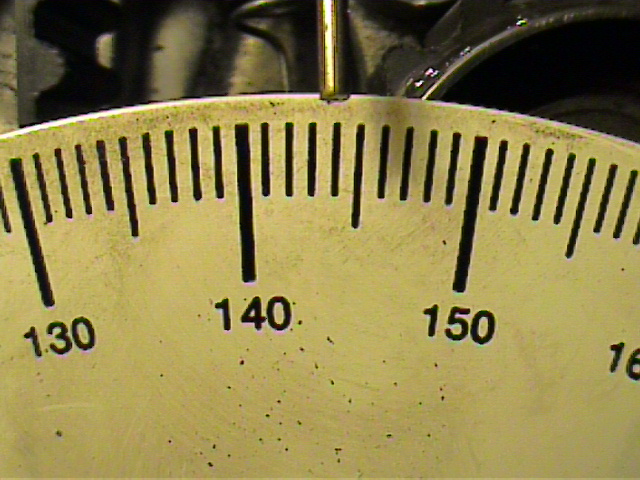

Opening (.050" @ 144 degrees ATDC)

Max lift (.371" @ 114 degrees BTDC):

Closing (.050" @ 7 degrees ATDC)

About closed (.001" @ 85 degrees ATDC)

That's all I got, please let me know if I'm doing anything wrong. I still need to figure where to get the information about where the valves are supposed to be opening. Once I get it all figured out I will try it on the motor in my car. Brad from RLZ gave me some numbers a while back, but they don't seem to be anywhere near what I'm seeing here, I'm guessing I don't understand what I'm doing yet.

Thanks to Hung and Danny at Phantasm in Raleigh, NC, for invaluable assistance with getting this setup together.

#3

Honda-Tech Member

Thread Starter

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by Dogginator »</TD></TR><TR><TD CLASS="quote">I glanced through and it looks reasonable.

Is there a spec for the optimal settings?</TD></TR></TABLE>

There probably is, but all I have here is the spec sheet for my Blox cams, which just says +2 on the intake. I need something that tells me how much they are supposed to open and when.

Is there a spec for the optimal settings?</TD></TR></TABLE>

There probably is, but all I have here is the spec sheet for my Blox cams, which just says +2 on the intake. I need something that tells me how much they are supposed to open and when.

#4

Daisy... Daisy...

Most people adjust cam gears by trial and error. I wonder what the optimal settings are for the stock cams and aftermarket cams? The degreeing method would minimize dyno time. (I'm too cheap to pay for dyno time.)

I've seen some data like these:

B Series Engine Specifications

I've seen some data like these:

B Series Engine Specifications

#5

Honda-Tech Member

Thread Starter

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by Dogginator »</TD></TR><TR><TD CLASS="quote">Most people adjust cam gears by trial and error. I wonder what the optimal settings are for the stock cams and aftermarket cams? The degreeing method would minimize dyno time. (I'm too cheap to pay for dyno time.)

I've seen some data like these:

B Series Engine Specifications</TD></TR></TABLE>

Thanks, that's exactly what I was looking for, sure wish my dial gauge was metric.

I've seen some data like these:

B Series Engine Specifications</TD></TR></TABLE>

Thanks, that's exactly what I was looking for, sure wish my dial gauge was metric.

#6

Daisy... Daisy...

1mm = 0.0394" (1/25.4)

You may need to factor the rocker arm ratio into the measurements. I'm not sure what that is. I'm not sure if the lift data are for the actual cam profile or the valve lift. You can measure that easily with your setup.

You may need to factor the rocker arm ratio into the measurements. I'm not sure what that is. I'm not sure if the lift data are for the actual cam profile or the valve lift. You can measure that easily with your setup.

#7

Honda-Tech Member

Thread Starter

I checked it again and got the following:

specification measured

Intake valve opens 1mm 10 BTDC 11 BTDC

Intake valve closes 1mm 40 ABDC 44 ABDC

Intake max lift 0.417 0.417

Exhaust valve opens 1mm 40 BBDC 40 BBDC

Exhaust valve closes 1mm 7 ATDC 10 ATDC

Exhaust max lift 0.37 0.373

I think that's not bad considering the motor is loosely assembled from junk parts.

I also talked to Tom at Portflow for a couple of minutes today and asked him about degreeing cams, he said I should try using the piston stop to determine TDC. Tom was right, the piston stop is faster, easier, and more accurate than the dial gauge.

I may be about ready to try this on the motor in my car. I just need to get the valve timing/lift specs from Blox, they aren't on the cam spec sheet.

specification measured

Intake valve opens 1mm 10 BTDC 11 BTDC

Intake valve closes 1mm 40 ABDC 44 ABDC

Intake max lift 0.417 0.417

Exhaust valve opens 1mm 40 BBDC 40 BBDC

Exhaust valve closes 1mm 7 ATDC 10 ATDC

Exhaust max lift 0.37 0.373

I think that's not bad considering the motor is loosely assembled from junk parts.

I also talked to Tom at Portflow for a couple of minutes today and asked him about degreeing cams, he said I should try using the piston stop to determine TDC. Tom was right, the piston stop is faster, easier, and more accurate than the dial gauge.

I may be about ready to try this on the motor in my car. I just need to get the valve timing/lift specs from Blox, they aren't on the cam spec sheet.

Trending Topics

#8

Honda-Tech Member

Join Date: Aug 2001

Location: Arlington, Texas, USA

Posts: 387

Likes: 0

Received 0 Likes

on

0 Posts

Looks like a comp cam degreeing kit, I hated mine cause I couldnt figure the **** out. Since then I've been schooled on the proper procedures on how to do so, from the looks of things you seem to have everthing straight. I was told the you should lash the valves at factory lash though on that part, and the gauge that you have 1mm = 40 on your gauge. Hope this help some cause I know from my experience that degreeing cams can be a bitch without alot of knowledge on how to do so, but you have the general idea..

#9

Honda-Tech Member

Thread Starter

Thanks for the input. I got the kit for $99 off of a Chevy dealer, but it does look like the Comp kit, just different graphics on the wheel. I had to modify it a bit, grind off the mounting bolt and tap it for a metric stud, plus extend the arm off of the dial gauge to fit down inside a Honda head and grind down the mounting shaft so it doesn't hit the cams. It's getting easier every time I practice with it, I'm really glad I built the dummy motor. If I can find some cam timing specs for my new cams, then I'll try it on the motor in my car this weekend.

Thread

Thread Starter

Forum

Replies

Last Post

Ryan15

All Motor / Naturally Aspirated

2

09-13-2006 06:45 AM

thehatchninja

All Motor / Naturally Aspirated

2

06-10-2005 11:37 AM

BryanPendleton

All Motor / Naturally Aspirated

9

03-17-2005 12:47 PM