Skunk2 PRO Series 70mm Throttle Body - design problem.

#1

Problem: Skunk2 intentionally designed the Throttle Body Idle Screw to only allow an adjustment of up to 75rpms - as compared to the OEM throttle body adjustment of over 450rpms.

Why?: It makes it a better part for the masses in order to aleviate problems with a hunting idle (which means there are other problems).

First of all, let me state that this is not a complaint (although I am bugged), but moreover an attempt to inform builders of an issue I have found with the 70mm Skunk2 Throttle Body. Feel free to comment please. The more awareness, the better for the customer.

For those that do not understand the way the idle works on the B-series engines, I feel it is necessary to explain a bit about it first.

The amount of air that circumvents the throttle plate designates the RPM at which the engine idles. This is accomplished through two devices.

1. The Idle Air Control Valve (IAC).

2. The throttle body idle screw.

Idle Air Control Valve: An electronic plunger based valve that can move to allow more or less air passed the throttle plate as the ECU recognizes that the engine needs it to prevent it from stalling, or from idling too high. Therefore, this is an inconsistent valve, meaning it is rarely in the same position, always moving around in small or large increments.

Throttle Body Idle Screw: A screw that once set, is designed to constantly allow the same amount of air around the throttle plate at any given time, only varying based on vacuum. Suffice it to say that because it is set and left, it is a constant valve, or port - always in the same position, always maintaining the same maximum flow characteristics.

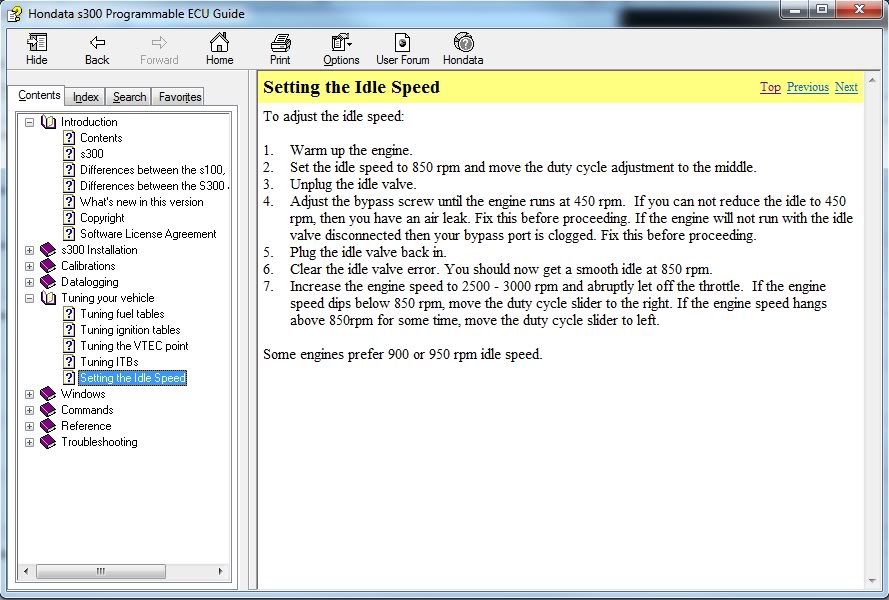

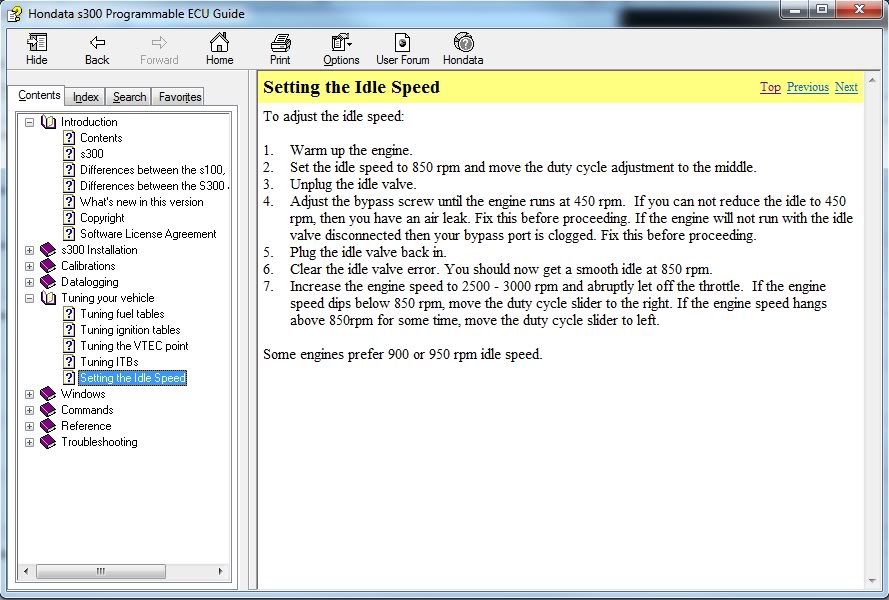

So what does all this have to do with the Skunk2 70mm Throttle Body? First, please see the Hondata s300 instructions for setting the idle in the image below.

The instructions state to warm the car up to operating temperature, and unplug the idle air control valve electrical connector. It states that if the car dies, the bypass port is plugged. If the idle cannot be reduced to 450 rpms there is an air leak.

I discovered this problem with the throttle body when I was unable to keep my car running after disconnecting the IAC electrical connector. I pulled the throttle body off and found it to be perfectly clean with all orifices clear (bypass port not plugged). I then called Skunk2 and spoke with Brian. He informed me that the OEM throttle body was designed to flow 450 rpms worth of air through the idle screw but that the Skunk2 had only been designed to flow "50-75rpms" worth of air through the idle screw.

This is where it becomes problematic. Let's imagine you are trying to idle your car at 850rpms (like me): With all but 75rpms of the air being controlled by the IAC, the vehicle is subject to much larger fluctuations in idle air due to the IAC plunger needing to adjust more in order to regulate the idle. When the throttle idle screw is supplying 450rpms of air to the idle, the IAC only needs to supply 400rpms of air to maintain a proper idle. Additionally, the duty cycle of the IAC needs to be increased to prevent the car from dying when letting off the gas, such as if you are approaching a stoplight) because at engine speed, the IAC is closed, but at idle it must be wide open to maintain an idle. If the throttle body were to provide the base 450rpms of idle air through the idle screw, the IAC would require less time, less adjustment, and a lower duty cycle in order to move the valve's plunger to meet the idle needs of the engine.

Another problem: idle Air/Fuel ratio. With a constantly moving idle valve, the air moving past the throttle plate will be constantly changing (thus, on my car a fluctuating idle of +/- 100-150rpms). Thus the reason it is difficult to get a consistent idle with the 70mm Skunk2 throttle body. Some believe it is simply an issue that comes with having a large throttle plate. It is not. The throttle plate is air tight on the Skunk2 70mm. It has everything to do with making the IAC do 90% of the work to supply the idle air, rather than sharing the load almost 50/50 with the idle screw.

So what is all the fuss? Well, getting the idle set properly cannot be accomplished, the car dies easier when letting off the gas because the IAC can't get open fast enough (the ligher the flywheel, the easier the engine dies because the less time it takes to rev down), and inconsistent idle Air/Fuel ratios. These are all problems for daily drivers, and those that want power and fuel economy (at idle, fully warm, my car can be at 12.1 or 15.5 on the A/F guage with no changes to the engine, and no vacuum leaks - the increase in air is the IAC valve - remember this increase is without any apparent throttle plate movement to the ECU since it is fully shut at idle). The IAC was never designed to have to adjust to the extremes that the Skunk2 70mm Throttle Body asks it to by making it do all of the work to supply the air to keep the car from dying.

So, learn from my experience. Choose wisely when investing in a throttle body because it is the #1 factor in the way your car idles.

In conclusion, Skunk2 admits to having designed the idle screw to only allow 50-75rpms of air through in order to prevent the idle hunting problem that so many have. Let's face it though, if you have an idle hunting issue, there are other problems. They also admitted to producing a product for the Honda enthusiast masses rather than one that was designed to work in conjunction with the way that Honda's computer expects it to. In the end, this means that this throttle body is good for noobs, and bad for those that know what they are doing. I'm sorry to have to say that because I like Skunk2. I like their customer service and the way they take care of the customer when there are problems. Unfortunately, there is nothing they can do about a design issue by replacing this product - to my dismay. All I can say is: demand good quality and accurate products and you will get them.

The Workaround: - added from below to bring to one spot on post.

Ok, let me preface this by stating that this is also "not ideal" but a good workaround that is totally viable and allows for fine tuning of the idle. This will work for ANY throttlebody that fails to adjust the idle properly. So, for those of you that have a Skunk2 or another brand, I have implemented this on my own car as of today - and it works.

Solution

If you have a spare vacuum connection, or can tap into another one that goes to the Intake Manifold (using a T connector), you should be able to pull this off.

Supplies:

1- 1/4" Threaded Needle Valve - Lowe's

3ft of icemaker hose (1/4"), the kind with threaded screw connectors at each end - Lowe's

So the problem is not enough air... So, the idea is to get more filtered air from in front of the throttle plate, yet behind the air filter. Best connection? The hose fitting on the intake pipe. This air will be run through the needle valve, the valve being the flow controller, and into the back of the intake manifold. (remember B-series is MAP based, not MAF - so no worries). Once you have followed the below instructions - you will be able to adjust your idle with the needle valve you have installed. This will give you the air you need to establish a base idle, per the instructions, and give your idle air control valve a rest too. After performing this operation, my idle is no longer accompanied by a massively loud hiss that used to be made by my overworked IAC. When I rev down, the car doesn't stall or get near it and my A/F ratio at idle is now consistent. It now idles as it should - no thanks to Skunk2's poor design choice.

1. Cut an end off the hose, giving yourself 8-10 inches of hose with one threaded connector at the end.

2. Screw it onto one side of the needle valve (doesn't matter what side).

3. Take the open end of the hose (the cut end of the hose that is now connected to the needle valve) and connect it to your intake manifold, either on a free fitting, or via a T-connector that goes inline with another vacuum hose.

4. Take the remaining hose and screw it the threaded connector to the remaining threaded end of the needle valve.

5. Measure the distance to the intake pipe hose port that is usually connected to the valve cover and connect the hose to that port. If that port is currently being used, you can T into the hose connected to it to get filtered air from behind the air filter, but in front of the throttle plate.

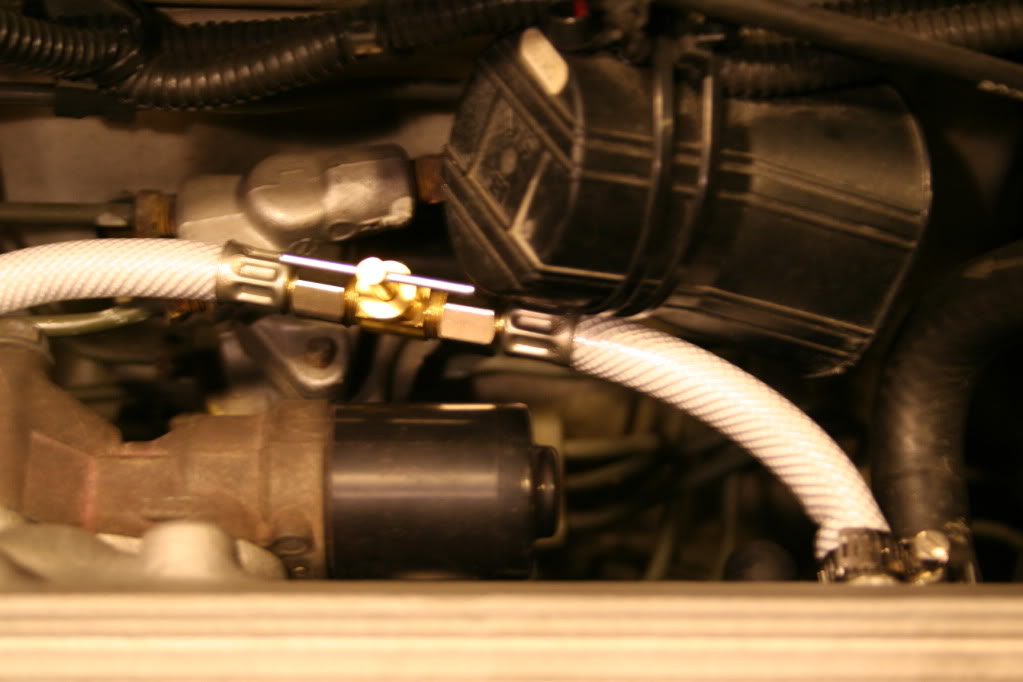

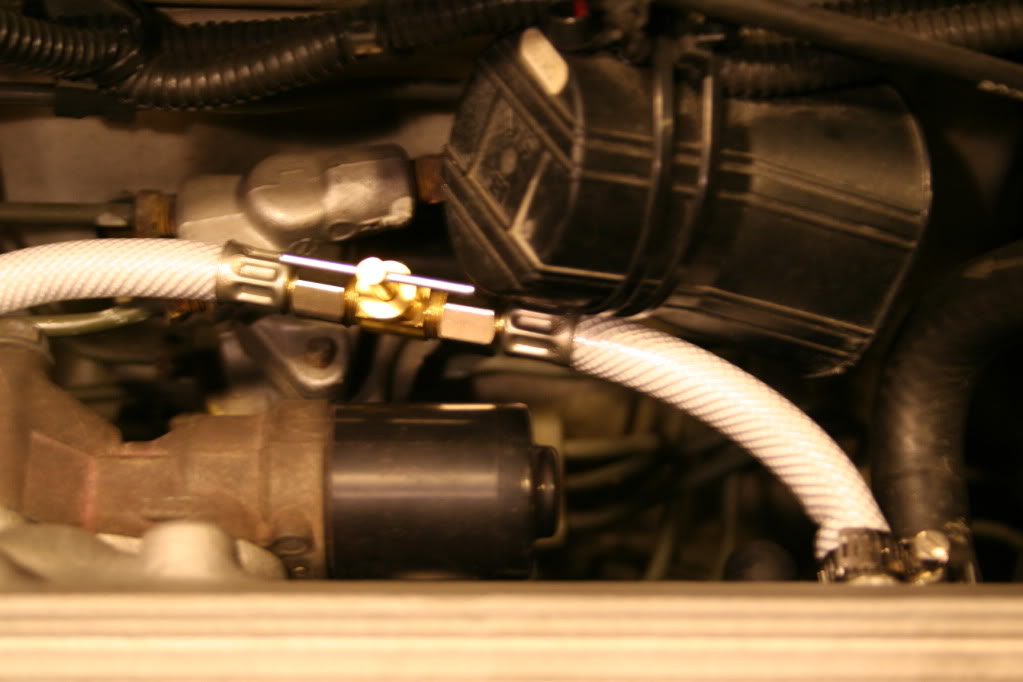

See pics:

__________________

If you have any questions or comments, I welcome them.

Update:

I started the car cold for the first time since implementing the above idle workaround. To no surprise of mine, the vehicle required very little coaxing to stay running - about 4-5 seconds on the throttle (prior to this, i had to baby the throttle to keep it from stalling). After that, the A/F ratio regulated and the car warmed up properly. Before, the engine would try and try to idle where the S300 has designated, but could never get to 1300 rpms because the IAC was simply unable to flow that volume of air. Now with the added air input at the back of the manifold, the IAC is doing less and therefore has more air to offer to the net amount of air received into the intake manifold. The car did achieved the targeted idle of 1300 rpms while cold and maintained a consisted A/F ratio during the entire warmup process. The hiss that was previously present was almost inaudible. This has definitely resolved my idle issues. The idle is stable now and for an engine that is fully built, that is not a bad feat (see signature for details).

Update #2 (5-22-11):

Went to c-speedracing in WA to have my car tuned two days ago. While we were tuning, we noticed that throttle was only able to open to 99% (hondata s300 confirmed). We made some adjustments but were unable to get it to open to 100% without making it impossible to close (throttle cable too tight after attempting to adjust). There is only one explanation for this. The throttle body cable cam (where the throttle cable connects to the throttle body) is the incorrect size (circumference). Yet another design problem from Skunk2. In my opinion, it is another big one. A throttle should be able to open to 100%, period.

Why?: It makes it a better part for the masses in order to aleviate problems with a hunting idle (which means there are other problems).

First of all, let me state that this is not a complaint (although I am bugged), but moreover an attempt to inform builders of an issue I have found with the 70mm Skunk2 Throttle Body. Feel free to comment please. The more awareness, the better for the customer.

For those that do not understand the way the idle works on the B-series engines, I feel it is necessary to explain a bit about it first.

The amount of air that circumvents the throttle plate designates the RPM at which the engine idles. This is accomplished through two devices.

1. The Idle Air Control Valve (IAC).

2. The throttle body idle screw.

Idle Air Control Valve: An electronic plunger based valve that can move to allow more or less air passed the throttle plate as the ECU recognizes that the engine needs it to prevent it from stalling, or from idling too high. Therefore, this is an inconsistent valve, meaning it is rarely in the same position, always moving around in small or large increments.

Throttle Body Idle Screw: A screw that once set, is designed to constantly allow the same amount of air around the throttle plate at any given time, only varying based on vacuum. Suffice it to say that because it is set and left, it is a constant valve, or port - always in the same position, always maintaining the same maximum flow characteristics.

So what does all this have to do with the Skunk2 70mm Throttle Body? First, please see the Hondata s300 instructions for setting the idle in the image below.

The instructions state to warm the car up to operating temperature, and unplug the idle air control valve electrical connector. It states that if the car dies, the bypass port is plugged. If the idle cannot be reduced to 450 rpms there is an air leak.

I discovered this problem with the throttle body when I was unable to keep my car running after disconnecting the IAC electrical connector. I pulled the throttle body off and found it to be perfectly clean with all orifices clear (bypass port not plugged). I then called Skunk2 and spoke with Brian. He informed me that the OEM throttle body was designed to flow 450 rpms worth of air through the idle screw but that the Skunk2 had only been designed to flow "50-75rpms" worth of air through the idle screw.

This is where it becomes problematic. Let's imagine you are trying to idle your car at 850rpms (like me): With all but 75rpms of the air being controlled by the IAC, the vehicle is subject to much larger fluctuations in idle air due to the IAC plunger needing to adjust more in order to regulate the idle. When the throttle idle screw is supplying 450rpms of air to the idle, the IAC only needs to supply 400rpms of air to maintain a proper idle. Additionally, the duty cycle of the IAC needs to be increased to prevent the car from dying when letting off the gas, such as if you are approaching a stoplight) because at engine speed, the IAC is closed, but at idle it must be wide open to maintain an idle. If the throttle body were to provide the base 450rpms of idle air through the idle screw, the IAC would require less time, less adjustment, and a lower duty cycle in order to move the valve's plunger to meet the idle needs of the engine.

Another problem: idle Air/Fuel ratio. With a constantly moving idle valve, the air moving past the throttle plate will be constantly changing (thus, on my car a fluctuating idle of +/- 100-150rpms). Thus the reason it is difficult to get a consistent idle with the 70mm Skunk2 throttle body. Some believe it is simply an issue that comes with having a large throttle plate. It is not. The throttle plate is air tight on the Skunk2 70mm. It has everything to do with making the IAC do 90% of the work to supply the idle air, rather than sharing the load almost 50/50 with the idle screw.

So what is all the fuss? Well, getting the idle set properly cannot be accomplished, the car dies easier when letting off the gas because the IAC can't get open fast enough (the ligher the flywheel, the easier the engine dies because the less time it takes to rev down), and inconsistent idle Air/Fuel ratios. These are all problems for daily drivers, and those that want power and fuel economy (at idle, fully warm, my car can be at 12.1 or 15.5 on the A/F guage with no changes to the engine, and no vacuum leaks - the increase in air is the IAC valve - remember this increase is without any apparent throttle plate movement to the ECU since it is fully shut at idle). The IAC was never designed to have to adjust to the extremes that the Skunk2 70mm Throttle Body asks it to by making it do all of the work to supply the air to keep the car from dying.

So, learn from my experience. Choose wisely when investing in a throttle body because it is the #1 factor in the way your car idles.

In conclusion, Skunk2 admits to having designed the idle screw to only allow 50-75rpms of air through in order to prevent the idle hunting problem that so many have. Let's face it though, if you have an idle hunting issue, there are other problems. They also admitted to producing a product for the Honda enthusiast masses rather than one that was designed to work in conjunction with the way that Honda's computer expects it to. In the end, this means that this throttle body is good for noobs, and bad for those that know what they are doing. I'm sorry to have to say that because I like Skunk2. I like their customer service and the way they take care of the customer when there are problems. Unfortunately, there is nothing they can do about a design issue by replacing this product - to my dismay. All I can say is: demand good quality and accurate products and you will get them.

The Workaround: - added from below to bring to one spot on post.

Ok, let me preface this by stating that this is also "not ideal" but a good workaround that is totally viable and allows for fine tuning of the idle. This will work for ANY throttlebody that fails to adjust the idle properly. So, for those of you that have a Skunk2 or another brand, I have implemented this on my own car as of today - and it works.

Solution

If you have a spare vacuum connection, or can tap into another one that goes to the Intake Manifold (using a T connector), you should be able to pull this off.

Supplies:

1- 1/4" Threaded Needle Valve - Lowe's

3ft of icemaker hose (1/4"), the kind with threaded screw connectors at each end - Lowe's

So the problem is not enough air... So, the idea is to get more filtered air from in front of the throttle plate, yet behind the air filter. Best connection? The hose fitting on the intake pipe. This air will be run through the needle valve, the valve being the flow controller, and into the back of the intake manifold. (remember B-series is MAP based, not MAF - so no worries). Once you have followed the below instructions - you will be able to adjust your idle with the needle valve you have installed. This will give you the air you need to establish a base idle, per the instructions, and give your idle air control valve a rest too. After performing this operation, my idle is no longer accompanied by a massively loud hiss that used to be made by my overworked IAC. When I rev down, the car doesn't stall or get near it and my A/F ratio at idle is now consistent. It now idles as it should - no thanks to Skunk2's poor design choice.

1. Cut an end off the hose, giving yourself 8-10 inches of hose with one threaded connector at the end.

2. Screw it onto one side of the needle valve (doesn't matter what side).

3. Take the open end of the hose (the cut end of the hose that is now connected to the needle valve) and connect it to your intake manifold, either on a free fitting, or via a T-connector that goes inline with another vacuum hose.

4. Take the remaining hose and screw it the threaded connector to the remaining threaded end of the needle valve.

5. Measure the distance to the intake pipe hose port that is usually connected to the valve cover and connect the hose to that port. If that port is currently being used, you can T into the hose connected to it to get filtered air from behind the air filter, but in front of the throttle plate.

See pics:

__________________

If you have any questions or comments, I welcome them.

Update:

I started the car cold for the first time since implementing the above idle workaround. To no surprise of mine, the vehicle required very little coaxing to stay running - about 4-5 seconds on the throttle (prior to this, i had to baby the throttle to keep it from stalling). After that, the A/F ratio regulated and the car warmed up properly. Before, the engine would try and try to idle where the S300 has designated, but could never get to 1300 rpms because the IAC was simply unable to flow that volume of air. Now with the added air input at the back of the manifold, the IAC is doing less and therefore has more air to offer to the net amount of air received into the intake manifold. The car did achieved the targeted idle of 1300 rpms while cold and maintained a consisted A/F ratio during the entire warmup process. The hiss that was previously present was almost inaudible. This has definitely resolved my idle issues. The idle is stable now and for an engine that is fully built, that is not a bad feat (see signature for details).

Update #2 (5-22-11):

Went to c-speedracing in WA to have my car tuned two days ago. While we were tuning, we noticed that throttle was only able to open to 99% (hondata s300 confirmed). We made some adjustments but were unable to get it to open to 100% without making it impossible to close (throttle cable too tight after attempting to adjust). There is only one explanation for this. The throttle body cable cam (where the throttle cable connects to the throttle body) is the incorrect size (circumference). Yet another design problem from Skunk2. In my opinion, it is another big one. A throttle should be able to open to 100%, period.

Last edited by criticallistenp; 05-22-2011 at 04:22 PM.

The following users liked this post:

#5

Honda-Tech Member

Join Date: Aug 2010

Location: Maryland

Posts: 2,686

Likes: 0

Received 0 Likes

on

0 Posts

#6

FSAE

My Omni TB doesn't have the idle adjust screw at all. Just use the throttle stop adjustment under the butterfly (threaded stud w/8mm allen lock nut).

If I can get my Pro-3 cam'd 2.0L to idle well at 850 without an adjustment screw, you should be just fine with your setup.

Good writeup though.

If I can get my Pro-3 cam'd 2.0L to idle well at 850 without an adjustment screw, you should be just fine with your setup.

Good writeup though.

#7

Honda-Tech Member

Join Date: Jul 2008

Location: Clatskanie, OR, USA

Posts: 711

Likes: 0

Received 0 Likes

on

0 Posts

^x2

My Professional Products idle screw didn't due crap, I ended up using the throttle stop to get my idle right.

My Professional Products idle screw didn't due crap, I ended up using the throttle stop to get my idle right.

Trending Topics

#8

First comments - followed by a workaround afterwards.

Comments:

Thank you for your comments everyone. I know that one can augment the idle air by adjusting the throttle plate stop screw. It works fairly well. There are a couple of issues with this fix though:

1. Aluminum expands with heat at a different rate than the throttle plate - not a huge deal, but it does cause a variation in the amount of air that gets by the throttle plate with heat soak and temperature variations throughout the year.

2. Carbon and oil vapor buildup as valve cover and egr gases are recirculated. They will build up on the throttle plate and eventually start filling in the gap that was made via the throttle plate stop screw - effectively lowering the idle as this occurs. I don't recirculate mine, but many do.

3. Skunk2 presets the position of the throttle plate for you before they ship out the unit so that it is completely sealed. Sealed is the ideal position for a throttle plate, period. Additionally, trying to adjust that screw for such a large moving surface is difficult when trying to dial in the idle.

4. Adjusting the throttle plate stop screw means that the TPS sensor must be recalibrated - annoying extra work that one should not have to do.

It works to adjust the stop screw, but it's not ideal. It is a great tip though when there is nothing else that can be done.

The Workaround:

Ok, let me preface this by stating that this is also "not ideal" but a good workaround that is totally viable and allows for fine tuning of the idle. This will work for ANY throttlebody that fails to adjust the idle properly. So, for those of you that have a Skunk2 or another brand, I have implemented this on my own car as of today - and it works.

Solution

If you have a spare vacuum connection, or can tap into another one that goes to the Intake Manifold (using a T connector), you should be able to pull this off.

Supplies:

1- 1/4" Threaded Needle Valve - Lowe's

3ft of icemaker hose (1/4"), the kind with threaded screw connectors at each end - Lowe's

So the problem is not enough air... So, the idea is to get more filtered air from in front of the throttle plate, yet behind the air filter. Best connection? The hose fitting on the intake pipe. This air will be run through the needle valve, the valve being the flow controller, and into the back of the intake manifold. (remember B-series is MAP based, not MAF - so no worries). Once you have followed the below instructions - you will be able to adjust your idle with the needle valve you have installed. This will give you the air you need to establish a base idle, per the instructions, and give your idle air control valve a rest too. After performing this operation, my idle is no longer accompanied by a massively loud hiss that used to be made by my overworked IAC. When I rev down, the car doesn't stall or get near it and my A/F ratio at idle is now consistent. It now idles as it should - no thanks to Skunk2's poor design choice.

1. Cut an end off the hose, giving yourself 8-10 inches of hose with one threaded connector at the end.

2. Screw it onto one side of the needle valve (doesn't matter what side).

3. Take the open end of the hose (the cut end of the hose that is now connected to the needle valve) and connect it to your intake manifold, either on a free fitting, or via a T-connector that goes inline with another vacuum hose.

4. Take the remaining hose and screw it the threaded connector to the remaining threaded end of the needle valve.

5. Measure the distance to the intake pipe hose port that is usually connected to the valve cover and connect the hose to that port. If that port is currently being used, you can T into the hose connected to it to get filtered air from behind the air filter, but in front of the throttle plate.

Comments:

Thank you for your comments everyone. I know that one can augment the idle air by adjusting the throttle plate stop screw. It works fairly well. There are a couple of issues with this fix though:

1. Aluminum expands with heat at a different rate than the throttle plate - not a huge deal, but it does cause a variation in the amount of air that gets by the throttle plate with heat soak and temperature variations throughout the year.

2. Carbon and oil vapor buildup as valve cover and egr gases are recirculated. They will build up on the throttle plate and eventually start filling in the gap that was made via the throttle plate stop screw - effectively lowering the idle as this occurs. I don't recirculate mine, but many do.

3. Skunk2 presets the position of the throttle plate for you before they ship out the unit so that it is completely sealed. Sealed is the ideal position for a throttle plate, period. Additionally, trying to adjust that screw for such a large moving surface is difficult when trying to dial in the idle.

4. Adjusting the throttle plate stop screw means that the TPS sensor must be recalibrated - annoying extra work that one should not have to do.

It works to adjust the stop screw, but it's not ideal. It is a great tip though when there is nothing else that can be done.

The Workaround:

Ok, let me preface this by stating that this is also "not ideal" but a good workaround that is totally viable and allows for fine tuning of the idle. This will work for ANY throttlebody that fails to adjust the idle properly. So, for those of you that have a Skunk2 or another brand, I have implemented this on my own car as of today - and it works.

Solution

If you have a spare vacuum connection, or can tap into another one that goes to the Intake Manifold (using a T connector), you should be able to pull this off.

Supplies:

1- 1/4" Threaded Needle Valve - Lowe's

3ft of icemaker hose (1/4"), the kind with threaded screw connectors at each end - Lowe's

So the problem is not enough air... So, the idea is to get more filtered air from in front of the throttle plate, yet behind the air filter. Best connection? The hose fitting on the intake pipe. This air will be run through the needle valve, the valve being the flow controller, and into the back of the intake manifold. (remember B-series is MAP based, not MAF - so no worries). Once you have followed the below instructions - you will be able to adjust your idle with the needle valve you have installed. This will give you the air you need to establish a base idle, per the instructions, and give your idle air control valve a rest too. After performing this operation, my idle is no longer accompanied by a massively loud hiss that used to be made by my overworked IAC. When I rev down, the car doesn't stall or get near it and my A/F ratio at idle is now consistent. It now idles as it should - no thanks to Skunk2's poor design choice.

1. Cut an end off the hose, giving yourself 8-10 inches of hose with one threaded connector at the end.

2. Screw it onto one side of the needle valve (doesn't matter what side).

3. Take the open end of the hose (the cut end of the hose that is now connected to the needle valve) and connect it to your intake manifold, either on a free fitting, or via a T-connector that goes inline with another vacuum hose.

4. Take the remaining hose and screw it the threaded connector to the remaining threaded end of the needle valve.

5. Measure the distance to the intake pipe hose port that is usually connected to the valve cover and connect the hose to that port. If that port is currently being used, you can T into the hose connected to it to get filtered air from behind the air filter, but in front of the throttle plate.

#10

First comments - followed by a workaround afterwards.

Comments:

Thank you for your comments everyone. I know that one can augment the idle air by adjusting the throttle plate stop screw. It works fairly well. There are a couple of issues with this fix though:

1. Aluminum expands with heat at a different rate than the throttle plate - not a huge deal, but it does cause a variation in the amount of air that gets by the throttle plate with heat soak and temperature variations throughout the year.

2. Carbon and oil vapor buildup as valve cover and egr gases are recirculated. They will build up on the throttle plate and eventually start filling in the gap that was made via the throttle plate stop screw - effectively lowering the idle as this occurs. I don't recirculate mine, but many do.

3. Skunk2 presets the position of the throttle plate for you before they ship out the unit so that it is completely sealed. Sealed is the ideal position for a throttle plate, period. Additionally, trying to adjust that screw for such a large moving surface is difficult when trying to dial in the idle.

4. Adjusting the throttle plate stop screw means that the TPS sensor must be recalibrated - annoying extra work that one should not have to do.

It works to adjust the stop screw, but it's not ideal. It is a great tip though when there is nothing else that can be done.

The Workaround:

Ok, let me preface this by stating that this is also "not ideal" but a good workaround that is totally viable and allows for fine tuning of the idle. This will work for ANY throttlebody that fails to adjust the idle properly. So, for those of you that have a Skunk2 or another brand, I have implemented this on my own car as of today - and it works.

Solution

If you have a spare vacuum connection, or can tap into another one that goes to the Intake Manifold (using a T connector), you should be able to pull this off.

Supplies:

1- 1/4" Threaded Needle Valve - Lowe's

3ft of icemaker hose (1/4"), the kind with threaded screw connectors at each end - Lowe's

So the problem is not enough air... So, the idea is to get more filtered air from in front of the throttle plate, yet behind the air filter. Best connection? The hose fitting on the intake pipe. This air will be run through the needle valve, the valve being the flow controller, and into the back of the intake manifold. (remember B-series is MAP based, not MAF - so no worries). Once you have followed the below instructions - you will be able to adjust your idle with the needle valve you have installed. This will give you the air you need to establish a base idle, per the instructions, and give your idle air control valve a rest too. After performing this operation, my idle is no longer accompanied by a massively loud hiss that used to be made by my overworked IAC. When I rev down, the car doesn't stall or get near it and my A/F ratio at idle is now consistent. It now idles as it should - no thanks to Skunk2's poor design choice.

1. Cut an end off the hose, giving yourself 8-10 inches of hose with one threaded connector at the end.

2. Screw it onto one side of the needle valve (doesn't matter what side).

3. Take the open end of the hose (the cut end of the hose that is now connected to the needle valve) and connect it to your intake manifold, either on a free fitting, or via a T-connector that goes inline with another vacuum hose.

4. Take the remaining hose and screw it the threaded connector to the remaining threaded end of the needle valve.

5. Measure the distance to the intake pipe hose port that is usually connected to the valve cover and connect the hose to that port. If that port is currently being used, you can T into the hose connected to it to get filtered air from behind the air filter, but in front of the throttle plate.

Comments:

Thank you for your comments everyone. I know that one can augment the idle air by adjusting the throttle plate stop screw. It works fairly well. There are a couple of issues with this fix though:

1. Aluminum expands with heat at a different rate than the throttle plate - not a huge deal, but it does cause a variation in the amount of air that gets by the throttle plate with heat soak and temperature variations throughout the year.

2. Carbon and oil vapor buildup as valve cover and egr gases are recirculated. They will build up on the throttle plate and eventually start filling in the gap that was made via the throttle plate stop screw - effectively lowering the idle as this occurs. I don't recirculate mine, but many do.

3. Skunk2 presets the position of the throttle plate for you before they ship out the unit so that it is completely sealed. Sealed is the ideal position for a throttle plate, period. Additionally, trying to adjust that screw for such a large moving surface is difficult when trying to dial in the idle.

4. Adjusting the throttle plate stop screw means that the TPS sensor must be recalibrated - annoying extra work that one should not have to do.

It works to adjust the stop screw, but it's not ideal. It is a great tip though when there is nothing else that can be done.

The Workaround:

Ok, let me preface this by stating that this is also "not ideal" but a good workaround that is totally viable and allows for fine tuning of the idle. This will work for ANY throttlebody that fails to adjust the idle properly. So, for those of you that have a Skunk2 or another brand, I have implemented this on my own car as of today - and it works.

Solution

If you have a spare vacuum connection, or can tap into another one that goes to the Intake Manifold (using a T connector), you should be able to pull this off.

Supplies:

1- 1/4" Threaded Needle Valve - Lowe's

3ft of icemaker hose (1/4"), the kind with threaded screw connectors at each end - Lowe's

So the problem is not enough air... So, the idea is to get more filtered air from in front of the throttle plate, yet behind the air filter. Best connection? The hose fitting on the intake pipe. This air will be run through the needle valve, the valve being the flow controller, and into the back of the intake manifold. (remember B-series is MAP based, not MAF - so no worries). Once you have followed the below instructions - you will be able to adjust your idle with the needle valve you have installed. This will give you the air you need to establish a base idle, per the instructions, and give your idle air control valve a rest too. After performing this operation, my idle is no longer accompanied by a massively loud hiss that used to be made by my overworked IAC. When I rev down, the car doesn't stall or get near it and my A/F ratio at idle is now consistent. It now idles as it should - no thanks to Skunk2's poor design choice.

1. Cut an end off the hose, giving yourself 8-10 inches of hose with one threaded connector at the end.

2. Screw it onto one side of the needle valve (doesn't matter what side).

3. Take the open end of the hose (the cut end of the hose that is now connected to the needle valve) and connect it to your intake manifold, either on a free fitting, or via a T-connector that goes inline with another vacuum hose.

4. Take the remaining hose and screw it the threaded connector to the remaining threaded end of the needle valve.

5. Measure the distance to the intake pipe hose port that is usually connected to the valve cover and connect the hose to that port. If that port is currently being used, you can T into the hose connected to it to get filtered air from behind the air filter, but in front of the throttle plate.

can you post a pic on wtat you mean.

#12

#13

Honda-Tech Member

Join Date: Oct 2002

Location: Bay Area, CA

Posts: 251

Likes: 0

Received 0 Likes

on

0 Posts

I'm running a Neptuned RTP P28 obd1 ecu in a Stock 97' B18C1. With my stock ECU my idle during warm up is normal. With the Neptune (I believe with any obd2a to obd1 ecu) I have a load hissing during warm up with a lil idle hunting. I thought It was due to the IAB's stuck open (high rpm), so I manually closed the IAB's during the hiss, no luck.

I believe maybe there might be a other idle controlling obd2a component not operating normally. Might this be my issue?

#14

I lil off topic but figured you would know the cause.

I'm running a Neptuned RTP P28 obd1 ecu in a Stock 97' B18C1. With my stock ECU my idle during warm up is normal. With the Neptune (I believe with any obd2a to obd1 ecu) I have a load hissing during warm up with a lil idle hunting. I thought It was due to the IAB's stuck open (high rpm), so I manually closed the IAB's during the hiss, no luck.

I believe maybe there might be a other idle controlling obd2a component not operating normally. Might this be my issue?

I'm running a Neptuned RTP P28 obd1 ecu in a Stock 97' B18C1. With my stock ECU my idle during warm up is normal. With the Neptune (I believe with any obd2a to obd1 ecu) I have a load hissing during warm up with a lil idle hunting. I thought It was due to the IAB's stuck open (high rpm), so I manually closed the IAB's during the hiss, no luck.

I believe maybe there might be a other idle controlling obd2a component not operating normally. Might this be my issue?

I can't tell you for certain what the problem is, but here is a framework within which you may discover it.

1. Hissing is a symptom of turbulence caused by a gas moving at high velocity.

2. Air, having been designated a fluid in science, is subject to Bernoulli's principle which is that as a fluid gains velocity, it loses pressure and as a fluid increases in pressure it decreases in velocity.

3. Turbulence is the moment when a fluid breaches the "boundary layer" and begins to flow in a disorganized manner (increases in entropy).

Ideas:

So, your problem is not in the IAB's. Although they can cause hissing, it is most prevalent when they are only barely open (air moving past the throttle plates would increase in velocity because of the small opening, thus increasing the characteristic turbulence of the flowing air). More than likely, you have a small amount of air, moving through a small orifice at high velocity causing this sound. If the sound is not present when using the oem computer and oem software, there must be a difference between the startup settings of the Neptune-tuned ECU and the OEM. I suspect the Neptune tune was designed to utilize the Idle Air Control valve (IAC) as a means of regulating the idle. If this is the case, it could be the cause of the loud hiss you are hearing. I can definitively witness, that if that is the case, the hiss will be very audible, even inside the cab. To rule this out, you need to allow air in behind the throttle body in a controlled manner so that it doesn't rev your engine much beyond idle. You can do so by following my instructions with the hose and needle valve at the beginning of the thread.

I suspect that your IAC is the source of the symptom (doesn't mean it is bad) because it is the only electronic device (connected to the ecu) that could cause the hiss. It doesn't mean it is bad, but if your Neptuned ECU is delivering more fuel at idle than the stock ecu, the engine ECU will do its best to keep the engine from stalling due to a richly mapped idle fuel setting. The ECU will compensate by adjusting timing and allowing the IAC to draw more air in. That is where your hiss is coming from. The timing adjustment and the additional air, with the wrong idle A/F ratio, can be the root of your hiss and idle hunting problem. Timing adjustments (automatic not) will cause the engine to rev up or down based on the adjustment (remember setting the timing with a timing light? As the distributor is clocked left and right,the idle rpms change), and since the ECU is automating the timing along with a varying amount of air coming through the IAC, you could get the engine into a loop consisting of a downward pattern of a stall followed by recovery from the ECU as it makes the above-mentioned adjustments - and it will continually do this, resulting in idle hunting.

Conclusions:

Your problem is tuning. It is not mechanical. If it were, the symptoms would be the same for both ECUs. I recommend taking the car back to the tuner and having them figure out how the current tune is causing your hunting idle. I hope this was helpful.

#15

Honda-Tech Member

Join Date: Oct 2002

Location: Bay Area, CA

Posts: 251

Likes: 0

Received 0 Likes

on

0 Posts

criticallistenp

Great write-up! Should Help many people wit idle issues even if not on a Skunk2 70mm TB.

Great write-up! Should Help many people wit idle issues even if not on a Skunk2 70mm TB.

#16

i have skunk 2 tb and manifold. my car doesnt die but almost and it goes up and down were can i tie the hose into on manifold for more air

#17

Honda-Tech Member

Join Date: Oct 2002

Location: Bay Area, CA

Posts: 251

Likes: 0

Received 0 Likes

on

0 Posts

Found My Source of Hissing noise. It's coming from my EVAP canister breather or whatever it's for going to the side of the fuel filter. Now I need to find out why my EVAP Purge valve is open during warm-up. I disconnected the connector to the evap purge valve and noise went away and engine stumbled as IAC compensated.

#18

I just installed the skunk2 intake manifold and the 70mm tb on my z6 coupe and I am having another sort of problem...not sure if it's related...but the butterfly plate seems to be sticking open allowing a little to much air in confusing my IACV and causing an idle hunt between 900 and 1200. When I start the car up it idles perfect at 750...than once I give it throttle the idle goes up to about 1200 than comes down to 900 slowly than starts to idle hunt. I know it's not another issue because I can fix it when it starts surging by pushing down the throttle linkage closing off the butterfly. Anyone have any remedies or experiences to fix the sticking? If not I feel like I'm going to end up parting ways with the skunk2 and getting an Omni power tb for like 100 bucks. It's a shame...I had high hopes for the skunk2...but this surge is embarrassing :/

#19

There are only a couple of things to focus on when fixing this problem.

1. You know it CAN close because you can close it by hand.

2. It is NOT closing presently.

3. Your throttle cable may be too tight. Loosen the throttle cable adjustment screws and adjust it so that it can close completely when releasing the throttle.

4. If 3 doesn't work, then your throttle cable may be offering too much resistance for the throttle return spring. - if so, replace throttle cable (not likely the problem imo).

5. Check these and get back to us.

All the best!

1. You know it CAN close because you can close it by hand.

2. It is NOT closing presently.

3. Your throttle cable may be too tight. Loosen the throttle cable adjustment screws and adjust it so that it can close completely when releasing the throttle.

4. If 3 doesn't work, then your throttle cable may be offering too much resistance for the throttle return spring. - if so, replace throttle cable (not likely the problem imo).

5. Check these and get back to us.

All the best!

I just installed the skunk2 intake manifold and the 70mm tb on my z6 coupe and I am having another sort of problem...not sure if it's related...but the butterfly plate seems to be sticking open allowing a little to much air in confusing my IACV and causing an idle hunt between 900 and 1200. When I start the car up it idles perfect at 750...than once I give it throttle the idle goes up to about 1200 than comes down to 900 slowly than starts to idle hunt. I know it's not another issue because I can fix it when it starts surging by pushing down the throttle linkage closing off the butterfly. Anyone have any remedies or experiences to fix the sticking? If not I feel like I'm going to end up parting ways with the skunk2 and getting an Omni power tb for like 100 bucks. It's a shame...I had high hopes for the skunk2...but this surge is embarrassing :/

#20

Well...to check if the throttle cable was the problem I just disconnected it all together and started the car...It idled fine warming up and eventually came down to around 750 and chilled. Gave it a little throttle and the idle increased to 1100...than sat there...once I kicked the air on and headlights to give the engine a load to decrease the idle...it dropped to 900 and started hunting between around 900 and 1200 again. I ordered the custom skunk2 gasket for the t.b. and when I did my motor swap all new gaskets/vaccum hoses were used. Heres thing's I have done:

1)Calibrated the tps to .499 and checked for dead spots (as I was opening and closing the skunk2 tb to calibrate it, I noticed the values of the tps would change as I closed the butterfly...sometimes it would be .499 sometimes .508...sometimes .503) Not sure if it will make a huge diff...but ECU's can be picky...almost seemed as if the butterfly was sticking in random spots throwing off the voltage.

2) I voltage tested all the power wires of sensors I believed could cause this (IACV, TPS, IAT) and all were getting proper voltage according to helm's. Only one I haven't checked is a bad map sensor...maybe causing an air/fuel imbalance?

3)I've replaced the IACV like 3 or 4 times with used ones I had after cleaning them out...

4) I've noticed if I turn out the idle mixture screw to set the idle at about 1200 it Idle's fine...no problems at all...even putting electrical loads on it...it will stay the same without surging. But I don't like to dick with the screw to rig something to work. It just seems anytime the idle drops to 900 it will hunt...the idle is also fine if it just sits at 750 after the car warms up as long as I don't give it throttle.

5) There's no fitv as the skunk2 has no place for it

The car is a boosted z6 chipped on a chipped CROME ecu...my buddy did my tune before my z6 swap and all the skunk2 stuff...so maybe it could be a tuning issue with the air/fuel? I've read that you can disable the IACV using crome...

Sorry to be long-winded...but I hate when there's little **** wrong...but I guess you can't be a perfectionist in the tuner world. Thanks for anyone's help. If anyone has similar problems...let me know...maybe we can get through this.

critical...thanks for the response...any thoughts?

1)Calibrated the tps to .499 and checked for dead spots (as I was opening and closing the skunk2 tb to calibrate it, I noticed the values of the tps would change as I closed the butterfly...sometimes it would be .499 sometimes .508...sometimes .503) Not sure if it will make a huge diff...but ECU's can be picky...almost seemed as if the butterfly was sticking in random spots throwing off the voltage.

2) I voltage tested all the power wires of sensors I believed could cause this (IACV, TPS, IAT) and all were getting proper voltage according to helm's. Only one I haven't checked is a bad map sensor...maybe causing an air/fuel imbalance?

3)I've replaced the IACV like 3 or 4 times with used ones I had after cleaning them out...

4) I've noticed if I turn out the idle mixture screw to set the idle at about 1200 it Idle's fine...no problems at all...even putting electrical loads on it...it will stay the same without surging. But I don't like to dick with the screw to rig something to work. It just seems anytime the idle drops to 900 it will hunt...the idle is also fine if it just sits at 750 after the car warms up as long as I don't give it throttle.

5) There's no fitv as the skunk2 has no place for it

The car is a boosted z6 chipped on a chipped CROME ecu...my buddy did my tune before my z6 swap and all the skunk2 stuff...so maybe it could be a tuning issue with the air/fuel? I've read that you can disable the IACV using crome...

Sorry to be long-winded...but I hate when there's little **** wrong...but I guess you can't be a perfectionist in the tuner world. Thanks for anyone's help. If anyone has similar problems...let me know...maybe we can get through this.

critical...thanks for the response...any thoughts?

#21

Honda-Tech Member

Join Date: Nov 2007

Location: PA, U.S.A.

Posts: 78

Likes: 0

Received 0 Likes

on

0 Posts

Wish I would have seen this thread before I got my 70mm skunk2 tbody. Think I would have went with a diffrent tbody.....Can't get my car to idle worth a crap unless I adjust the throttle plate stop screw.

#22

Honda-Tech Member

iTrader: (1)

Join Date: Apr 2004

Location: Burnout Box, IA, U.S.A.

Posts: 2,876

Likes: 0

Received 0 Likes

on

0 Posts

The majority of throttle bodies out there are going to be exactly the same with little adjustment and in alot of cases no idle screw, its just the nature of the beast when you move away from stock parts. Theres sooo many factors that figure into idle besides the throttle body... cam profiles, overlap, ignition timing, afr etc that I dont think its fair to say theres a design issue.

I've ran the S2 70mm in the past on an allmotor setup with no iacv and the car idled great, from 90* weather clear down to -20*, the majority of that was accomplished in the tuning and not the position of the throttle blade. When I did need more air I would adjust the throttle stop, you dont want to get that set too low however because then you will have sticking problems. I'm currently running the same throttle body on my daily driver, this time with an iacv and its working very well, never been a problem.

I'm not completely sure what you were trying to accomplish, but the way I would set it up is like this... Use the stop screw to set idle with the iacv unplugged 2-300 rpms lower than your target idle, then set the computer up to hit your target idle, plug the iacv and let it do the rest. If you are trying to get your car to idle down at 450 rpm I dont think thats going to happen, I would set the throttle body up to idle closer to your target on its own, and let the iacv do only minor adjustments rather than most of the work. If you adjust the stop screw make sure to reset your tps min/max settings so that it reads 100 percent when fully open. If your cable doesnt have enough travel to get to 100 percent then thats another issue.

Hunting idle is normally caused by a lean to rich condition near the target idle rpm and is usually blamed on the iacv when its really a tuning issue. If a cell on the fuel map is leaner than it should be the rpm is naturally going to creep upward, if the cell next to it is richer than it should be its going to slow it down. Therefore if the car is at 800rpms idling a bit too lean in one cell and the rpm climbs enough to move to the next cell (which is on the rich side) the rich mixture will slow the rpm down and kick it back over into the leaner cell and it will sit there and bounce back and forth between the cells and the motor will rev up and down causing the "hunting idle". If you can watch this in real time with your tuning software its pretty easy to see and track down the cell that needs more fuel.

If you need help with anything feel free to email or PM me and I will help you out as best as I can.

-Shawn

I've ran the S2 70mm in the past on an allmotor setup with no iacv and the car idled great, from 90* weather clear down to -20*, the majority of that was accomplished in the tuning and not the position of the throttle blade. When I did need more air I would adjust the throttle stop, you dont want to get that set too low however because then you will have sticking problems. I'm currently running the same throttle body on my daily driver, this time with an iacv and its working very well, never been a problem.

I'm not completely sure what you were trying to accomplish, but the way I would set it up is like this... Use the stop screw to set idle with the iacv unplugged 2-300 rpms lower than your target idle, then set the computer up to hit your target idle, plug the iacv and let it do the rest. If you are trying to get your car to idle down at 450 rpm I dont think thats going to happen, I would set the throttle body up to idle closer to your target on its own, and let the iacv do only minor adjustments rather than most of the work. If you adjust the stop screw make sure to reset your tps min/max settings so that it reads 100 percent when fully open. If your cable doesnt have enough travel to get to 100 percent then thats another issue.

Hunting idle is normally caused by a lean to rich condition near the target idle rpm and is usually blamed on the iacv when its really a tuning issue. If a cell on the fuel map is leaner than it should be the rpm is naturally going to creep upward, if the cell next to it is richer than it should be its going to slow it down. Therefore if the car is at 800rpms idling a bit too lean in one cell and the rpm climbs enough to move to the next cell (which is on the rich side) the rich mixture will slow the rpm down and kick it back over into the leaner cell and it will sit there and bounce back and forth between the cells and the motor will rev up and down causing the "hunting idle". If you can watch this in real time with your tuning software its pretty easy to see and track down the cell that needs more fuel.

If you need help with anything feel free to email or PM me and I will help you out as best as I can.

-Shawn

#24

I can see how the quoted is "OK" advice for someone that is able to get their car to idle at all. If you read through my original post, you'll note that the car would not idle at all. This thread was never about hunting idles. It was about Skunk2's throttle body that will not allow for enough air through the idle screw orifice to enable the engine to run. In my case, my motor is fully built with 95mm stroke and 84mm bore which means that it is going to want substantially more air to idle (and fuel) than one that has not been bored and stroked to that extent. I concur that relying on the idle air control valve to regulate the idle is a bad idea; however, adjusting the throttle plate is just a bandaid to an engineered problem in this case. There is no tuning that will regulate an idle without a minimal amount of oxygen. So, to tune the problem away is impossible without getting that air past the throttle plate. Additionally, setting the idle is not possible if the IAC is unplugged and the throttle plate is shut all the way (as it should be) when the Idle screw orifice is so small that it will only allow up to 75 rpms worth of air through it (Skunk2's word). The engine will not run. It will die upon closing the throttle plate.

If you want to install a throttle body properly then the following should be true:

1. The throttle plate should be closed all the way. No water, or air should make it past the throttle plate when closed. (I say water, because this is a good way to test it when the part is not yet installed).

2. The idle needs to be set in accordance with the way that the engine was designed to run. The procedure for doing this is the same as is recommended in the OEM manual or if you are using the Hondata S300, the instructions listed above are accurate too. In other words, ignition timing should be set correctly, IACV disconnected, and throttle completely closed.

3. (this is where the Skunk2 fails). The Idle screw should then be adjusted to bring the idle to the desired point. Some motors like it a bit high some lower. Bigger displacement will usually like it a bit higher. Mine sits between 850-900rpms and is smooth.

4. In order to set the idle, the car must run on its own and have no vacuum leaks aside from the small one created by the idle screw which you will be adjusting. You can do whatever you want to timing, air, and fuel in the tuning settings but without the minimal amount of oxygen the car will not run.

Using the throttle plate screw to set the idle is a bad idea for a number of reasons:

1. Aluminum expands and contracts when fluctuating in temperature. On colder days, the idle will be lower than on warmer days (which is partly to blame for why the car does not idle well in the cold - there is less clearance for air to make it around the throttle plate.

2. It's rather difficult with big bore throttle bodies to adjust that screw just right and then lock it down with the nut. It's a pain really. Once you get it set, you go to tighten the nut and... crap, the nut turned the set screw a bit and now the idle is off. Start over. Remember when dealing with surface area and circles, the larger the radius of a circle the area increases by an exponent of 2, remember 3.14 x r^2 = area. So the larger the bore of a throttle body, the more sensitive the idle will be to the throttle plate adjustment. Which also means, that the idle fluctuation delta will be greater with temperature change.

3. Once you've moved your throttle plate closed position, you have to recalibrate your TPS. This is just one more step that is not necessary. Sure, with Hondata and some other engine management systems, you can just compensate for it in tune, but once again. That's one more thing you have to do and then you have to remember that you did that in the event you'll need to make future tune adjustments.

The secret here is: do it right the first time and you won't have to deal with all the hassle of creating another way to get it done that is actually more work.

If Skunk2 had designed these correctly, the idle would be easy to set. Because they didn't, they passed it on to those who own their throttle body to find a way around their poor design.

Anything worth doing, is worth doing correctly and if that means doing a workaround... do the best one you can. The needle valve is a constant and stable way to set your idle when using the Skunk 2 throttlebody for three reasons:

1. It is not subject to contraction and expansion the way that a large aluminum throttle body is.

2. It does not require a recalibration of the TPS sensor or an adjustment to the tune.

3. It allows for extremely accurate idle rpm tuning - as good as or better than the screw.

If you want to install a throttle body properly then the following should be true:

1. The throttle plate should be closed all the way. No water, or air should make it past the throttle plate when closed. (I say water, because this is a good way to test it when the part is not yet installed).

2. The idle needs to be set in accordance with the way that the engine was designed to run. The procedure for doing this is the same as is recommended in the OEM manual or if you are using the Hondata S300, the instructions listed above are accurate too. In other words, ignition timing should be set correctly, IACV disconnected, and throttle completely closed.

3. (this is where the Skunk2 fails). The Idle screw should then be adjusted to bring the idle to the desired point. Some motors like it a bit high some lower. Bigger displacement will usually like it a bit higher. Mine sits between 850-900rpms and is smooth.

4. In order to set the idle, the car must run on its own and have no vacuum leaks aside from the small one created by the idle screw which you will be adjusting. You can do whatever you want to timing, air, and fuel in the tuning settings but without the minimal amount of oxygen the car will not run.

Using the throttle plate screw to set the idle is a bad idea for a number of reasons:

1. Aluminum expands and contracts when fluctuating in temperature. On colder days, the idle will be lower than on warmer days (which is partly to blame for why the car does not idle well in the cold - there is less clearance for air to make it around the throttle plate.

2. It's rather difficult with big bore throttle bodies to adjust that screw just right and then lock it down with the nut. It's a pain really. Once you get it set, you go to tighten the nut and... crap, the nut turned the set screw a bit and now the idle is off. Start over. Remember when dealing with surface area and circles, the larger the radius of a circle the area increases by an exponent of 2, remember 3.14 x r^2 = area. So the larger the bore of a throttle body, the more sensitive the idle will be to the throttle plate adjustment. Which also means, that the idle fluctuation delta will be greater with temperature change.

3. Once you've moved your throttle plate closed position, you have to recalibrate your TPS. This is just one more step that is not necessary. Sure, with Hondata and some other engine management systems, you can just compensate for it in tune, but once again. That's one more thing you have to do and then you have to remember that you did that in the event you'll need to make future tune adjustments.

The secret here is: do it right the first time and you won't have to deal with all the hassle of creating another way to get it done that is actually more work.

If Skunk2 had designed these correctly, the idle would be easy to set. Because they didn't, they passed it on to those who own their throttle body to find a way around their poor design.

Anything worth doing, is worth doing correctly and if that means doing a workaround... do the best one you can. The needle valve is a constant and stable way to set your idle when using the Skunk 2 throttlebody for three reasons:

1. It is not subject to contraction and expansion the way that a large aluminum throttle body is.

2. It does not require a recalibration of the TPS sensor or an adjustment to the tune.

3. It allows for extremely accurate idle rpm tuning - as good as or better than the screw.

The majority of throttle bodies out there are going to be exactly the same with little adjustment and in alot of cases no idle screw, its just the nature of the beast when you move away from stock parts. Theres sooo many factors that figure into idle besides the throttle body... cam profiles, overlap, ignition timing, afr etc that I dont think its fair to say theres a design issue.

I've ran the S2 70mm in the past on an allmotor setup with no iacv and the car idled great, from 90* weather clear down to -20*, the majority of that was accomplished in the tuning and not the position of the throttle blade. When I did need more air I would adjust the throttle stop, you dont want to get that set too low however because then you will have sticking problems. I'm currently running the same throttle body on my daily driver, this time with an iacv and its working very well, never been a problem.

I'm not completely sure what you were trying to accomplish, but the way I would set it up is like this... Use the stop screw to set idle with the iacv unplugged 2-300 rpms lower than your target idle, then set the computer up to hit your target idle, plug the iacv and let it do the rest. If you are trying to get your car to idle down at 450 rpm I dont think thats going to happen, I would set the throttle body up to idle closer to your target on its own, and let the iacv do only minor adjustments rather than most of the work. If you adjust the stop screw make sure to reset your tps min/max settings so that it reads 100 percent when fully open. If your cable doesnt have enough travel to get to 100 percent then thats another issue.

Hunting idle is normally caused by a lean to rich condition near the target idle rpm and is usually blamed on the iacv when its really a tuning issue. If a cell on the fuel map is leaner than it should be the rpm is naturally going to creep upward, if the cell next to it is richer than it should be its going to slow it down. Therefore if the car is at 800rpms idling a bit too lean in one cell and the rpm climbs enough to move to the next cell (which is on the rich side) the rich mixture will slow the rpm down and kick it back over into the leaner cell and it will sit there and bounce back and forth between the cells and the motor will rev up and down causing the "hunting idle". If you can watch this in real time with your tuning software its pretty easy to see and track down the cell that needs more fuel.

If you need help with anything feel free to email or PM me and I will help you out as best as I can.

-Shawn

I've ran the S2 70mm in the past on an allmotor setup with no iacv and the car idled great, from 90* weather clear down to -20*, the majority of that was accomplished in the tuning and not the position of the throttle blade. When I did need more air I would adjust the throttle stop, you dont want to get that set too low however because then you will have sticking problems. I'm currently running the same throttle body on my daily driver, this time with an iacv and its working very well, never been a problem.

I'm not completely sure what you were trying to accomplish, but the way I would set it up is like this... Use the stop screw to set idle with the iacv unplugged 2-300 rpms lower than your target idle, then set the computer up to hit your target idle, plug the iacv and let it do the rest. If you are trying to get your car to idle down at 450 rpm I dont think thats going to happen, I would set the throttle body up to idle closer to your target on its own, and let the iacv do only minor adjustments rather than most of the work. If you adjust the stop screw make sure to reset your tps min/max settings so that it reads 100 percent when fully open. If your cable doesnt have enough travel to get to 100 percent then thats another issue.

Hunting idle is normally caused by a lean to rich condition near the target idle rpm and is usually blamed on the iacv when its really a tuning issue. If a cell on the fuel map is leaner than it should be the rpm is naturally going to creep upward, if the cell next to it is richer than it should be its going to slow it down. Therefore if the car is at 800rpms idling a bit too lean in one cell and the rpm climbs enough to move to the next cell (which is on the rich side) the rich mixture will slow the rpm down and kick it back over into the leaner cell and it will sit there and bounce back and forth between the cells and the motor will rev up and down causing the "hunting idle". If you can watch this in real time with your tuning software its pretty easy to see and track down the cell that needs more fuel.

If you need help with anything feel free to email or PM me and I will help you out as best as I can.

-Shawn