i noticed this upon engine tear down...

#1

Honda-Tech Member

Thread Starter

Join Date: Feb 2003

Location: schooling kids in ny, usa

Posts: 9,813

Likes: 0

Received 9 Likes

on

9 Posts

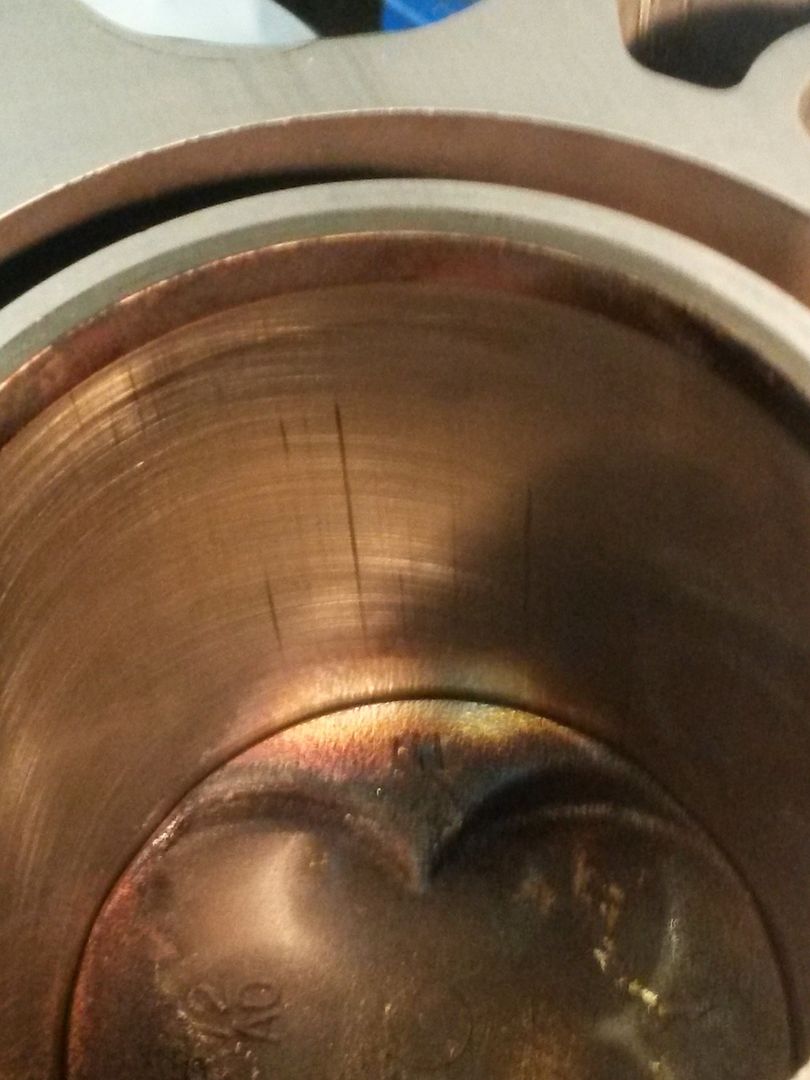

So this motor had a bit of an issue with detonation which i guess im blaming on oil contamination in the cylinders. it was only able to tolerate quite low timing values before the knocksense became active. whats up with the lines on the cyl walls. they arent deep and just barely catch the fingernail if at all. if they were located only on the thrust surfaces id assume it to be wear or improper ptw but these are at random spots around the bore. did i get something in the oil?

speaking of oil, this is what the valve stems looked like.

look like leaking valve seals?... most of the cyls had some oil on the stems most noticeable toward the bottom and ending in a very small pool when it fans out onto the valve but none of it reached all the way to the outside of the valve face. just trying to get a solid handle so i can learn from my mistakes and rebuild it better.

82x89mm lsvtec, gsr pistons on ls rods which were milled down to accept the pistons. the head was stock itr valvetrain (minus valves) and cams in a pr3 head. zeal says static was like 10.8:1

#2

Honda-Tech Member

If I had to guess, I'd say the ptw was maybe a bit tight. Since its not in line with the ring gaps (or shouldn't be), I'd say the rings are not the cause (initial thought was a bur or sharp age on the ring gap).

Did you have an external crankcase breather? If so all the oil vapor should be vented to atmosphere if that's how you have it setup and should not recirculate back in the intake. I'd say valveseals would most likely be the culprit.

Did you have an external crankcase breather? If so all the oil vapor should be vented to atmosphere if that's how you have it setup and should not recirculate back in the intake. I'd say valveseals would most likely be the culprit.

#4

Honda-Tech Member

Thread Starter

Join Date: Feb 2003

Location: schooling kids in ny, usa

Posts: 9,813

Likes: 0

Received 9 Likes

on

9 Posts

slight chance but id say no offhand. it didnt smoke or burn oil or anything.

i ran two -12's off the valve cover to a catchcan it was the setup from my turbo motor. i will certainly be measuring the ptw when i pull the block apart i told the machine shop between .0015 and .002 but who knows. i can see where the top ring is and its on the exhaust side off of the side valve relief

i ran two -12's off the valve cover to a catchcan it was the setup from my turbo motor. i will certainly be measuring the ptw when i pull the block apart i told the machine shop between .0015 and .002 but who knows. i can see where the top ring is and its on the exhaust side off of the side valve relief

#5

DO IT ON ALL FOURS

Looks like stuck rings or broken lands / rings to me too and even more so since you say you can lightly catch a nail on them. The bores are pretty hard compared to the pistons and such. Did you file fit the rings? If so, did you check for rotation by compressing them into the ring grooves?

It also depends on which ring broke or is hanging up as well. I have seen rings break when using a ring compressor to install pistons. In one instance the engine ran seemingly fine, but always had oil in one cylinder. No smoke really due to catalytic converter burning it off would be my guess. There is a slight chance it could also be too tight of PTW clearance, but I am skeptical due to the way your bores look.

As far as the valves go, definitely leaking valve stem seals. This could be because the valve guides are worn though and it's happening more when the engine is seeing high RPM. The fuel will help clean off the underhead part of the valve. Just think about how the airflow hits the valve and is forcibly disrupted into the chamber.

It also depends on which ring broke or is hanging up as well. I have seen rings break when using a ring compressor to install pistons. In one instance the engine ran seemingly fine, but always had oil in one cylinder. No smoke really due to catalytic converter burning it off would be my guess. There is a slight chance it could also be too tight of PTW clearance, but I am skeptical due to the way your bores look.

As far as the valves go, definitely leaking valve stem seals. This could be because the valve guides are worn though and it's happening more when the engine is seeing high RPM. The fuel will help clean off the underhead part of the valve. Just think about how the airflow hits the valve and is forcibly disrupted into the chamber.

#6

i had similar markings on a h22a that i broke ringlands on spraying a 60 wet shot...though you could not catch a nail on them in my situation, but the marks look the same.

Trending Topics

#8

Honda-Tech Member

that happened to me when i picked up a b18b block, it was the piston rings ,i changed them and used a flex-a-hone to hone the block

#9

Honda-Tech Member

Thread Starter

Join Date: Feb 2003

Location: schooling kids in ny, usa

Posts: 9,813

Likes: 0

Received 9 Likes

on

9 Posts

from what i can see the top ring did slide around, maybe about 1/8th of the way in the bore. was contributing that to the bit of knocking the motor saw. rings are je proseal's actually from a vr6. they were 82mm bore and had the same 1/1.2/2.8 thicknesses. motor was assembled using a fixed bore 82mm ring compressor.

it only had a few thousand miles on it and was really to keep my car up and running while i rebuilt the turbo motor and setup. still though i want to know what happened so i can put this back together and keep it as a spare motor. i may disassemble the block today but i gotta see if i have time before i go see Van Halen tonight lol!

it only had a few thousand miles on it and was really to keep my car up and running while i rebuilt the turbo motor and setup. still though i want to know what happened so i can put this back together and keep it as a spare motor. i may disassemble the block today but i gotta see if i have time before i go see Van Halen tonight lol!

#10

Honda-Tech Member

Thread Starter

Join Date: Feb 2003

Location: schooling kids in ny, usa

Posts: 9,813

Likes: 0

Received 9 Likes

on

9 Posts

van halen was fantastic, this motor not so much..

#2 and 3 cyls intake side. you can see the groves run almost the whole bore.

#2 cyl exhaust side. looks like too tight ptw?? the notch at the bottom of the bore is from the original oe motor spun some rod bearings. this build has been bored/honed over twice and is using different rods, crank, pistons etc...

upper rod bearing, i think #3 cyl. acl race spec'd out at .002. does it look a bit blue in spots or is it just me? the rod had no discoloration. motor always had good oil pressure.

#3 piston exhaust side. you can see the rings rotated to be almost aligned. they were 90* off on assembly with the top ring remaining almost stationary and the 2nd ring rotating over from the intake side. could they have rotated due to the bit of det. the motor experienced?

#2 piston intake side where the worst scoring was. you can also see all the little black bits of carbon. they were everywhere. are they abrasive enough to scratch the piston/sleeve if they got into the oil and got in between.

just looking to retrace the issues with this about why it was all fudged up and knocking so i can avoid the same issues in the future.

#2 and 3 cyls intake side. you can see the groves run almost the whole bore.

#2 cyl exhaust side. looks like too tight ptw?? the notch at the bottom of the bore is from the original oe motor spun some rod bearings. this build has been bored/honed over twice and is using different rods, crank, pistons etc...

upper rod bearing, i think #3 cyl. acl race spec'd out at .002. does it look a bit blue in spots or is it just me? the rod had no discoloration. motor always had good oil pressure.

#3 piston exhaust side. you can see the rings rotated to be almost aligned. they were 90* off on assembly with the top ring remaining almost stationary and the 2nd ring rotating over from the intake side. could they have rotated due to the bit of det. the motor experienced?

#2 piston intake side where the worst scoring was. you can also see all the little black bits of carbon. they were everywhere. are they abrasive enough to scratch the piston/sleeve if they got into the oil and got in between.

just looking to retrace the issues with this about why it was all fudged up and knocking so i can avoid the same issues in the future.

#11

DO IT ON ALL FOURS

That thing was definitely running hot and most certainly detonating at times. Do you have an EGT gauge?

The second picture is the classic skirt scuffing you find with heavy piston contact. Obviously, you already took it apart and verified the skirt is trashed. Look at where it was happening in the bore - when the piston is near it's highest. This gives you insight that either you have a tapered bore or the more likely scenario that there were very high EGTs.

There is a very high possibility that they didn't machine the bores to your spec. It happens ALL the time with machine shops. They are the machinist and know better than you... LOL! Did you hone your own cylinders? The cross hatching looks a little too horizontal to me.

The second picture is the classic skirt scuffing you find with heavy piston contact. Obviously, you already took it apart and verified the skirt is trashed. Look at where it was happening in the bore - when the piston is near it's highest. This gives you insight that either you have a tapered bore or the more likely scenario that there were very high EGTs.

There is a very high possibility that they didn't machine the bores to your spec. It happens ALL the time with machine shops. They are the machinist and know better than you... LOL! Did you hone your own cylinders? The cross hatching looks a little too horizontal to me.

#12

Honda-Tech Member

Thread Starter

Join Date: Feb 2003

Location: schooling kids in ny, usa

Posts: 9,813

Likes: 0

Received 9 Likes

on

9 Posts

I do have an egt I dont remember it being any more than 700c. I di did not hone this one it was all machine shop. I told them I wanted between .0015 and .002 ptw. I know it was detonating I had a calibrated knocksense on it so I backed the timing off a bunch to keep it from knocking. I think it was down to like 24 total degrees in vtec afr mid to high 12s.

im just trying to redo the sequence of events that made it be like this. leaking oil from bad valve seals reduced octane causing knock leading to the damage?

im just trying to redo the sequence of events that made it be like this. leaking oil from bad valve seals reduced octane causing knock leading to the damage?

#13

DO IT ON ALL FOURS

1,300° F max during WOT? Definitely on the lower end of the middle. I assume it's on #3, but how far away from the head?

24° total with no turbo? Dang. Well of course there is always the possibility that oil was diluting your gas or that you were getting bad gas. With that being said, I am skeptical a significant amount of oil was being pulled in for that. Anything is a possibility.

I would verify your PTW clearances were set properly...

24° total with no turbo? Dang. Well of course there is always the possibility that oil was diluting your gas or that you were getting bad gas. With that being said, I am skeptical a significant amount of oil was being pulled in for that. Anything is a possibility.

I would verify your PTW clearances were set properly...

#14

Honda-Tech Member

Thread Starter

Join Date: Feb 2003

Location: schooling kids in ny, usa

Posts: 9,813

Likes: 0

Received 9 Likes

on

9 Posts

there's the header i used maybe 2" max from the head. ill swap the egt gauge with the one in my other car (both greddys) see if it was broken. ill also check the ptw ive got the feeling it was tight

#16

Honda-Tech Member

Thread Starter

Join Date: Feb 2003

Location: schooling kids in ny, usa

Posts: 9,813

Likes: 0

Received 9 Likes

on

9 Posts

im not sure but id hope so for the boring at a minimum. when I hone blocks myself I dont have a tq plate and those motors dont seem to have any issues. ..

#17

Honda-Tech Member

Join Date: Jan 2008

Location: Ottawa, ON, Canada

Posts: 177

Likes: 0

Received 0 Likes

on

0 Posts

The wall scoring on Cylinder #2 is bad. It's common to find ware marks on the thrust sides of the walls, I'd be more inclined to say that the bores are egg shaped and not a general 'to tight' on the PTW clearance.

You said that you used a fixed bore ring compressor which to me is the only way to do things. They are miles better than any other ring compressor for the simple reason that you can keep the rings in the correct orientation.

Are the JE Pro Seal rings low tension?

What kinda of valve seals are you using?

You said that you used a fixed bore ring compressor which to me is the only way to do things. They are miles better than any other ring compressor for the simple reason that you can keep the rings in the correct orientation.

Are the JE Pro Seal rings low tension?

What kinda of valve seals are you using?

#18

Honda-Tech Member

Thread Starter

Join Date: Feb 2003

Location: schooling kids in ny, usa

Posts: 9,813

Likes: 0

Received 9 Likes

on

9 Posts

these were supertech valve seals. i had oe seals in the head on the last build and they leaked so i replaced them with supertechs. that stopped the oil dripping into the cyls so i figured they were good to go still...

not sure about the je rings, they are just the shelf ones. actually they were for a vr6 which comes stock bore 82mm and the same 1,1.2,2.8 thicknesses. is there a good high tension ring set that comes recommended?

again im curious, is the carbon buildup from the cylinders enough in its own right to get between the skirt and cylinder and scratch the walls up?

not sure about the je rings, they are just the shelf ones. actually they were for a vr6 which comes stock bore 82mm and the same 1,1.2,2.8 thicknesses. is there a good high tension ring set that comes recommended?

again im curious, is the carbon buildup from the cylinders enough in its own right to get between the skirt and cylinder and scratch the walls up?

The wall scoring on Cylinder #2 is bad. It's common to find ware marks on the thrust sides of the walls, I'd be more inclined to say that the bores are egg shaped and not a general 'to tight' on the PTW clearance.

You said that you used a fixed bore ring compressor which to me is the only way to do things. They are miles better than any other ring compressor for the simple reason that you can keep the rings in the correct orientation.

Are the JE Pro Seal rings low tension?

What kinda of valve seals are you using?

You said that you used a fixed bore ring compressor which to me is the only way to do things. They are miles better than any other ring compressor for the simple reason that you can keep the rings in the correct orientation.

Are the JE Pro Seal rings low tension?

What kinda of valve seals are you using?

#19

Honda-Tech Member

Join Date: Jan 2008

Location: Ottawa, ON, Canada

Posts: 177

Likes: 0

Received 0 Likes

on

0 Posts

these were supertech valve seals. i had oe seals in the head on the last build and they leaked so i replaced them with supertechs. that stopped the oil dripping into the cyls so i figured they were good to go still...

not sure about the je rings, they are just the shelf ones. actually they were for a vr6 which comes stock bore 82mm and the same 1,1.2,2.8 thicknesses. is there a good high tension ring set that comes recommended?

again im curious, is the carbon buildup from the cylinders enough in its own right to get between the skirt and cylinder and scratch the walls up?

not sure about the je rings, they are just the shelf ones. actually they were for a vr6 which comes stock bore 82mm and the same 1,1.2,2.8 thicknesses. is there a good high tension ring set that comes recommended?

again im curious, is the carbon buildup from the cylinders enough in its own right to get between the skirt and cylinder and scratch the walls up?

I've seen a few people have problems with low tension rings. I'm more of the thought train of reliability and simplicity so I use normal high tension rings. I have used NPR and they seem to be alright. I try to use Hastings in most builds and have recently used the Hastings Racing Rings; still too early to see if the Hastings Racing Rings are worth the extra coin.

I'm not sure about the skit situation

#20

Honda-Tech Member

Thread Starter

Join Date: Feb 2003

Location: schooling kids in ny, usa

Posts: 9,813

Likes: 0

Received 9 Likes

on

9 Posts

thanks for the replies you guys have good insight.

yesterday i had a bit of time to measure the ptw.

pistons were all pretty close in diameter, roughly 3.2240 +/- .0005.

bore was measured from intake to exhaust at the top and middle of the bore.

cylinders 2 and 3 were .001 tighter than 1 and 4 as measured at the middle of the bore.

top of the cylinder the ptw was .0012-.0007-.0014-.0018 from cylinders 4->1 respectively.

since i dont have a jig for my press, i had the machine shop mount the pistons on the rods (they had to shave the small end anyway to fit the p72's). a more consistent ptw could have been had by mixmatching the pistons and cylinders. anyhow, #1 cyl really didnt have extraordinary wear at .0018, the others had wear with 2 and 3 being the worst. im sure there were issues in the tune as well having perhaps not enough timing but i also take away that .002 may be a better goal for ptw rather than .0015

yesterday i had a bit of time to measure the ptw.

pistons were all pretty close in diameter, roughly 3.2240 +/- .0005.

bore was measured from intake to exhaust at the top and middle of the bore.

cylinders 2 and 3 were .001 tighter than 1 and 4 as measured at the middle of the bore.

top of the cylinder the ptw was .0012-.0007-.0014-.0018 from cylinders 4->1 respectively.

since i dont have a jig for my press, i had the machine shop mount the pistons on the rods (they had to shave the small end anyway to fit the p72's). a more consistent ptw could have been had by mixmatching the pistons and cylinders. anyhow, #1 cyl really didnt have extraordinary wear at .0018, the others had wear with 2 and 3 being the worst. im sure there were issues in the tune as well having perhaps not enough timing but i also take away that .002 may be a better goal for ptw rather than .0015

#21

Honda-Tech Member

Join Date: Jan 2008

Location: Ottawa, ON, Canada

Posts: 177

Likes: 0

Received 0 Likes

on

0 Posts

The machine shop should be able to hold a tighter tolerance than 0.001" for out of round and taper. I usually run a loose piston to wall clearance. People may comment saying that you'll have terrible blow by but I haven't found that to be the case. I don't rip the **** out of a cold engine and once the water temps are decent the piston to wall clearance is tighter but not super tight.

Having a goal of 0.002" ptw clearance is fine however if the machine shop can only hold a tolerance of 0.001" than you could have a 0.001" ptw clearance which is to tight IMO.

Having a goal of 0.002" ptw clearance is fine however if the machine shop can only hold a tolerance of 0.001" than you could have a 0.001" ptw clearance which is to tight IMO.

Thread

Thread Starter

Forum

Replies

Last Post

SkoundrelUSA

Tech / Misc

1

10-15-2006 02:29 PM

Toda Party

Acura Integra Type-R

2

02-13-2002 10:25 PM