Flywheel bolts......sheard

#1

Honda-Tech Member

Thread Starter

Join Date: Oct 2007

Location: San Jose, CA, USA

Posts: 850

Likes: 0

Received 0 Likes

on

0 Posts

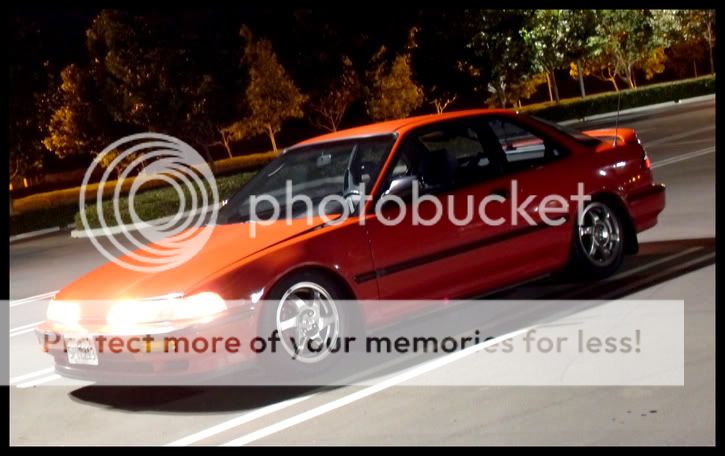

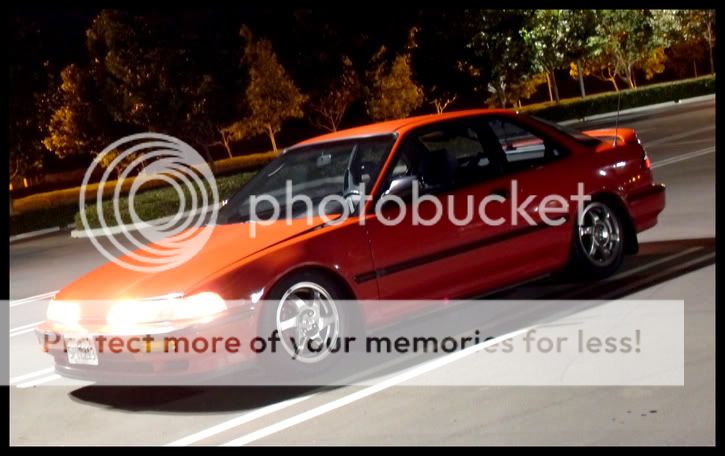

I heard a roaring noise in between shifting, and found out it was my "throwout bearing" i immediately drove it home "30 miles away" 1/2 a mile away from my home it started to RUMBLE pretty hard, towed it home...

jacked up the car and got started removing the transmission.

and saw this..

The Starter was chipped up pretty good. but it still spins..

and than i saw this...

heres a pic of the block..that is suppose to be holding the Flywheel, clutch and Pressure plate

now i gotta find a way to take off the broken bolts that are suppose to hold the flywheel to the crankshaft, Honda parts unlimited are charging $3.25 a bolt and the throwout bearing is gonna cost me $45. which isnt bad...

looks like ima need a transmission housing or a good welder....but hows my crankshaft???

Modified by HybridcivicLS-T at 11:04 PM 9/3/2008

jacked up the car and got started removing the transmission.

and saw this..

The Starter was chipped up pretty good. but it still spins..

and than i saw this...

heres a pic of the block..that is suppose to be holding the Flywheel, clutch and Pressure plate

now i gotta find a way to take off the broken bolts that are suppose to hold the flywheel to the crankshaft, Honda parts unlimited are charging $3.25 a bolt and the throwout bearing is gonna cost me $45. which isnt bad...

looks like ima need a transmission housing or a good welder....but hows my crankshaft???

Modified by HybridcivicLS-T at 11:04 PM 9/3/2008

#3

Honda-Tech Member

iTrader: (1)

Join Date: Jan 2002

Location: Nowhere and Everywhere

Posts: 29,530

Likes: 0

Received 52 Likes

on

46 Posts

crap dude, I have NEVER seen flywheel bolts sheared off like that. When was the last time you had the tranny/clutch off? Did you tighten the flywheel bolts and apply thread lock like you should have?

#4

Honda-Tech Member

Thread Starter

Join Date: Oct 2007

Location: San Jose, CA, USA

Posts: 850

Likes: 0

Received 0 Likes

on

0 Posts

wow, that could of been the problem..i didnt own any power tools so we tighten it as hard as we could.

what is this Tread lock u speak of?

Modified by Ricextacy at 1:35 AM 9/9/2008

what is this Tread lock u speak of?

Modified by Ricextacy at 1:35 AM 9/9/2008

#6

Jet Life Til' The Next Life

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by PatrickGSR94 »</TD></TR><TR><TD CLASS="quote">crap dude, I have NEVER seen flywheel bolts sheared off like that. </TD></TR></TABLE>

OP, how long from when you tightened them until that happened?

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by IntegraMark »</TD></TR><TR><TD CLASS="quote">shame on you rebecca.</TD></TR></TABLE>

Hope it comes out good

OP, how long from when you tightened them until that happened?

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by IntegraMark »</TD></TR><TR><TD CLASS="quote">shame on you rebecca.</TD></TR></TABLE>

Hope it comes out good

#7

Honda-Tech Member

Join Date: Sep 2006

Location: Huntington Beach, Ca, United States

Posts: 864

Likes: 0

Received 0 Likes

on

0 Posts

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by Ricextacy »</TD></TR><TR><TD CLASS="quote">

now i gotta find a way to take off the broken bolts that are suppose to hold the flywheel to the crankshaft

</TD></TR></TABLE>

To get the broken bolts out, drill them and use an easy out. As far as your crank goes, If the threads are fine and you can get an accurate torqe on the bolts you should be ok.

now i gotta find a way to take off the broken bolts that are suppose to hold the flywheel to the crankshaft

</TD></TR></TABLE>

To get the broken bolts out, drill them and use an easy out. As far as your crank goes, If the threads are fine and you can get an accurate torqe on the bolts you should be ok.

Trending Topics

#8

Honda-Tech Member

holy jesus. that scares the crap out of me. i didnt use loctite on mine when i installed the new flywheel, although i did torque them to spec. good luck man!

#11

Honda-Tech Member

Join Date: Sep 2003

Location: jacksonville, fl

Posts: 7,421

Likes: 0

Received 0 Likes

on

0 Posts

from the looks of the flywheel and bolts i would call installer error.

overtorquing steel is one thing, but when you over torque(it looks aluminum). it will mushroom the metal and the the object will get play and move around and cause that.

i would say crank threads are damaged. normally if a bolt head breaks the remaining thread loose their stretch and can be threaded out by hand. Goodluck. i would start looking for a different bottom

just look on how many time people have overtorqued aluminum cam gears and cause damage.

overtorquing steel is one thing, but when you over torque(it looks aluminum). it will mushroom the metal and the the object will get play and move around and cause that.

i would say crank threads are damaged. normally if a bolt head breaks the remaining thread loose their stretch and can be threaded out by hand. Goodluck. i would start looking for a different bottom

just look on how many time people have overtorqued aluminum cam gears and cause damage.

#12

Honda-Tech Member

Thread Starter

Join Date: Oct 2007

Location: San Jose, CA, USA

Posts: 850

Likes: 0

Received 0 Likes

on

0 Posts

it is an installation error. i had a couple guys help install my clutch (cuz ive never done it bfore)

they didnt: grease up the shaft, lube the bearing in the flywheel and didnt tighten down to specs...

it was running perfect for a good 2 months. i even took it down to Las Vegas and back to the Bay Area. and that day when i got back home..it happened.

Now. im on a hunt for money. my friend is selling me his GSR Built short block.

Is anybody looking for a 97 GSR short block with 130k on it. bolts are broken in the crankshaft but pistons and rods are great. PM me.

they didnt: grease up the shaft, lube the bearing in the flywheel and didnt tighten down to specs...

it was running perfect for a good 2 months. i even took it down to Las Vegas and back to the Bay Area. and that day when i got back home..it happened.

Now. im on a hunt for money. my friend is selling me his GSR Built short block.

Is anybody looking for a 97 GSR short block with 130k on it. bolts are broken in the crankshaft but pistons and rods are great. PM me.

#13

Honda-Tech Member

Join Date: Dec 2006

Location: NY

Posts: 3,824

Likes: 0

Received 0 Likes

on

0 Posts

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by Ricextacy »</TD></TR><TR><TD CLASS="quote">

Is anybody looking for a 97 GSR short block with 130k on it. bolts are broken in the crankshaft but pistons and rods are great. PM me.</TD></TR></TABLE>

Hahaha...don't know why but that made me chuckle!

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by Ricextacy »</TD></TR><TR><TD CLASS="quote">

they didnt: grease up the shaft, lube the bearing in the flywheel and didnt tighten down to specs...

</TD></TR></TABLE>

Thats a whole lot of errors. You live and you learn, next time get the proper torque specs and a tube of Loctite

Is anybody looking for a 97 GSR short block with 130k on it. bolts are broken in the crankshaft but pistons and rods are great. PM me.</TD></TR></TABLE>

Hahaha...don't know why but that made me chuckle!

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by Ricextacy »</TD></TR><TR><TD CLASS="quote">

they didnt: grease up the shaft, lube the bearing in the flywheel and didnt tighten down to specs...

</TD></TR></TABLE>

Thats a whole lot of errors. You live and you learn, next time get the proper torque specs and a tube of Loctite

#14

Honda-Tech Member

Join Date: Sep 2003

Location: jacksonville, fl

Posts: 7,421

Likes: 0

Received 0 Likes

on

0 Posts

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by Topher. »</TD></TR><TR><TD CLASS="quote">

Hahaha...don't know why but that made me chuckle!

Thats a whole lot of errors. You live and you learn, next time get the proper torque specs and a tube of Loctite </TD></TR></TABLE>

</TD></TR></TABLE>

<<<doesnt use locktite, i just tq to spec and let it go. if you need locktite to hold the bolt then you need a new one. its tensile strength is gone.

Hahaha...don't know why but that made me chuckle!

Thats a whole lot of errors. You live and you learn, next time get the proper torque specs and a tube of Loctite

</TD></TR></TABLE>

</TD></TR></TABLE><<<doesnt use locktite, i just tq to spec and let it go. if you need locktite to hold the bolt then you need a new one. its tensile strength is gone.

#16

Hype-R Stalker

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by projectTeG »</TD></TR><TR><TD CLASS="quote">

<<<doesnt use locktite, i just tq to spec and let it go. if you need locktite to hold the bolt then you need a new one. its tensile strength is gone.</TD></TR></TABLE>

Sure, you can torque most things down without it, but some it says to use loctite.

What about factory bolts that come out all red and gunky?

<<<doesnt use locktite, i just tq to spec and let it go. if you need locktite to hold the bolt then you need a new one. its tensile strength is gone.</TD></TR></TABLE>

Sure, you can torque most things down without it, but some it says to use loctite.

What about factory bolts that come out all red and gunky?

#17

Honda-Tech Member

Join Date: Sep 2003

Location: jacksonville, fl

Posts: 7,421

Likes: 0

Received 0 Likes

on

0 Posts

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by CleanLikeJdm »</TD></TR><TR><TD CLASS="quote">

Sure, you can torque most things down without it, but some it says to use loctite.

What about factory bolts that come out all red and gunky? </TD></TR></TABLE>

</TD></TR></TABLE>

mine didnt come out red and gunky.

no where in the helms does it say apply threadlocker.

Sure, you can torque most things down without it, but some it says to use loctite.

What about factory bolts that come out all red and gunky?

</TD></TR></TABLE>

</TD></TR></TABLE>mine didnt come out red and gunky.

no where in the helms does it say apply threadlocker.

#19

Honda-Tech Member

Join Date: Nov 2001

Location: Southern cali or boston

Posts: 5,699

Likes: 0

Received 0 Likes

on

0 Posts

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by projectTeG »</TD></TR><TR><TD CLASS="quote">from the looks of the flywheel and bolts i would call installer error.

overtorquing steel is one thing, but when you over torque(it looks aluminum). it will mushroom the metal and the the object will get play and move around and cause that.

i would say crank threads are damaged. normally if a bolt head breaks the remaining thread loose their stretch and can be threaded out by hand. Goodluck. i would start looking for a different bottom

just look on how many time people have overtorqued aluminum cam gears and cause damage.</TD></TR></TABLE>

dont forget how important the torque sequence is as well.

No torque sequence, no torque wrench, epic fail.

overtorquing steel is one thing, but when you over torque(it looks aluminum). it will mushroom the metal and the the object will get play and move around and cause that.

i would say crank threads are damaged. normally if a bolt head breaks the remaining thread loose their stretch and can be threaded out by hand. Goodluck. i would start looking for a different bottom

just look on how many time people have overtorqued aluminum cam gears and cause damage.</TD></TR></TABLE>

dont forget how important the torque sequence is as well.

No torque sequence, no torque wrench, epic fail.

#21

Senior Member

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by projectTeG »</TD></TR><TR><TD CLASS="quote">mine didnt come out red and gunky.

no where in the helms does it say apply threadlocker.</TD></TR></TABLE>

Agreed. I've probably done 50 clutch/flywheel jobs in miscellaneous Honda's and never have I seen mention of using any type of thread locker.

Not greasing the shaft and not lubing the bearing are relatively common oversights and tend to kill the pressure plate fingers and the input shaft, but overtightening is definitely the culprit here.

You have a very interesting and very correct bit of information above regarding overtorquing aluminum. I've seen pilot bearings seize and wobbles develop from overtorquing aluminum flywheels. I've never seen these issues arise from steel/chromoly ones.

no where in the helms does it say apply threadlocker.</TD></TR></TABLE>

Agreed. I've probably done 50 clutch/flywheel jobs in miscellaneous Honda's and never have I seen mention of using any type of thread locker.

Not greasing the shaft and not lubing the bearing are relatively common oversights and tend to kill the pressure plate fingers and the input shaft, but overtightening is definitely the culprit here.

You have a very interesting and very correct bit of information above regarding overtorquing aluminum. I've seen pilot bearings seize and wobbles develop from overtorquing aluminum flywheels. I've never seen these issues arise from steel/chromoly ones.

#22

Honda-Tech Member

Join Date: Sep 2002

Location: Little Rock, AR

Posts: 1,856

Likes: 0

Received 0 Likes

on

0 Posts

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by projectTeG »</TD></TR><TR><TD CLASS="quote">

<<<doesnt use locktite, i just tq to spec and let it go. if you need locktite to hold the bolt then you need a new one. its tensile strength is gone.</TD></TR></TABLE>

Redundancy is your friend! An ounce of prevention is worth a pound of cure! Better safe than sorry!

<<<doesnt use locktite, i just tq to spec and let it go. if you need locktite to hold the bolt then you need a new one. its tensile strength is gone.</TD></TR></TABLE>

Redundancy is your friend! An ounce of prevention is worth a pound of cure! Better safe than sorry!

#23

Honda-Tech Member

Thread Starter

Join Date: Oct 2007

Location: San Jose, CA, USA

Posts: 850

Likes: 0

Received 0 Likes

on

0 Posts

i had to learn the hard way, i hope everybody will learn from my mistake..

and tips on how to pull out this flywheel? it seems stuck but still spins.

and tips on how to pull out this flywheel? it seems stuck but still spins.

#24

Honda-Tech Member

Join Date: Sep 2003

Location: jacksonville, fl

Posts: 7,421

Likes: 0

Received 0 Likes

on

0 Posts

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by C_Rock77 »</TD></TR><TR><TD CLASS="quote">

Redundancy is your friend! An ounce of prevention is worth a pound of cure! Better safe than sorry!</TD></TR></TABLE>

well lets see here, does honda add threadlocker to their mass produced cars? no, so what should i change anything in that equation. honda did their research. plus if you understand how a bolt works as a spring.

Redundancy is your friend! An ounce of prevention is worth a pound of cure! Better safe than sorry!</TD></TR></TABLE>

well lets see here, does honda add threadlocker to their mass produced cars? no, so what should i change anything in that equation. honda did their research. plus if you understand how a bolt works as a spring.

#25

Honda-Tech Member

Join Date: Sep 2003

Location: jacksonville, fl

Posts: 7,421

Likes: 0

Received 0 Likes

on

0 Posts

<TABLE WIDTH="90%" CELLSPACING=0 CELLPADDING=0 ALIGN=CENTER><TR><TD>Quote, originally posted by Kendall »</TD></TR><TR><TD CLASS="quote">

Agreed. I've probably done 50 clutch/flywheel jobs in miscellaneous Honda's and never have I seen mention of using any type of thread locker.

Not greasing the shaft and not lubing the bearing are relatively common oversights and tend to kill the pressure plate fingers and the input shaft, but overtightening is definitely the culprit here.

You have a very interesting and very correct bit of information above regarding overtorquing aluminum. I've seen pilot bearings seize and wobbles develop from overtorquing aluminum flywheels. I've never seen these issues arise from steel/chromoly ones.</TD></TR></TABLE>

thanks i like to see that people share in the same experiences.

Agreed. I've probably done 50 clutch/flywheel jobs in miscellaneous Honda's and never have I seen mention of using any type of thread locker.

Not greasing the shaft and not lubing the bearing are relatively common oversights and tend to kill the pressure plate fingers and the input shaft, but overtightening is definitely the culprit here.

You have a very interesting and very correct bit of information above regarding overtorquing aluminum. I've seen pilot bearings seize and wobbles develop from overtorquing aluminum flywheels. I've never seen these issues arise from steel/chromoly ones.</TD></TR></TABLE>

thanks i like to see that people share in the same experiences.