♠ Shaved, Tucked, Customized Engine Bays - Pics, Theory, Discussion ♠

#1

EFSS153

Thread Starter

This is an informational thread. We try to stay on topic and discuss anything engine bay related. This post has reference info at the bottom to make everyones life easier. If you have any info you'd like to contribute, feel free to post it, or PM me, and I'll add it.

[/quote]

<FONT COLOR="red">Rywire.com - G e t _ R y w i r e d .</FONT>

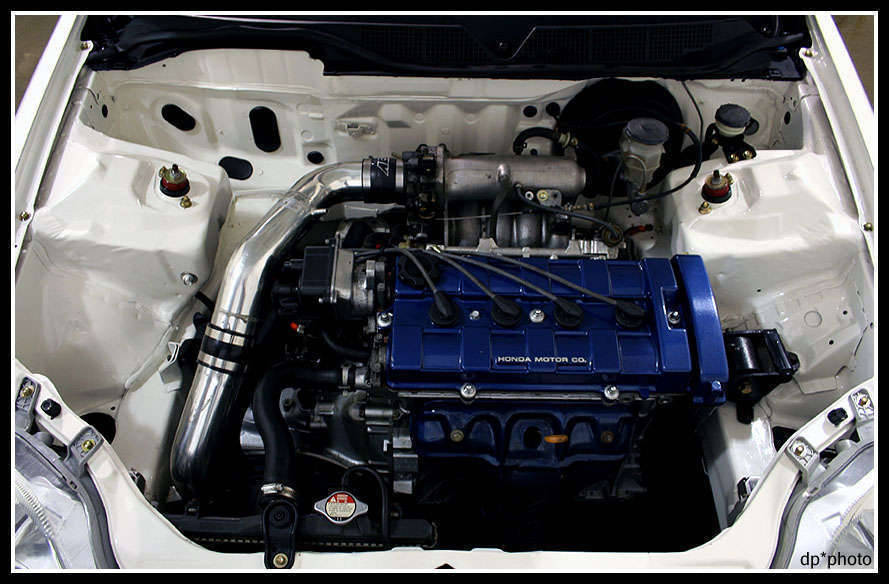

Look at this harness ive been working on

mockup

More mocking up...

Phew, all done... this harness is the hardest ive made as of yet...

Let me clear up some stuff for everyone.

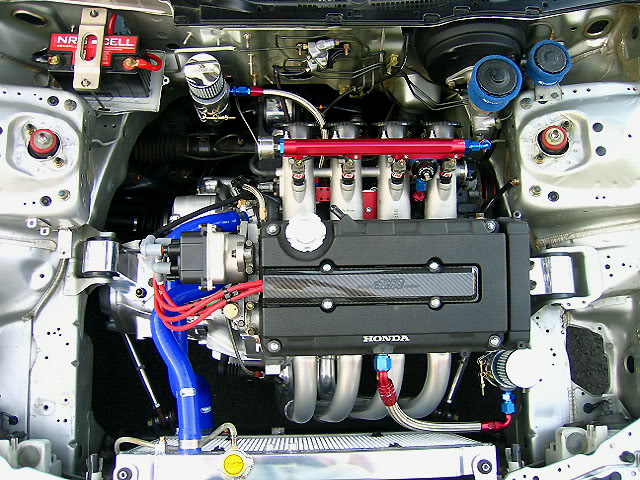

The wire is milspec, its very expensive... I did the harness in a power/ground/signal setup, so thats why there is 3 colors. Its not hard at all to diagnose with a multimeter. All wires are new, and military grade. The pins are all new, and it took me a crazy long time to source them all... I really dont want to give any pins out, plus I have a limited supply.

Someone also asked me on another forum why I thought it was the hardest harness as of yet... if you havent made a harness all the way back to the ecu with all new wires, and expensive parts that you dont want to ruin, dont ask

People also asked where the back half is on this harness, I do have it made, but its not cut into the firewall yet, there will be pix soon. I leave that half in just zipties, so if changes ever need to be made, they can be made on that end.

If anyone ever looks at the wiring harness on a exotic race spec car, Porsche/ bmw

they will notice similar characteristics between the harnesses, thats the look I was going for... Some people are gunna say this is overkill, and it sure is, but this is what I do for a living, and excess is necessary.

-Ryan

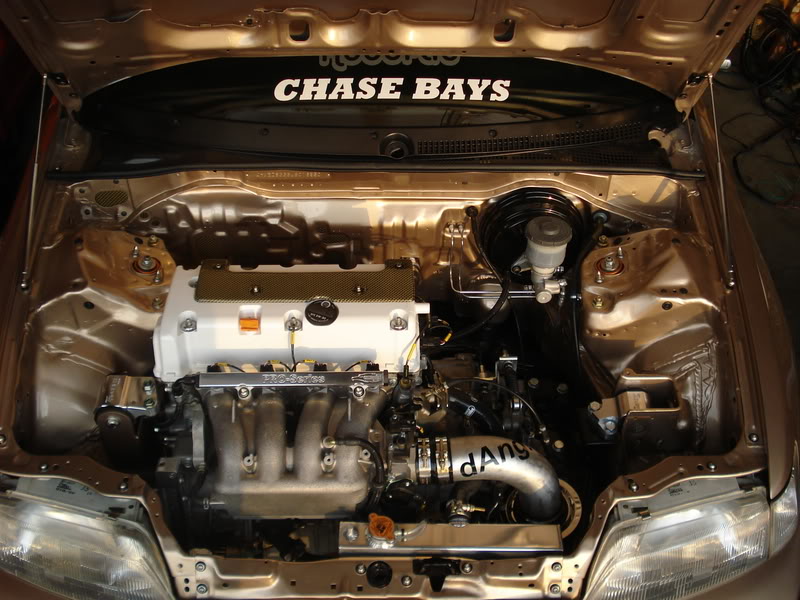

Chase

phunhaus

Fresh'86

outdated

Mr Pho King

STREETWERKZ

Red Zone

game over

Rywire

EF8kid

nickrps

Lenthrax

Some Hawaii dood

Not so JdmDan

t.blizzard

Questoyz by RHanDy

Harajuka

RIP V8s

Serio. Ferio.

ATS*EK24

crxsir88

SkankyEJ7

RickyGD (F/K/A CRXWolf)

EG6AAARRR!!!

JDM EJ1 95

Pandahatch

humbleg

lgda92gsr's

neema

black88si

J-specCb4

SlepT ej6

R.I.P Nick Haines - NHswaps13203

ATS*EG2

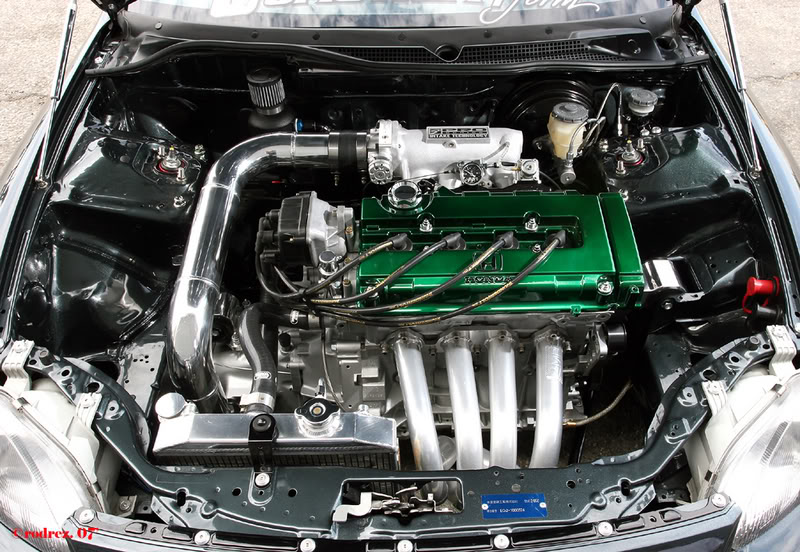

rodrez

sheepey

DarkBB4

VEEE*

H8 O ATE

EjSex

HeyMikeyyyy

Luserkid

maxpsi

mr_k20

Brad Pitts

Pics happily removed at the request of the owner.

.

.

.

.

.

.

.

.

.

.

<FONT COLOR="teal"><FONT SIZE="5">Reference Info:</FONT></FONT>

http://www.hondamarketplace.co...age=1

I'm gonna be using the braided loom from cableorganizer.com (http://cableorganizer.com/fray-resistant/#B) when I do my harness... and I just ordered my Odyssey PC680MJT!

I tried alot of different kinds and my favorite was actually this 80 grit stuff from home depot. (to sand filler down) It kept its grit the longest. Its like whiteish with blueish dots somewhat.

After u get it shaped you sand it with 320 so theres no sanding scratches. I liked the home depot stuff best again.

Then for wetsanding primer i used 3m jobpack 600grit and it worked good. Then wetsanding the clear i used 1600 and 2000 3m jobpack.

awesome! I love wires yay.

I love wires yay.

Actually, the link on page one is shitty. They dont offer enough sizes.

HEY EVERYONE, HERE'S WHERE I BUY MY HELLA KEWL SLEEVING AND HEATSHRINK FROM:

http://www.wirecare.com

You should NEVER NEVER NEVER use a caulk gun style seam sealer, use the 2 part sealer, it is more durable and will last 10x's longer as it DOES NOT shrink. It is catalyzed to harden and the single part **** is not.

sem makes a good 2 part seam sealer.... part# 39337

http://www.gruberpower.com/gru...0.asp

$48.95

Works great, used this battery when I did my wire tuck, have been starting the car about 3 times a day for a the past month or so with no problems.

I posted this information a while back, just thought I would do a sort of review on it.

Anyone ever use this battery or do you think this battery would be OK?

http://cgi.ebay.com/ebaymotors...ZWDVW

Planning on using it on my rarely driven show DA with a kill switch for storage.

Its between this or the odessy battery, this ones cheaper which would help since christmas is around the corner and I haven't started shopping yet, LOL!

Check out their disclaimer...

"SPECIAL NOTE

This battery is much lower cost than a comparable brand that rhymes with "Modyssey"

We cannot tell you the brand, but you may figure it out.

Someone is unhappy with us selling our batteries...you may be also be

able to figure who that is as well.

This completely comparable battery is lower cost only because

it does not have a half a dozen margin hungry companies in the food chain

driving the cost to the consumer beyond reasonable levels.

You be the judge....pay more for a over-distributed brand, or get a replacement

with the same specifications and performance for 1/2 the price."

lol

I'd say give it a shot.

<u>To answer future questions about this</u>....

<u>To answer future questions about this</u>....

I talked to Fast Brakes the other day and they said both chambers in the Honda master cylinder are the same size; (15/16) in my case. Therefore it does not matter which port on the MC goes to either input on the prop. valve. (The rear outputs still have to go the the rear, front to the fronts and input's to the MC.)

Thanks

OK, I'm thinking it does not matter so I am going to go off that... If someone knows otherwise PLEASE let me know asap so I dont wast my time bleading and all that for the bias to be off. Here is an image for reference. Just by looking at the desgin of the prop valve I am thinking it doesn't matter. http://www.we-todd-did-racing....e.jpg

<FONT COLOR="red">Thanks to Dumpgears for sourcing these quotes/info.</FONT>

Quote, originally posted by NathanMorris »

when you guys are taking out the charcoal canister stuff on the firewall - how are you dealing with that? IE: what are you doing with the fuel vapors, how are you setting up the PCV vent, etc. As many details about this would be wonderful as I'm looking to get rid of that set of big ugly black boxes if possible.

Nathan

Quote, originally posted by JDMlyfestyle »

have mine Routing out the side of my car.. its attached the the Front passanger Lift point so that the vapors are not coming into the cabin

Quote, originally posted by not so JDM Dan »

when i converted my fuel lines to stainless steel under the car, the smallest hard line which is the vent tube for the charcoal canister i cut at the back of the car near the tank and i ran a rubber hose back along the trailing arm. all the vapors vent out behind the car

<FONT COLOR="red">DONE MY CHASE MCMASTER (EF8kid)</FONT>

Quick link for you guys. Found this website that has a ton of the factory honda service manuals including wiring diagrams etc. You do have to register for the site to download the manuals, but there is no charge whatsoever.

http://www.hondahookup.com/manuals

http://www.waytekwire.com

http://www.delcity.net

Waytek Wire usually has lower minimum buying quantities on connectors so you're not stuck buying per hundred.

http://www.terminalsupplyco.com

They don't list their pricing on their site (which I know can be an inconvenience) but I know if you request a price quote and ask them to beat Del City or Waytek pricing they usually can. Sometimes there are minimum quantities for that pricing tho.

All 3 carry a wide variety of fittings/connectors/loom/shink tubing.

Just a few parts to help ease your relocating and give ideas:

Prefab battery holds:

http://odysseybatteries.com/im...m.jpg

http://odysseybatteries.com/im...m.jpg

Popular Battery's used:

Odyssey PC680MJT

http://odysseybatteries.com/ba...g.jpg

Odyssey PC680

http://odysseybatteries.com/battery/pc680_lg.jpg

Baker Precision

http://us.st11.yimg.com/us.st....82003

Accessories:

Battery Terminals

http://static.summitracing.com...w.jpg

Terminal Mounts

http://static.summitracing.com...w.jpg

Can be found at:

http://www.summitracing.com

http://www.odysseybatteries.com

http://www.inlinefour.com

http://www.bakerprecision.com

first you got the ac plug: part#91631-SR3-000

second this plug covers the stock engine harness hole/pass healight harness hole part #91610-sf4-003

pic

driver side plug part#90621-SE0-000

pic

3030 - 9.4" front / drum rear

3035 - 9.4" front / larger drum rear

3040 - 9.4 front / 9.3" disk rear

4040 - 10.25" front / 9.3" disk rear

4035 - 10.25" front / larger drum rear

4030 - 9.4" front / 9.3" disk

it helped me to understand some...

[b][b][b]<FONT SIZE="4">Continued on next two posts...</FONT>

Modified by -NA-aLL-thE-wAy- at 12:58 PM 10/28/2008

Originally Posted by Pworld

Who cares if its polished, chrome, or gold, its a personal expression of the car builder, his canvas to paint his picture that he wants to paint. If its done tastefully, I'm all for it.

Originally Posted by sh!tsWEAK

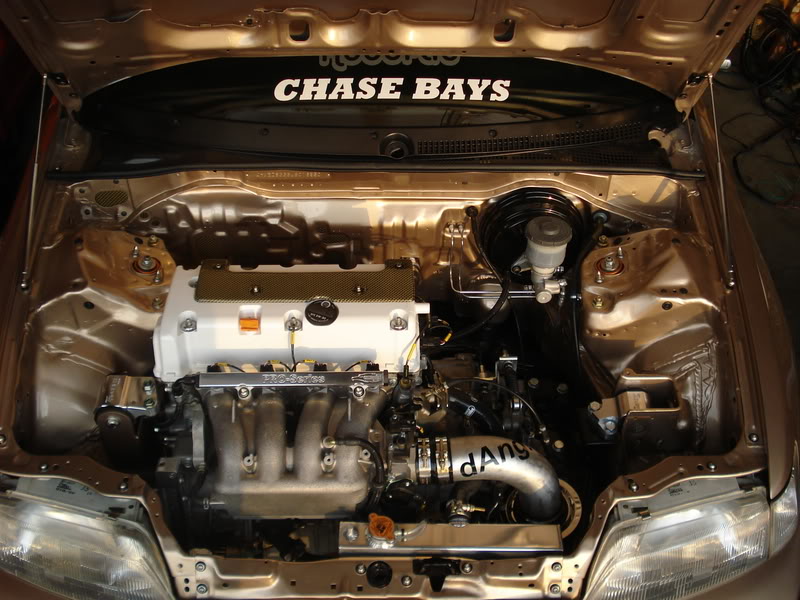

::ChaseBays::

Originally Posted by sh!tsWEAK

For all your custom engine bay needs (wire tucks, brakelines, fuel setups, tuck harnesses)! --> http://www.hondamarketplace.co...70366

[/quote]

Originally Posted by Rywire

<FONT COLOR="red">Rywire.com - G e t _ R y w i r e d .</FONT>

Look at this harness ive been working on

mockup

More mocking up...

Phew, all done... this harness is the hardest ive made as of yet...

Let me clear up some stuff for everyone.

The wire is milspec, its very expensive... I did the harness in a power/ground/signal setup, so thats why there is 3 colors. Its not hard at all to diagnose with a multimeter. All wires are new, and military grade. The pins are all new, and it took me a crazy long time to source them all... I really dont want to give any pins out, plus I have a limited supply.

Someone also asked me on another forum why I thought it was the hardest harness as of yet... if you havent made a harness all the way back to the ecu with all new wires, and expensive parts that you dont want to ruin, dont ask

People also asked where the back half is on this harness, I do have it made, but its not cut into the firewall yet, there will be pix soon. I leave that half in just zipties, so if changes ever need to be made, they can be made on that end.

If anyone ever looks at the wiring harness on a exotic race spec car, Porsche/ bmw

they will notice similar characteristics between the harnesses, thats the look I was going for... Some people are gunna say this is overkill, and it sure is, but this is what I do for a living, and excess is necessary.

-Ryan

phunhaus

Fresh'86

outdated

Mr Pho King

STREETWERKZ

Red Zone

game over

Rywire

EF8kid

nickrps

Lenthrax

Some Hawaii dood

Not so JdmDan

t.blizzard

Questoyz by RHanDy

Harajuka

RIP V8s

Serio. Ferio.

ATS*EK24

crxsir88

SkankyEJ7

RickyGD (F/K/A CRXWolf)

EG6AAARRR!!!

JDM EJ1 95

Pandahatch

humbleg

lgda92gsr's

neema

black88si

J-specCb4

SlepT ej6

R.I.P Nick Haines - NHswaps13203

ATS*EG2

rodrez

sheepey

DarkBB4

VEEE*

H8 O ATE

EjSex

HeyMikeyyyy

Luserkid

maxpsi

mr_k20

Brad Pitts

Pics happily removed at the request of the owner.

.

.

.

.

.

.

.

.

.

.

<FONT COLOR="teal"><FONT SIZE="5">Reference Info:</FONT></FONT>

http://www.hondamarketplace.co...age=1

Originally Posted by -NA-aLL-thE-wAy-

<u>AN Lines and Fittings</u>

Originally Posted by -NA-aLL-thE-wAy-

Originally Posted by LKSi

<U>AN Plumbing How To Videos</U>

Originally Posted by LKSi

I figured these videos would help some people...

(all thanks to anplumbing.com)

AN flaring-

http://www.anplumbing.com/PARKER_FLARING_TOOL.html

Cutting hose and attaching Swivel-Seal hose ends-

http://www.anplumbing.com/SWIV....html

And here is their info on AN threads

http://www.anplumbing.com/thread.html

(all thanks to anplumbing.com)

AN flaring-

http://www.anplumbing.com/PARKER_FLARING_TOOL.html

Cutting hose and attaching Swivel-Seal hose ends-

http://www.anplumbing.com/SWIV....html

And here is their info on AN threads

http://www.anplumbing.com/thread.html

Originally Posted by donut.

<U>Pic of Tucked Fuse Box</U>

Originally Posted by donut.

Originally Posted by g2_teg_

<u>Guide to Tucking Brake Lines</u>

Originally Posted by g2_teg_

Originally Posted by Slappy

<U>Slappy on FLARE TOOLS</U>

Originally Posted by Slappy

Don't skimp out on good tools. Getting a cheap tool isn't worth the "possible "consequences later if they happen. Jesse(I_Hate_JDM) is right, the Rigid tool is very nice and well worth the money. It's pretty much dummy proof when making a flare.

Originally Posted by -NA-aLL-thE-wAy-

<U>TILTON</U>

Originally Posted by -NA-aLL-thE-wAy-

Originally Posted by -NA-aLL-thE-wAy-

<U>Titanium Bolts</U>

Originally Posted by -NA-aLL-thE-wAy-

Originally Posted by LKSi

<u>Wire Loom</u>

Originally Posted by LKSi

I'm gonna be using the braided loom from cableorganizer.com (http://cableorganizer.com/fray-resistant/#B) when I do my harness... and I just ordered my Odyssey PC680MJT!

Originally Posted by EF8kid

<U>WRITE UP: How to convert your fuel lines and ugly filter to Stainless -6AN hoses</U>

Originally Posted by EF8kid

Originally Posted by EF8kid

<u>Sandpaper</u>

Originally Posted by EF8kid

I tried alot of different kinds and my favorite was actually this 80 grit stuff from home depot. (to sand filler down) It kept its grit the longest. Its like whiteish with blueish dots somewhat.

After u get it shaped you sand it with 320 so theres no sanding scratches. I liked the home depot stuff best again.

Then for wetsanding primer i used 3m jobpack 600grit and it worked good. Then wetsanding the clear i used 1600 and 2000 3m jobpack.

Originally Posted by Slappy

You asked for it...........91631-SR3-000

Originally Posted by Slappy

I work @ Honda....if you need anything Matt, just hit me up on AIM.

Number 16

Number 16

Originally Posted by MLRtime

<U>Removing ABS</U>

Originally Posted by MLRtime

Originally Posted by EF8kid

<u>Wire Loom/Sleeving</u>

Originally Posted by EF8kid

awesome!

I love wires yay.

I love wires yay.Actually, the link on page one is shitty. They dont offer enough sizes.

HEY EVERYONE, HERE'S WHERE I BUY MY HELLA KEWL SLEEVING AND HEATSHRINK FROM:

http://www.wirecare.com

Originally Posted by Stoich EG2

<u>Wire Loom/Sleeving</u>

Originally Posted by Stoich EG2

Originally Posted by Pandahatch

<u>Replacement Seam Sealer</u>

Originally Posted by Pandahatch

You should NEVER NEVER NEVER use a caulk gun style seam sealer, use the 2 part sealer, it is more durable and will last 10x's longer as it DOES NOT shrink. It is catalyzed to harden and the single part **** is not.

Originally Posted by hybridzOr

<U>Seam Sealer Replacement </U>

Originally Posted by hybridzOr

sem makes a good 2 part seam sealer.... part# 39337

Originally Posted by h22apwrdcivic

<u>Blocking the coolant ports pg 356 & 357</u>

Originally Posted by h22apwrdcivic

Originally Posted by Slappy

<U>Heater Core Plug</U>

Originally Posted by Slappy

Here ya go..............

#1 is 12208-PR3-000

#2 is 12209-PR3-000

#1 is 12208-PR3-000

#2 is 12209-PR3-000

Originally Posted by B16B_coupe

ps: i think you should add this to the front page. its the <u>fuse box wire hole cover</u>

Originally Posted by B16B_coupe

honda part number 91610-sf4-003 was on a ek.. might fit others.

Originally Posted by stillrockin18s

<u>Cheaper alternative the the PC-680</u> (Odyssey) dry cell battery

Originally Posted by stillrockin18s

http://www.gruberpower.com/gru...0.asp

$48.95

Works great, used this battery when I did my wire tuck, have been starting the car about 3 times a day for a the past month or so with no problems.

I posted this information a while back, just thought I would do a sort of review on it.

Originally Posted by stillrockin18s

<u>Cheaper alternative the the PC-680</u>

Originally Posted by stillrockin18s

Anyone ever use this battery or do you think this battery would be OK?

http://cgi.ebay.com/ebaymotors...ZWDVW

Planning on using it on my rarely driven show DA with a kill switch for storage.

Its between this or the odessy battery, this ones cheaper which would help since christmas is around the corner and I haven't started shopping yet, LOL!

Originally Posted by -NA-aLL-thE-wAy-

<u>Cheaper alternative the the PC-680</u>

Originally Posted by -NA-aLL-thE-wAy-

Check out their disclaimer...

"SPECIAL NOTE

This battery is much lower cost than a comparable brand that rhymes with "Modyssey"

We cannot tell you the brand, but you may figure it out.

Someone is unhappy with us selling our batteries...you may be also be

able to figure who that is as well.

This completely comparable battery is lower cost only because

it does not have a half a dozen margin hungry companies in the food chain

driving the cost to the consumer beyond reasonable levels.

You be the judge....pay more for a over-distributed brand, or get a replacement

with the same specifications and performance for 1/2 the price."

lol

I'd say give it a shot.

Originally Posted by White Smoke

<u>Brake Proportioning Valve Diagram.</u>

Originally Posted by White Smoke

I talked to Fast Brakes the other day and they said both chambers in the Honda master cylinder are the same size; (15/16) in my case. Therefore it does not matter which port on the MC goes to either input on the prop. valve. (The rear outputs still have to go the the rear, front to the fronts and input's to the MC.)

Originally Posted by White Smoke

Quick question, does it matter if the front output of the brake MC goes to the opisite input on the prop valve? Just like theoretically switching the front MC line to the back and the back to the front... Looking in the Helms to try and figure out now but figured I would ask.

Originally Posted by White Smoke

Thanks

OK, I'm thinking it does not matter so I am going to go off that... If someone knows otherwise PLEASE let me know asap so I dont wast my time bleading and all that for the bias to be off. Here is an image for reference. Just by looking at the desgin of the prop valve I am thinking it doesn't matter. http://www.we-todd-did-racing....e.jpg

Originally Posted by -NA-aLL-thE-wAy-

<U>Charcoal Canister</U>

Originally Posted by -NA-aLL-thE-wAy-

<FONT COLOR="red">Thanks to Dumpgears for sourcing these quotes/info.</FONT>

Quote, originally posted by NathanMorris »

when you guys are taking out the charcoal canister stuff on the firewall - how are you dealing with that? IE: what are you doing with the fuel vapors, how are you setting up the PCV vent, etc. As many details about this would be wonderful as I'm looking to get rid of that set of big ugly black boxes if possible.

Nathan

Quote, originally posted by JDMlyfestyle »

have mine Routing out the side of my car.. its attached the the Front passanger Lift point so that the vapors are not coming into the cabin

Quote, originally posted by not so JDM Dan »

when i converted my fuel lines to stainless steel under the car, the smallest hard line which is the vent tube for the charcoal canister i cut at the back of the car near the tank and i ran a rubber hose back along the trailing arm. all the vapors vent out behind the car

Originally Posted by Weak!EG

<U>Example of Braided Brake Lines</U>

Originally Posted by Weak!EG

<FONT COLOR="red">DONE MY CHASE MCMASTER (EF8kid)</FONT>

Originally Posted by EF8kid

<U>Example of Hard Brake Lines</U>

Originally Posted by EF8kid

Originally Posted by -NA-aLL-thE-wAy-

<U>Example of Hard Brake Lines</U>

Originally Posted by -NA-aLL-thE-wAy-

Originally Posted by Weak!EG

<U>BRAKE LINE TUCK WRITE UP</U>

Originally Posted by Weak!EG

I took the time to compile a small base of information for a general brake line tuck write up.

hopefully it will keep a lot of the same questions and confusion out of this thread.

link: https://honda-tech.com/zerothread?id=2103425

enjoy and if you have any suggestions please post.

hopefully it will keep a lot of the same questions and confusion out of this thread.

link: https://honda-tech.com/zerothread?id=2103425

enjoy and if you have any suggestions please post.

Originally Posted by GarretCRX

<U>BRAKE LINE TUCK - NO LINES IN ENG BAY</U>

Originally Posted by GarretCRX

I think this is the location for an EF brake-line-tuck.

Originally Posted by 8520

<u>A ton of the factory honda service manuals.</u>

Originally Posted by 8520

Quick link for you guys. Found this website that has a ton of the factory honda service manuals including wiring diagrams etc. You do have to register for the site to download the manuals, but there is no charge whatsoever.

http://www.hondahookup.com/manuals

Originally Posted by OSK Automotive

<U>WIRE LOOM</U>

Originally Posted by OSK Automotive

http://www.waytekwire.com

http://www.delcity.net

Waytek Wire usually has lower minimum buying quantities on connectors so you're not stuck buying per hundred.

http://www.terminalsupplyco.com

They don't list their pricing on their site (which I know can be an inconvenience) but I know if you request a price quote and ask them to beat Del City or Waytek pricing they usually can. Sometimes there are minimum quantities for that pricing tho.

All 3 carry a wide variety of fittings/connectors/loom/shink tubing.

Originally Posted by MidwestSiR

<U>Battery Relocation</U>

Originally Posted by MidwestSiR

Just a few parts to help ease your relocating and give ideas:

Prefab battery holds:

http://odysseybatteries.com/im...m.jpg

http://odysseybatteries.com/im...m.jpg

Popular Battery's used:

Odyssey PC680MJT

http://odysseybatteries.com/ba...g.jpg

Odyssey PC680

http://odysseybatteries.com/battery/pc680_lg.jpg

Baker Precision

http://us.st11.yimg.com/us.st....82003

Accessories:

Battery Terminals

http://static.summitracing.com...w.jpg

Terminal Mounts

http://static.summitracing.com...w.jpg

Can be found at:

http://www.summitracing.com

http://www.odysseybatteries.com

http://www.inlinefour.com

http://www.bakerprecision.com

Originally Posted by Hawkze_2.3

<U>Pic of Battery/Fuse Box Relocation</U>

Originally Posted by Hawkze_2.3

Originally Posted by -NA-aLL-thE-wAy-

<U>Battery Relocation Thread</U>

Originally Posted by -NA-aLL-thE-wAy-

Originally Posted by Hayce

<u>HOLE IN FIREWALL FOR TUCK HARNESS</u>

Originally Posted by Hayce

QUOTE=JSPECSIR i may have missed this somewhere in the almost 500 pages, but does anybody have any pics of the firewall harness after is modded to exit in the center to go out under the hood, mainly inside of the car side of the firewall. and where is the best place to go out of the firewall if im keepin heat, right below the heater core hole maybe? thanks for any input and if i missed it please let me know what page it was on. /QUOTE

You didn't state which chassis, but heres my EK:

(no not finished wiring)

(no not finished hole)

You didn't state which chassis, but heres my EK:

(no not finished wiring)

(no not finished hole)

Originally Posted by B16B_coupe

first you got the ac plug: part#91631-SR3-000

second this plug covers the stock engine harness hole/pass healight harness hole part #91610-sf4-003

pic

driver side plug part#90621-SE0-000

pic

Originally Posted by Cpt. xThread

I've found a cheaper place to buy the dress up bolts. Fastenal. The PN for M6x20mm [FHSCS] (10mm fender bolts, etc) bolt is M42550020A20000. They're priced at $31.83 per 100. The washers I used are 1133144. I believe I paid $7 for 100.

Originally Posted by Cpt. xThread

Here's a picture for reference. Ignore the old one. It was steel and rusted, so I replaced them with the SS bolts.

Originally Posted by Cpt. xThread

AC plug for DA9/DB2/DB1 Honda PN is 90851-SB2-000

Originally Posted by Cpt. xThread

https://www.masterdistributors...t.cfm has ECU pins, but minimum order quantity is $35 (which is 875 pins...)

Originally Posted by TehMan

Originally Posted by pheurton-skeurto

i found this info on the proportioning valves and codes for them:

Originally Posted by pheurton-skeurto

3030 - 9.4" front / drum rear

3035 - 9.4" front / larger drum rear

3040 - 9.4 front / 9.3" disk rear

4040 - 10.25" front / 9.3" disk rear

4035 - 10.25" front / larger drum rear

4030 - 9.4" front / 9.3" disk

it helped me to understand some...

Modified by -NA-aLL-thE-wAy- at 12:58 PM 10/28/2008

Last edited by -NA-aLL-thE-wAy-; 09-23-2010 at 12:45 PM.

#2

Honda-Tech Member

Join Date: Feb 2004

Location: Franklin, TN

Posts: 3,504

Likes: 0

Received 0 Likes

on

0 Posts

Post Edited by -NA-aLL-thE-wAy-

<FONT SIZE="6"><FONT COLOR="red">A HUGE thanks to Fresh '86 (fka Dumpgears) for indexing all of the information below!!!</FONT></FONT>

<u>Brake Lines, Fuel Lines, Clutch Line conversions</u>

<u>Converting Your Fuel Line/Hydro Clutch Line To Braided W/ Fittings</u>

pg20:

Page 63

Page 66

Page 88

I planned on using stainless hardline, but I didn't want to spend a ton of money on the flare tool. Then I decided I didn't like the look of the rear hardlines being inside the car (since the int is stripped) so I decided after I get it dipped I'll redo them with braided.

I have also heard about leakage problems. That's usually caused by the flare being done wrong: either the wrong degree of flare, or the end of the flare cracking do to overflaredness.

I said overflaredness. [quote=SHG_EasyE]some updated pics of mine....

[quote=SHG_EasyE]some updated pics of mine....

http://i159.photobucket.com/al...8.jpg

http://i159.photobucket.com/al...3.jpg

<u>Tucking Your Brake Lines</u>

Page 25

Page 62

<u>[H]Painting, Applying Filler, Welding[/H]</u>

<u>Shaving/Painting Your Engine Bay</u>

Page 24

I think that is what (Bryan)Pandahatch used.......Ive heard good things about it too.

http://www.evercoat.com/productDetail.aspx?pID=1

http://www.evercoat.com/imgs/p...e.jpg

The Paint/Body special issue of Hot Rod Magazine said as long as it's 1/4 of an inch or less, and the chemicals are mixed correctly, you won't have an issue with cracking. Naturally you want it much thinner than 1/4".

<u>Seam Sealer/Stitch Welding/Welding</u>

Most people weld that seam; one for rigidity, two for aesthetics.

The tack's is stitch welding, He did multiple tacks on the one seam as u can see so he could make it all metal work and minimal filler.

http://img.photobucket.com/alb...e.jpg

<u>[H]Wiring/Electrical[/H]</u>

<u>Main Engine Harness Tuck</u>

Page 85

[quote=ECKOTYPER]what u wanna do is connect the passanger and driver side on the interior side of the firewall, and get all ur connections to come out of a central hole  ... i cut a hole about as big as the driver side hole, underneath the heater core, and ran my harness in through that, ( i retained my heater core) so the heatercore hoses kinda disguise the harness below

... i cut a hole about as big as the driver side hole, underneath the heater core, and ran my harness in through that, ( i retained my heater core) so the heatercore hoses kinda disguise the harness below  <TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote »</TD></TR><TR><TD CLASS="quote">

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote »</TD></TR><TR><TD CLASS="quote">

Page 86

Page 88

[QUOTE=SkankyEJ7]

the only thing that MAY (its been talked about but never really proven) affect your engines performance would be altering the length of the wires would be the injectors. so i left the injector wiring the stock length on my harness, but everything else its custom length. and my car runs fine. </TD></TR></TABLE>

</TD></TR></TABLE>

<u>Tucking Your Headlight Harness</u>

Page 100

Page 102

I'm guessing you have white instead of blue...

http://www.6thgearadvertising....x.jpg

ignore the resistor box part. this is if you were looking at your motor from the front.

YEL - BLUE - RED - BRN

http://www.6thgearadvertising....2.jpg

Here's looking at the injectors from the opposite side.

BRN - RED - BLU - YEL

be sure to double check them with a meter

but there will be a power drop of around .1 volts at the points where you connect and solder

that is why you avoid cutting the o2 sensor wires because their signal to the ecu is between .1 and .9 volts

you can use a stock honda resitor box and the wires are already at the end of the harness on the driverside strut box..... its the dead plug with the yellow/black wires....4 wires go to the injectors. If you trace out the wires at the dead plug, one wire will go to each injector. there should also be a power wire at the dead plug that turns on with the key. If you tap into this power wire and connect it to the power wire ont he resistor box and connect the 4 wires from the injectors to the 4 wires on the resistor box you will be able to now use low impedance injectors.

this is all assuming you have a civic or integra with a d or b engine

<u>Pins</u>

<u>Special Wire Loom (Sleeving)</u>

I went to SVC "www.svc.com" [thanks EF8Kid aka Cha$e aka ballaholic] and just used the black sleeving kit. I have a good amount left over, I just might do a once over on mine so I dont have it as a waste.

<u>Wiring/Soldering Basics</u>

<u>Ground Wire On Your Valve Cover</u>

Page 60

<u>Fuse Box Tuck</u>

Page 65

<u>Low Brake Fluid Switch</u>

Page 69

<FONT SIZE="6"><FONT COLOR="red">A HUGE thanks to Fresh '86 (fka Dumpgears) for indexing all of the information below!!!</FONT></FONT>

<u>Brake Lines, Fuel Lines, Clutch Line conversions</u>

<u>Converting Your Fuel Line/Hydro Clutch Line To Braided W/ Fittings</u>

pg20:

Originally Posted by hayce

Is there any write ups out there (like the very helpful fuel line threads

) for converting the hydro clutch line to braided w/ fittings?

) for converting the hydro clutch line to braided w/ fittings?

) for converting the hydro clutch line to braided w/ fittings?

) for converting the hydro clutch line to braided w/ fittings?

Originally Posted by BoostedJeff

its easy...

(2) -3 to 10mm adapter

-3 line

me and dan did ours with a 3ft line and a 2ft -3 line, with a -3 union in between

(2) -3 to 10mm adapter

-3 line

me and dan did ours with a 3ft line and a 2ft -3 line, with a -3 union in between

Originally Posted by SPOON_BeIgHtEeNsEe

or PM Flamenco-T he sells the line and fittings for 75 shipped  .... line is 72" long

.... line is 72" long

Also, a VERY resourceful thread for this for those who like pictures:

https://honda-tech.com/zerothread?id=1545386

.... line is 72" long

.... line is 72" longAlso, a VERY resourceful thread for this for those who like pictures:

https://honda-tech.com/zerothread?id=1545386

Originally Posted by nerdsports

Originally Posted by phresh_5

Fuel system wire harness installed:

Brake lines behind firewall (completed). Rear lines are SS untill they go behind the subframe, then they go back to hard lines all the way back. All other lines are SS.

Brake lines behind firewall (completed). Rear lines are SS untill they go behind the subframe, then they go back to hard lines all the way back. All other lines are SS.

Originally Posted by JDMorgan

all brake/clutch lines are 3/16" line with m10x1.0 fittings, if you want to run an fittings run -3 tube sleeves/nuts. the only brake line not m10x1.0 is the front fitting on an abs master cylinder is actually m12x1.5. it still uses 3/16" line tho.

Originally Posted by -NA-aLL-thE-wAy-

I planned on using stainless hardline, but I didn't want to spend a ton of money on the flare tool. Then I decided I didn't like the look of the rear hardlines being inside the car (since the int is stripped) so I decided after I get it dipped I'll redo them with braided.

I have also heard about leakage problems. That's usually caused by the flare being done wrong: either the wrong degree of flare, or the end of the flare cracking do to overflaredness.

I said overflaredness.

http://i159.photobucket.com/al...8.jpg

http://i159.photobucket.com/al...3.jpg

Originally Posted by SHG_EasyE

since so many ppl have asked already this is the list of parts i used off summit racing.

(substitute one -6an hose end for a 45 deg one)

EAR-230206ERL Fuel Filter, Inline Mount, Blue, 85 Microns, -6 AN Male Inlet/Outlet, 1

EAR-581805ERL Fitting, Tube Nut, -5 AN, Aluminum, Blue, Pair, 1

EAR-581905ERL Fitting, Adapter, Tube Sleeve -5 AN, Aluminum, Blue, Pair, 1

EAR-991907ERL Fitting, Union Reducer, Male -6 AN to Male -5 AN, Male, Aluminum, Blue, 1

EAR-991945ERL Fitting, Carburetor Inlet, -6 AN Male to 12mm x 1.25 Male, Aluminum, Blue, 1

SUM-220690 Fitting, Hose End, Straight, -6 AN Hose to Female -6 AN, Aluminum, Red/Blue Anodized, 4

SUM-G1001 Hose, Braided Stainless Steel, -6 AN, 18 in. Length, 2

whole setup cost a little under 100 bucks including the new filter

(substitute one -6an hose end for a 45 deg one)

EAR-230206ERL Fuel Filter, Inline Mount, Blue, 85 Microns, -6 AN Male Inlet/Outlet, 1

EAR-581805ERL Fitting, Tube Nut, -5 AN, Aluminum, Blue, Pair, 1

EAR-581905ERL Fitting, Adapter, Tube Sleeve -5 AN, Aluminum, Blue, Pair, 1

EAR-991907ERL Fitting, Union Reducer, Male -6 AN to Male -5 AN, Male, Aluminum, Blue, 1

EAR-991945ERL Fitting, Carburetor Inlet, -6 AN Male to 12mm x 1.25 Male, Aluminum, Blue, 1

SUM-220690 Fitting, Hose End, Straight, -6 AN Hose to Female -6 AN, Aluminum, Red/Blue Anodized, 4

SUM-G1001 Hose, Braided Stainless Steel, -6 AN, 18 in. Length, 2

whole setup cost a little under 100 bucks including the new filter

Originally Posted by g2_teg_

http://i23.photobucket.com/alb...1.jpg

where in the world can i get those banjo bolts from? the ones i got from summit were too long.

where in the world can i get those banjo bolts from? the ones i got from summit were too long.

Originally Posted by 1 Fly SI

Page 25

Originally Posted by RotiEatter

I want to relocate the brake lines, but I'm scared of messing with them... haha.

Anyone have good pictures of how they relocated their brake lines and what kinds of lines they used? Thanks.

Anyone have good pictures of how they relocated their brake lines and what kinds of lines they used? Thanks.

Originally Posted by EF8kid

Go look at the page before this for pics of mine. They sell all differents lengths of line @ your auto parts store and theyre like 5 bucks a peice. 3/16th size line for japanese/metric/import etc...I bent them with my hands!

Originally Posted by kidkombo

dood the hardlines will kink when you re route them....they are already bent in intricate ways, there is no way in hell you can do a clean tuck behind the firewall...so yes i think its a stupid question as well  lol all you need is a tubing bender, tube nuts and sleeves and a ton of reverse flare -3 fittings to -3male...and you will be set for life!

lol all you need is a tubing bender, tube nuts and sleeves and a ton of reverse flare -3 fittings to -3male...and you will be set for life!

lol all you need is a tubing bender, tube nuts and sleeves and a ton of reverse flare -3 fittings to -3male...and you will be set for life!

lol all you need is a tubing bender, tube nuts and sleeves and a ton of reverse flare -3 fittings to -3male...and you will be set for life!

Originally Posted by stillrockin18s

Where can I pick up some metal brake lines and fittings online so I can tuck my portioning valve and brake lines. I prefer just straight pieces, my boy has a good bender and flaring tool.

Also can the portioning valve be mounted on its side? I am thinking of tucking them under the wiper cowl.

Also can the portioning valve be mounted on its side? I am thinking of tucking them under the wiper cowl.

Originally Posted by hondaZvic

the metal lines and fittings can be picked up at your local autozone or whatever autoparts store you have, the lines come in rolls, and you can buy it by the foot or however much you need. at least here anyway.

Originally Posted by spriggan

<u>Shaving/Painting Your Engine Bay</u>

Page 24

Originally Posted by JDMorgan

usc icing is an example of a filler you can use. all polyester fillers are pretty much the same, it comes down to what they sell at your local auto parts store. i use evercoat products.

Originally Posted by fventura03

do you (or anyone else) recommend using this on the shock towers and to cover small bolt holes in the engine bay? i'm trying to make my engine bay as clean as possible, but i dont want it to start cracking in a couple of years...

Originally Posted by nerdsports

you need to weld the holes shut first. then grind the weld down.

the icing is just a thin layer over the metal surface to cover the imperfections and leave a smooth flowing finish.

the icing is just a thin layer over the metal surface to cover the imperfections and leave a smooth flowing finish.

Originally Posted by EF8kid

bondo sucks, i used Evercoat Metal Glaze.

Originally Posted by I_HATE_JDM

evercoat rage extreme filler is your friend.

Originally Posted by JDMorgan

i never use normal fillers anymore. if i absolutely have to use a bunch of filler i use evercoat duraglass, but i like the polyester filler by evercoat. its expensive but it works awsome. it's very thin so you can feather it out quickly. i hate bondo brand products.... wont use them. evercoat has a sweet line of products so they have pretty much something for everyone.

Originally Posted by JDMFantasy2k

Any of you guys that have painted your bays, have you heard/seen/used this stuff??

https://www.paintscratch.com/

Apparently they sell OE paint in aerosol cans. Appears to have amazing feedback about the products and it's like 25/can.

Seems like a neat alternative for those guys who don't wanna krylon it and don't have a hvlp gun. I'm pretty interested in it i must say.

https://www.paintscratch.com/

Apparently they sell OE paint in aerosol cans. Appears to have amazing feedback about the products and it's like 25/can.

Seems like a neat alternative for those guys who don't wanna krylon it and don't have a hvlp gun. I'm pretty interested in it i must say.

Originally Posted by Slappy

Originally Posted by DarkBB4

USC ICING

http://www.evercoat.com/productDetail.aspx?pID=1

http://www.evercoat.com/imgs/p...e.jpg

Originally Posted by -NA-aLL-thE-wAy-

The Paint/Body special issue of Hot Rod Magazine said as long as it's 1/4 of an inch or less, and the chemicals are mixed correctly, you won't have an issue with cracking. Naturally you want it much thinner than 1/4".

Originally Posted by Pandahatch

I do a LOT of metal work, grinding, smoothing, etc...you don't necessarily have to seam weld. If I have a seam I grind it down almost flush to the panel under it and apply a couple spot welds to minimize distortion and warpage and grind those down, I apply filelr and end up taking off over half of what I apply. It's a long tedious project as well.

Originally Posted by ezza

I was told that when removing the seam sealant stuff you have to weld the seems for strength  what exactly does seam welding do, and when you say a couple of spot welds, like 1 per 3 inches?

what exactly does seam welding do, and when you say a couple of spot welds, like 1 per 3 inches?

what exactly does seam welding do, and when you say a couple of spot welds, like 1 per 3 inches?

what exactly does seam welding do, and when you say a couple of spot welds, like 1 per 3 inches?

Originally Posted by EF8kid

I did ALL sanding by hand on the my Cr-x's bay and the EK bay, cept on the core support like Brian...

oh evercoat metal glaze is kewl.

oh evercoat metal glaze is kewl.

Originally Posted by JDMorgan

hand sanding with a block is about the best finish you will get, 2nd to an inline sander. rotating sanders tend to make **** wavy if you arent careful. most of the bay you cant even use an inline sander on tho so you have to pick between smaller blocks or rotating sanders.

evercoat and usc both have great products, just be sure to use the right product for your application and use it properly.

evercoat and usc both have great products, just be sure to use the right product for your application and use it properly.

Originally Posted by DarkBB4

wats a good THICK primer to spray to help fill scratches, i.e. make it easier to see flaws. etc.?

Originally Posted by 4d_ek9

I dont know if you can get in the US but in the uk i tend to use a brand called U POL and its called reface it awsome stuff you can whallop it on as thick as you wish and it will sag into the inperfections, you can get away with covering 40ish grit marks with it, and when its dry jus guide coat and wet flat it with 500 / 800 depending on how thick u applied it.

Originally Posted by Slappy

My painter used a greenish filler primer(U-POL) that is thicker than your average primer. Once that first coat was layed on, any imperfections were more visible and could be touched up. Then a second coat was applied.

http://autobodystore.net/Merch...t.jpg

http://i95.photobucket.com/alb...0.jpg

http://autobodystore.net/Merch...t.jpg

http://i95.photobucket.com/alb...0.jpg

Originally Posted by -NA-aLL-thE-wAy-

So is it best to use the metal glaze directly on the metal, then sand, then primer, or prime the bare metal, then glaze, then primer again? I know the metal glaze is designed to be used directly on bare metal, but I wasn't sure if one way was better than another. You know, chemical vs. mechanical bond and whatnot.

Originally Posted by I_HATE_JDM

I use evercoat rage extreme and it works very well.

Originally Posted by PatrickGSR94

So what are you doing if you remove the seam sealer? I'm sure it has a reason for being there, are you sure it's a good idea to remove it?

Originally Posted by -NA-aLL-thE-wAy-

Originally Posted by JDMFantasy2k

hey how are you guys getting rid of that seam sealer **** that is everywhere?

Originally Posted by h22apwrdcivic

sand blast

Originally Posted by hondaboy4life

or heat it up with a propane torch then wire wheel in places where you can reach.

Originally Posted by -NA-aLL-thE-wAy-

A torch and a wire wheel is actually faster/easier than sand blasting. I've done both. Sandblasting works, but it's time consuming, and time consuming means a lot of sand, and a lot of sand means more money. You can buy a wire wheel (for pneumatic tools, would be best) and a propane torch for under $20. The sheet metal is so thin on our cars I'm reluctant to sand blast in the same area for an extended period of time (like for the thicker seam sealer). Get a little heat in the sealer then hit it with a wire wheel, it'll come right out.

Originally Posted by EF8kid

I scraped every inch of seam sealer in my entire car mostly with this tool. Small prybar(also works great for seperating spot welds):

http://i161.photobucket.com/al...8.jpg

Some places i used a wire wheel too

http://i161.photobucket.com/al...8.jpg

Some places i used a wire wheel too

Originally Posted by JKGONZALEZ3

well i should ask i just took some seam sealer off and did some welding on the strut tower but i was wondering if you grind your weld down wont it weaken it or should it still be stronger than oem seam sealer was?

Originally Posted by donut.

welding makes the metal weaker in certain areas exept the particular area you weld. make sure you have the right setting

Originally Posted by Boosted Rex

The stuff your looking for is called self-leveling seam sealer. You use this stuff exactly like regular seam sealer BUT the key thing is that it is sandable because it is catalized. It costs about 30 bucks and comes in 2 tubes.

I can't remember the brand I used, but it was very similar to this

http://www.azautobodysupply.com/123fufamacas.html

I can't remember the brand I used, but it was very similar to this

http://www.azautobodysupply.com/123fufamacas.html

Originally Posted by Hayce

You or anyone else mind elaborating on this?

Im up to here in my build now and Im unsure how to tackle it. Like is welding the seams the only options can you take it back flat and smooth it or? any ideas are good

Im up to here in my build now and Im unsure how to tackle it. Like is welding the seams the only options can you take it back flat and smooth it or? any ideas are good

Originally Posted by EF8kid

The tack's is stitch welding, He did multiple tacks on the one seam as u can see so he could make it all metal work and minimal filler.

http://img.photobucket.com/alb...e.jpg

Originally Posted by -NA-aLL-thE-wAy-

The seam sealer is there to prevent water and moisture from getting in there and causing rust. If you stitch weld the seams (1-3" apart), around the strut towers for example, it adds strength to the chassis, as all the panels are tied together. Some choose to weld the entire seam continuously and then grind it down, but Panda is saying that isn't necessary.

Originally Posted by hondaboy4life

with sheet metal u just have to do a series of tack welds. Do one at one side, then another furthest away from the one u just did, then go back and do one 1 inch from the 1st one, etc etc. JUst dont let it get too hot.

Originally Posted by sic944t

i dont know if this will work its a trick my dad talked about from torch welding but you could get a wet wool sock and put it on the back side as a heat sink to prevent some of the warping

Originally Posted by civicandy

But from what i'm told, it's because it's in the middle of a large area, with no support to keep it from warping. Unlike when you do an antenna, which has curved metal around it to keep it from warping.

Originally Posted by turbob18si

water promotes rust, use a piece of copper on the backside of where your welding. Copper is a excellent heat sink and will pull the heat away from where your welding. There is a copper tool for this with a handle. check http://www.eastwoodco.com, they have alot of things that help out on our projects

<u>Main Engine Harness Tuck</u>

Page 85

Originally Posted by drevinder

engine baY'S LOOK good..but one question where do u guy's put the driver side harness ...and the passenger side ....make hole somewhere ? if so where..i'm stumped

... i cut a hole about as big as the driver side hole, underneath the heater core, and ran my harness in through that, ( i retained my heater core) so the heatercore hoses kinda disguise the harness below

... i cut a hole about as big as the driver side hole, underneath the heater core, and ran my harness in through that, ( i retained my heater core) so the heatercore hoses kinda disguise the harness below  <TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote »</TD></TR><TR><TD CLASS="quote">

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote »</TD></TR><TR><TD CLASS="quote">Page 86

Originally Posted by ECKOTYPER

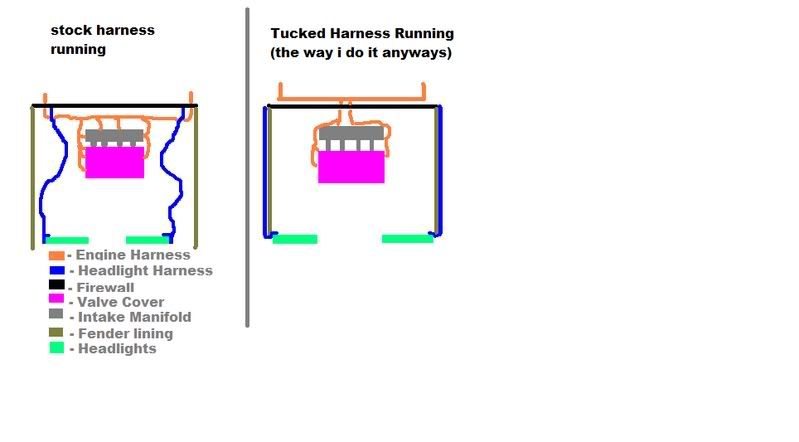

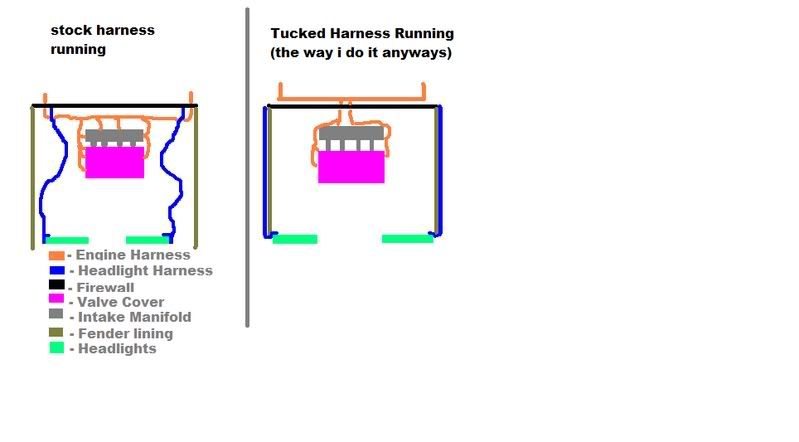

some people ahve been asking me how to do some tucks and stuff, so i made a simple diagram showing more or less hwo a stock engine is routed, and how a tucked one is routed (when i do it) im not getting into detail because if u read this thread instead of looking for pictures theres alot of helpful material in here... heres 1 visual... so please stop asking for help  (j.k im glad to help)

(j.k im glad to help)

(j.k im glad to help)

(j.k im glad to help)

[QUOTE=SkankyEJ7]

the only thing that MAY (its been talked about but never really proven) affect your engines performance would be altering the length of the wires would be the injectors. so i left the injector wiring the stock length on my harness, but everything else its custom length. and my car runs fine.

</TD></TR></TABLE>

</TD></TR></TABLE>

Originally Posted by Rywire

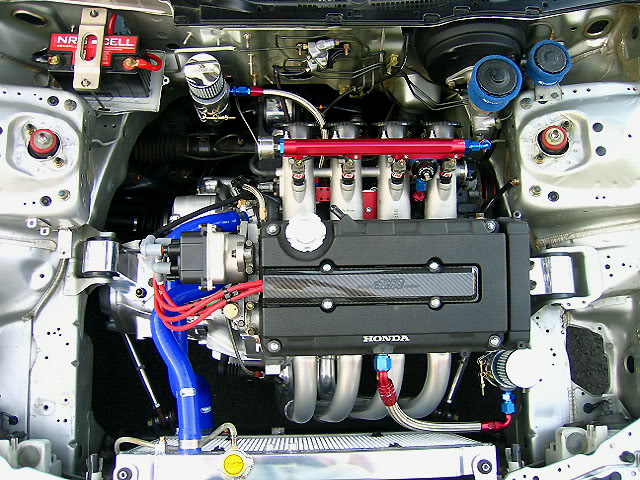

What are we looking at?? This is a harness for a bseries obd1 car (ill make them for obd0/2 also)

Its basically like a EK harness witout the drivers side shocktower plug. One end is all the engine functions ready for a Bseries with chipped obd1 ecu (to turn off things like vtec oil pressure, eld, and o2 heater).

The other end has the ecu /jumper intergrated. It also has the fuse box power wire setup to be used under the dash as well as the drivers side 14pin connector and 2 pin connector ready to be plugged in under the dash out of sight...

Feeding it through the firewall can be done easily once the stock harness is removed and pulled inside.

This is my first attempt at a tuck harness, and im sure it will improve as I learn more tricks... The only change I can think to make on this is to cover the long loom areas with that shiny plastic covering over split wire loom.

Give me feedback on this please, thanks everyone! Oh, and these are not going to be cheap.

-Ryan

http://i70.photobucket.com/alb...1.jpg

http://i70.photobucket.com/alb...6.jpg

http://i70.photobucket.com/alb...5.jpg

http://i70.photobucket.com/alb...4.jpg

[ur;]http://i70.photobucket.com/albums/i85/droppedcrxsi/wiretuck002.jpg[/url]

Its basically like a EK harness witout the drivers side shocktower plug. One end is all the engine functions ready for a Bseries with chipped obd1 ecu (to turn off things like vtec oil pressure, eld, and o2 heater).

The other end has the ecu /jumper intergrated. It also has the fuse box power wire setup to be used under the dash as well as the drivers side 14pin connector and 2 pin connector ready to be plugged in under the dash out of sight...

Feeding it through the firewall can be done easily once the stock harness is removed and pulled inside.

This is my first attempt at a tuck harness, and im sure it will improve as I learn more tricks... The only change I can think to make on this is to cover the long loom areas with that shiny plastic covering over split wire loom.

Give me feedback on this please, thanks everyone! Oh, and these are not going to be cheap.

-Ryan

http://i70.photobucket.com/alb...1.jpg

http://i70.photobucket.com/alb...6.jpg

http://i70.photobucket.com/alb...5.jpg

http://i70.photobucket.com/alb...4.jpg

[ur;]http://i70.photobucket.com/albums/i85/droppedcrxsi/wiretuck002.jpg[/url]

Originally Posted by Civichatch2k

What gauge of wire to you need if you are extending the harness?

Originally Posted by JDMorgan

no thicker than it is now, but some of the wires are shielded. why would you ever want to add more wires to a car? most of us are ripping out every wire possible and shortening ones that are required.

Originally Posted by Civichatch2k

Let me rephrase. I may have to extend the headlight harness and the horn. I was just wanting to match the gauge of wire if that has to occur. Other than that I am not doing anything other than tucking the wires.

Originally Posted by JDMorgan

i think most of the wiring is around 18awg. not 100% sure tho. i actually have a box of wire from crap i took out of my harness, when i need wire i look for the same color and size and its normally there.

Page 100

Originally Posted by Civichatch2k

on the Ek's how are you guys hiding the headlight harnesses.

I know you are running them through the fenders but because they run in the front of the car and then to two main plugs after you get the harness off, what are you doing to re-route them?

I have the harness on the passenger side which is connected to the fuse box and I have the driverside which runs to the fire wall.

I know you are running them through the fenders but because they run in the front of the car and then to two main plugs after you get the harness off, what are you doing to re-route them?

I have the harness on the passenger side which is connected to the fuse box and I have the driverside which runs to the fire wall.

Originally Posted by gabebauman

Originally Posted by JDMFantasy2k

on mine, i routed the headlight harness through the drivers side only. All of the wires in the passenger side of the harness are for AC components aside from the wires for the horn and cooling fan. So i ran those wires through the interior, re-pinned them into the connectors on the drivers side, and then ran wires through the harness for them.

Originally Posted by Slappy

here are a couple of mine.

http://i95.photobucket.com/alb...1.jpg

http://i95.photobucket.com/alb...1.jpg

http://i95.photobucket.com/alb...1.jpg

http://i95.photobucket.com/alb...1.jpg

Originally Posted by American.Graffiti

Question:

After stripping my harness I see that some wires have interference (sp?) insulation, my question is how do you advoid cutting the wires to length for the tuck? (Hope my question is clear).

After stripping my harness I see that some wires have interference (sp?) insulation, my question is how do you advoid cutting the wires to length for the tuck? (Hope my question is clear).

Originally Posted by B18EG6

you are referring to RF shield for some of the signals (distributor, knock are two that come to mind quickly).

If you choose to cut these, the best option is to replace the whole length from pin to pin with an already shielded wire. Some have had success with cutting the whole wire, soldering the conductors together, and resoldering the RF braid over top of them... however this is not perfect.

If you choose to cut these, the best option is to replace the whole length from pin to pin with an already shielded wire. Some have had success with cutting the whole wire, soldering the conductors together, and resoldering the RF braid over top of them... however this is not perfect.

Originally Posted by NJcoupe

Where did u purchase the stuff to re-loom your harness. and what sizes?

Originally Posted by B18EG6

bought the smaller expandable sleeving from waytek wire, and the larger sleeving locally. The sleeving ranged from 3/16" - 1/2" when collapsed. I also got a few rolls of wire from waytek for some good price  Towards the end of assembly, I didnt plan too well and thats why there is electrical tape

Towards the end of assembly, I didnt plan too well and thats why there is electrical tape

The connectors were bought from Allied, along with their crimpers. The two posts on the firewall are for the starter and alternator leads, both 4ga.'

I'll get some better pictures away from my yellow shop light as soon as the weather is nice enough to push the car out

http://www.sebastianstewart.net/progress2.jpg

http://www.sebastianstewart.net/progress5.jpg

Towards the end of assembly, I didnt plan too well and thats why there is electrical tape

Towards the end of assembly, I didnt plan too well and thats why there is electrical tape

The connectors were bought from Allied, along with their crimpers. The two posts on the firewall are for the starter and alternator leads, both 4ga.'

I'll get some better pictures away from my yellow shop light as soon as the weather is nice enough to push the car out

http://www.sebastianstewart.net/progress2.jpg

http://www.sebastianstewart.net/progress5.jpg

Originally Posted by .adam.

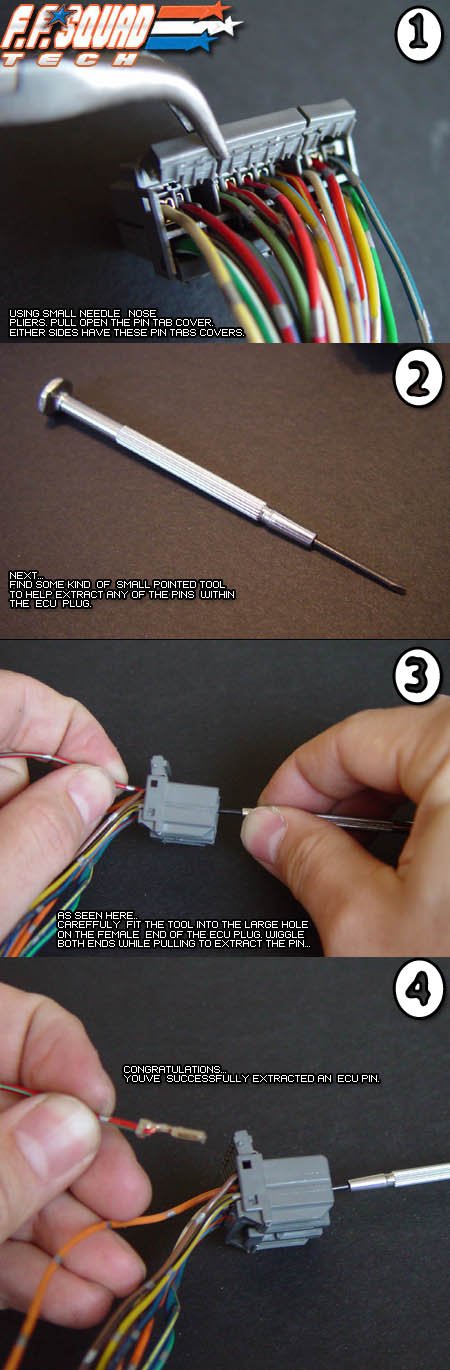

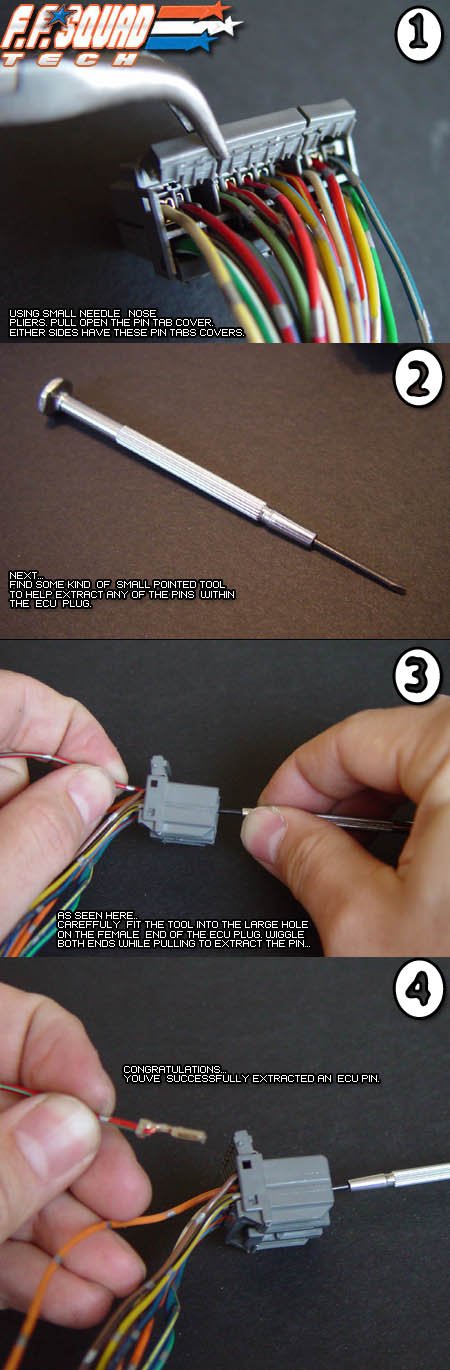

can someone give me some advice on depinning the connectors on the engine harness....i am tryin to put the braided sleeving on and cant get the connectors off. i know to take out the white inner piece, but then i get stuck. anyone got some pics or advice.

Originally Posted by Hayce

Tiny screwdriver or use a de-pinner...

What sleeving are you using? Stuff I used had velco and wrapped around the loom.

What sleeving are you using? Stuff I used had velco and wrapped around the loom.

Originally Posted by .adam.

i was planning on ordering this:

http://www.xoxide.com/techflex.html

http://www.xoxide.com/techflex.html

Originally Posted by blackb18c1eg

try Snap On, I just ordered a universal de-pinning tool from them. I think it lists for like $45, sorry I dont have a pic or a link.

Originally Posted by .adam.

o yeah and for the injectors i have yellow, white, red, and brown.....can anyone verify which colors go with which cylinder?

Originally Posted by teal_dx

I'm guessing you have white instead of blue...

http://www.6thgearadvertising....x.jpg

ignore the resistor box part. this is if you were looking at your motor from the front.

YEL - BLUE - RED - BRN

http://www.6thgearadvertising....2.jpg

Here's looking at the injectors from the opposite side.

BRN - RED - BLU - YEL

be sure to double check them with a meter

Originally Posted by black88si

I am having a hell of a time figuring out how to de-pin my injector plugs....

Anybody know if it is even possible?

Anybody know if it is even possible?

Originally Posted by .adam.

to depin the injector plugs get some needle noce pliers and pull really really hard on the little white circle tab thing sticking out where the two wires come out.

Originally Posted by eblucarbonem1

quick question tho, when doing the main harness are you guys just extending wires or are there certain resistances that need to be met? how hard is this exactly any quick tips? thanks

Originally Posted by AnToNy

Shortening or extending a wire does not change the resistance going through it.

so it will not make a difference

so it will not make a difference

Originally Posted by DC2 Mang

but there will be a power drop of around .1 volts at the points where you connect and solder

that is why you avoid cutting the o2 sensor wires because their signal to the ecu is between .1 and .9 volts

Originally Posted by eblucarbonem1

so if im running 770's and doing a tuck harness do i need to run the wires through a custom resistor box or what?

Originally Posted by RedZone

you can use a stock honda resitor box and the wires are already at the end of the harness on the driverside strut box..... its the dead plug with the yellow/black wires....4 wires go to the injectors. If you trace out the wires at the dead plug, one wire will go to each injector. there should also be a power wire at the dead plug that turns on with the key. If you tap into this power wire and connect it to the power wire ont he resistor box and connect the 4 wires from the injectors to the 4 wires on the resistor box you will be able to now use low impedance injectors.

this is all assuming you have a civic or integra with a d or b engine

Originally Posted by ejwan

finally found the company that does our oem honda pins

its Tyco Amp here is the link to our pin that we need Tyco Amp Pin (Note: Under Instruction Sheets: click on the first link its a PDF file)

Not sure if its P/N 316836 which is the female pin size S. (size M is 316838). this is the 040 series there is also the 070.

I don't know the P/N for the male plug yet (if someone know it would be helpful)

They refer Female pins to Receptacle Contact

http://i49.photobucket.com/alb...6.jpg

and Male pins as Tab Contact

http://i49.photobucket.com/albums/f2...jpg[/QUOTE]

PM user tony1. I believe he has a bunch of the pins. <u>Distributor Wiring</u>

<u>Distributor Wiring</u>

Page 45

<u>Tucking Your HID Kit</u>

QUOTE=SHG_EasyE]i ran my auxillary fan and hid wiring through the main harness to the fuse box and dash (for the fan switch) http://i29.photobucket.com/alb...8.jpg

[url]http://i29.photobucket.com/albums/c294/sohondaeg6/P1020691.jpg[/url ]

its Tyco Amp here is the link to our pin that we need Tyco Amp Pin (Note: Under Instruction Sheets: click on the first link its a PDF file)

Not sure if its P/N 316836 which is the female pin size S. (size M is 316838). this is the 040 series there is also the 070.

I don't know the P/N for the male plug yet (if someone know it would be helpful)

They refer Female pins to Receptacle Contact

http://i49.photobucket.com/alb...6.jpg

and Male pins as Tab Contact

http://i49.photobucket.com/albums/f2...jpg[/QUOTE]

Originally Posted by .dave

PM user tony1. I believe he has a bunch of the pins.

Page 45

Originally Posted by not so JDM Dan

you shouldnt have to shorten the distributor wires, i ran mine under the manifold and it came out perfect

Originally Posted by hayce

hmm done things a little different,

The wires that come out from the distributor (like your pic there) I have lengthened so the plug is under the manifold (mine orginally were shorter than yours, I aws your pics & believe me I tried )

)

The problem lies with the other end of the loom. I want to have the 5 plugs from the motor stopping under the heater hoses. Then the cabin side wires that connect to them peaking out a hole ive made there. So with that in mind the length of the wires wrapped up in the black plastic + braid is too long.

The wires that come out from the distributor (like your pic there) I have lengthened so the plug is under the manifold (mine orginally were shorter than yours, I aws your pics & believe me I tried

)

)The problem lies with the other end of the loom. I want to have the 5 plugs from the motor stopping under the heater hoses. Then the cabin side wires that connect to them peaking out a hole ive made there. So with that in mind the length of the wires wrapped up in the black plastic + braid is too long.

Originally Posted by not so JDM Dan

oh i see, hmm so you want to be able to disconnect the engine harness from the engine bay under the heater hoses?

Originally Posted by hayce

Yeah. This is actually my 2nd go as the first time I did it I just ran the wires through the hole and then put the plugs on which, when I pulled the motor left the loom stranded/trapped in the firewall so I had to chop it (hole is not big enough to pass all the plugs through it)

Originally Posted by Beau Gotti

Question for people with HIDs: where is everyone hiding their sh*t

Originally Posted by SkankyEJ7

[img=http://i17.photobucket.com/albums/b79/todd-ej7/DSC00676.jpg]http://i17.photobucket.com/alb...6.jpg[/img]

and dont worry im pretty sure most all HID stuf is water RESISTANT! Noticce i did not say water proof, so im not liable if you try to submegre you hid's and cut them on

and dont worry im pretty sure most all HID stuf is water RESISTANT! Noticce i did not say water proof, so im not liable if you try to submegre you hid's and cut them on

Originally Posted by H8 O ATE

Originally Posted by H8 O ATE

no problems so far , but i am using rubber stand offs, rubber washers, 2 reg bolts, 2 nylon bolts, and lock washers all around , might say its over kill, but i dont want my dis-continued HID's falling off on the freeway somewhere

as far as mounting, the Catz hid's have 4 bolt hole mounts on each corner, so all i did was drill & tap mounting holes on the frame rails

as far as mounting, the Catz hid's have 4 bolt hole mounts on each corner, so all i did was drill & tap mounting holes on the frame rails

[url]http://i29.photobucket.com/albums/c294/sohondaeg6/P1020691.jpg[/url ]

<u>Special Wire Loom (Sleeving)</u>

Originally Posted by KILLA_EK9

Where do u get this special wire loom thingy??? Anybody..

Originally Posted by teamsoy1320

it is for computer wire...go to xoxide.com or newegg.com and you can get it there

Originally Posted by wEaK Squad *ATL*

1/8", 1/4", 1/2", 3/4", and 1" are the loom sizes I’ve used

Originally Posted by BolivianFuego

Im a little late here, but to all good little boys who ask... Just call Clause...

http://www.partsexpress.com/we...D=161

http://www.partsexpress.com/we...D=161

Originally Posted by eblucarbonem1

how much and what sizes of this stuff are you guys using to do main harnesses?

http://cableorganizer.com/f6-wrap-around/

http://cableorganizer.com/f6-wrap-around/

Originally Posted by American.Graffiti

I went to SVC "www.svc.com" [thanks EF8Kid aka Cha$e aka ballaholic] and just used the black sleeving kit. I have a good amount left over, I just might do a once over on mine so I dont have it as a waste.

Originally Posted by civicandy

Since most of you guys are so good at wiring, I figured I would ask for tips. My current method is to use flux core solder and a soldering pen. I find that 2 hands is not really enough, since there are 2 wires, the solder and the soldering pen. Tips?

Originally Posted by h22apwrdcivic

get a clothes hanger and solder two aligator clips at two different points then use that to hold the wire tight while you solder. its what i use.

Originally Posted by B18EG6

I just strip ~.25 - .5" of insulation from the wire, line the two wires up side by side, and twist them lengthwise around each other.

The end result is a soldered section no larger than the insulated wire, with no pointy pieces that could poke through the heat shrink

I doubt a picture is needed, but if you want one lemme know.

Also - hemostats work very well when holding wires while soldering

The end result is a soldered section no larger than the insulated wire, with no pointy pieces that could poke through the heat shrink

I doubt a picture is needed, but if you want one lemme know.

Also - hemostats work very well when holding wires while soldering

Originally Posted by PatrickGSR94

I like to strip about 1" or a little more off each wire, make each wire into a hook shape, hook the wire ends together, then twist the ends and solder. That will make the absolute strongest solder joint, but you do end up with a slightly larger diameter than the original wire. If you have lots of wires with solders all next to each other then I guess that could be a problem.

Originally Posted by EF8kid

Follow these steps:

http://img.photobucket.com/alb...4.jpg

http://img.photobucket.com/alb...8.jpg

http://img.photobucket.com/alb...9.jpg

then solder

http://img.photobucket.com/alb...4.jpg

http://img.photobucket.com/alb...8.jpg

http://img.photobucket.com/alb...9.jpg

then solder

Originally Posted by wEaK Squad *ATL*

^ correct ^

but dont twist them too tightly because you want the solder to be able to penetrate each thread... solder does NOT sit on top in a bubble... when correctly done, it almost soaks into the wire and itll be very hard to pull apart again

but dont twist them too tightly because you want the solder to be able to penetrate each thread... solder does NOT sit on top in a bubble... when correctly done, it almost soaks into the wire and itll be very hard to pull apart again

Originally Posted by PatrickGSR94

yep, and to do that, you need to heat up the wire so that the wire itself melts the solder. Don't melt the solder against the iron and let it drip onto the wires.

Originally Posted by gabebauman

PS: Don't forget to slide the heat shrink tube over one of the wires and set it back out of the way while soldering.

Originally Posted by h22apwrdcivic

Oh yeah and you heat the wire and not the solder that way the heat sucks in the solder making a permanent connection.

Page 60

Originally Posted by B18C Turbo

One thing I have noticed about all these sick bays are no one is using the ground for the valve cover? What are you guys doing, not using one at all or is it invisible?

Anyone got pics of where every ground should be? I know of the battery -, valve cover, and tranny.

Anyone got pics of where every ground should be? I know of the battery -, valve cover, and tranny.

Originally Posted by EF8kid

Put it on the back VC bolt

Page 65

Originally Posted by B18EG6

Would it be possible to extend the wires, and mount the underhood fusebox in the trunk? I thought about doing this... use 18ga wire to extend the smmaller wires, some 10ga and 8ga for the bigger ones.

Also I have about 20 ft of 0ga for the battery wires, and 4ga to run from the alternator to the fusebox

Also I have about 20 ft of 0ga for the battery wires, and 4ga to run from the alternator to the fusebox

Originally Posted by JDMorgan

its VERY possible but thats like maybe ten 12 gauge wires, and an 8 gauge... thats alot of wire. not to mention the smaller gauge wires. the wire to the battery itself could be super short tho if you ran a wire right from the battery to the fuse block.

Originally Posted by 95jdmej1

as for a custom batt. tray do you mean just weld a smaller tray there ??????

What is the hard part about heater box and fuse box ? can i do it myself???

What is the hard part about heater box and fuse box ? can i do it myself???

Originally Posted by JDMorgan

section the stock tray so that the bottem is the same size as your battery. if you relocated the fuse box under the dash i bet you could fit the whole battery in the space between the fwall and strut tower(instead of sticking out like oe battery does).

with the dash out the heater core, ac evap, and blower motor only have a few nuts and bolts holding them in. you could yank all of it out pretty quick, then just make a panel to weld or rivet in where the heater hose came thru the fwall. i am pretty sure on eg civics you can even put a din block off where the hvac controls were. i am not a fan of removing heat in general, but if you think it's worth it... go for it. there are actually a couple options if you did want to daily drive this car with no oem hvac ****... you can either run a universal heater box so you still have heat and defrost, these are electric so there is no hole in the fwall. the other option is heated windshield.

there are actually a couple options if you did want to daily drive this car with no oem hvac ****... you can either run a universal heater box so you still have heat and defrost, these are electric so there is no hole in the fwall. the other option is heated windshield.

the fuse box relocation is pretty basic but takes a little work, mostly just unwrapping and rewrapping wires. if you are pretty good with wiring give it a shot.

with the dash out the heater core, ac evap, and blower motor only have a few nuts and bolts holding them in. you could yank all of it out pretty quick, then just make a panel to weld or rivet in where the heater hose came thru the fwall. i am pretty sure on eg civics you can even put a din block off where the hvac controls were. i am not a fan of removing heat in general, but if you think it's worth it... go for it.

there are actually a couple options if you did want to daily drive this car with no oem hvac ****... you can either run a universal heater box so you still have heat and defrost, these are electric so there is no hole in the fwall. the other option is heated windshield.

there are actually a couple options if you did want to daily drive this car with no oem hvac ****... you can either run a universal heater box so you still have heat and defrost, these are electric so there is no hole in the fwall. the other option is heated windshield.

the fuse box relocation is pretty basic but takes a little work, mostly just unwrapping and rewrapping wires. if you are pretty good with wiring give it a shot.

Originally Posted by DarkBB4

just a ?, when relocating fuse box.. how do u get the oem honda plugs through teh firewall?

Originally Posted by Madness

Uhmm.... Definately not. Disconnect them from the box, and push them throught the firewall one at a time.

Originally Posted by h22apwrdcivic

yeah they all disconnect from the fuse box, there are about 5-6 plugs on the back of the fuse box, disconnect and pull them back through the firewall and then reconnect. that was the easiest part. if you figured that part is confusing you might want to cease all further projects.

Originally Posted by American.Graffiti

http://img480.imageshack.us/im...9.jpg

Thats a test fit before I put the dash back in the car. Dont mind the cover, its fu_ked and I have a brand new one anyway.

Thats a test fit before I put the dash back in the car. Dont mind the cover, its fu_ked and I have a brand new one anyway.

Originally Posted by JDMFantasy2k

how bout this for a fusebox relocation

http://img.photobucket.com/alb...6.jpg http://img.photobucket.com/alb...8.jpg

yeah that took a lot of creativity. Works good though, plus the glove box is still useable

http://img.photobucket.com/alb...6.jpg http://img.photobucket.com/alb...8.jpg

yeah that took a lot of creativity. Works good though, plus the glove box is still useable

Originally Posted by NHswaps13203

run no heat haha, wait dont do that thats why i sold that car.

[url]http://img108.imageshack.us/img108/961/h2b25uf9.jpg[/ur;]

[url]http://img108.imageshack.us/img108/961/h2b25uf9.jpg[/ur;]

Page 69

Originally Posted by B18C Turbo

Just wondering what to do about holes that im drilling to run wires thru. I need to cover the holes with a water tight seal, for example I drilled a hole in the vents in front of the windshield for the wiper wires to go under the dash rather thru the brake booster.

SO now i need to seal that hole up, and seal up the hole where the wires originally came thru to the engine bay, help.

SO now i need to seal that hole up, and seal up the hole where the wires originally came thru to the engine bay, help.

Originally Posted by JDMorgan

brake fluid switch: remove the ground from the ground block and the signal pin from the connector right behind the firewall. then you can just take the switch off the cap and it looks way cleaner. if you dont notice your brake fluid low on your own maybe cars aren't your thing. ahaha.

wiper wiring: is a bitch. the best way to do it is cut a rectangle around the grommet hole already there, then another rectangle the same size on the firewall between the cabin and the cowl area so it isnt visible from the bay. then just but weld the pieces of metal in the opposite hole. then just run the wiring all inside your cabin right to the cowl and ur done.

wiper wiring: is a bitch. the best way to do it is cut a rectangle around the grommet hole already there, then another rectangle the same size on the firewall between the cabin and the cowl area so it isnt visible from the bay. then just but weld the pieces of metal in the opposite hole. then just run the wiring all inside your cabin right to the cowl and ur done.

#3

Honda-Tech Member

Join Date: Jul 2003

Location: Ontario & Alberta, Canada

Posts: 1,344

Likes: 0

Received 1 Like

on

1 Post

(Continued)

<u>Air Conditioning, Power Steering and Heating</u>

<u>Resevoir Tank/Power Steering Deleting/Tucking</u>

page 56

Page 57

Page 81

<u>A/C Removal</u>

Page 63

Page 97

<u>”Heater” removal Removal</u>

you can get a rubber plug from pepboys for both of them. or for the one on the side of the head, you can take out the spout with a (21mm?) socket and plug it. i plugged mine with the bronzish plug thing near the dizzy. it takes an alen wrench

Oh you guys meant on the engine? Mine is looped for now. I am removing the water pipes, and welding the ports shut soon though. <u><FONT SIZE="3">Miscellaneous Engine Bay Component</FONT></u>

<u><FONT SIZE="3">Miscellaneous Engine Bay Component</FONT></u>

<u>Getting Rid of the Carbon Canister</u>

Like this? Have a hose from

there

http://img512.imageshack.us/im...6.jpg

to here? this is on the firewall haha shitty picture

http://img512.imageshack.us/im...6.jpg

That's how we did it on my buddy's coupe.

Connect the hose to the plastic drain tube that dumps out below the car.

Where is the pressure bypass located? Currently I just ran a hose from the vent down below the crossmember