Turbo failure breakdown: Why proper maintenance is critical on turbo motors

#1

Who is Mr Robot?

Thread Starter

iTrader: (2)

Join Date: Jul 2004

Location: ATL - Where the Pimps and Players dwell

Posts: 21,474

Likes: 0

Received 10 Likes

on

10 Posts

So to most of the people on here proper maintenance is a common sense kind of thing, however, everyone else seems to be lacking. With a turbocharged car following a proper maintenance schedule, using quality fluids, and treating the car properly are the most important things for a reliable long term setup.

The most important maintenance item has to be engine oil. With a turbocharged motor a proper viscosity high grade synthetic with zinc and phosphorus is probably the best thing you can do. Most everyone still changes their oil every 3,000 miles but with the technological advances in oil it isn't a mandatory interval. Some oils will sustain a 7,500 mile oil change interval. Whatever interval you decide on, stick with it. A good way to figure out a proper oil change interval is to have your oil tested after so many thousand miles (3,000 5,000 7,500 and so on) to determine when it starts to break down.

You are about to see what happens to a turbocharger when you do not follow a set maintenance schedule...

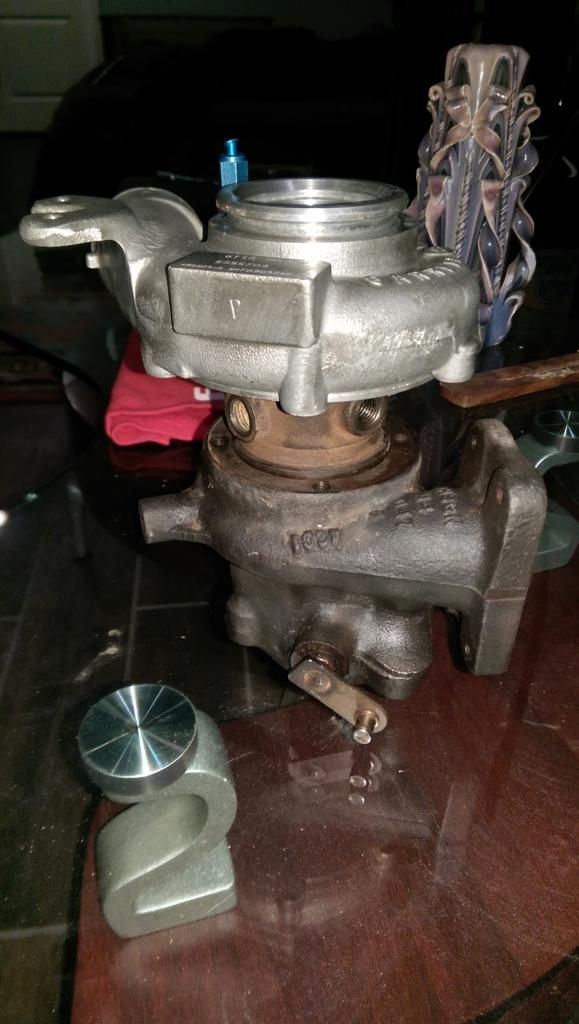

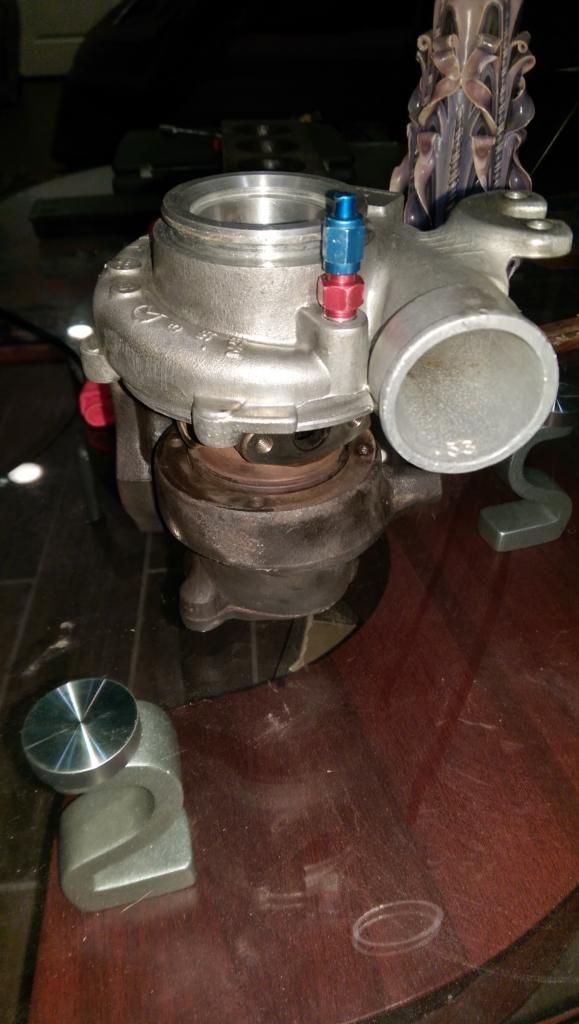

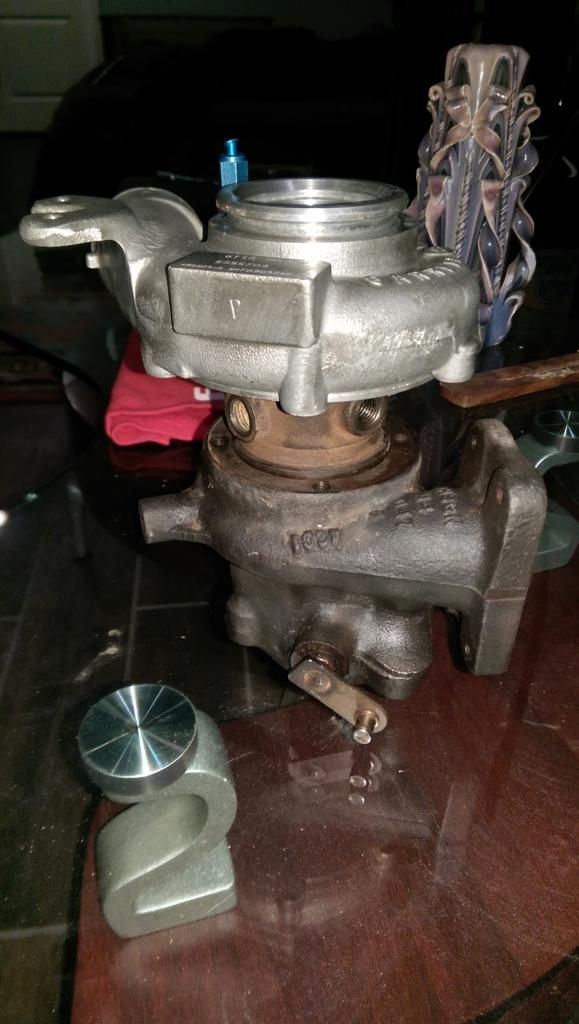

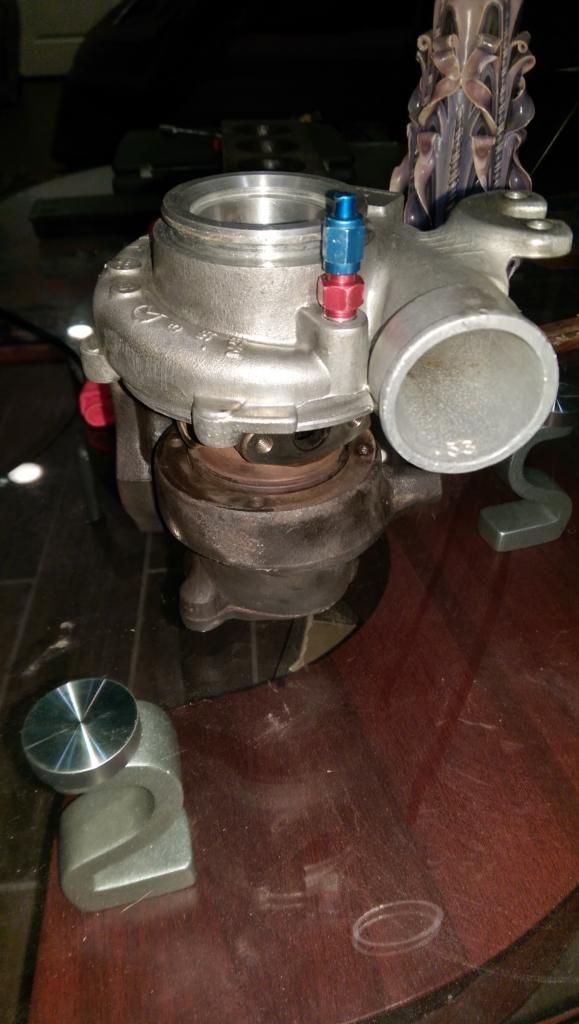

First some background on the turbocharger... I picked up this Garrett GT1752 a number of years ago for a turbo go kart project me and a friend were working on that we just ran out of time for. This turbo was used by Saab in their 9-5 chassis in a low pressure system. I picked it up for around 30-40 dollars knowing it needed a rebuild, however I didn't expect what I found when I finally tore it down last week.

Externally it looks just like any other turbo. There were no outward signs of a problem other than the excessive shaft play when you move the shaft.

However that quickly changed as soon as the compressor cover was removed.

You can see signs that the wheel contacted the housing both on the cover and the wheel itself. There are also signs that the compressor side seal is allowing oil to escape.

Story was also the same on the turbine side. You could see where the wheel touched the housing and signs of oil seepage (forgot to take photos before teardown)

It got really interesting once I started to disassemble the CHRA.

Once I removed the compressor wheel you could see on the back just how much oil had been seeping through the seal and just how hot the shaft got (slight heat patina around shaft area)

Pulling the turbine wheel I found even more signs of a lack of maintenance and a complete bearing system failure. You can see where the thrust play was so bad that the base of the turbine wheel actually wore through the heat shield. You can also see where the bottom of the blades has worn away from contact with the shield.

Inspecting the shaft and underneath the turbine heat shield I immediately noticed obvious signs of coking within the CHRA. You can also see discoloration from heat, I assume from the oiling passages being blocked by coke preventing the proper amount of oil to flow through the CHRA to cool it.

and that is after I cleaned both up a small amount so I could handle them without leaving a mess everywhere!

Now here's where it gets a bit weird. After removing the 4 bolts holding the backplate on I had to use a rubber mallet to get it loose. I don't know if there was a pre-existing fracture or if I did it but after 3 gentle taps the backplate broke in half.

The oil coking and varnish is clearly visible in the above photo.

From there teardown is what I expected to see... Lots of varnish and entirely too much coking on any surface oil touched.

You can also see signs of heat and oil on the outside edge of the compressor seal retainer

There are even signs of coking within the bearing itself

Better shot of the turbine end of the shaft. I think it speaks for itself

Even coke on the outside of the feed inlet!

So it is pretty evident from these photos that whoever owned the vehicle this turbo was removed from didn't follow any sort of maintenance schedule nor practice turbocharged vehicle basics, namely letting the turbo cool down before shutoff. Turbo is also water cooled but it didn't seem to matter in this instance.

This person must have changed the oil whenever convenient a few times past the point of oil breakdown and there's no telling what grade, viscosity, or quality of oil was used. It's also obvious they didn't let the car idle for any significant period of time before turning the motor off.

Follow basic maintenance and common sense and you too can avoid this fate for you turbocharger

The most important maintenance item has to be engine oil. With a turbocharged motor a proper viscosity high grade synthetic with zinc and phosphorus is probably the best thing you can do. Most everyone still changes their oil every 3,000 miles but with the technological advances in oil it isn't a mandatory interval. Some oils will sustain a 7,500 mile oil change interval. Whatever interval you decide on, stick with it. A good way to figure out a proper oil change interval is to have your oil tested after so many thousand miles (3,000 5,000 7,500 and so on) to determine when it starts to break down.

You are about to see what happens to a turbocharger when you do not follow a set maintenance schedule...

First some background on the turbocharger... I picked up this Garrett GT1752 a number of years ago for a turbo go kart project me and a friend were working on that we just ran out of time for. This turbo was used by Saab in their 9-5 chassis in a low pressure system. I picked it up for around 30-40 dollars knowing it needed a rebuild, however I didn't expect what I found when I finally tore it down last week.

Externally it looks just like any other turbo. There were no outward signs of a problem other than the excessive shaft play when you move the shaft.

However that quickly changed as soon as the compressor cover was removed.

You can see signs that the wheel contacted the housing both on the cover and the wheel itself. There are also signs that the compressor side seal is allowing oil to escape.

Story was also the same on the turbine side. You could see where the wheel touched the housing and signs of oil seepage (forgot to take photos before teardown)

It got really interesting once I started to disassemble the CHRA.

Once I removed the compressor wheel you could see on the back just how much oil had been seeping through the seal and just how hot the shaft got (slight heat patina around shaft area)

Pulling the turbine wheel I found even more signs of a lack of maintenance and a complete bearing system failure. You can see where the thrust play was so bad that the base of the turbine wheel actually wore through the heat shield. You can also see where the bottom of the blades has worn away from contact with the shield.

Inspecting the shaft and underneath the turbine heat shield I immediately noticed obvious signs of coking within the CHRA. You can also see discoloration from heat, I assume from the oiling passages being blocked by coke preventing the proper amount of oil to flow through the CHRA to cool it.

and that is after I cleaned both up a small amount so I could handle them without leaving a mess everywhere!

Now here's where it gets a bit weird. After removing the 4 bolts holding the backplate on I had to use a rubber mallet to get it loose. I don't know if there was a pre-existing fracture or if I did it but after 3 gentle taps the backplate broke in half.

The oil coking and varnish is clearly visible in the above photo.

From there teardown is what I expected to see... Lots of varnish and entirely too much coking on any surface oil touched.

You can also see signs of heat and oil on the outside edge of the compressor seal retainer

There are even signs of coking within the bearing itself

Better shot of the turbine end of the shaft. I think it speaks for itself

Even coke on the outside of the feed inlet!

So it is pretty evident from these photos that whoever owned the vehicle this turbo was removed from didn't follow any sort of maintenance schedule nor practice turbocharged vehicle basics, namely letting the turbo cool down before shutoff. Turbo is also water cooled but it didn't seem to matter in this instance.

This person must have changed the oil whenever convenient a few times past the point of oil breakdown and there's no telling what grade, viscosity, or quality of oil was used. It's also obvious they didn't let the car idle for any significant period of time before turning the motor off.

Follow basic maintenance and common sense and you too can avoid this fate for you turbocharger

#2

Who is Mr Robot?

Thread Starter

iTrader: (2)

Join Date: Jul 2004

Location: ATL - Where the Pimps and Players dwell

Posts: 21,474

Likes: 0

Received 10 Likes

on

10 Posts

If I had to take a stab at the series of events leading up to the complete failure it would be as follows...

Owner ignores any sort of maintenance routine

Over time oil breakdown and hot shutoffs start causing oil to coke, reducing oil flow to vital components.

The turbo starts to develop shaft play from reduced oil flow.

Shaft play becomes so bad that the thrust bearing fails, allowing wheels to contact housing and eventually wear down certain components

Thrust play eventually damages both oil seals, at this point the amount of smoke from the exhaust would be impossible to miss

Guy probably kept driving even then until the turbo could no longer maintain any sort of functional shaft speed at which point the power loss would be evident and the turbo was finally removed, or considering the engine itself was probably in similar or worse condition, scrapped.

Owner ignores any sort of maintenance routine

Over time oil breakdown and hot shutoffs start causing oil to coke, reducing oil flow to vital components.

The turbo starts to develop shaft play from reduced oil flow.

Shaft play becomes so bad that the thrust bearing fails, allowing wheels to contact housing and eventually wear down certain components

Thrust play eventually damages both oil seals, at this point the amount of smoke from the exhaust would be impossible to miss

Guy probably kept driving even then until the turbo could no longer maintain any sort of functional shaft speed at which point the power loss would be evident and the turbo was finally removed, or considering the engine itself was probably in similar or worse condition, scrapped.

#3

I never narc'd on nobody!

iTrader: (1)

You overestimate the average car owner, wantboost. My boss has a 9-3. She had no clue the turbo was shot until she was blowing blue smoke. Replaced it. Then her charge piping cracked. No pressure = no power, but she didn't even notice a difference. If the CEL hadn't come on, she wouldn't have even known there was a problem.

That being said...it's such a cute little tiny thing!

That being said...it's such a cute little tiny thing!

#4

Honda-Tech Member

Join Date: Dec 2014

Location: Baltimore, MD

Posts: 647

Likes: 0

Received 0 Likes

on

0 Posts

That's a disgusting looking internal to a turbo. This is the exact reason I break my bank and go for new turbos every time. I really go new with everything. The only used part I put on my vitara build last month was an oem b20 iat sensor just so I could screw in to the charge piping vs my y8 iat sensor that blows out under any decent psi.

Thanks for the display and making me feel better about splurging on new turbos.

Thanks for the display and making me feel better about splurging on new turbos.

#6

I was talking about oil change intervals yesterday at work, one guy with an older diesel dodge blew my mind and said his truck has a 16 quart capacity or something crazy, he then made my jaw drop when he thought that meant he didnt have to change his oil in 50,0000km (30k miles?)..... needless to say his truck runs like crap and makes blue clouds, Id imagine his turbo is quite similar internally.

Im assuming your turbo is most likely headed for the parts pile, maybe sell the housings?

Im assuming your turbo is most likely headed for the parts pile, maybe sell the housings?

#7

Honda-Tech Member

Join Date: Dec 2014

Location: Baltimore, MD

Posts: 647

Likes: 0

Received 0 Likes

on

0 Posts

I give a compliment and says thanks for the breakdown and say this is why I don't trust used turbos. Never said it was a comparison and that's the response I get. Habitual pessimism, its hard to break free from in this world

Last edited by ek9_beast; 01-26-2015 at 04:42 PM.

Trending Topics

#8

Moderator

iTrader: (14)

This is going WAY over your head. ek9_beast. No one was asking for complement or criticism regarding this phenomenon. These symptoms can easily happen to a brand new turbocharger as in as much as it could happen to a used system. Proper maintenance begins the minute the turbo is mounted, oil feed installed, and the car turned over and running with the proper equipment. But this thread was a good idea because many a new turbocharger prematurely die simply because the owner got cheap in using substandard equipment (improper restrictor styles, makeshift feed lines, improperly run return lines, etc.). But instead of being true to self, they want to make a warranty claim on something that in its very nature is not feasible.

This thread doesn't appear to show pessimism, optimism, or cordiality. This is reality when it comes to care of any turbocharger regardless of make, model, or purpose. Some are inherently more sensitive to oil conditions than others, but it still bases itself moreso on the shoulders of the owner.

No one's feelings should be hurt here. This is strictly informational. If it helps you sleep better at night to get new, great.. But that wasn't the intent from what I can see.

This thread doesn't appear to show pessimism, optimism, or cordiality. This is reality when it comes to care of any turbocharger regardless of make, model, or purpose. Some are inherently more sensitive to oil conditions than others, but it still bases itself moreso on the shoulders of the owner.

No one's feelings should be hurt here. This is strictly informational. If it helps you sleep better at night to get new, great.. But that wasn't the intent from what I can see.

#9

Who is Mr Robot?

Thread Starter

iTrader: (2)

Join Date: Jul 2004

Location: ATL - Where the Pimps and Players dwell

Posts: 21,474

Likes: 0

Received 10 Likes

on

10 Posts

Yea sorry I didn't mean to come off as an ***.

This is basically what happens (over a long period of time) when you don't properly maintain a turbocharged drivetrain (or really any motor for that matter). The kind of coking seen in this CHRA would take years of misuse to form, especially on the oil feed port that isn't even inside the CHRA. On a new turbocharger it would take at least a year for any signs of oil coking to show up externally, mostly as small signs when you change the oil, if you ran the discharge through a screen. Damage can occur much faster though if adequate considerations are not given to the feed line, return, coolant lines, and so on.

Even though the 1752 is small, this is me holding the compressor cover in my hand below, I find it strangely interesting.

I'll probably end up rebuilding it... either with an extended tip billet 1752 replacement wheel or I'll snag the backplate and cover from a gt2056s which is a direct replacement for the 1752 components at which point I'll probably put a standard replacement billet wheel in it, along with porting the turbine housing... it really needs loving in that area. I have a few small displacement low boost projects that might be popping up soon and this would be a good candidate for one.

When you consider that I can buy another core 1752 for a mere 45 dollars I've already saved money on buying a new backplate.

Part of me is fighting the urge to try this in a small compound setup on a smaller displacement hyper mileage setup. maybe a 1752 as primary with a t25, gt25, or similar sized turbo as the secondary atmospheric turbo.

The curse of having too many turbos I suppose

This is basically what happens (over a long period of time) when you don't properly maintain a turbocharged drivetrain (or really any motor for that matter). The kind of coking seen in this CHRA would take years of misuse to form, especially on the oil feed port that isn't even inside the CHRA. On a new turbocharger it would take at least a year for any signs of oil coking to show up externally, mostly as small signs when you change the oil, if you ran the discharge through a screen. Damage can occur much faster though if adequate considerations are not given to the feed line, return, coolant lines, and so on.

Even though the 1752 is small, this is me holding the compressor cover in my hand below, I find it strangely interesting.

I'll probably end up rebuilding it... either with an extended tip billet 1752 replacement wheel or I'll snag the backplate and cover from a gt2056s which is a direct replacement for the 1752 components at which point I'll probably put a standard replacement billet wheel in it, along with porting the turbine housing... it really needs loving in that area. I have a few small displacement low boost projects that might be popping up soon and this would be a good candidate for one.

When you consider that I can buy another core 1752 for a mere 45 dollars I've already saved money on buying a new backplate.

Part of me is fighting the urge to try this in a small compound setup on a smaller displacement hyper mileage setup. maybe a 1752 as primary with a t25, gt25, or similar sized turbo as the secondary atmospheric turbo.

The curse of having too many turbos I suppose

#10

Honda-Tech Member

Join Date: Dec 2014

Location: Baltimore, MD

Posts: 647

Likes: 0

Received 0 Likes

on

0 Posts

That statement came from WAY more than this thread alone. We all have a common goal and its learning more. I found this informative, that was it and left an opinion like every other person does. Theres enough bs that comes at us the honda world without upsizing each other. Its cool regardless guys.

Thread

Thread Starter

Forum

Replies

Last Post

You Know I Got SOL!

Forced Induction

23

07-12-2006 06:38 PM

vtec.dc2

Forced Induction

10

01-07-2003 07:17 PM