Help with a broken head bolt thread slot b16a2

#1

Honda-Tech Member

Thread Starter

Join Date: Oct 2002

Location: Da boogie Down, Bronx, USA

Posts: 1,887

Likes: 0

Received 0 Likes

on

0 Posts

Hey guys, was wondering if anyone has ever had the thread the bolt goes thru that the Valve cover bolts down too break? i was changing the bolt threads on the head of my em1 and the damn metal thread housing broke off as i was putting on a oem thread bolt.. which if any epoxy is best to get this thing back on ? I figure i could epoxy it, hold the broken piece and thread the bolt in? There are alot of epoxy to choose from tho.. anyone know which I should use or another better method to fix this?

thanks in advance

thanks in advance

#2

Honda-Tech Member

What do you mean you were "changing the bolt threads"?

****, that's a **** position to be in...

That broken part is actually part of the cam cap correct? (I can't picture it in my head). Best thing I would consider is to replace the actual cam cap with another one. You will need to maybe hit a junkyard and see if you can source a used one. I wouldn't trust any type of epoxy on there, which if it doesn't hold(probably won't due to oil/temp), it will mean that chunk of metal will be rattling around your valvetrain and will destroy your engine.

Yes, the cam caps should never be just swapped about, but in the position your are in, I say you have no other choice. Install the new/used cap, torque everything to spec, let the engine idle for about 5-10 minutes. Remove the cap and inspect for excessive signs of rubbing/gouging/overheating. If all looks okay, let it idle for another 10min and then change the oil. If it looks bad, change the oil immediately, take dremmel with a polishing tool to the cap, reinstall and go back to idling the car. Change the oil after another day of driving and maybe another week later.

Good luck!

****, that's a **** position to be in...

That broken part is actually part of the cam cap correct? (I can't picture it in my head). Best thing I would consider is to replace the actual cam cap with another one. You will need to maybe hit a junkyard and see if you can source a used one. I wouldn't trust any type of epoxy on there, which if it doesn't hold(probably won't due to oil/temp), it will mean that chunk of metal will be rattling around your valvetrain and will destroy your engine.

Yes, the cam caps should never be just swapped about, but in the position your are in, I say you have no other choice. Install the new/used cap, torque everything to spec, let the engine idle for about 5-10 minutes. Remove the cap and inspect for excessive signs of rubbing/gouging/overheating. If all looks okay, let it idle for another 10min and then change the oil. If it looks bad, change the oil immediately, take dremmel with a polishing tool to the cap, reinstall and go back to idling the car. Change the oil after another day of driving and maybe another week later.

Good luck!

#3

Honda-Tech Member

Join Date: Jun 2014

Location: St. Louis, Missouri

Posts: 234

Likes: 0

Received 0 Likes

on

0 Posts

You could try finding a shop to weld it back on, I wouldn't trust epoxy, honestly the best thing to do is get a new head with matching cam caps. My car was stolen and they stole the camshafts and cam caps off the engine (crazy right?), so we got a used complete set of cam caps and had them line bored to the head and have been running like that for years with no issues.

The cam caps are specific to the head they come on, since they are line bored at the factory. I have seen people/heard of people doing what Joey1320 mentioned and they replace the one and make sure it isn't binding, etc...

The cam caps are specific to the head they come on, since they are line bored at the factory. I have seen people/heard of people doing what Joey1320 mentioned and they replace the one and make sure it isn't binding, etc...

#5

Honda-Tech Member

#6

This.

Cast aluminum is the ideal material for regular 2 part JB Weld cold weld.

clean both surfaces with non-chlorinated brake cleaner to remove all oil. Put the epxoy on and squeeze it together, with the bolt in place. If you can clamp it in place and let sit for over 24 hours, that would be best. Also, you can lightly lube the threads of the bolt with oil so the JB weld doesn't stick to it during the cure.

Don't tighten the bolt all the way down, have it a little loose. It's just to have the threades all aligned properly for the cure.

The other option is to clamp it without the bolt hand aligned as best as possible but you may need to retap to clean it up after it cures.

Cast aluminum is the ideal material for regular 2 part JB Weld cold weld.

clean both surfaces with non-chlorinated brake cleaner to remove all oil. Put the epxoy on and squeeze it together, with the bolt in place. If you can clamp it in place and let sit for over 24 hours, that would be best. Also, you can lightly lube the threads of the bolt with oil so the JB weld doesn't stick to it during the cure.

Don't tighten the bolt all the way down, have it a little loose. It's just to have the threades all aligned properly for the cure.

The other option is to clamp it without the bolt hand aligned as best as possible but you may need to retap to clean it up after it cures.

#7

Honda-Tech Member

Thread Starter

Join Date: Oct 2002

Location: Da boogie Down, Bronx, USA

Posts: 1,887

Likes: 0

Received 0 Likes

on

0 Posts

is that this product here? i dont daily the car so it can sit for over a week if i wanted too

CarGo Thermosteel Thermosteel 2400°F Cold Weld 18003TRI: Advance Auto Parts

Thanks in advance

Is that this?

CarGo Thermosteel Thermosteel 2400°F Cold Weld 18003TRI: Advance Auto Parts

Thanks in advance

Originally Posted by TomCat39

Cast aluminum is the ideal material for regular 2 part JB Weld cold weld.

clean both surfaces with non-chlorinated brake cleaner to remove all oil. Put the epxoy on and squeeze it together, with the bolt in place. If you can clamp it in place and let sit for over 24 hours, that would be best. Also, you can lightly lube the threads of the bolt with oil so the JB weld doesn't stick to it during the cure.

Don't tighten the bolt all the way down, have it a little loose. It's just to have the threades all aligned properly for the cure.

The other option is to clamp it without the bolt hand aligned as best as possible but you may need to retap to clean it up after it cures.

clean both surfaces with non-chlorinated brake cleaner to remove all oil. Put the epxoy on and squeeze it together, with the bolt in place. If you can clamp it in place and let sit for over 24 hours, that would be best. Also, you can lightly lube the threads of the bolt with oil so the JB weld doesn't stick to it during the cure.

Don't tighten the bolt all the way down, have it a little loose. It's just to have the threades all aligned properly for the cure.

The other option is to clamp it without the bolt hand aligned as best as possible but you may need to retap to clean it up after it cures.

Is that this?

Last edited by TomCat39; 02-25-2017 at 02:30 PM.

Trending Topics

#8

Fish Twig

Join Date: Nov 2005

Location: Still hunting that foo up there

Posts: 15,555

Received 309 Likes

on

285 Posts

gob that **** on there, make sure everything lines up. Try to thread the 10mm bolt in, if it doesn't just tap it to the same bolt thread. Done

#9

No that isn't it. This is, from the same website:

JB Weld Original Coldweld Epoxy 8265-S: Advance Auto Parts

JB Weld Original Coldweld Epoxy 8265-S: Advance Auto Parts

#10

-Intl Steve Krew

You could try finding a shop to weld it back on, I wouldn't trust epoxy, honestly the best thing to do is get a new head with matching cam caps. My car was stolen and they stole the camshafts and cam caps off the engine (crazy right?), so we got a used complete set of cam caps and had them line bored to the head and have been running like that for years with no issues.

The cam caps are specific to the head they come on, since they are line bored at the factory. I have seen people/heard of people doing what Joey1320 mentioned and they replace the one and make sure it isn't binding, etc...

The cam caps are specific to the head they come on, since they are line bored at the factory. I have seen people/heard of people doing what Joey1320 mentioned and they replace the one and make sure it isn't binding, etc...

It'd probably be cheaper to get a new cap and have it line bored to the head.

#11

-Intl Steve Krew

No that isn't it. This is, from the same website:

JB Weld Original Coldweld Epoxy 8265-S: Advance Auto Parts

JB Weld Original Coldweld Epoxy 8265-S: Advance Auto Parts

#12

That part looks like it only holds the valve cover.

I would not trust it if it's the cam cap. Only if it's a frame part off the cam cap that holds the valve cover on. Valve cover only bolts don't take much stress.

If it's a pass through to keep the cap clamped down over the cam..... It would need to be welded to have the strength.

But to my eyes, it's not. The cam cap bolts are the larger bolts with the reinforced aluminum piece and the stronger larger bolts, are they not?

I would not trust it if it's the cam cap. Only if it's a frame part off the cam cap that holds the valve cover on. Valve cover only bolts don't take much stress.

If it's a pass through to keep the cap clamped down over the cam..... It would need to be welded to have the strength.

But to my eyes, it's not. The cam cap bolts are the larger bolts with the reinforced aluminum piece and the stronger larger bolts, are they not?

#13

Honda-Tech Member

Thread Starter

Join Date: Oct 2002

Location: Da boogie Down, Bronx, USA

Posts: 1,887

Likes: 0

Received 0 Likes

on

0 Posts

That part looks like it only holds the valve cover.

I would not trust it if it's the cam cap. Only if it's a frame part off the cam cap that holds the valve cover on. Valve cover only bolts don't take much stress.

If it's a pass through to keep the cap clamped down over the cam..... It would need to be welded to have the strength.

But to my eyes, it's not. The cam cap bolts are the larger bolts with the reinforced aluminum piece and the stronger larger bolts, are they not?

I would not trust it if it's the cam cap. Only if it's a frame part off the cam cap that holds the valve cover on. Valve cover only bolts don't take much stress.

If it's a pass through to keep the cap clamped down over the cam..... It would need to be welded to have the strength.

But to my eyes, it's not. The cam cap bolts are the larger bolts with the reinforced aluminum piece and the stronger larger bolts, are they not?

#14

Honda-Tech Member

do people seriously think jb welding is the right answer? take it to get welded by someone who welds aluminum.

Last thing you want is for that thing to fall off and cause even more damage.

Last thing you want is for that thing to fall off and cause even more damage.

#15

If you research what JB weld was formulated for, you might have a better understanding of it's uses.

This particular part is a prime candidate. The key is only the clean up and prep. Do not sand it, do not scuff the mating surfaces, but clean it thoroughly with non-chlorinated brake cleaner so no residue is left behind and it will work well. And the reason you don't scuff or sand is the mating surfaces are broken cast so it's already rough and a perfect mate to each other, this makes for the strongest bond you can get.

If you don't clean the mating surfaces well enough, that is where the problem will occur.

Welding is the best answer of course. For me, I have no qualms of using JB weld for a situation like this because I know the limitations and strengths of the epoxy.

I also know just how much glue is used in the automotive industry now, it's all about the proper formula glue for the application. And know what applications are acceptable for a glue and what are not.

And I will close with this, JB Weld has been used to repair air fins on motors that the fins are still intact years later with all the heat and vibration. It's also been used for intake porting. Of all the places you would want to know it can't fall off is inside an air intake tube. Gasoline and chemicals don't seem to affect the epoxy and it performs for years.

If used correctly, JB weld is a very good epoxy.

#16

A thought occurred to me and I feel it's important to share.

What is the car being used for?

This detail has been overlooked in the suggested repair possibilities.

I think it's important to cover the possibilities of the car's uses as that will really dictate what kind of fix is appropriate or fitting.

Addendum:

To add on onto what is here for future searchers.

The B16 is a coveted motor and so for many, the ONLY answer is to weld or better.

I personally don't mind the use of JB weld and am willing to take the risk of using it and possible failure. Some may think failure is inevitable and they may be right.

However, for the above situation posted by the OP, you can minimize the risk. The fear is if the piece drops down into the valve springs and manages to wedge into the spring(s). It would be very much like if the spring binds and could cause substantial damage.

Here is a method to prevent that and would be the most likely route I would go if I was to use JB weld. For one, I wouldn't goop the crap out of the piece. For me, the more material (glue) you use, the higher chance of the stuff chipping away and falling into the oiling system.

After I cleaned and JB welded the piece into place. I would cut and shape some aluminum from a can, steel wire brush the mating surface and glue it to the bottom and sides of the whole arm. This way if the piece does break free, it won't fall into the head anywhere.

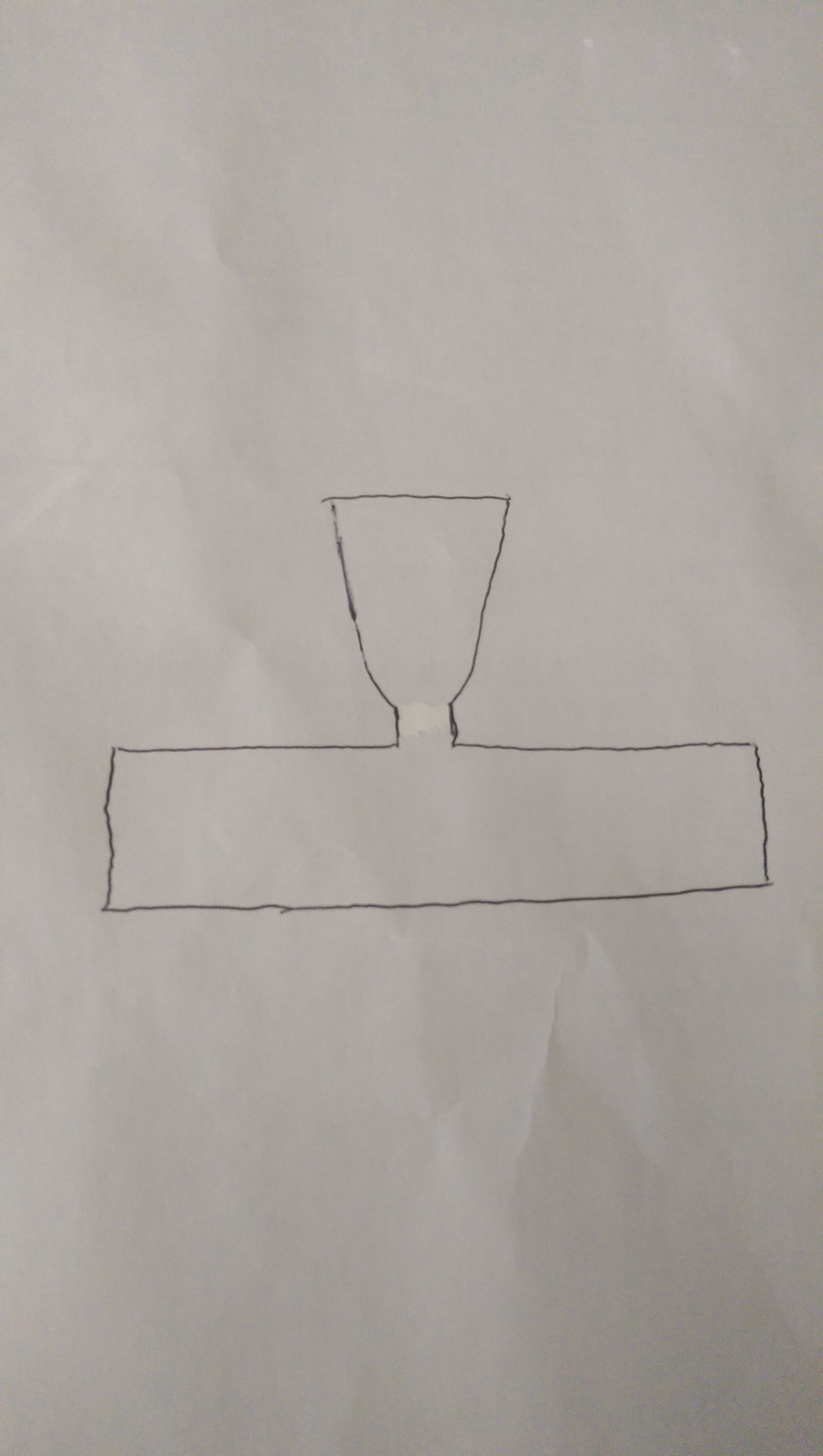

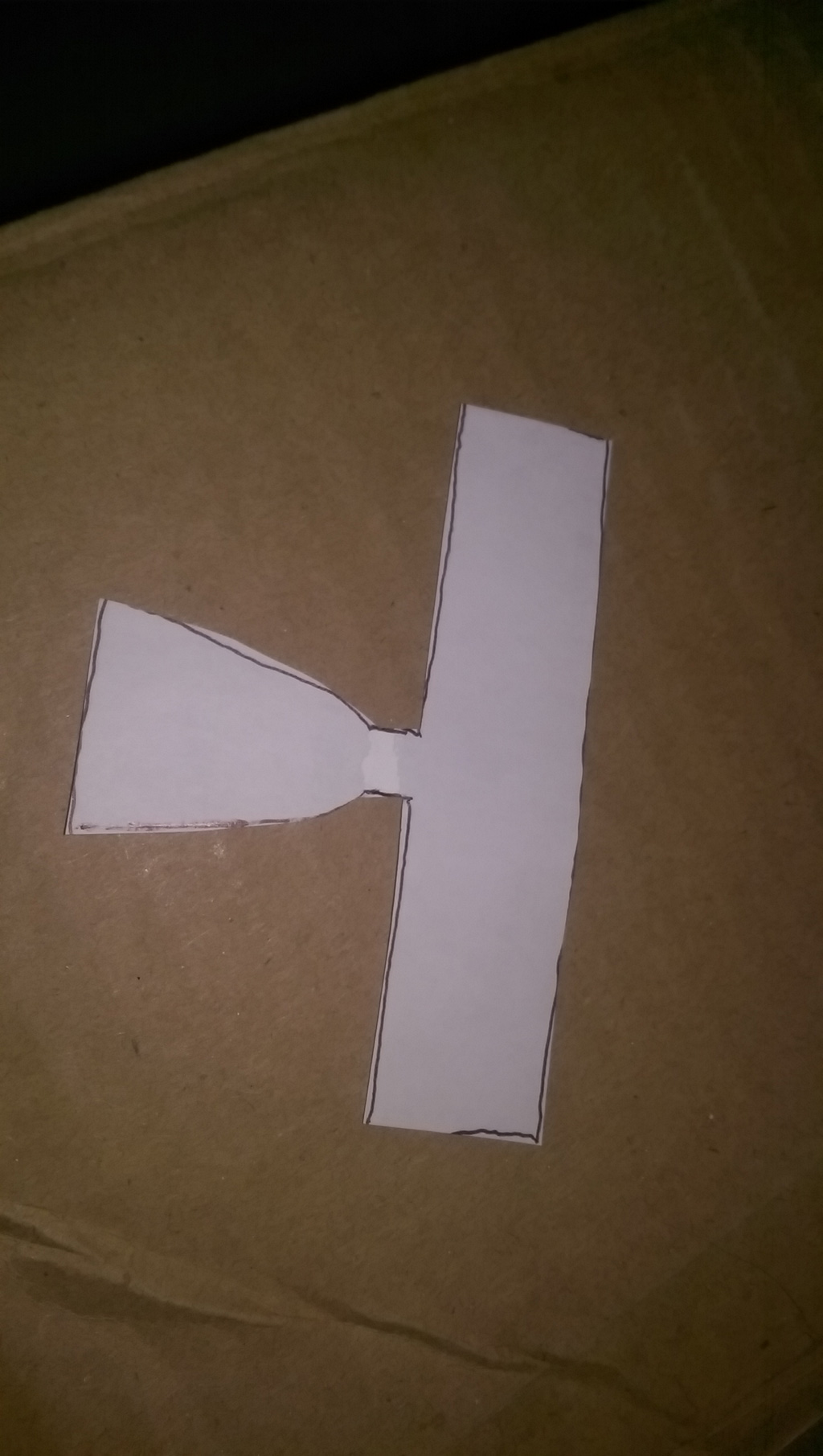

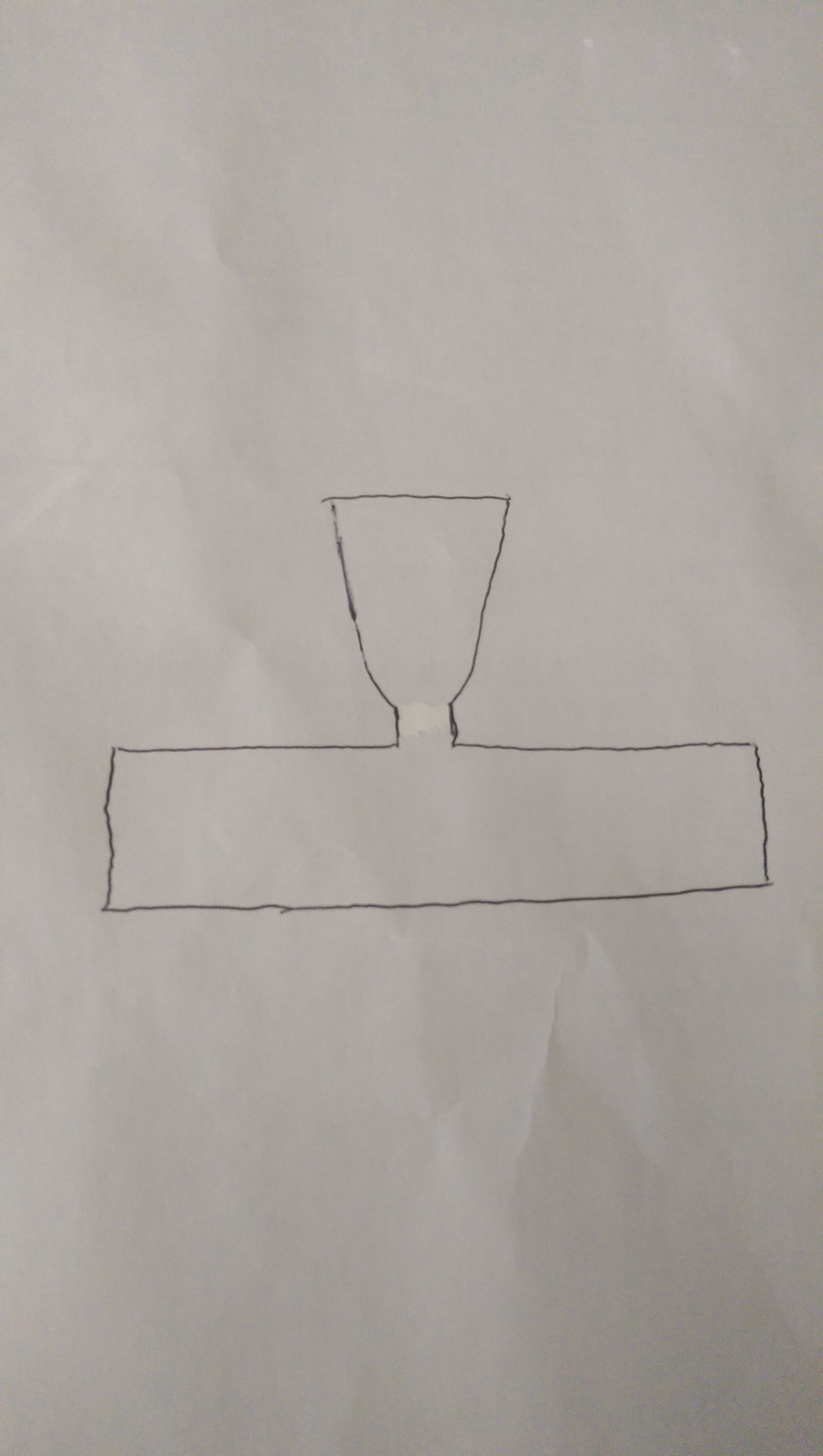

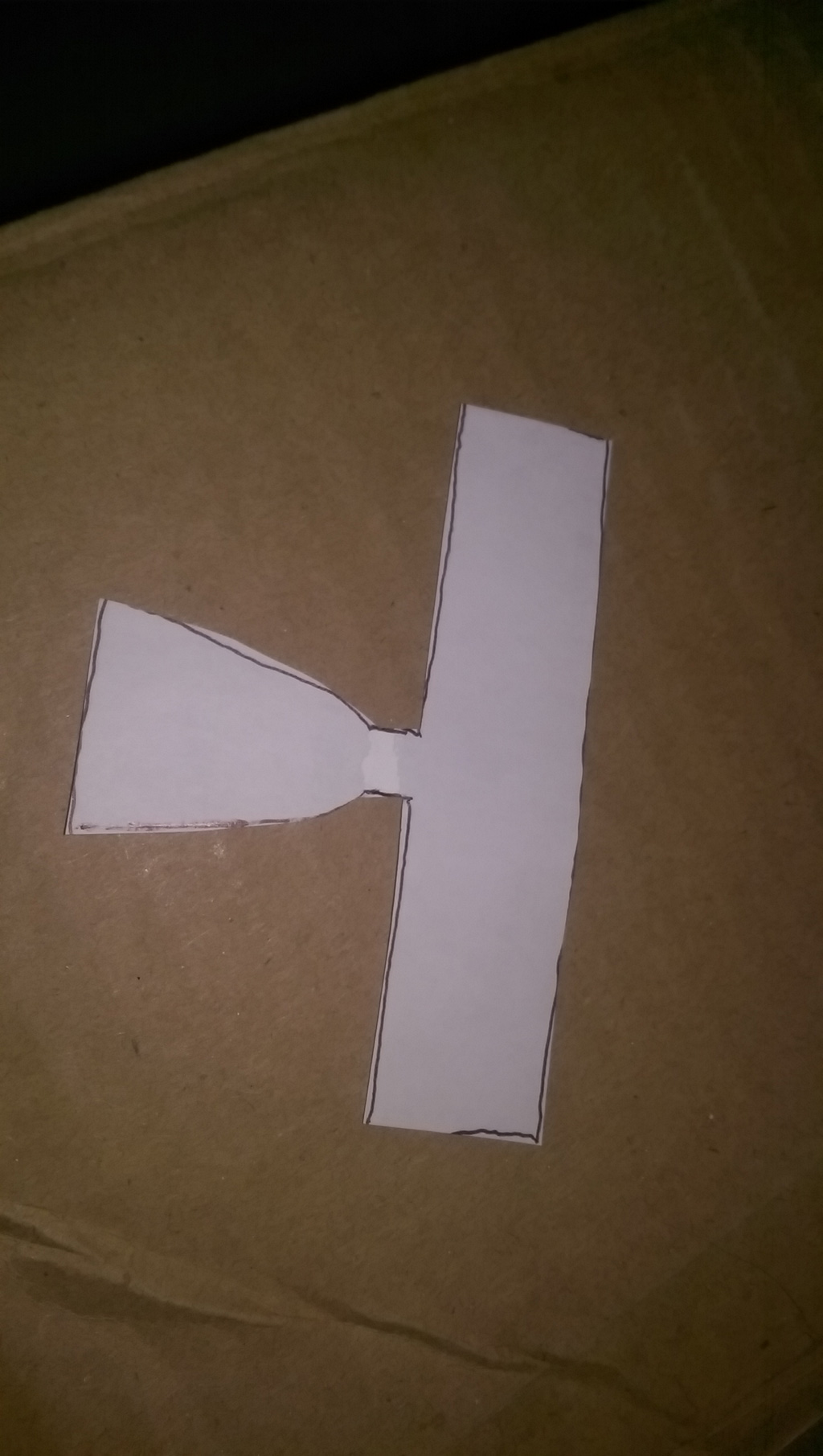

The piece would look like this:

Is this the right answer.... Probably not, would I do this, most definitely. Am I taking a risk, probably.

JB Weld is brittle and so if any crumbly bits (from failure) of it fall into the head, it will most likely travel down to the oil pan, and if it can pass the oil pickup screen (quite likely) it should be caught by the oil filter. If it passes the oil filter then something else is way wrong and the engine won't last anyway from the general neglect.

Let it be known, this is the most incorrect answer for many. Use at your own risk.

What is the car being used for?

This detail has been overlooked in the suggested repair possibilities.

- Show car trailer queen. Fix - New head or new cap and frame and machine work to restore to virgin OEM status.

- Keeper car not on display or extra concerned about aesthetics per say but do want the fix to last 50 years or more so you can hand the car down to the kids or grand kids. Fix - Weld and grind and tap.

- Daily driver likely going to be motor swapped down the road sometime or retired and junked, not going to sell to another user without disclosure. Fix - JB weld.

I think it's important to cover the possibilities of the car's uses as that will really dictate what kind of fix is appropriate or fitting.

Addendum:

To add on onto what is here for future searchers.

The B16 is a coveted motor and so for many, the ONLY answer is to weld or better.

I personally don't mind the use of JB weld and am willing to take the risk of using it and possible failure. Some may think failure is inevitable and they may be right.

However, for the above situation posted by the OP, you can minimize the risk. The fear is if the piece drops down into the valve springs and manages to wedge into the spring(s). It would be very much like if the spring binds and could cause substantial damage.

Here is a method to prevent that and would be the most likely route I would go if I was to use JB weld. For one, I wouldn't goop the crap out of the piece. For me, the more material (glue) you use, the higher chance of the stuff chipping away and falling into the oiling system.

After I cleaned and JB welded the piece into place. I would cut and shape some aluminum from a can, steel wire brush the mating surface and glue it to the bottom and sides of the whole arm. This way if the piece does break free, it won't fall into the head anywhere.

The piece would look like this:

Is this the right answer.... Probably not, would I do this, most definitely. Am I taking a risk, probably.

JB Weld is brittle and so if any crumbly bits (from failure) of it fall into the head, it will most likely travel down to the oil pan, and if it can pass the oil pickup screen (quite likely) it should be caught by the oil filter. If it passes the oil filter then something else is way wrong and the engine won't last anyway from the general neglect.

Let it be known, this is the most incorrect answer for many. Use at your own risk.

Last edited by TomCat39; 03-03-2017 at 12:47 PM.

#17

Honda-Tech Member

Thread Starter

Join Date: Oct 2002

Location: Da boogie Down, Bronx, USA

Posts: 1,887

Likes: 0

Received 0 Likes

on

0 Posts

I went ahead and just used the @tomcat39 method and it seems fine, thanks again again

#18

you can't jb weld or epoxy **** internally, its retarded...you will **** that engine up and b16a2's aren't cheap, please do yourself a favor and replace that part or just buy a used head on craigslist

#19

Honda-Tech Member

Thread

Thread Starter

Forum

Replies

Last Post

spidermancivic

Honda Civic / Del Sol (1992 - 2000)

5

10-03-2006 09:41 PM

B16CRXT

Tech / Misc

7

01-31-2004 09:20 PM