My beginner's progression into welding/fabrication

#1

-Intl Steve Krew

Thread Starter

<p>Hi guys. I know this subsection doesn't get much traffic anymore, but I just started my foray into welding/fabrication and wanted to start a little progress thread. </p><p>A little backstory on me. I'm now 30 years old, and finally figuring out what I want to do with my life. Some of us know from 4 years old what they want to do. Some of us never figure it out. Some of us figure it out late. I'm one of those people. In high school I was in a program which touched on architecture, computer electronics (building a robot) welding, CAD, etc. I learned how to sketch and do orthographic projections, 2 point perspectives etc. It was one thing that really stuck with me. I tried to get into the architecture/engineering field, but back when I first graduated high school, the lure of money, a full time job, and working on cars was more important to me. </p><p>I've flirted with welding for a couple of years now. My first experience was on a Harbor Freight mig special, back when I had a Jeep Wrangler. It had a busted tailgate, and my buddy said he knew how to weld. I tried it out, and pretty much just globbed metal onto the torn sheetmetal. Literally tack weld after talk weld. I thought it was awesome. A couple years later (last August) I decided I needed to go back to school, and that I'd give welding a try. I started the introductory class at my local junior college, which was Arc and Gas welding. 2 months into that, I found out I would be laid off at the end of the year (Dec 31st 2014) I did some research prior to the layoff and discovered I could go to the local Trade School (Cal-Trade Welding School) and get it partially paid for by the county once I got laid off, get as many certifications that I could, and then go find a job in the 'field.' I passed the intro class with an A. I learned how to stick weld flat, horizontal, vertical, and overhead. </p><p>The first day. No, those welds on the bottom are not mine. That splatter? That was me, learning how to strike an arc. </p><p> </p><p>First successful bead I ever made. </p><p>

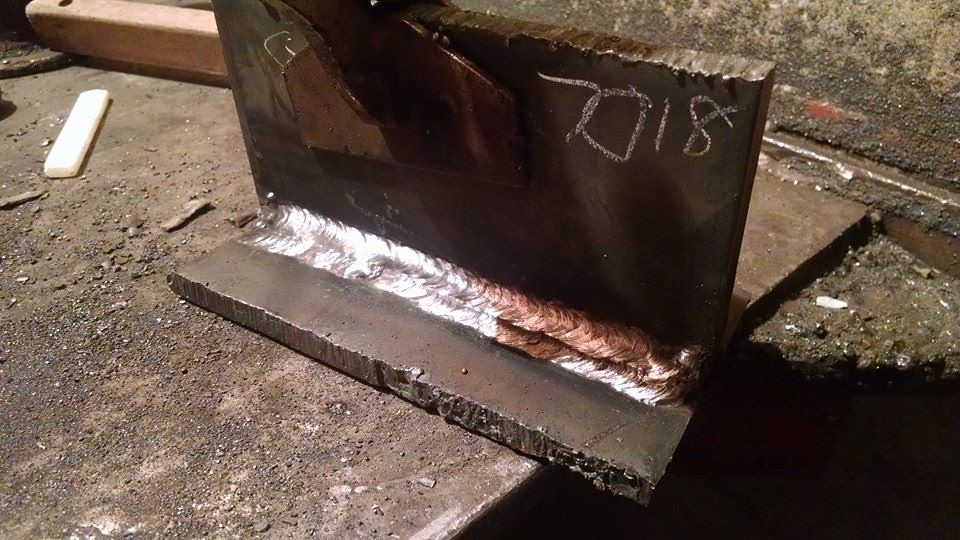

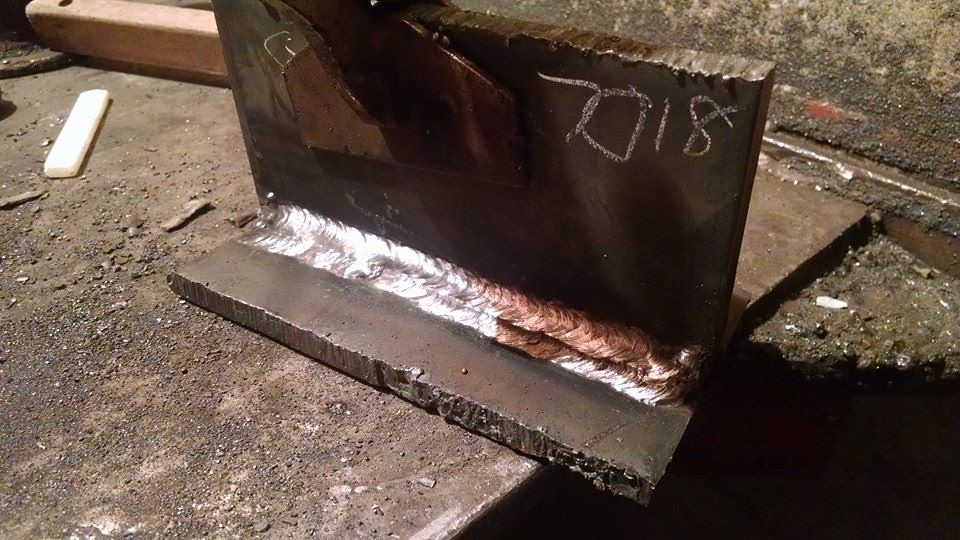

</p><p>First successful bead I ever made. </p><p> </p><p>Progression- Horizontal 7018 multipass:</p><p>

</p><p>Progression- Horizontal 7018 multipass:</p><p> </p><p>Something vertical, most likely 6010. I preferred 6010 over 6011. (We focused on 6010/11 and 7018 in the class, as well as learning how to use a gas torch to cut and weld)</p><p>

</p><p>Something vertical, most likely 6010. I preferred 6010 over 6011. (We focused on 6010/11 and 7018 in the class, as well as learning how to use a gas torch to cut and weld)</p><p> </p><p>The last weld I did for that semester..overhead 6011 iirc</p><p>

</p><p>The last weld I did for that semester..overhead 6011 iirc</p><p> </p><p> </p><p>(Keep in mind, these classes are 16 weeks long, 1 night a week, 3 hours a night of welding, so it's really only 48 hours of experience...I'm not expecting people to be like OOH #WELDPORN!!) </p><p> </p><p>That first plan didn't work out. My company kept me on passed the layoff date. I fast forward 3 more 'pending layoff' notices, and I've wasted one semester at the local JC sitting out waiting to get laid off, so I could go to the school. Back in May I decided this job is not going to hold me back any longer, one way or another I was becoming a welder/fabricator. </p><p> </p><p>Spending the current year still working has been a double edged sword. On one side I've been able to keep working, and it has given me time to figure out what I want to do. I want to be certified (mostly in GTAW) and I want to finish the welding program at the JC and end up with my AS degree. From there I don't know. I'm planning on working for a few years in the field, and then move into the fabrication side of things, be it engineering or something of the sort. Maybe inspecting welds? Maybe running a fabrication shop. I have found that the opportunities are plenty, and I will always be able to find something within the field to do. On the other side of the sword, I just wish I could be laid off so I can go to school full time and kick butt and get into the field faster. "If wishes were wings, pigs would fly" is the saying that comes to mind...</p><p> </p><p>May 2015 I started the GMAW/FCAW class. I found out about half way through the class that the JC offered certification in 1/16" dualshield and innershield? I can't remember right now. I was tempted to take the dualshield cert test, I was able to run a 'decent' 3g groove weld on a 1/2" plate. I didn't know what I could do with 1 certification though, and thought it'd be a better idea not to rush it and waste the money on the test if I couldn't find a job before the certification expired. I ended up passing this class with an A as well, and the instructor said that unless I completely bomb the final, there was no way that grade was changing. After taking this class I'm pretty confident that with enough wire and gas and voltage I can GMAW/FCAW pretty much anything. So far I've welded an axleback exhaust together for my brother, started on a compost bin (was supposed to be a bbq but I found out I need to get it the barrel sandblasted first) that is being made out of a barrel, and helped do some welding to setup a Dana 60 on a Jeep CJ5. I've taught people who 'knew how to weld' (who's knowledge consist of watching youtube videos) a few tricks...so these 'useless classes' must have been good for something!</p><p> </p><p>

</p><p> </p><p>(Keep in mind, these classes are 16 weeks long, 1 night a week, 3 hours a night of welding, so it's really only 48 hours of experience...I'm not expecting people to be like OOH #WELDPORN!!) </p><p> </p><p>That first plan didn't work out. My company kept me on passed the layoff date. I fast forward 3 more 'pending layoff' notices, and I've wasted one semester at the local JC sitting out waiting to get laid off, so I could go to the school. Back in May I decided this job is not going to hold me back any longer, one way or another I was becoming a welder/fabricator. </p><p> </p><p>Spending the current year still working has been a double edged sword. On one side I've been able to keep working, and it has given me time to figure out what I want to do. I want to be certified (mostly in GTAW) and I want to finish the welding program at the JC and end up with my AS degree. From there I don't know. I'm planning on working for a few years in the field, and then move into the fabrication side of things, be it engineering or something of the sort. Maybe inspecting welds? Maybe running a fabrication shop. I have found that the opportunities are plenty, and I will always be able to find something within the field to do. On the other side of the sword, I just wish I could be laid off so I can go to school full time and kick butt and get into the field faster. "If wishes were wings, pigs would fly" is the saying that comes to mind...</p><p> </p><p>May 2015 I started the GMAW/FCAW class. I found out about half way through the class that the JC offered certification in 1/16" dualshield and innershield? I can't remember right now. I was tempted to take the dualshield cert test, I was able to run a 'decent' 3g groove weld on a 1/2" plate. I didn't know what I could do with 1 certification though, and thought it'd be a better idea not to rush it and waste the money on the test if I couldn't find a job before the certification expired. I ended up passing this class with an A as well, and the instructor said that unless I completely bomb the final, there was no way that grade was changing. After taking this class I'm pretty confident that with enough wire and gas and voltage I can GMAW/FCAW pretty much anything. So far I've welded an axleback exhaust together for my brother, started on a compost bin (was supposed to be a bbq but I found out I need to get it the barrel sandblasted first) that is being made out of a barrel, and helped do some welding to setup a Dana 60 on a Jeep CJ5. I've taught people who 'knew how to weld' (who's knowledge consist of watching youtube videos) a few tricks...so these 'useless classes' must have been good for something!</p><p> </p><p> </p><p>

</p><p> </p><p>

</p><p> </p><p>And now for my current classes. I'm taking the GTAW class, and a blueprint design/fabrication class. </p><p>In the GTAW class, I have learned that it has a very steep learning curve. When I took the GMAW/FCAW class, it felt like I was a veteran returning to my grounds, I walked in, kicked butt, and had fun in that class. TIG welding is like I'm a noob welder once again (not that i'm more than a toddler in this welding life) Some similarities to Oxy-Acetylene welding, but there are many differences too.</p><p>I have been frustrated today. First, keeping that tungsten sharp, and from getting contaminated. This seems like the major key to GTAW. Second, clean metal. If the one thing you do is forget to clean your metal, you're not going to have a good time. I've knocked myself down a few notches...my head has been deflated a bit. But I know I'll master this skill. It will just take some time. The TIG gloves I have are horrible, I'm going to get some new ones. These were some Tillman Deerskin gloves. All the little furries like to touch my tungsten. And get on the metal. And get all over my clothes, and generally just like to ruin my day. These are going to be some backup gloves now. I'll order some pigskin leathers that don't have this problem.. </p><p>I need to definitely learn how to handle the torch. I think it needs to be different than I'm used to. A MIG gun or a stick gun are very similar in the way you hold it. The TIG torch needs a different 'flair.' That and learning to dip in the filler rod, the rhythm I need to get down, the amperage control. We use foot pedals. It's not too hard to use them, Just like a gas pedal it seems like. The first time is always quick, you're done before you realize it, you didn't do much, and you're worried that she's not impressed. Wait, are we still talking about TIG welding? <img alt="" src="https://honda-tech.com/forums/images/smilies/emsmilep.gif" title="Tongue" /></p><p> </p><p>Onto the blueprint/fabrication class. </p><p>Last Wednesday I started that. We learned how to measure to 1/16"! (Elementary stuff, right?) yet some people don't actually know how to do this. Fortunately I already do..but yeah. That was lesson 1. </p><p>Secondly we learned how to do orthographic projections. Again, I already knew how to do this...but this is something a lot of people don't know how to do. We had to draw a U shaped block to scale, front/top/side views, and write in the dimensions. It felt good to get back on a drafting table, measure out those lines, get everything 'just right'. The class will be heavy in these drawings. Also Isometric and Oblique sketches. Again, I know these, but it's always nice to do something you like, right? </p><p>I have do come blueprint and build a project of my own design, that's the final for this class. I'm not sure what I want to do. There are so many things that I have dreamed up already, I swear it's like I have ADHD when it comes to design. Something as simple as a porch rail, to as elaborate as an outdoor kitchen counter structure. In between that I have a fire pit idea, and a 'cart' for my Weber bbq. A pie cut exhaust for my civic. An outdoor patio table. The list goes on and on! As the class progresses I'll narrow it down to what I want to build. We have to buy our own metal, so that is a factor. Storage will also be a factor, I don't know if we have to take these projects home after each class session, so that may limit my designs to what I can fit in my car.</p><p>I'll stop rambling now, I've written enough for one night. I'll update y'all after my next class. </p><p> </p><p> </p>

</p><p>And now for my current classes. I'm taking the GTAW class, and a blueprint design/fabrication class. </p><p>In the GTAW class, I have learned that it has a very steep learning curve. When I took the GMAW/FCAW class, it felt like I was a veteran returning to my grounds, I walked in, kicked butt, and had fun in that class. TIG welding is like I'm a noob welder once again (not that i'm more than a toddler in this welding life) Some similarities to Oxy-Acetylene welding, but there are many differences too.</p><p>I have been frustrated today. First, keeping that tungsten sharp, and from getting contaminated. This seems like the major key to GTAW. Second, clean metal. If the one thing you do is forget to clean your metal, you're not going to have a good time. I've knocked myself down a few notches...my head has been deflated a bit. But I know I'll master this skill. It will just take some time. The TIG gloves I have are horrible, I'm going to get some new ones. These were some Tillman Deerskin gloves. All the little furries like to touch my tungsten. And get on the metal. And get all over my clothes, and generally just like to ruin my day. These are going to be some backup gloves now. I'll order some pigskin leathers that don't have this problem.. </p><p>I need to definitely learn how to handle the torch. I think it needs to be different than I'm used to. A MIG gun or a stick gun are very similar in the way you hold it. The TIG torch needs a different 'flair.' That and learning to dip in the filler rod, the rhythm I need to get down, the amperage control. We use foot pedals. It's not too hard to use them, Just like a gas pedal it seems like. The first time is always quick, you're done before you realize it, you didn't do much, and you're worried that she's not impressed. Wait, are we still talking about TIG welding? <img alt="" src="https://honda-tech.com/forums/images/smilies/emsmilep.gif" title="Tongue" /></p><p> </p><p>Onto the blueprint/fabrication class. </p><p>Last Wednesday I started that. We learned how to measure to 1/16"! (Elementary stuff, right?) yet some people don't actually know how to do this. Fortunately I already do..but yeah. That was lesson 1. </p><p>Secondly we learned how to do orthographic projections. Again, I already knew how to do this...but this is something a lot of people don't know how to do. We had to draw a U shaped block to scale, front/top/side views, and write in the dimensions. It felt good to get back on a drafting table, measure out those lines, get everything 'just right'. The class will be heavy in these drawings. Also Isometric and Oblique sketches. Again, I know these, but it's always nice to do something you like, right? </p><p>I have do come blueprint and build a project of my own design, that's the final for this class. I'm not sure what I want to do. There are so many things that I have dreamed up already, I swear it's like I have ADHD when it comes to design. Something as simple as a porch rail, to as elaborate as an outdoor kitchen counter structure. In between that I have a fire pit idea, and a 'cart' for my Weber bbq. A pie cut exhaust for my civic. An outdoor patio table. The list goes on and on! As the class progresses I'll narrow it down to what I want to build. We have to buy our own metal, so that is a factor. Storage will also be a factor, I don't know if we have to take these projects home after each class session, so that may limit my designs to what I can fit in my car.</p><p>I'll stop rambling now, I've written enough for one night. I'll update y'all after my next class. </p><p> </p><p> </p>

</p><p>First successful bead I ever made. </p><p>

</p><p>First successful bead I ever made. </p><p> </p><p>Progression- Horizontal 7018 multipass:</p><p>

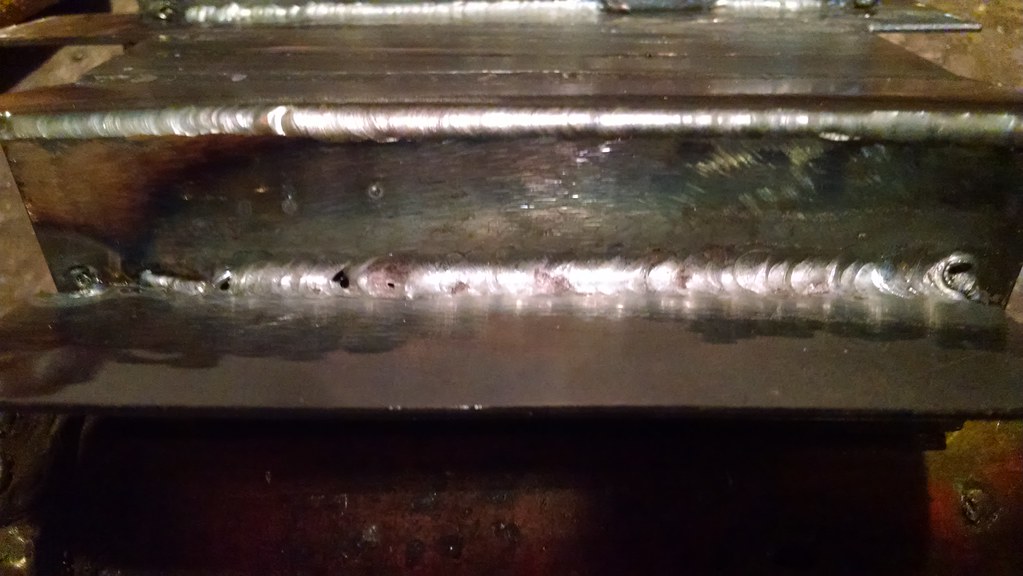

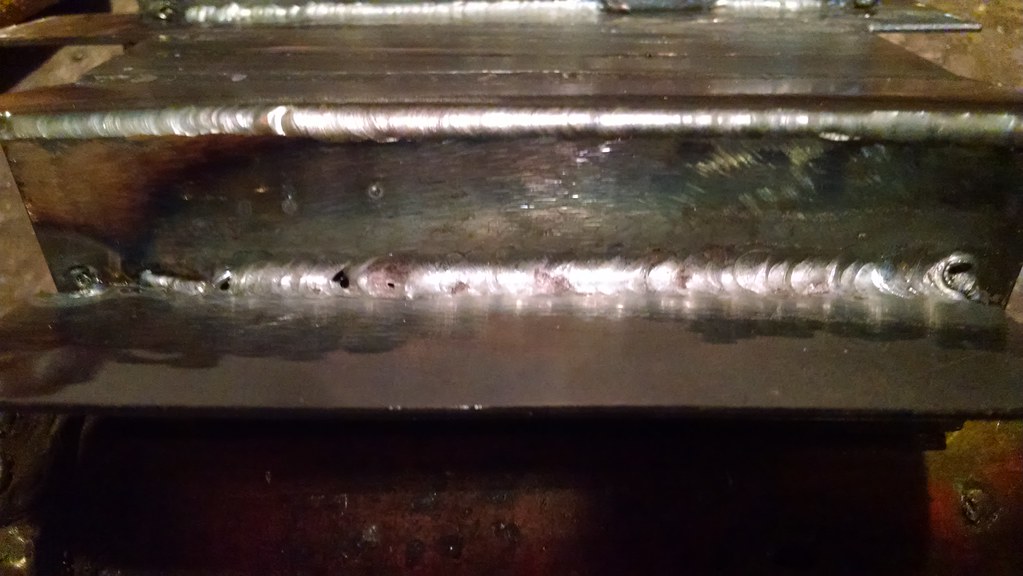

</p><p>Progression- Horizontal 7018 multipass:</p><p> </p><p>Something vertical, most likely 6010. I preferred 6010 over 6011. (We focused on 6010/11 and 7018 in the class, as well as learning how to use a gas torch to cut and weld)</p><p>

</p><p>Something vertical, most likely 6010. I preferred 6010 over 6011. (We focused on 6010/11 and 7018 in the class, as well as learning how to use a gas torch to cut and weld)</p><p> </p><p>The last weld I did for that semester..overhead 6011 iirc</p><p>

</p><p>The last weld I did for that semester..overhead 6011 iirc</p><p> </p><p> </p><p>(Keep in mind, these classes are 16 weeks long, 1 night a week, 3 hours a night of welding, so it's really only 48 hours of experience...I'm not expecting people to be like OOH #WELDPORN!!) </p><p> </p><p>That first plan didn't work out. My company kept me on passed the layoff date. I fast forward 3 more 'pending layoff' notices, and I've wasted one semester at the local JC sitting out waiting to get laid off, so I could go to the school. Back in May I decided this job is not going to hold me back any longer, one way or another I was becoming a welder/fabricator. </p><p> </p><p>Spending the current year still working has been a double edged sword. On one side I've been able to keep working, and it has given me time to figure out what I want to do. I want to be certified (mostly in GTAW) and I want to finish the welding program at the JC and end up with my AS degree. From there I don't know. I'm planning on working for a few years in the field, and then move into the fabrication side of things, be it engineering or something of the sort. Maybe inspecting welds? Maybe running a fabrication shop. I have found that the opportunities are plenty, and I will always be able to find something within the field to do. On the other side of the sword, I just wish I could be laid off so I can go to school full time and kick butt and get into the field faster. "If wishes were wings, pigs would fly" is the saying that comes to mind...</p><p> </p><p>May 2015 I started the GMAW/FCAW class. I found out about half way through the class that the JC offered certification in 1/16" dualshield and innershield? I can't remember right now. I was tempted to take the dualshield cert test, I was able to run a 'decent' 3g groove weld on a 1/2" plate. I didn't know what I could do with 1 certification though, and thought it'd be a better idea not to rush it and waste the money on the test if I couldn't find a job before the certification expired. I ended up passing this class with an A as well, and the instructor said that unless I completely bomb the final, there was no way that grade was changing. After taking this class I'm pretty confident that with enough wire and gas and voltage I can GMAW/FCAW pretty much anything. So far I've welded an axleback exhaust together for my brother, started on a compost bin (was supposed to be a bbq but I found out I need to get it the barrel sandblasted first) that is being made out of a barrel, and helped do some welding to setup a Dana 60 on a Jeep CJ5. I've taught people who 'knew how to weld' (who's knowledge consist of watching youtube videos) a few tricks...so these 'useless classes' must have been good for something!</p><p> </p><p>

</p><p> </p><p>(Keep in mind, these classes are 16 weeks long, 1 night a week, 3 hours a night of welding, so it's really only 48 hours of experience...I'm not expecting people to be like OOH #WELDPORN!!) </p><p> </p><p>That first plan didn't work out. My company kept me on passed the layoff date. I fast forward 3 more 'pending layoff' notices, and I've wasted one semester at the local JC sitting out waiting to get laid off, so I could go to the school. Back in May I decided this job is not going to hold me back any longer, one way or another I was becoming a welder/fabricator. </p><p> </p><p>Spending the current year still working has been a double edged sword. On one side I've been able to keep working, and it has given me time to figure out what I want to do. I want to be certified (mostly in GTAW) and I want to finish the welding program at the JC and end up with my AS degree. From there I don't know. I'm planning on working for a few years in the field, and then move into the fabrication side of things, be it engineering or something of the sort. Maybe inspecting welds? Maybe running a fabrication shop. I have found that the opportunities are plenty, and I will always be able to find something within the field to do. On the other side of the sword, I just wish I could be laid off so I can go to school full time and kick butt and get into the field faster. "If wishes were wings, pigs would fly" is the saying that comes to mind...</p><p> </p><p>May 2015 I started the GMAW/FCAW class. I found out about half way through the class that the JC offered certification in 1/16" dualshield and innershield? I can't remember right now. I was tempted to take the dualshield cert test, I was able to run a 'decent' 3g groove weld on a 1/2" plate. I didn't know what I could do with 1 certification though, and thought it'd be a better idea not to rush it and waste the money on the test if I couldn't find a job before the certification expired. I ended up passing this class with an A as well, and the instructor said that unless I completely bomb the final, there was no way that grade was changing. After taking this class I'm pretty confident that with enough wire and gas and voltage I can GMAW/FCAW pretty much anything. So far I've welded an axleback exhaust together for my brother, started on a compost bin (was supposed to be a bbq but I found out I need to get it the barrel sandblasted first) that is being made out of a barrel, and helped do some welding to setup a Dana 60 on a Jeep CJ5. I've taught people who 'knew how to weld' (who's knowledge consist of watching youtube videos) a few tricks...so these 'useless classes' must have been good for something!</p><p> </p><p> </p><p>

</p><p> </p><p>

</p><p> </p><p>And now for my current classes. I'm taking the GTAW class, and a blueprint design/fabrication class. </p><p>In the GTAW class, I have learned that it has a very steep learning curve. When I took the GMAW/FCAW class, it felt like I was a veteran returning to my grounds, I walked in, kicked butt, and had fun in that class. TIG welding is like I'm a noob welder once again (not that i'm more than a toddler in this welding life) Some similarities to Oxy-Acetylene welding, but there are many differences too.</p><p>I have been frustrated today. First, keeping that tungsten sharp, and from getting contaminated. This seems like the major key to GTAW. Second, clean metal. If the one thing you do is forget to clean your metal, you're not going to have a good time. I've knocked myself down a few notches...my head has been deflated a bit. But I know I'll master this skill. It will just take some time. The TIG gloves I have are horrible, I'm going to get some new ones. These were some Tillman Deerskin gloves. All the little furries like to touch my tungsten. And get on the metal. And get all over my clothes, and generally just like to ruin my day. These are going to be some backup gloves now. I'll order some pigskin leathers that don't have this problem.. </p><p>I need to definitely learn how to handle the torch. I think it needs to be different than I'm used to. A MIG gun or a stick gun are very similar in the way you hold it. The TIG torch needs a different 'flair.' That and learning to dip in the filler rod, the rhythm I need to get down, the amperage control. We use foot pedals. It's not too hard to use them, Just like a gas pedal it seems like. The first time is always quick, you're done before you realize it, you didn't do much, and you're worried that she's not impressed. Wait, are we still talking about TIG welding? <img alt="" src="https://honda-tech.com/forums/images/smilies/emsmilep.gif" title="Tongue" /></p><p> </p><p>Onto the blueprint/fabrication class. </p><p>Last Wednesday I started that. We learned how to measure to 1/16"! (Elementary stuff, right?) yet some people don't actually know how to do this. Fortunately I already do..but yeah. That was lesson 1. </p><p>Secondly we learned how to do orthographic projections. Again, I already knew how to do this...but this is something a lot of people don't know how to do. We had to draw a U shaped block to scale, front/top/side views, and write in the dimensions. It felt good to get back on a drafting table, measure out those lines, get everything 'just right'. The class will be heavy in these drawings. Also Isometric and Oblique sketches. Again, I know these, but it's always nice to do something you like, right? </p><p>I have do come blueprint and build a project of my own design, that's the final for this class. I'm not sure what I want to do. There are so many things that I have dreamed up already, I swear it's like I have ADHD when it comes to design. Something as simple as a porch rail, to as elaborate as an outdoor kitchen counter structure. In between that I have a fire pit idea, and a 'cart' for my Weber bbq. A pie cut exhaust for my civic. An outdoor patio table. The list goes on and on! As the class progresses I'll narrow it down to what I want to build. We have to buy our own metal, so that is a factor. Storage will also be a factor, I don't know if we have to take these projects home after each class session, so that may limit my designs to what I can fit in my car.</p><p>I'll stop rambling now, I've written enough for one night. I'll update y'all after my next class. </p><p> </p><p> </p>

</p><p>And now for my current classes. I'm taking the GTAW class, and a blueprint design/fabrication class. </p><p>In the GTAW class, I have learned that it has a very steep learning curve. When I took the GMAW/FCAW class, it felt like I was a veteran returning to my grounds, I walked in, kicked butt, and had fun in that class. TIG welding is like I'm a noob welder once again (not that i'm more than a toddler in this welding life) Some similarities to Oxy-Acetylene welding, but there are many differences too.</p><p>I have been frustrated today. First, keeping that tungsten sharp, and from getting contaminated. This seems like the major key to GTAW. Second, clean metal. If the one thing you do is forget to clean your metal, you're not going to have a good time. I've knocked myself down a few notches...my head has been deflated a bit. But I know I'll master this skill. It will just take some time. The TIG gloves I have are horrible, I'm going to get some new ones. These were some Tillman Deerskin gloves. All the little furries like to touch my tungsten. And get on the metal. And get all over my clothes, and generally just like to ruin my day. These are going to be some backup gloves now. I'll order some pigskin leathers that don't have this problem.. </p><p>I need to definitely learn how to handle the torch. I think it needs to be different than I'm used to. A MIG gun or a stick gun are very similar in the way you hold it. The TIG torch needs a different 'flair.' That and learning to dip in the filler rod, the rhythm I need to get down, the amperage control. We use foot pedals. It's not too hard to use them, Just like a gas pedal it seems like. The first time is always quick, you're done before you realize it, you didn't do much, and you're worried that she's not impressed. Wait, are we still talking about TIG welding? <img alt="" src="https://honda-tech.com/forums/images/smilies/emsmilep.gif" title="Tongue" /></p><p> </p><p>Onto the blueprint/fabrication class. </p><p>Last Wednesday I started that. We learned how to measure to 1/16"! (Elementary stuff, right?) yet some people don't actually know how to do this. Fortunately I already do..but yeah. That was lesson 1. </p><p>Secondly we learned how to do orthographic projections. Again, I already knew how to do this...but this is something a lot of people don't know how to do. We had to draw a U shaped block to scale, front/top/side views, and write in the dimensions. It felt good to get back on a drafting table, measure out those lines, get everything 'just right'. The class will be heavy in these drawings. Also Isometric and Oblique sketches. Again, I know these, but it's always nice to do something you like, right? </p><p>I have do come blueprint and build a project of my own design, that's the final for this class. I'm not sure what I want to do. There are so many things that I have dreamed up already, I swear it's like I have ADHD when it comes to design. Something as simple as a porch rail, to as elaborate as an outdoor kitchen counter structure. In between that I have a fire pit idea, and a 'cart' for my Weber bbq. A pie cut exhaust for my civic. An outdoor patio table. The list goes on and on! As the class progresses I'll narrow it down to what I want to build. We have to buy our own metal, so that is a factor. Storage will also be a factor, I don't know if we have to take these projects home after each class session, so that may limit my designs to what I can fit in my car.</p><p>I'll stop rambling now, I've written enough for one night. I'll update y'all after my next class. </p><p> </p><p> </p>

Last edited by Caoboy; 09-15-2015 at 07:43 PM.

#4

very nice , read it great post. Check out dezertrangers fab section , mostly all from california, lots of mig that looks like tig

#5

-Intl Steve Krew

Thread Starter

So yesterday was finally my first 'official' day of GTAW welding.

CLEAN METAL makes all the difference.

Puddling:

Butt Joint (no filler) :

Bottom one was too hot, moving too fast, massive undercut. Top bead I slowed down.

Outside Corner Joint (no filler) :

First or second attempt at 'walking the cup' on a T joint (1/16" filler rod) (sorry pics are bad..potato cam, bad lighting in the booth, too much Redbull etc)

All of this was on 10 and 12ga mild steel. None of this was cleaned up after I ran the beads.

So far I've learned that Auto-genus (sp?) welding is pretty cool. It seems easy enough to do, but takes lots of practice to do well.

I suck at dabbing with filler. I believe the problem is that I was dabbing with my non dominant hand. (I'm left handed, so things are usually 'backwards' when they are explained to me, and I have to figure out my own way of doing things) I switched it up at the end of the night, put the torch in my right hand and the filler rod in my left, and I was able to dab better. BUT then my torch was wobbly since my right hand was like WTF ARE YOU DOING WITH ME...practice will fix that part.

I picked up walking the cup pretty easy. Yes it looks bad, but I literally only ran 2 beads wtc last night. The motion was more fluid, easier to keep a rhythm, more comfortable.

Grinding Tungsten is an art in itself it seems like...about 1 in every 10 times I get that perfect conical point.

CLEAN METAL makes all the difference.

Puddling:

Butt Joint (no filler) :

Bottom one was too hot, moving too fast, massive undercut. Top bead I slowed down.

Outside Corner Joint (no filler) :

First or second attempt at 'walking the cup' on a T joint (1/16" filler rod) (sorry pics are bad..potato cam, bad lighting in the booth, too much Redbull etc)

All of this was on 10 and 12ga mild steel. None of this was cleaned up after I ran the beads.

So far I've learned that Auto-genus (sp?) welding is pretty cool. It seems easy enough to do, but takes lots of practice to do well.

I suck at dabbing with filler. I believe the problem is that I was dabbing with my non dominant hand. (I'm left handed, so things are usually 'backwards' when they are explained to me, and I have to figure out my own way of doing things) I switched it up at the end of the night, put the torch in my right hand and the filler rod in my left, and I was able to dab better. BUT then my torch was wobbly since my right hand was like WTF ARE YOU DOING WITH ME...practice will fix that part.

I picked up walking the cup pretty easy. Yes it looks bad, but I literally only ran 2 beads wtc last night. The motion was more fluid, easier to keep a rhythm, more comfortable.

Grinding Tungsten is an art in itself it seems like...about 1 in every 10 times I get that perfect conical point.

#7

-Intl Steve Krew

Thread Starter

It's been awhile since I've updated this...

I made a quick little video of my tube welding. Yes, it's messy...those bigger blobs are from blowouts from sucking at tackwelding the tubing...I filled them with rod.

Bottom is autogenous, top is 1/16" 308L filler.

This was also 3g (6g?) it was welded in the vertical position.

I made a quick little video of my tube welding. Yes, it's messy...those bigger blobs are from blowouts from sucking at tackwelding the tubing...I filled them with rod.

Bottom is autogenous, top is 1/16" 308L filler.

This was also 3g (6g?) it was welded in the vertical position.

Trending Topics

#8

Honda-Tech Member

good man keep going! I think that I'm at your same level. I found hard to mantain the same width of the bead when adding the filler... If I joint two pipes without filler it cames almost good on the other hand when adding the filler everything mess up. :D

#9

B*a*n*n*e*d

iTrader: (15)

Join Date: Jul 2008

Location: montebello, ca, us

Posts: 6,632

Likes: 0

Received 15 Likes

on

10 Posts

Originally Posted by Cabletie

good man keep going! I think that I'm at your same level. I found hard to mantain the same width of the bead when adding the filler... If I joint two pipes without filler it cames almost good on the other hand when adding the filler everything mess up. :D

#10

DO IT ON ALL FOURS

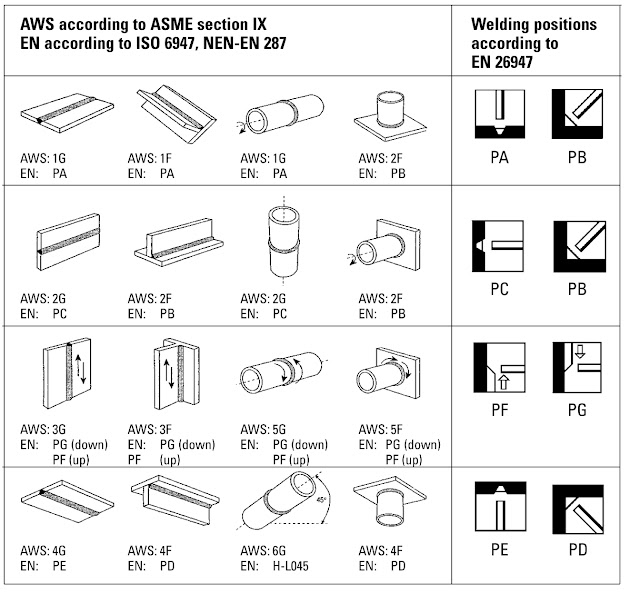

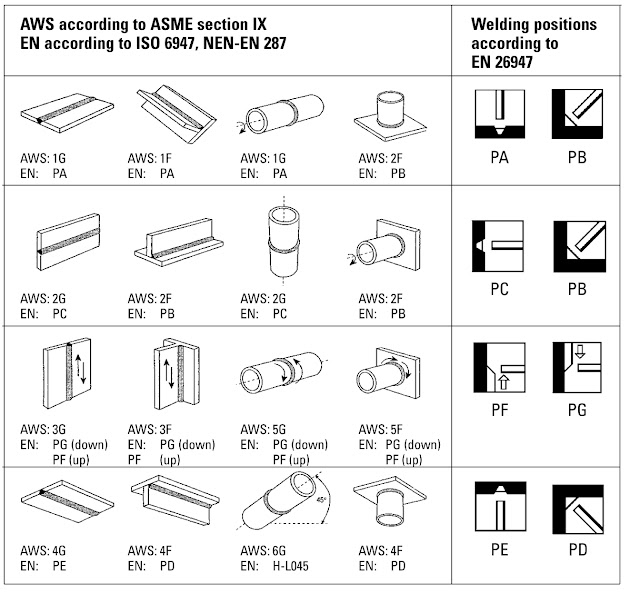

Not to be rude, but if the pipe was vertical, you were welding 2G. Only when the pipe gets rather huge (24" minimum) can you weld 3G or 4G on a pipe. 1G pipe is rolled, 2G pipe is vertical (weld is horizontal), 5G pipe is laying horizontal, 6G the pipe is at a 45° incline, 6G-R is same as 6G but with a restrictor plate on one side of the groove.

"G" meaning Groove ... "F" meaning Fillet

"G" meaning Groove ... "F" meaning Fillet

#11

-Intl Steve Krew

Thread Starter

Thanks for the info.

When I take an actual pipe welding class, I'm pretty sure I'll learn what position is what.

I just know that position 1 2 3 4 is flat horizontal vertical and overhead for plate.

When I get into the 'intermediate' stick welding class, I'll get the groove/fillet monikers drilled into me as that class is all about learning how to weld well enough to pass D1-1 certs iirc.

When I take an actual pipe welding class, I'm pretty sure I'll learn what position is what.

I just know that position 1 2 3 4 is flat horizontal vertical and overhead for plate.

When I get into the 'intermediate' stick welding class, I'll get the groove/fillet monikers drilled into me as that class is all about learning how to weld well enough to pass D1-1 certs iirc.

#12

Honda-Tech Member

#13

DO IT ON ALL FOURS

AWS D1.1 coding (part of D1.X group of codes) is only for any thickness (depending on test given) carbon steel plate in the 1, 2, 3, and 4G/F positions.  Most schools only offer up to 3G qualifications and don't do the 4G position. You will want both at minimum in the real world if you want to do structural work.

Most schools only offer up to 3G qualifications and don't do the 4G position. You will want both at minimum in the real world if you want to do structural work.

You are most likely looking for AWS B2.1 coding. The regular codes are pretty open to interpretation depending on what you are doing.

There is a lot to learn when it comes to welding BS in the industrial world. Once you are in it for a few years, you get used to it LOL. My hopes are to become a CWI soon. You have to have years of field experience or even more years as an instructor to even be allowed to test for CWI.

Most schools only offer up to 3G qualifications and don't do the 4G position. You will want both at minimum in the real world if you want to do structural work.

Most schools only offer up to 3G qualifications and don't do the 4G position. You will want both at minimum in the real world if you want to do structural work.You are most likely looking for AWS B2.1 coding. The regular codes are pretty open to interpretation depending on what you are doing.

There is a lot to learn when it comes to welding BS in the industrial world. Once you are in it for a few years, you get used to it LOL. My hopes are to become a CWI soon. You have to have years of field experience or even more years as an instructor to even be allowed to test for CWI.

Thread

Thread Starter

Forum

Replies

Last Post

a1320honda

Engine Management and Tuning

52

04-29-2013 06:20 PM

RineRacing

Road Racing / Autocross & Time Attack

26

03-30-2003 03:37 PM