B-series transmission teardown/rebuild tutorial

#26

Solbros Owns Me

#28

Solbros Owns Me

me...old? I am bald, but not old

Like I said, I used to flip them over...but as a flat rate tech...time was money I'd bang out an ISB/clutch/fw/rr main job in under 90 minutes

I'd bang out an ISB/clutch/fw/rr main job in under 90 minutes

Like I said, I used to flip them over...but as a flat rate tech...time was money

I'd bang out an ISB/clutch/fw/rr main job in under 90 minutes

I'd bang out an ISB/clutch/fw/rr main job in under 90 minutes

#29

Honda-Tech Member

Thread Starter

Join Date: Nov 2004

Location: 40.201N, 77.189W, PA

Posts: 4,738

Likes: 0

Received 7 Likes

on

4 Posts

Two more random pics of damage.

Broken synchro spring:

New and used dog teeth on the sychronizer sleeves:

#30

Honda-Tech Member

Thread Starter

Join Date: Nov 2004

Location: 40.201N, 77.189W, PA

Posts: 4,738

Likes: 0

Received 7 Likes

on

4 Posts

K-SERIES:

To do a K-series, you can for the most part follow the B-series guide step by step. The following photos and explanations are what need changed. Beyond that, it's the same basic principle. Just always take your time and keep things in order and make sure they get back together correctly.

Tools:

Same as B-series for the most part.

14mm allen socket (1/2")

8mm allen socket (3/8")

Small pick or screwdriver (possibly)

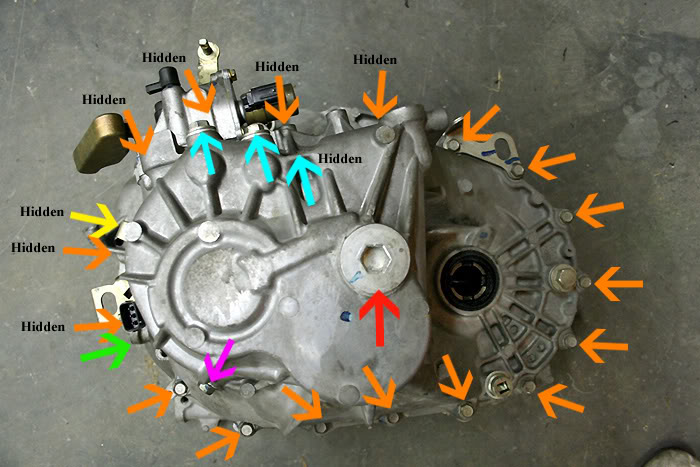

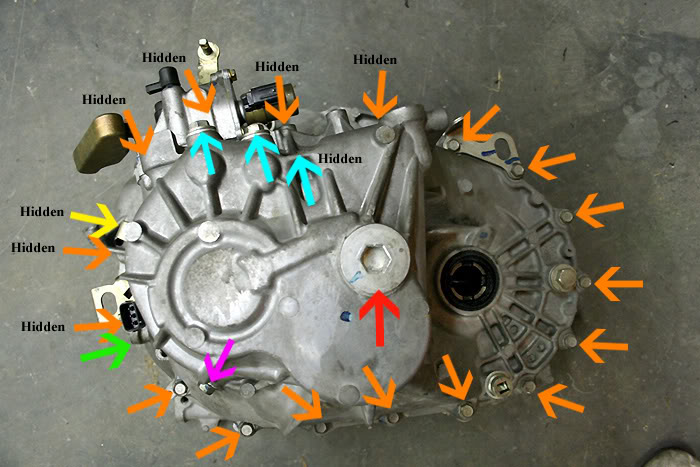

Here is the overall bird's view of the K-series. Yes, it's opposite the B-series. Diff to the right and what not.

These are the majority of the bolts you will be removing. There are still 17 12mm transmission case bolts (ORANGE ARROWS). As a general rule, remove these bolts last during teardown. During rebuild, these go in first. For the other bolts, it's safe to remove them in any order you wish for the most part. The shift fork bolts retaining the ***** and springs (TEAL ARROWS) are still there as well, excepte there are three now, instead of two. There is also the standard 14mm reverse idler shaft bolt (PURPLE ARROW). The bolt which covers the c-clip is now a 14mm allen bolt (RED ARROW) rather than the 1/2" square bolt of the B-series.

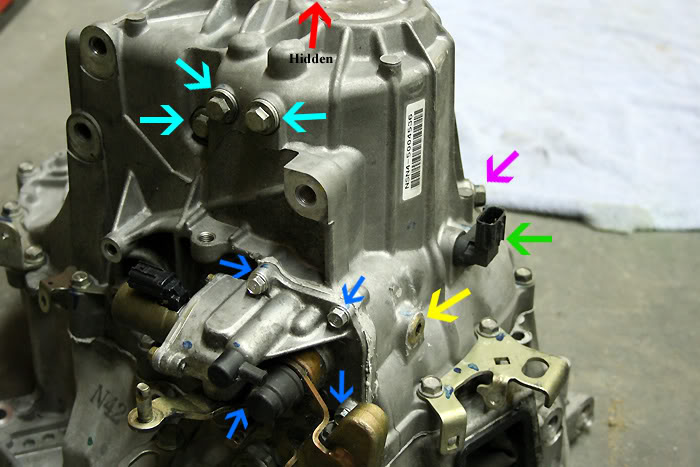

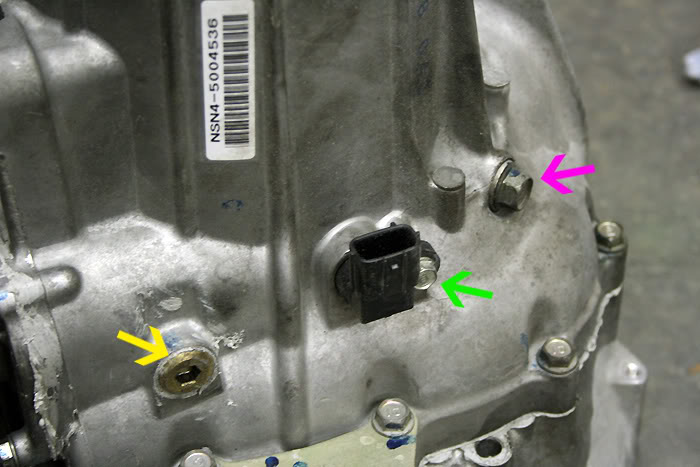

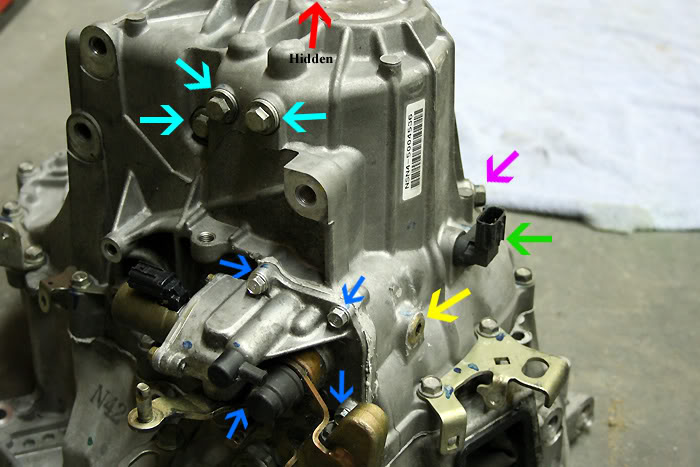

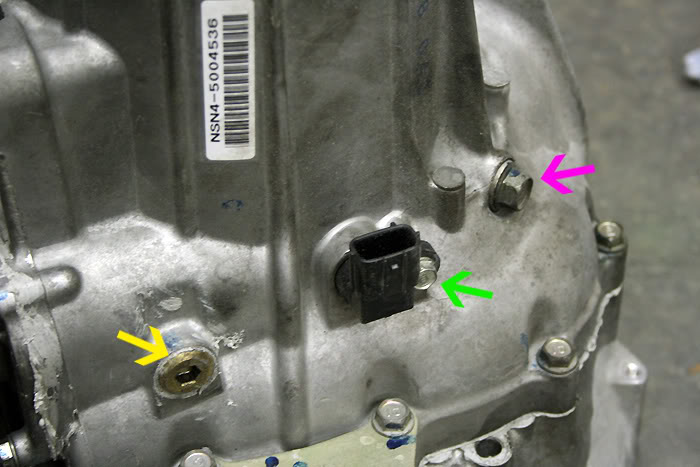

For the shift change assembly, which is drastically different, you will remove 5 bolts. There is one 8mm allen bolt (YELLOW ARROW), as well as four 10mm bolts (BLUE ARROWS and HIGHLIGHTS). Once these are removed, this entire piece will simply pull out. It may stick a bit if there is Honda Bond on the mating surface.

NOTE: In the 6-speed models with the magnetic speed sensor reading from the 3rd gear (2005-2006 6-speed transmissions exclusively I believe), you must remove a 10mm bolt and pull the speed sensor out before lifting up the casing. More than likely, if you don't, you will severely damage the magnet as it is pulled up past the 3-4 and 5-6 synchronize sleeves.

The only other bolts are inside the casing. There are two 10mm black bolts which hold the reverse change assembly to the casing, just like in the B-series.

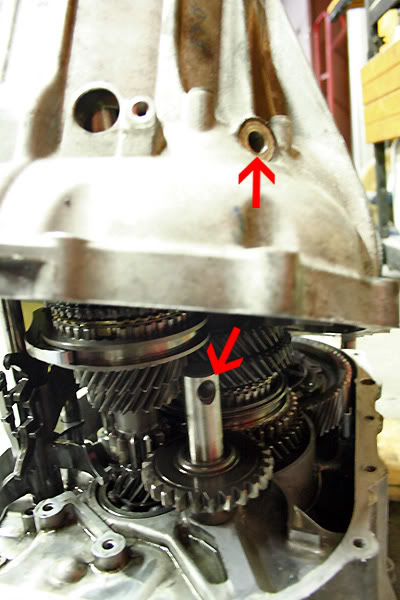

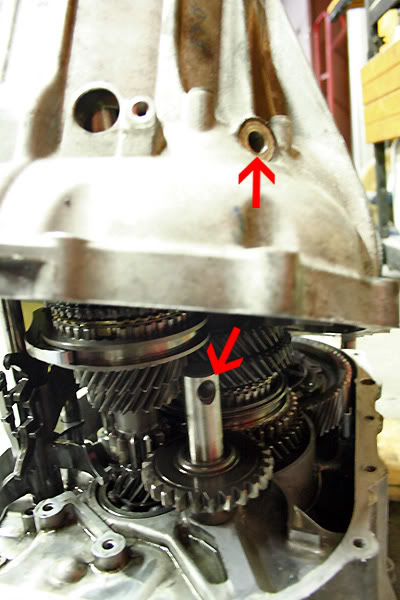

This is the c-clip design - open in the photo. The case is alot more shallow, but the c-clip in general is much easier to open up than a B-series.

There is also an annoying difference with the reverse idler shaft in the K-series transmissions. The shafts do not have the locating pin for the case, even though the case has a location for that pin. :scratches head: Be sure to line up the bolt hole in the shaft to its rough location on the transmission case (RED ARROWS). Even if it is a little off, you can still use a pick or small screwdriver to get in there and rotate the shaft around so it all lines up. The first K-series I rebuilt I never took notice to this, and when I went to thread the reverse bolt back in, the hole in the shaft wasn't even in sight! With a pick, I still managed to rotate it around so that I didn't have to separate the case and possibly do any more work to the sealant.

To do a K-series, you can for the most part follow the B-series guide step by step. The following photos and explanations are what need changed. Beyond that, it's the same basic principle. Just always take your time and keep things in order and make sure they get back together correctly.

Tools:

Same as B-series for the most part.

14mm allen socket (1/2")

8mm allen socket (3/8")

Small pick or screwdriver (possibly)

Here is the overall bird's view of the K-series. Yes, it's opposite the B-series. Diff to the right and what not.

These are the majority of the bolts you will be removing. There are still 17 12mm transmission case bolts (ORANGE ARROWS). As a general rule, remove these bolts last during teardown. During rebuild, these go in first. For the other bolts, it's safe to remove them in any order you wish for the most part. The shift fork bolts retaining the ***** and springs (TEAL ARROWS) are still there as well, excepte there are three now, instead of two. There is also the standard 14mm reverse idler shaft bolt (PURPLE ARROW). The bolt which covers the c-clip is now a 14mm allen bolt (RED ARROW) rather than the 1/2" square bolt of the B-series.

For the shift change assembly, which is drastically different, you will remove 5 bolts. There is one 8mm allen bolt (YELLOW ARROW), as well as four 10mm bolts (BLUE ARROWS and HIGHLIGHTS). Once these are removed, this entire piece will simply pull out. It may stick a bit if there is Honda Bond on the mating surface.

NOTE: In the 6-speed models with the magnetic speed sensor reading from the 3rd gear (2005-2006 6-speed transmissions exclusively I believe), you must remove a 10mm bolt and pull the speed sensor out before lifting up the casing. More than likely, if you don't, you will severely damage the magnet as it is pulled up past the 3-4 and 5-6 synchronize sleeves.

The only other bolts are inside the casing. There are two 10mm black bolts which hold the reverse change assembly to the casing, just like in the B-series.

This is the c-clip design - open in the photo. The case is alot more shallow, but the c-clip in general is much easier to open up than a B-series.

There is also an annoying difference with the reverse idler shaft in the K-series transmissions. The shafts do not have the locating pin for the case, even though the case has a location for that pin. :scratches head: Be sure to line up the bolt hole in the shaft to its rough location on the transmission case (RED ARROWS). Even if it is a little off, you can still use a pick or small screwdriver to get in there and rotate the shaft around so it all lines up. The first K-series I rebuilt I never took notice to this, and when I went to thread the reverse bolt back in, the hole in the shaft wasn't even in sight! With a pick, I still managed to rotate it around so that I didn't have to separate the case and possibly do any more work to the sealant.

#34

just a quick question, what are some of the symptoms if the input shaft bearing or the piolot bearing need replacing. i think i got to do those on my car, when it was idle i would hear that grinding sound once in a while then about 3 days ago my car died. has a little bit of trouble going into gear, does not drive unless it is in neutral then will get up to like 5mph and thats it. kinda seems like its almost stuck in gear. tks

#35

Solbros Owns Me

input shaft or end case mainshaft bearing will make noise when mainshaft is spinning- in neutral with foot off clutch, or while driving in gear. Noise will go away with foot on clutch.

Pilot bearing sometimes makes a slight whirring noise, but you will hardly ever hear one of these go bad.

Sounds like maybe a disc spring popped out, or is intermittently causing issues.

Wait- so you cant move past 5mph?

Pilot bearing sometimes makes a slight whirring noise, but you will hardly ever hear one of these go bad.

Sounds like maybe a disc spring popped out, or is intermittently causing issues.

Wait- so you cant move past 5mph?

#36

input shaft or end case mainshaft bearing will make noise when mainshaft is spinning- in neutral with foot off clutch, or while driving in gear. Noise will go away with foot on clutch.

Pilot bearing sometimes makes a slight whirring noise, but you will hardly ever hear one of these go bad.

Sounds like maybe a disc spring popped out, or is intermittently causing issues.

Wait- so you cant move past 5mph?

Pilot bearing sometimes makes a slight whirring noise, but you will hardly ever hear one of these go bad.

Sounds like maybe a disc spring popped out, or is intermittently causing issues.

Wait- so you cant move past 5mph?

#41

Honda-Tech Member

Thread Starter

Join Date: Nov 2004

Location: 40.201N, 77.189W, PA

Posts: 4,738

Likes: 0

Received 7 Likes

on

4 Posts

thanks for the write up. but i am having so much trouble with the snap ring. I open the snap ring with pliers and i used 4 (12mm) bolts to close the case.

Although the case closed flush. the bearing only went high enough to hold the snap ring wide open but not seat it in the groove of the bearing.

So I bang the tranny on a phone book but no go. I look at the snap ring and the grove in the bearing isn't even close.... what should I do?

Although the case closed flush. the bearing only went high enough to hold the snap ring wide open but not seat it in the groove of the bearing.

So I bang the tranny on a phone book but no go. I look at the snap ring and the grove in the bearing isn't even close.... what should I do?

#43

Honda-Tech Member

Thread Starter

Join Date: Nov 2004

Location: 40.201N, 77.189W, PA

Posts: 4,738

Likes: 0

Received 7 Likes

on

4 Posts

Hmmm... that's a weird one. Post some pics of it if you get a chance. Honestly, I can't say I've had an issue like that, so can't really suggest anything other than the case being too tight (which I've done before). But if the snap ring moves around, the case isn't too tight for you. I was going to suggest that perhaps the countershaft bearing was upside-down (judging by you saying that the clip is nowhere near the groove for it), but if you just did a diff swap, you never would have messed with that.

#46

ok so uhh....i got the same problem as aznlaoboi315 as far as the clip not wanting to do its job....but my shifter fork and shaft are ALL locked up shifter wont move and main shaft wont turn...HELP!!!

#47

Honda-Tech Member

Thread Starter

Join Date: Nov 2004

Location: 40.201N, 77.189W, PA

Posts: 4,738

Likes: 0

Received 7 Likes

on

4 Posts

Man, another one like that?

Ok. Well, what is the clip doing? Are you spreading the ends and it just won't stay open? Does it stay open, but no matter what you do, the countershaft won't drop into place up into the clip?

Also, what do you mean the shift forks are locked up? With the case on it? Or with the case off? If the mainshaft won't turn, possibly the forks have shifted, moving atleast two sliders into gears. When you have two gears selected at the same time, it will lock up.

Ok. Well, what is the clip doing? Are you spreading the ends and it just won't stay open? Does it stay open, but no matter what you do, the countershaft won't drop into place up into the clip?

Also, what do you mean the shift forks are locked up? With the case on it? Or with the case off? If the mainshaft won't turn, possibly the forks have shifted, moving atleast two sliders into gears. When you have two gears selected at the same time, it will lock up.

#48

the clip stays open and no matter what i do the countershaft wont drop...i already put the bolts back in and it wont go side to side so i guess thats in a bind but i dont know if that has anything to do with the shifter not wanting to move...the shifter didnt want to move even before i put the 4 12mm bolts in...

#50

Honda-Tech Member

Thread Starter

Join Date: Nov 2004

Location: 40.201N, 77.189W, PA

Posts: 4,738

Likes: 0

Received 7 Likes

on

4 Posts

Is the c-clip free to move around when you've got the case on? Or is it tight?

With the shifter not being able to move... it's possible that one or more of your sliders are really loose and fall down easily. Sometimes, when you put the case on, the case will contact the top of a shift fork and bump it down into gear, keeping the shift change assembly from moving much. Once you get the case closed and go to move the shifter around, the shift change assembly will actually rotate out of the middle of the three shift forks, as well, and lock into the 1-2 fork, which possibly fell easily since the slider was loose and had play. I've had this happen a couple of times on cable B-series. Once the shifter gets locked into that shift fork, it won't be able to rotate back into the neutral region. Not sure why entirely, but it just locks up. Perhaps that's what's happened with yours. You can try to put a screwdriver or any rod in below the three shift fork tabs to keep them held up as you press the case down. Then just remove the screwdriver or whatever as the case is finally closing.

Hope this helps somewhat.

With the shifter not being able to move... it's possible that one or more of your sliders are really loose and fall down easily. Sometimes, when you put the case on, the case will contact the top of a shift fork and bump it down into gear, keeping the shift change assembly from moving much. Once you get the case closed and go to move the shifter around, the shift change assembly will actually rotate out of the middle of the three shift forks, as well, and lock into the 1-2 fork, which possibly fell easily since the slider was loose and had play. I've had this happen a couple of times on cable B-series. Once the shifter gets locked into that shift fork, it won't be able to rotate back into the neutral region. Not sure why entirely, but it just locks up. Perhaps that's what's happened with yours. You can try to put a screwdriver or any rod in below the three shift fork tabs to keep them held up as you press the case down. Then just remove the screwdriver or whatever as the case is finally closing.

Hope this helps somewhat.