DIY Bilstein revalve project

#1

Honda-Tech Member

Thread Starter

Intro:

Since I was starting to get fed up with the "black magic" in paying others to revalve shocks (*cough* Koni *cough*) I decided to go with a set of Bilsteins and practice revalving them myself. The good thing about Bilsteins is that they encourage (sort of) users to do this by selling all the parts, and the guys at the North Carolina division are pretty helpful as well. Another nice thing is that pretty much all their shocks use the same internals, so you can go with the lowly commodity circle track or dirt racing shocks.

Things you will need:

0: A stubborn DIY attitude that considers your time to be worth nothing, and the unwillingness to pay others to "work magic" for you. (However, going to a machinist or welder is fine since you know what they are doing)

1: Shock dyno. I built a ghetto one here for about $200:

https://honda-tech.com/zerothread?id=2325055

You will also need some kind of data acquisition (e.g. USB ADC and DAC converter for ~$150).

You will also need to be able to use MATLAB or some other kind of data analysis program. At some point, I might bundle my matlab code into an executable which you can just run.

2:Access to a machine shop, or at least the ability to use drills and bandsaws to make a few simple pieces

Let's begin:

First, you need to acquire a set of shocks. Ideally, you would get some OEM ones (make sure they are the 46mm version) that would fit your car. But since this is practice, I got some commodity circle track shocks that were double eyelet for a mere $25 each. I was lucky that these shocks had already been rebuilt once so there was already a schrader valve attached to the gas side. Otherwise, it would involve a drill and tap or weld. The next set of shocks I'm getting doesn't have the schraeder, so I'll post again how to prep them.

Depressurize the shock and take off the end cap. There are a few different designs, but this is the kind with the snap rings. First you need to squeeze down the end cap a touch using the "top cap squishing down tool" I mention later. Next, you can use a dental pick to take out the snap ring. Again, since mine were already rebuilt previously, there were grooves in the end cap for your to pry them out. Otherwise, I think you'll have to carefully pressurize it out.

Take out second lower snap ring

Piston comes out

Now would be a good time to change the oil, and/or the piston band (teflon strip that goes along the outer edge of the piston and scrapes against the tube wall.) IF you think the dividing piston oring is worn, you can pop that out and change it too.

Take off the nut at the end of the shaft to get the piston and shims off

OK, now here's the part that you tend to pay money for - what shims or piston to use to get the dyno plot you want. Bilstein has three types of pistons (as far as I know)

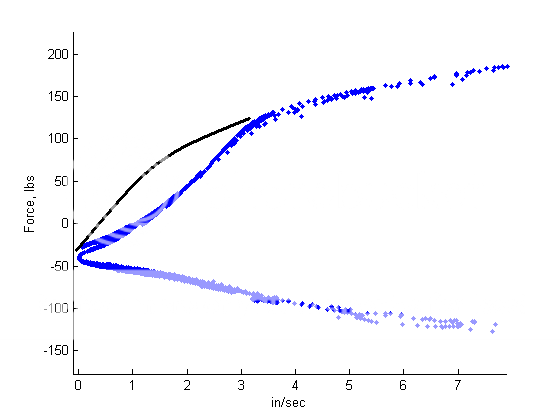

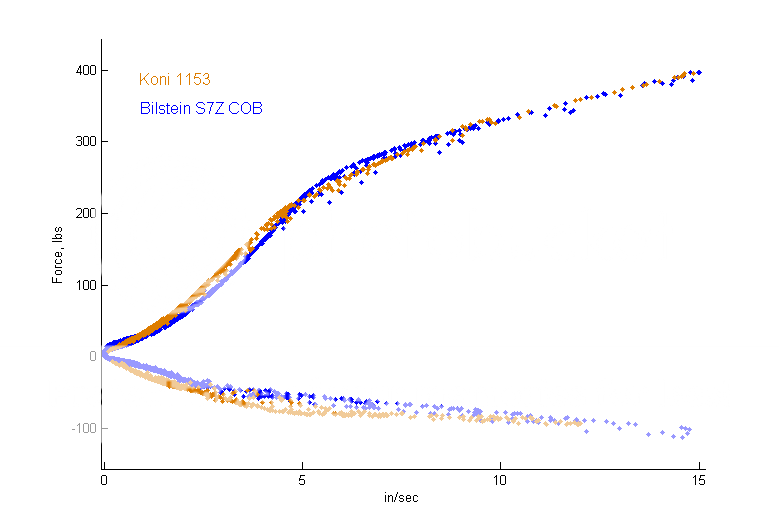

On the left is their linear piston. It has more flow in one direction than another by some factor that I forgot. In the middle is their old school digressive piston, which has the same bleed in rebound as compression. On the right is their new "COB" digressive piston. It has a check valve so that you can get different bleed in compression and rebound. To get an idea of how to shim these, go to the bilstein webpage, downloads, and oval track valving manual. But in general, the digressive valving consists of only 4 shims : preload, bleed, main, and high speed. The type of dyno plot you will get with this configuration is in general a progressive-digressive-linear curve, as shown in the blue plot here (COB piston):

The progressive part is due to the bleed shim. The point at which the curve turns over is set by the preload shim, and the slope and magnitude of the higher speed part is due to the main and high speed shims. If instead you use a stack that doesn't have any bleed, or has the series of decreasing radius shims stacked on top of each other, or use the linear piston, you'll get something that looks more like the black curve. Right now I'm still trying to figure out whether the black or blue curve is better, and I'm also learning about how to make a bleed-less decreasing radius shim stack.

To put things back together, you need to make sure that the dividing piston level and oil level are correct. When in doubt, set the dividing piston height by using the piston shaft to push it down far enough that it won't hit the piston when the shock is about 1/2 or 1/4" from bottoming out. (Note that these instructions are very unofficial) Put the piston and shaft back in, inserted maybe 2/3 of the way in. Put in the lower circlip. Ok, now fill almost to the top with oil, and pump the piston to get the bubbles out. Put on the top cap until the oring is just above the level of the shock body, and push down on the piston to squeeze out as much air as possible.

The reason I didn't push the dividing piston down all the way is because now when you press in the top cap the rest of the way, it's going to displace the dividing piston downwards further. TO push the top cap back on, you can use bilstein's official tool, or you can bandsaw and drill an aluminum block and threaded rod together to make a contraption as follows:

Squeeze the cap down and put the other circlip back in.

If you are pro, you can use compressed nitrogen to refill the shock, but I got cheap and used a mountain bike shock pump. I figure that the gas space isn't going to heat up enough such that any miniscule amounts of water vapor are going to cause any problems. But if you want, you can buy some compressed nitrogen in a spray bottle thats used to keep wine fresh, and surround the pump with a plastic bag.

Pressurize a little bit, back off but don't take off the end cap clamp device. Check that snap ring is working ok. Pressure the shock the rest of the way. The bilstein manual states 180 psi, but the guy from bilstein said anywhere from 100 to 300. If I feel like it, I'll later go on and on about the effects of the gas pressure, but the short version is you want it high enough to prevent cavitation.

Take off clamp, put on dyno, measure. The spring rate from the air space is only very slightly progressive, so if for example it increases by more than 50% from full extension to full compression, you might have put in too much oil.

OK, that's it for now. Have fun and don't kill yourself. I'll update more later as I end up learning more about how shims work and stuff.

PS: If anybody knows how to figure out a dyno plot from a no bleed shim stack, or knows of a program that simulates it, please let me know.

Modified by beanbag at 4:49 AM 10/24/2008

Since I was starting to get fed up with the "black magic" in paying others to revalve shocks (*cough* Koni *cough*) I decided to go with a set of Bilsteins and practice revalving them myself. The good thing about Bilsteins is that they encourage (sort of) users to do this by selling all the parts, and the guys at the North Carolina division are pretty helpful as well. Another nice thing is that pretty much all their shocks use the same internals, so you can go with the lowly commodity circle track or dirt racing shocks.

Things you will need:

0: A stubborn DIY attitude that considers your time to be worth nothing, and the unwillingness to pay others to "work magic" for you. (However, going to a machinist or welder is fine since you know what they are doing)

1: Shock dyno. I built a ghetto one here for about $200:

https://honda-tech.com/zerothread?id=2325055

You will also need some kind of data acquisition (e.g. USB ADC and DAC converter for ~$150).

You will also need to be able to use MATLAB or some other kind of data analysis program. At some point, I might bundle my matlab code into an executable which you can just run.

2:Access to a machine shop, or at least the ability to use drills and bandsaws to make a few simple pieces

Let's begin:

First, you need to acquire a set of shocks. Ideally, you would get some OEM ones (make sure they are the 46mm version) that would fit your car. But since this is practice, I got some commodity circle track shocks that were double eyelet for a mere $25 each. I was lucky that these shocks had already been rebuilt once so there was already a schrader valve attached to the gas side. Otherwise, it would involve a drill and tap or weld. The next set of shocks I'm getting doesn't have the schraeder, so I'll post again how to prep them.

Depressurize the shock and take off the end cap. There are a few different designs, but this is the kind with the snap rings. First you need to squeeze down the end cap a touch using the "top cap squishing down tool" I mention later. Next, you can use a dental pick to take out the snap ring. Again, since mine were already rebuilt previously, there were grooves in the end cap for your to pry them out. Otherwise, I think you'll have to carefully pressurize it out.

Take out second lower snap ring

Piston comes out

Now would be a good time to change the oil, and/or the piston band (teflon strip that goes along the outer edge of the piston and scrapes against the tube wall.) IF you think the dividing piston oring is worn, you can pop that out and change it too.

Take off the nut at the end of the shaft to get the piston and shims off

OK, now here's the part that you tend to pay money for - what shims or piston to use to get the dyno plot you want. Bilstein has three types of pistons (as far as I know)

On the left is their linear piston. It has more flow in one direction than another by some factor that I forgot. In the middle is their old school digressive piston, which has the same bleed in rebound as compression. On the right is their new "COB" digressive piston. It has a check valve so that you can get different bleed in compression and rebound. To get an idea of how to shim these, go to the bilstein webpage, downloads, and oval track valving manual. But in general, the digressive valving consists of only 4 shims : preload, bleed, main, and high speed. The type of dyno plot you will get with this configuration is in general a progressive-digressive-linear curve, as shown in the blue plot here (COB piston):

The progressive part is due to the bleed shim. The point at which the curve turns over is set by the preload shim, and the slope and magnitude of the higher speed part is due to the main and high speed shims. If instead you use a stack that doesn't have any bleed, or has the series of decreasing radius shims stacked on top of each other, or use the linear piston, you'll get something that looks more like the black curve. Right now I'm still trying to figure out whether the black or blue curve is better, and I'm also learning about how to make a bleed-less decreasing radius shim stack.

To put things back together, you need to make sure that the dividing piston level and oil level are correct. When in doubt, set the dividing piston height by using the piston shaft to push it down far enough that it won't hit the piston when the shock is about 1/2 or 1/4" from bottoming out. (Note that these instructions are very unofficial) Put the piston and shaft back in, inserted maybe 2/3 of the way in. Put in the lower circlip. Ok, now fill almost to the top with oil, and pump the piston to get the bubbles out. Put on the top cap until the oring is just above the level of the shock body, and push down on the piston to squeeze out as much air as possible.

The reason I didn't push the dividing piston down all the way is because now when you press in the top cap the rest of the way, it's going to displace the dividing piston downwards further. TO push the top cap back on, you can use bilstein's official tool, or you can bandsaw and drill an aluminum block and threaded rod together to make a contraption as follows:

Squeeze the cap down and put the other circlip back in.

If you are pro, you can use compressed nitrogen to refill the shock, but I got cheap and used a mountain bike shock pump. I figure that the gas space isn't going to heat up enough such that any miniscule amounts of water vapor are going to cause any problems. But if you want, you can buy some compressed nitrogen in a spray bottle thats used to keep wine fresh, and surround the pump with a plastic bag.

Pressurize a little bit, back off but don't take off the end cap clamp device. Check that snap ring is working ok. Pressure the shock the rest of the way. The bilstein manual states 180 psi, but the guy from bilstein said anywhere from 100 to 300. If I feel like it, I'll later go on and on about the effects of the gas pressure, but the short version is you want it high enough to prevent cavitation.

Take off clamp, put on dyno, measure. The spring rate from the air space is only very slightly progressive, so if for example it increases by more than 50% from full extension to full compression, you might have put in too much oil.

OK, that's it for now. Have fun and don't kill yourself. I'll update more later as I end up learning more about how shims work and stuff.

PS: If anybody knows how to figure out a dyno plot from a no bleed shim stack, or knows of a program that simulates it, please let me know.

Modified by beanbag at 4:49 AM 10/24/2008

#3

Bilstien will actually work with you on valving and they are pretty cheap compared to Koni. I think they will revalve for 65$. I talked to the guys up in NC not to long ago and they seemed really interested in helping out. Plus there are a bunch of circle track shops that can help out with the Bilstien shocks. Something else to think about.

#6

Honda-Tech Member

Join Date: Oct 2003

Location: Chicago

Posts: 6,619

Likes: 0

Received 0 Likes

on

0 Posts

This great, thanks!

I talked to a couple engineers in the California office last year and they were extremely helpful. Knew quite a bit about Honda suspension. I strongly believe that monotubes are superior to twin-tubes like Koni in performance apps. And as a bonus Bilstein Sport's come shortened from the factory. They cost nothing extra over oem replacement HD's.

Modified by vinuneuro at 7:40 PM 10/24/2008

I talked to a couple engineers in the California office last year and they were extremely helpful. Knew quite a bit about Honda suspension. I strongly believe that monotubes are superior to twin-tubes like Koni in performance apps. And as a bonus Bilstein Sport's come shortened from the factory. They cost nothing extra over oem replacement HD's.

Modified by vinuneuro at 7:40 PM 10/24/2008

#7

Honda-Tech Member

Join Date: Feb 2000

Location: Richmond VA

Posts: 2,159

Likes: 0

Received 0 Likes

on

0 Posts

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by vinuneuro »</TD></TR><TR><TD CLASS="quote"> I strongly believe that monotubes are superior to twin-tubes like Koni in performance apps.</TD></TR></TABLE>

Why?

BTW, the higher-end Koni 30 and 28-series are monotubes, but plenty of people have had success with revalved Sports.

Why?

BTW, the higher-end Koni 30 and 28-series are monotubes, but plenty of people have had success with revalved Sports.

Trending Topics

#8

Honda-Tech Member

Join Date: Nov 2003

Location: SE, PA, usa

Posts: 1,743

Likes: 0

Received 0 Likes

on

0 Posts

Great thread. I love the fact that Bilstein is so willing to help and share info. It sucks they don't sell the sport shocks for any older Honda applications.

#9

Honda-Tech Member

Join Date: Jan 2006

Location: Charlotte, North Carolina, USA

Posts: 228

Likes: 0

Received 0 Likes

on

0 Posts

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by Furyof4 »</TD></TR><TR><TD CLASS="quote">Great thread. I love the fact that Bilstein is so willing to help and share info. It sucks they don't sell the sport shocks for any older Honda applications.</TD></TR></TABLE>

Yeah, but you should be able to re-valve a Bilstein HD just the same. Longer strut rod of course, but maybe Bilstein can take care of that.

That said, I have not yet looked into using Bilstein shocks on my Accord.

But I will since their shop is like 30 minutes from me.

Yeah, but you should be able to re-valve a Bilstein HD just the same. Longer strut rod of course, but maybe Bilstein can take care of that.

That said, I have not yet looked into using Bilstein shocks on my Accord.

But I will since their shop is like 30 minutes from me.

#10

Honda-Tech Member

Thread Starter

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by turboteener »</TD></TR><TR><TD CLASS="quote">Bilstien will actually work with you on valving and they are pretty cheap compared to Koni. I think they will revalve for 65$. I talked to the guys up in NC not to long ago and they seemed really interested in helping out. Plus there are a bunch of circle track shops that can help out with the Bilstien shocks. Something else to think about.</TD></TR></TABLE>

Thanks for reminding me. Circle track shops near me have been fairly helpful in getting Bilstein parts as well. However, nobody was willing to sell me a shim stack based on a given dyno curve. For some reason, all shock rebuilders I have talked to are very hush hush about this, in that they just want you to send them your shocks so that they can revalve it themselves. It's like shim stacks are a secret recipe of 11 herbs and spices or something.

Modified by beanbag at 6:15 PM 10/24/2008

Thanks for reminding me. Circle track shops near me have been fairly helpful in getting Bilstein parts as well. However, nobody was willing to sell me a shim stack based on a given dyno curve. For some reason, all shock rebuilders I have talked to are very hush hush about this, in that they just want you to send them your shocks so that they can revalve it themselves. It's like shim stacks are a secret recipe of 11 herbs and spices or something.

Modified by beanbag at 6:15 PM 10/24/2008

#11

Honda-Tech Member

Thread Starter

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by WRXRacer111 »</TD></TR><TR><TD CLASS="quote">

Why?

BTW, the higher-end Koni 30 and 28-series are monotubes, but plenty of people have had success with revalved Sports.

</TD></TR></TABLE>

Of all the reasons I have read as to why monotubes are better than twin tubes, the only one I really believe is that they use larger pistons. Larger pistons result in smaller pressure changes for a given force, and that somehow reduces pathologies. I'm a fan of the 82 series Koni twin tubes, which are larger diameter than the Sports.

At some point, I'll put my Koni Sports on the dyno and try to show what kinds of pathlologies they have, if any.

Why?

BTW, the higher-end Koni 30 and 28-series are monotubes, but plenty of people have had success with revalved Sports.

</TD></TR></TABLE>

Of all the reasons I have read as to why monotubes are better than twin tubes, the only one I really believe is that they use larger pistons. Larger pistons result in smaller pressure changes for a given force, and that somehow reduces pathologies. I'm a fan of the 82 series Koni twin tubes, which are larger diameter than the Sports.

At some point, I'll put my Koni Sports on the dyno and try to show what kinds of pathlologies they have, if any.

#12

Honda-Tech Member

Join Date: Oct 2003

Location: Chicago

Posts: 6,619

Likes: 0

Received 0 Likes

on

0 Posts

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by WRXRacer111 »</TD></TR><TR><TD CLASS="quote">

Why?

BTW, the higher-end Koni 30 and 28-series are monotubes, but plenty of people have had success with revalved Sports.

</TD></TR></TABLE>

I'm not saying all of Koni's shocks are bad. Hell, McLaren uses them in the F1 car.

-Monotubes tend to have larger pistons for the most part.

-The inherent difference in design allows monotubes to run cooler. Probably the most important difference since it means more consistent damping.

-They can be run inverted, thus reducing unsprung weight.

-I've read that the plain christmas-tree design in monotubes is more precise than with the extra orifices/valves in twin-tubes.

And on Koni ots shocks, I'm sure all of us are aware of David Grant's findings regarding their quality as far as consistency in valving, shock-shock.

Why?

BTW, the higher-end Koni 30 and 28-series are monotubes, but plenty of people have had success with revalved Sports.

</TD></TR></TABLE>

I'm not saying all of Koni's shocks are bad. Hell, McLaren uses them in the F1 car.

-Monotubes tend to have larger pistons for the most part.

-The inherent difference in design allows monotubes to run cooler. Probably the most important difference since it means more consistent damping.

-They can be run inverted, thus reducing unsprung weight.

-I've read that the plain christmas-tree design in monotubes is more precise than with the extra orifices/valves in twin-tubes.

And on Koni ots shocks, I'm sure all of us are aware of David Grant's findings regarding their quality as far as consistency in valving, shock-shock.

#13

Honda-Tech Member

Join Date: Feb 2000

Location: Richmond VA

Posts: 2,159

Likes: 0

Received 0 Likes

on

0 Posts

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by beanbag »</TD></TR><TR><TD CLASS="quote">

It's like shim stacks are a secret recipe of 11 herbs and spices or something.

</TD></TR></TABLE>

I think Ohlins has software you can download that will show you what theoretical curve a shim combination will give you.

It's like shim stacks are a secret recipe of 11 herbs and spices or something.

</TD></TR></TABLE>

I think Ohlins has software you can download that will show you what theoretical curve a shim combination will give you.

#14

Honda-Tech Member

Thread Starter

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by vinuneuro »</TD></TR><TR><TD CLASS="quote">

I'm not saying all of Koni's shocks are bad. Hell, McLaren uses them in the F1 car.

-Monotubes tend to have larger pistons for the most part.

</TD></TR></TABLE>

That's pretty much true

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote »</TD></TR><TR><TD CLASS="quote">

-The inherent difference in design allows monotubes to run cooler. Probably the most important difference since it means more consistent damping.

</TD></TR></TABLE>

Probably depends on the application, but even after driving over bumpy roads for an extended period of time, my rear 8211 didn't get hot at all, just barely warm. The way these work is that on every compression stroke, fluid squirts out the base valve into the outer tube, and later gets sucked back in at the top of the inner tube. So the fluid is always recirculating. I would say that the cooling is only a little worse than a monotube. Also, the shock might come with a crappy fluid that has a low VI. When I replaced the fluid in my 8211's with Redline suspension fluid, it seemed to give much more consistent damping performance.

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote »</TD></TR><TR><TD CLASS="quote">

-They can be run inverted, thus reducing unsprung weight.

</TD></TR></TABLE>

Depending on design, twin tubes can also be run inverted.

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote »</TD></TR><TR><TD CLASS="quote">

-I've read that the plain christmas-tree design in monotubes is more precise than with the extra orifices/valves in twin-tubes.

</TD></TR></TABLE>

I'd like to find out more about this. In principle, the valving configuration between a twin tube, and a monotube with external compression adjust is very similar.

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote »</TD></TR><TR><TD CLASS="quote">

And on Koni ots shocks, I'm sure all of us are aware of David Grant's findings regarding their quality as far as consistency in valving, shock-shock.</TD></TR></TABLE>

So far, I have dyno'd 6 Koni shocks (3 pairs), and found the adjusters were very consistent.

I'm not saying all of Koni's shocks are bad. Hell, McLaren uses them in the F1 car.

-Monotubes tend to have larger pistons for the most part.

</TD></TR></TABLE>

That's pretty much true

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote »</TD></TR><TR><TD CLASS="quote">

-The inherent difference in design allows monotubes to run cooler. Probably the most important difference since it means more consistent damping.

</TD></TR></TABLE>

Probably depends on the application, but even after driving over bumpy roads for an extended period of time, my rear 8211 didn't get hot at all, just barely warm. The way these work is that on every compression stroke, fluid squirts out the base valve into the outer tube, and later gets sucked back in at the top of the inner tube. So the fluid is always recirculating. I would say that the cooling is only a little worse than a monotube. Also, the shock might come with a crappy fluid that has a low VI. When I replaced the fluid in my 8211's with Redline suspension fluid, it seemed to give much more consistent damping performance.

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote »</TD></TR><TR><TD CLASS="quote">

-They can be run inverted, thus reducing unsprung weight.

</TD></TR></TABLE>

Depending on design, twin tubes can also be run inverted.

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote »</TD></TR><TR><TD CLASS="quote">

-I've read that the plain christmas-tree design in monotubes is more precise than with the extra orifices/valves in twin-tubes.

</TD></TR></TABLE>

I'd like to find out more about this. In principle, the valving configuration between a twin tube, and a monotube with external compression adjust is very similar.

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote »</TD></TR><TR><TD CLASS="quote">

And on Koni ots shocks, I'm sure all of us are aware of David Grant's findings regarding their quality as far as consistency in valving, shock-shock.</TD></TR></TABLE>

So far, I have dyno'd 6 Koni shocks (3 pairs), and found the adjusters were very consistent.

#15

Honda-Tech Member

Join Date: May 2000

Location: SoCal

Posts: 1,612

Likes: 0

Received 0 Likes

on

0 Posts

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by turboteener »</TD></TR><TR><TD CLASS="quote">Bilstien will actually work with you on valving and they are pretty cheap compared to Koni. I think they will revalve for 65$. I talked to the guys up in NC not to long ago and they seemed really interested in helping out. Plus there are a bunch of circle track shops that can help out with the Bilstien shocks. Something else to think about.</TD></TR></TABLE>

Just FIY, Bilstein revalves Non-adjustable shocks (HD, SP) for $65. Try asking about revalving their adjustable shocks (PSS-9) and you'll get a different price. The Koni Sports are 1 way adjustable shocks, and I believe that's why they're more expensive to revalve.

Just FIY, Bilstein revalves Non-adjustable shocks (HD, SP) for $65. Try asking about revalving their adjustable shocks (PSS-9) and you'll get a different price. The Koni Sports are 1 way adjustable shocks, and I believe that's why they're more expensive to revalve.

#16

Honda-Tech Member

Thread Starter

I figured out a neat trick to make sure that when you put the shock back together, you get out as much air as possible. Using a rat tail file, cut a small notch in the body like so:

Then when you put the cap back on, tilt the shock and push down the shaft to squeeze out the rest of the air thru this notch.

Then when you put the cap back on, tilt the shock and push down the shaft to squeeze out the rest of the air thru this notch.

#17

Honda-Tech Member

Thread Starter

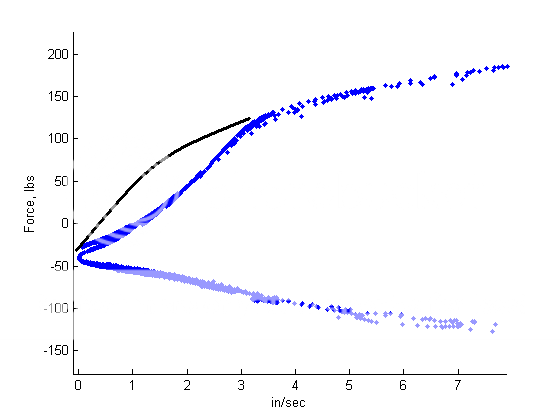

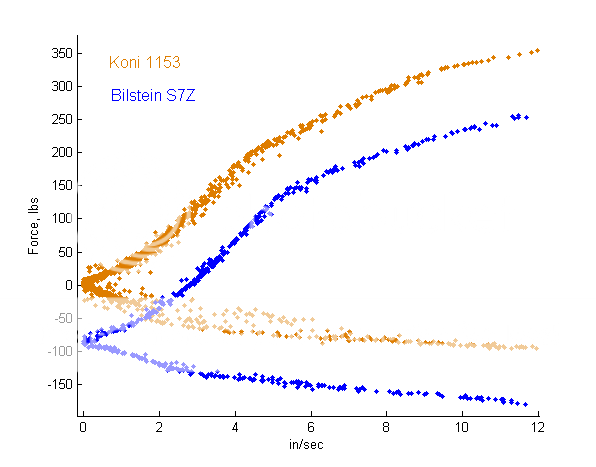

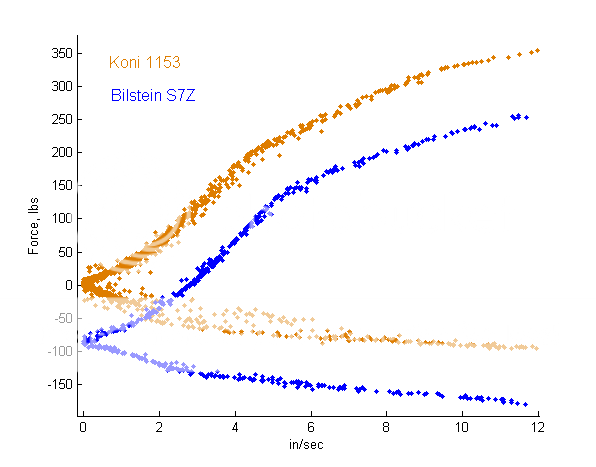

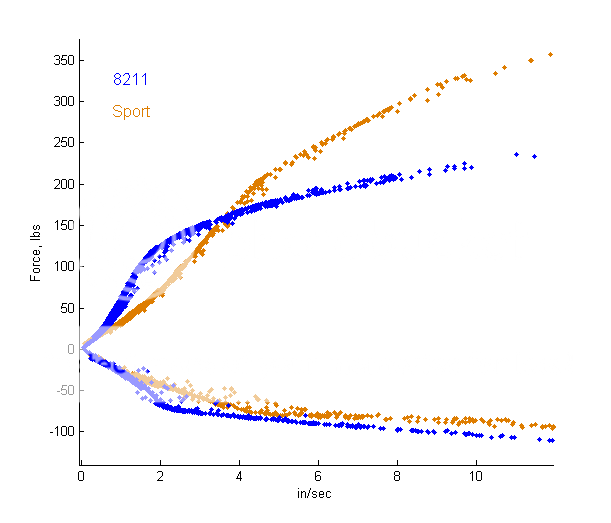

The first goal of this project is to get the Bilstein to look like a Koni Sport. So here's a dyno plot of the shocks next to each other:

What I need to do on the Bilstein:

Bigger main rebound shim

Maybe back the preload down a notch to take into account this bigger plate

Slightly smaller compression bleed plate

After:

OK, so I missed a little on the compression stroke. Shrug. One thing that kind of surprised me was how little low speed rebound the koni has relative to the compression damping. The ratio is nearly 1:1, so why did I even both whipping out the COB piston for this? Anyway, unless I accidentally turned the rebound ****, the Koni shock was set for 300# springs, which I think is about 1 turn or so.

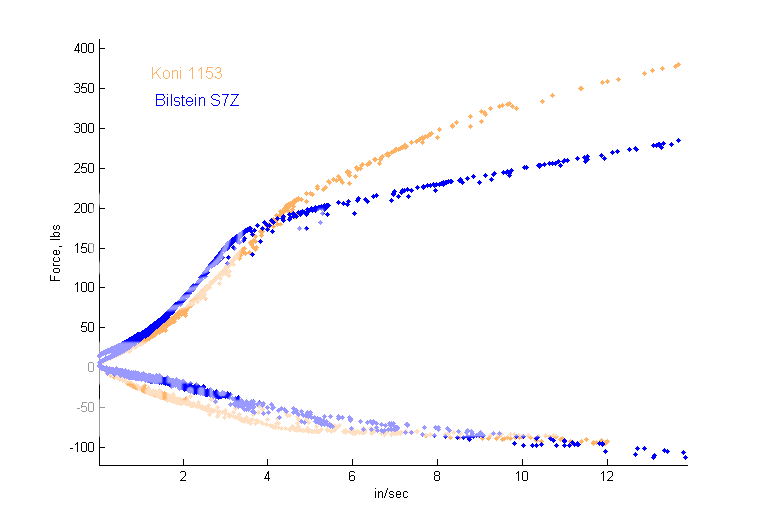

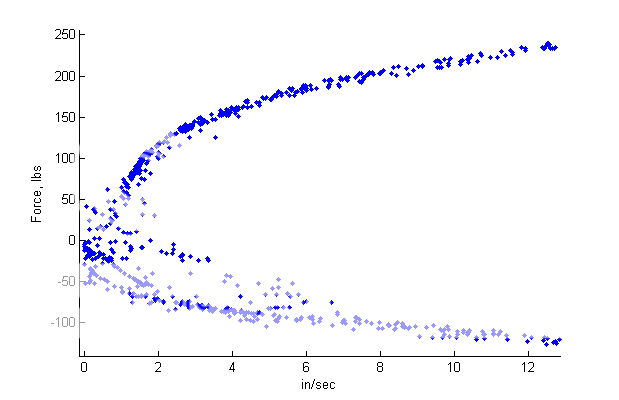

Now let's do some "twin tube vs monotube" comparisons:

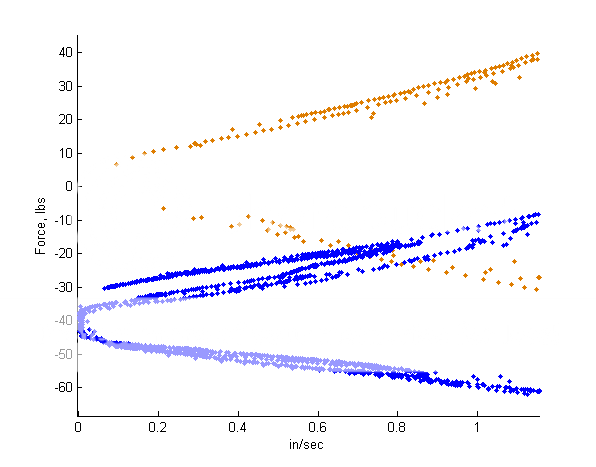

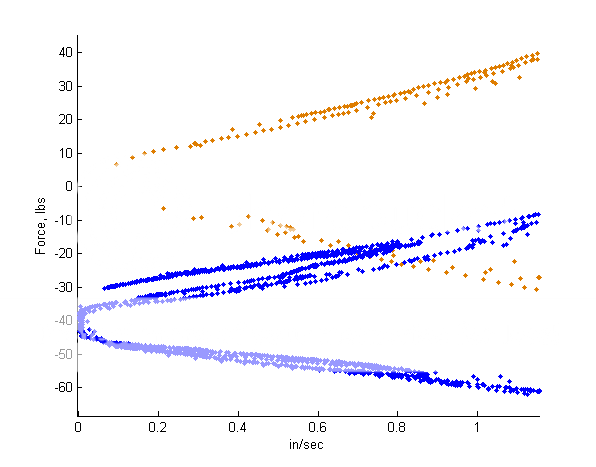

First up is very low speed performance (hitting small bumps, daily driving)

The twin tube has two branches that pretty much converge to zero, while the monotube has a gap and also some additional offshoots on the rebound branch (albeit very small). Some of this is due to stuff like additional seal friction, floating piston friction, and maybe some other factors.

My conclusion: Twin tube is probably more "comfortable" for daily driving. The monotube could probably be improved by having something like a flexible bladder instead of a floating pistion (like AFCO uses) and lower friction seals. Maybe I could also run it at a lower pressure.

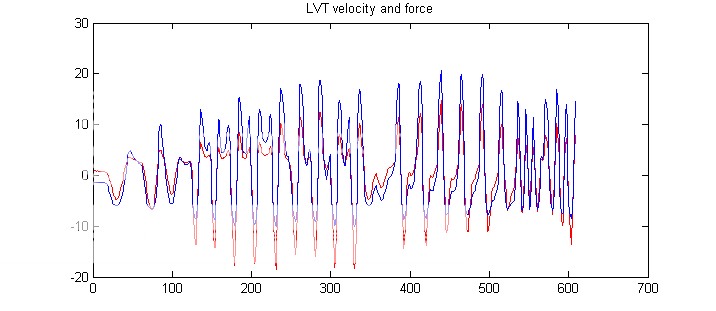

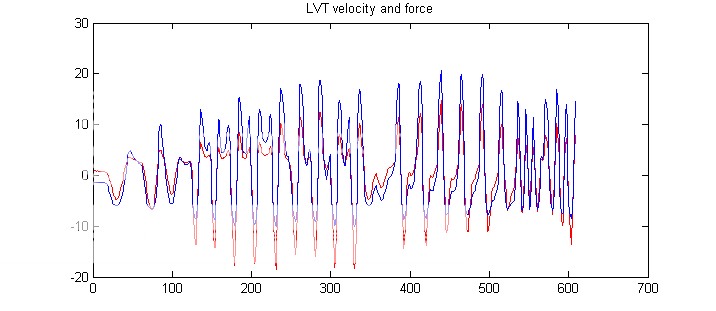

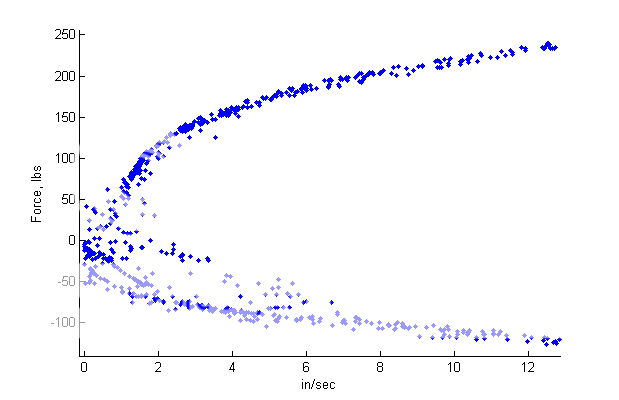

Next comparison: what if you give the shocks a pathlological waveform that has lots of spikes and "shocks"? Something like so:

Here's the dyno plots of the shocks again, sampled at 60Hz:

The monotube data is much less noisy, meaning that under conditions other than the nice smooth sinusoids that most dynometers use, a monotube still "does what it says it does", while a twin tube is much less consistent.

So the next time somebody says that two shocks can look the same on the dyno, but perform differently, you can say:

"well, YEAH, if you use a dyno that only has smooth waveforms and then averages the data into 6 points".

I could sample at a higher rate, or start doing plots of force vs acceleration or etc, but I think you get the point anyway.

My conclusion: Monotubes work more consistently under "extreme" conditions.

What I need to do on the Bilstein:

Bigger main rebound shim

Maybe back the preload down a notch to take into account this bigger plate

Slightly smaller compression bleed plate

After:

OK, so I missed a little on the compression stroke. Shrug. One thing that kind of surprised me was how little low speed rebound the koni has relative to the compression damping. The ratio is nearly 1:1, so why did I even both whipping out the COB piston for this? Anyway, unless I accidentally turned the rebound ****, the Koni shock was set for 300# springs, which I think is about 1 turn or so.

Now let's do some "twin tube vs monotube" comparisons:

First up is very low speed performance (hitting small bumps, daily driving)

The twin tube has two branches that pretty much converge to zero, while the monotube has a gap and also some additional offshoots on the rebound branch (albeit very small). Some of this is due to stuff like additional seal friction, floating piston friction, and maybe some other factors.

My conclusion: Twin tube is probably more "comfortable" for daily driving. The monotube could probably be improved by having something like a flexible bladder instead of a floating pistion (like AFCO uses) and lower friction seals. Maybe I could also run it at a lower pressure.

Next comparison: what if you give the shocks a pathlological waveform that has lots of spikes and "shocks"? Something like so:

Here's the dyno plots of the shocks again, sampled at 60Hz:

The monotube data is much less noisy, meaning that under conditions other than the nice smooth sinusoids that most dynometers use, a monotube still "does what it says it does", while a twin tube is much less consistent.

So the next time somebody says that two shocks can look the same on the dyno, but perform differently, you can say:

"well, YEAH, if you use a dyno that only has smooth waveforms and then averages the data into 6 points".

I could sample at a higher rate, or start doing plots of force vs acceleration or etc, but I think you get the point anyway.

My conclusion: Monotubes work more consistently under "extreme" conditions.

#19

Honda-Tech Member

Join Date: Feb 2005

Location: Shake Hands with the Dremel

Posts: 206

Likes: 0

Received 0 Likes

on

0 Posts

Amazing thread beanbag. I love reading actual tech.

I would be interested to know your on car experiences with rebuilt Bilsteins compared to Koni sports.

I would be interested to know your on car experiences with rebuilt Bilsteins compared to Koni sports.

#20

Honda-Tech Member

Thread Starter

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by uniseriate »</TD></TR><TR><TD CLASS="quote"> to know your on car experiences with rebuilt Bilsteins compared to Koni sports.</TD></TR></TABLE>

Sorry to disappoint, but since I like the performance of my 8211's more, I'm going to valve the Bilsteins to be more like them. Which reminds me, I put one of those on the dyno today.

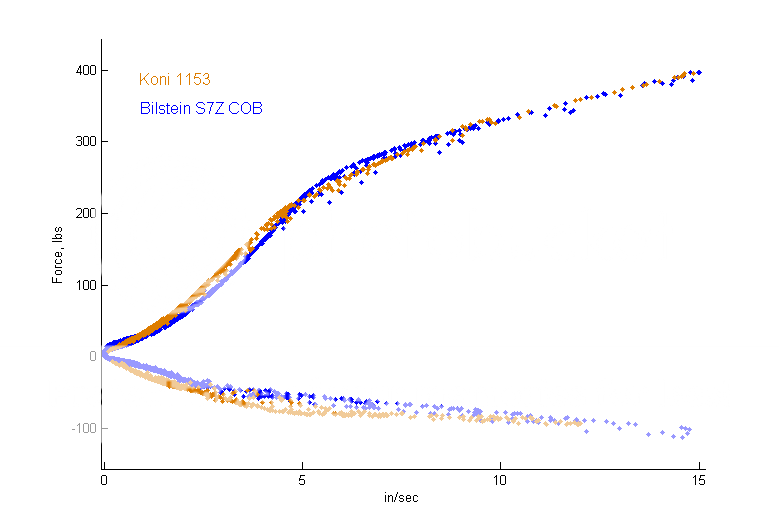

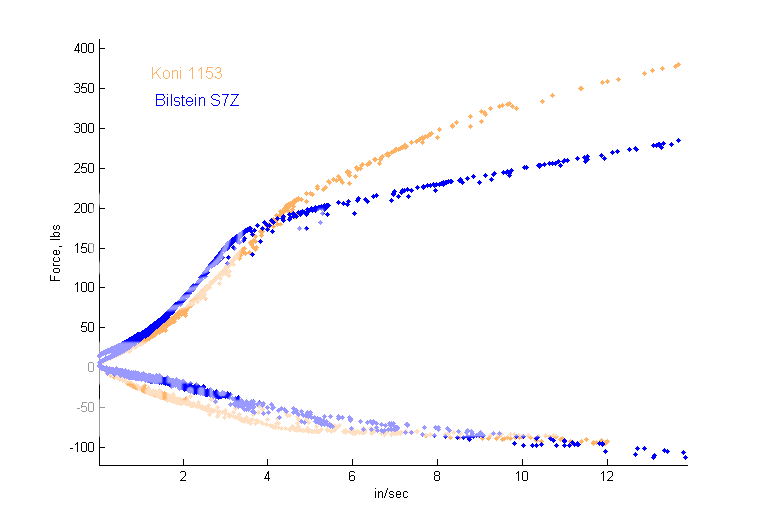

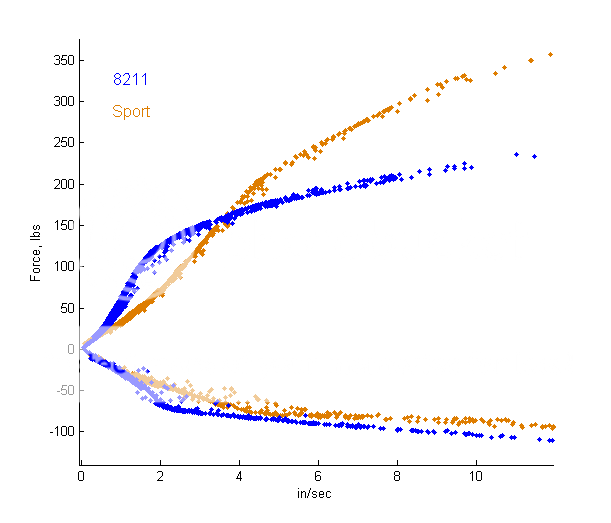

Here's a plot of 8211's previously compresession revalved by me and adjusted for 250# springs, vs Koni Yellow 1153's adjusted for 300# springs. By "adjusted", that means that I turned the ***** until it "felt about right". Keep in mind that I'm kind of an atypical driver. I like to drive on the curvy and bumpy backroads of northern California, so I like to adjust the shocks for ride comfort, swerve stability, and road holding ability. I don't use damping to tune "turn in" and these aren't optimized for "lap times" or anything.

So even though the 8211's were running softer springs, I still ended up with much more low speed damping and less high speed damping. As I mentioned in my other thread, I valved these to have a touch more compression damping than the sports.

What happens when you send a pathological waveform to these shocks?

OMG, it's all over the place!

How can something that Looks So Bad Feel So Good? First, I gotta take back my statement that the 8211's have less pathlologies than the 8041's. But there might be several reasons:

The 8211's run without any gas pressure, so maybe hysteresis or cavitation is a much bigger problem.

The 8211's where dyno'd with two spherical bearings, whereas the Sport had one rubber bushing. This shouldn't matter since the lvt doesn't measure the bushing deflection. I checked the acceleration on the two waveforms, and they're comparable.

Maybe it's pathological in such as way as to maximize comfort or some other positive attribute?

Maybe real world waveforms aren't really that bad and the "normal" dyno plot of the 8211's just works better for me?

Anyway, for the first round, I'm probably going to try and valve the Bilsteins to look like the 8211's, but maybe a touch less low speed rebound and a touch more high speed.

Sorry to disappoint, but since I like the performance of my 8211's more, I'm going to valve the Bilsteins to be more like them. Which reminds me, I put one of those on the dyno today.

Here's a plot of 8211's previously compresession revalved by me and adjusted for 250# springs, vs Koni Yellow 1153's adjusted for 300# springs. By "adjusted", that means that I turned the ***** until it "felt about right". Keep in mind that I'm kind of an atypical driver. I like to drive on the curvy and bumpy backroads of northern California, so I like to adjust the shocks for ride comfort, swerve stability, and road holding ability. I don't use damping to tune "turn in" and these aren't optimized for "lap times" or anything.

So even though the 8211's were running softer springs, I still ended up with much more low speed damping and less high speed damping. As I mentioned in my other thread, I valved these to have a touch more compression damping than the sports.

What happens when you send a pathological waveform to these shocks?

OMG, it's all over the place!

How can something that Looks So Bad Feel So Good? First, I gotta take back my statement that the 8211's have less pathlologies than the 8041's. But there might be several reasons:

The 8211's run without any gas pressure, so maybe hysteresis or cavitation is a much bigger problem.

The 8211's where dyno'd with two spherical bearings, whereas the Sport had one rubber bushing. This shouldn't matter since the lvt doesn't measure the bushing deflection. I checked the acceleration on the two waveforms, and they're comparable.

Maybe it's pathological in such as way as to maximize comfort or some other positive attribute?

Maybe real world waveforms aren't really that bad and the "normal" dyno plot of the 8211's just works better for me?

Anyway, for the first round, I'm probably going to try and valve the Bilsteins to look like the 8211's, but maybe a touch less low speed rebound and a touch more high speed.

#21

Honda-Tech Member

Join Date: Oct 2003

Location: Chicago

Posts: 6,619

Likes: 0

Received 0 Likes

on

0 Posts

The thread is coming along very nicely!

Couple questions:

1. What velocity do you focus on to match the valving to a certain spring rate?

2. How are you mounting your double-eyelet shocks?

Couple questions:

1. What velocity do you focus on to match the valving to a certain spring rate?

2. How are you mounting your double-eyelet shocks?

#22

Honda-Tech Member

Thread Starter

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by vinuneuro »</TD></TR><TR><TD CLASS="quote">The thread is coming along very nicely!

Couple questions:

1. What velocity do you focus on to match the valving to a certain spring rate?

2. How are you mounting your double-eyelet shocks?</TD></TR></TABLE>

1: I don't know. I just turn the **** on the adjusters until it "feels right". I find that if I set the damping too low, the car tends to get "floppy" and shoots back from bump too fast. If I set it too high, the ride gets harsher, and the car develops a new higher frequency bounciness, which might have to do with the wheels jacking down.

2. See here:

https://honda-tech.com/zerothread?id=2282475

Couple questions:

1. What velocity do you focus on to match the valving to a certain spring rate?

2. How are you mounting your double-eyelet shocks?</TD></TR></TABLE>

1: I don't know. I just turn the **** on the adjusters until it "feels right". I find that if I set the damping too low, the car tends to get "floppy" and shoots back from bump too fast. If I set it too high, the ride gets harsher, and the car develops a new higher frequency bounciness, which might have to do with the wheels jacking down.

2. See here:

https://honda-tech.com/zerothread?id=2282475

#23

Honda-Tech Member

Thread Starter

Oh, are you referring to the formula about 65% critical at low speed and 25% at high speed? Yeah, I guess I can calculate that

#25

Member

Join Date: Jun 2005

Location: Northern, CA, USA

Posts: 1,637

Likes: 0

Received 0 Likes

on

0 Posts

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by beanbag »</TD></TR><TR><TD CLASS="quote">Oh, are you referring to the formula about 65% critical at low speed and 25% at high speed? Yeah, I guess I can calculate that</TD></TR></TABLE>

I hear that allot the 65% critical dampening is a good starting place as read here as well. http://www.farnorthracing.com/....html

But I have no idea how to calculate it.

I hear that allot the 65% critical dampening is a good starting place as read here as well. http://www.farnorthracing.com/....html

But I have no idea how to calculate it.